Today we are returning to the topic of CV joints for VAZ cars. For the first time, the Transservice magazine analyzed the retail segment for this group of products. Autobusiness" was held exactly two years ago, in the spring of 2011. Today we decided to check which brands were able to retain their places in the windows of Siberian auto stores, and how much the average price for these units has increased.

The increased interest in VAZ “grenades” is not accidental. All AvtoVAZ cars today use front-wheel drive. This is a huge market - several million cars. Every year the Russian plant sells at least 500,000 new cars. And this entire fleet is covered by only two standard sizes of CV joints: external (2110 - 2215012) and internal (2108 - 2215056). At the same time, the calculated service life of CV joints for VAZ cars noticeably lags behind those indicators demonstrated by constant velocity joints of most foreign cars. If for foreign-made cars the norm for an external CV joint is considered to be a mileage of 130 - 150 thousand kilometers, then a VAZ joint that grinds on a turn after 100 thousand kilometers is unlikely to surprise anyone much. Naturally, in very careful driver’s hands and with constant monitoring of the boot, VAZ CV joints show miracles of endurance - 180-200 thousand kilometers each. But such long-livers are rather the exception to the rule. It is not surprising that in recent years this market segment has become of great interest to numerous manufacturers of automotive components and engineering companies from various regions. Today, about 20 fairly well-known brands and at least 10 little-known and “gray” brands compete in this segment. There are brands that appear for one or two years, but the majority of players enter this market seriously and for a long time. This is explained by the fact that the production of constant velocity joints is a rather complicated production process. It requires the most modern metalworking technologies, so it makes no sense to start creating a line of CV joints in order to quickly make money on a cheap and low-quality product. The CV joint changes, as a rule, 1 - 2 times during the entire period of operation of the car, and most consumers prefer not to save on this purchase.

Well, now let’s start comparing data on the retail market of the Siberian region. Let us recall that our research is carried out using a telephone survey of merchandisers and car dealers in four large cities of Russia. A total of 200 retail outlets were surveyed. As part of this study, experts were asked 4 questions:

1. What brands of CV joint 2110-2215012 (outer) are presented in your store?

2. What is the retail price of each item?

3. What brands of CV joints 2108 – 2215056 (internal) are presented in your store?

4. What is the retail price of each item?

We compared the results of this study with data obtained in a similar survey conducted in 2011. The results turned out to be very interesting. Some manufacturers managed to keep their places in the windows, but many had to make room, giving way to new brands.

CV joint 2110-2215012

Let's start with the most popular outer CV joint. In 2013, only the market share of CV joints of the original brand remained unchanged. In general, the market picture has undergone serious changes. Let's start with the fact that the representation of Finwhalle brand CV joints, which have been the main competitors of original units in the struggle for leadership on product shelves for many years now, has noticeably decreased (see diagram 1). In 2011, CV joints of this brand were presented in 17% of retail outlets (see diagram 2). In 2013, the representation of this brand decreased to 13%. Who pushed him aside? As it turned out, the reduction in Finwhalle's presence in this segment is most likely due to the development of the Lynx Auto brand. In two years, CV joints of this brand were able to almost quadruple the share of their presence in auto shops in Siberian cities - from 3 to 11%. This is a very good result. The marketers of the Liga Group company (LGR brand) also deserved praise. In 2011, LGR CV joints were barely visible on the chart (1%). In the new study, LGR is already represented in every 10th of the surveyed auto stores, displacing the traditional middle peasants in its price segment - brands such as BelMag, Kraft and some others. Trademarks that should be recorded as liabilities for the last two years include ZMZ, Keno and Kroner. Their products were not included in the 2013 chart, since we did not find CV joints of these brands in the retail chain.

Why do you need a CV joint?

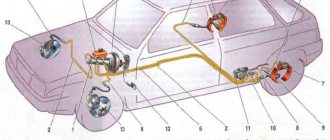

Today, CV joints are one of the most efficient mechanisms that smoothly transmit torque from the engine through the gearbox to the turning drive wheels without loss of power. Typically, the outer and inner joints are attached to a splined shaft using thrust rings and circlips. The outer one connects to the wheel hub. It transmits torque to the wheel and ensures turning.

The internal one is adapted to axial movements and is installed on the drive from the gearbox side. From it rotation is transmitted to the drive shaft. In this case, the rotation speed of the input and output shafts is the same; it does not change depending on the angle of operation of the hinge.

Pricing factors

Today, most car owners are trying to make financially profitable purchases. But a cheap part does not always turn out to be of high quality. This must be remembered when choosing a CV joint for a VAZ 2112.

To make the purchase profitable, you need to visit different places where this part is sold and compare the performance parameters and cost. The price at different sales points will vary greatly. It is important to understand that the cost is influenced by the following factors:

- Quality.

- State.

- View.

- Originality.

- Company manufacturer.

- Place of purchase.

- The need for product delivery.

- Seller popularity.

What are the differences between tripoid and ball

They differ from each other in that the ball type has balls, dividing grooves or levers, while the tripoid type has rollers with a spherical surface and a fork.

The joint where balls are used is usually:

- frame;

- clip with grooves;

- six balls in the grooves of the cage;

- a separator holding these balls;

- protective cover with CV joint lubricant.

This CV joint is connected to the drive shaft through splines.

The tripoid joint has a housing that houses the three-arm fork. It is pressed onto the splines of the output shaft. Three rollers with a hemispherical surface, rotating on needle bearings, are mounted on the fork arms. Under them, grooves are cut out in the tripoid body, thanks to which the desired angle of rotation of the hinge is created and the possibility of longitudinal displacement is created. The functions it performs differ depending on whether the CV joint is internal or external.

Thus, the main difference between CV joints is that the first rotates with the help of balls, and the second - thanks to needle bearings.

CV joint: Responsible for the drive

Today there is abundance in the CV joint market. Which, however, does not make life easier for those consumers who are targeting the use of non-original hinges.

The domestic market for spare parts (at least spare parts for passenger cars) is dominated by two main types of CV joints - ball and tripod.

Vladimir Shrusov, head of the expert department:

— The most common are ball joints. Tripods are used on more modern cars, usually as internal CV joints. Moreover, it happens that for the same car model, different manufacturers supply both tripod and ball joints as internal CV joints. In this case, you can install any of them. They are interchangeable. The type is determined by the original part manufacturer number

Drive belts are usually supplied assembled to the CV joint conveyor. Also assembled - the entire assembly - with CV joint, original hinges are sold. And the manufacturers themselves recommend replacing, if any of the CV joint components fail, the entire assembly, and not just one worn component. However, there are many spare parts for rebuilding drive shafts on the aftermarket.

Still, the CV joint is a fairly reliable unit. When used correctly, its lifespan is often comparable to the lifespan of the car itself.

Vladimir Shrusov: — Drive shafts, boots, clamps, retaining rings and other components for repairing CV joints for many car models are sold separately.

For many, but not for all. For new, newly released cars, only the original is supplied for the first time. Assembled. And something may not be on the market even for those models that have been in production for a long time. For example, on the KIA Sorento, not only the components for the CV joint, but even the original joint itself will most likely have to be ordered in Korea. The following principle applies here: basically only spare parts that are in demand are sold.

Still, the drive shaft is a fairly reliable unit. When used correctly, its lifespan is often comparable to the lifespan of the car itself. Because of this, it is not always profitable for independent suppliers to invest in the production of CV joint components that are not in demand. Conveyor suppliers, as already mentioned, produce only assembled units.

Vladimir Shrusov: — In general, there are no problems with spare parts for CV joint repairs. There are both original and non-original CV joints, there are assembled drive shafts, and there are separate components for rebuilding CV joints from various manufacturers. Nevertheless, situations when a part has to be ordered from a manufacturer because it cannot be found on the open market arise quite often. On many cars, the drive shaft breaks quite rarely, and, accordingly, it is not very profitable for manufacturers to manufacture their components.

As for manufacturers, in the case of CV joints, essentially the same principle applies as for most other auto components. All manufacturers of CV joints and their components are conventionally divided into four groups. At the top are the suppliers of the car plant's assembly line.

Dmitry Molchanov, director of the Auto Parts department at SKF:

— Conveyor suppliers are traditionally European, Japanese and North American companies.

Many of them simultaneously supply parts to the free market, thus constituting a class of manufacturers of non-original spare parts, but the quality is practically indistinguishable from the original ones. This also includes manufacturing companies that are not suppliers of production, but at the same time produce quite high-quality non-original products. The leaders on the market today are brands such as GKN-Spidan, Loebro, Metelli, SKF, Febest, etc.

And finally, there are numerous manufacturers who have not made a name for themselves. Among these there are especially many Chinese companies.

Dmitry Molchanov: — Chinese manufacturers reign in the auto parts market. Moreover, they are often hidden behind boxes on which the European country of origin is written.

Chinese production does not necessarily automatically mean low quality of the product. However, if the buyer does not understand the situation, he often takes risks when purchasing goods of Chinese origin. Turning to trusted suppliers allows you to avoid risk.

In the case of CV joints, the parts in the vast majority of cases are not interchangeable. Each car model requires its own hinge.

Dmitry Molchanov:

— The part for each model is unique, because... calculated for certain loads and resources. Interchangeability exists only within some automakers, such as the VAG group of cars. But even here you cannot simply move parts from one car to another without checking.

Therefore, the selection of CV joints is made strictly according to the VIN of the car. In addition, when choosing a non-original part, you also need to pay attention to a number of other parameters. So, it is advisable to choose CV joints coated with a layer of zinc to protect against corrosion.

Dmitry Molchanov:

— When choosing, you should pay attention to phosphating—coating with a layer of zinc to protect against corrosion. This coating gives the CV joint a dark gray color. Thanks to it, ABS seals and rings have an increased service life.

The quality of the material also matters. Important

the parameters are quality and level of hardening. An insufficient level of hardening leads to loss of hardness, and an excessive level of hardening

- to the fragility of the material.

The CV joint kit is always supplied with lubricant. When purchasing, you need to check its quantity. Some manufacturers save on this, which is unacceptable.

The kit should also include installation instructions and all necessary hardware.

Dmitry Molchanov:

— SKF kits always contain detailed instructions for correct installation of CV joints and all disposable parts for professional repairs - bolts, nuts, clamps, etc.

Finally, all parts in the CV joint kit must have their own separate high-quality packaging. Its task is to prevent them from being damaged during transportation. Therefore, when choosing, you need to pay attention to the quality of packaging. The parts must be isolated from each other. They are usually packaged in bags or plastic packaging for boots, CV joints, and clamps.

And finally, you need to keep in mind that there are a lot of counterfeit products on the market. Counterfeits primarily concern certain brands, mainly those under which CV joints for domestic cars are supplied.

Dmitry Molchanov: — The concept of “counterfeit” can be divided into two components: “gray” import and fake. Fortunately, we have not yet encountered such a problem with SKF CV joints and drives. But we are familiar with it from the products of the GLO brand, which also belongs to the SKF group. Here, the sales of counterfeit CV joints have become alarming. We are faced with a huge amount of imitation of our own products.

Fake parts are very often indistinguishable from the original in appearance, but are made from low quality materials. Some counterfeits have absolutely identical product packaging. Unfortunately, internal defects and violations of production technologies for counterfeit parts can lead to serious damage when driving a car, cause a traffic accident, and endanger the life and health of the driver and passengers. Recently, manufacturers of counterfeits have reached the maximum external resemblance to the original product, but in pursuit of greater profits, the quality is becoming lower and lower; the counterfeit has a very small resource.

A company representative spoke about the methodology used by SKF to combat counterfeit goods. In order to protect the original product, it was decided to use a special patented anti-counterfeiting system, which will help the supplier’s representatives to distinguish the original from the fake with absolute accuracy, thanks to which it will be possible to protect the buyer and hold retailers and outlets distributing counterfeit products accountable. For this purpose, in 2014 the company plans to conduct inspections of trading enterprises in the CIS in order to identify cases of sales of counterfeit products; internal affairs bodies and the police will be involved in these inspections.

Here are some of the differences between a counterfeit and an original part, the identification of which is also the basis of the anti-counterfeit system developed by SKF. GLO constant velocity joints are subjected to special thermal hardening. It increases the service life of the product under the most unfavorable operating conditions, increases strength and elasticity, which allows it to withstand heavy loads. A fake can also have a thermal coating, but it is applied with violations of technology, which is why such a coating turns out to be of poor quality. Thus, these parts do not maintain the required thickness of the hardened layer, which is very important for the normal operation of the hinge. If the depth of heat treatment is insufficient, the material becomes excessively flexible and there is a risk of deformation. If it is excessive, the metal becomes brittle, which leads to internal fractures.

Unfortunately, internal defects and violations of production technologies for counterfeit parts can lead to serious damage when driving a car, cause a traffic accident, and endanger the life and health of the driver and passengers.

The next point is that the original GLO CV joints are always phosphated (have a dark gray coating). Phosphated products can withstand or exceed stringent corrosion testing requirements. Counterfeit products, as a rule, do not have such a coating. Therefore, the dark gray CV joint coating allows you to quickly distinguish original GLO products from fakes. In addition, all phosphated CV joints are also necessarily marked with the GLO brand name. Another detail - the original GLO CV joints are pre-lubricated. A high-tech CV joint lubrication process at the factory ensures that lubricant penetrates into hard-to-reach areas, ensuring trouble-free operation throughout its entire service life. It also reduces the work time of the technician, who does not need to spend time putting lubricant into the CV joint. This is an additional benefit for car services. Absence or insufficient lubrication will indicate a fake.

Naturally, the buyer himself cannot carry out all such tests when purchasing a product. Therefore, the only thing that can guarantee against counterfeiting is cooperation with trusted suppliers.

Denis Yutapov

Which CV joint is better

On the Internet you can find many opinions of specialists and car owners regarding which CV joint, tripod or ball, performs better. Most of them note the advantages of a tripod CV joint:

- the ability to operate at a 45-degree angle without backlash or shock loads, ensuring sufficient wheel turning;

- more reliable and durable, does not fail instantly;

- greater longitudinal movement than a ball one, which allows you to compensate for loads;

- when the hinge is rotated at a large angle, it better resists loads;

- significantly more resistant to torsion;

- low losses during axial movement and lightly lubricated needle bearings give it high efficiency;

- ease of installation, replacement and maintenance due to sufficient space at the installation site;

- excellent interchangeability with similar devices;

- tripoid has fewer parts and is cheaper to manufacture.

What is needed to replace CV joints on a VAZ 2110?

If you want to get acquainted with step-by-step repair instructions, then on the website remont-vaz2110.ru you can see material on replacing the CV joint on a VAZ 2110 with your own hands.

Below is a short list of what needs to be done.

The first step is to stock up on the necessary tools, and here you may need the following set:

- Heads for 17, 19 and 32 mm

- Driver and ratchet handle

- Hammer

- Punch

- Mount

- Pliers

- Vise

- Screwdrivers

Well, it goes without saying that this type of repair is best done in an inspection pit, so that everything is done as conveniently as possible.

It is also advisable to drain the oil from the gearbox so that when removing the drive it does not flow out of the holes. And of course, do not forget that when installing new CV joints, we carefully lubricate them with a lubricant such as Litol or CV joint.

Also, please note that when tightening all unscrewed connections during this procedure, it is necessary to adhere to the tightening torques that are specified in the factory maintenance recommendations.

If you are not confident in your own abilities, then you should contact a service station so that specialists can do all the work for you. Of course, you will have to pay a lot of money, but you can be sure that everything will be done as expected and you won’t have to worry again.

Reliability of CV joints

For durable operation, the tripod and ball CV joints are made of high-strength metals. This ensures the geometric accuracy of these mechanisms and the ability to transmit torque without loss.

Both types of hinges are subject to increased sealing requirements. To do this, they are protected by a rubber or silicone sealed cover, which protects the mechanisms from dirt, water and dust. Such a case ensures many years of operation of the hinge. Its damage and untimely replacement leads to rapid failure of the CV joint.

Tripoids require constant attention because they can break even if a small amount of dust and dirt gets into them.

Nissan X-Trail › Logbook › Inner left front grenade - damn it)))

I don’t even know where to start)) How much time I wasted: - searching for useful information on the Internet; — visited all the investigations in the city; — called investigations in cities that are closer; — how many people have I troubled with my problem))). etc. Finally I made up my mind and ordered a low-quality substitute for Febest (0211-T30LH). By the way, it’s cheaper at www.repart.ru/.

Internal CV joint, gearbox side (0211-T30LH)

When purchasing the car, I immediately noticed the torn boot of the inner left grenade. Well, okay, I thought))).Then I’ll put on the dust cover and that’s it)))…that’s not the case. I called some stores in the city (I was looking for a boot), everywhere from 1500 rubles. and higher. I decided to wait and order through existential for 750 rubles. Febest (0215-071T)

Internal CV joint boot (0215-071T)

While I was waiting for the boot, I wrapped a bag))) with lubricant)). I noticed a slight vibration especially during acceleration. Well, it’s a small thing)))… I waited for the boot. I changed it, it took about 2 hours to replace it… Then I went for a ride)) only then I read on the Internet about the vibration during acceleration. Everyone who wrote about vibration mentioned the torn left boot! In existential terms, the cheap Febest substitute at that time cost 4,700 rubles, a couple of months later it began to cost 3,200 rubles.)) Having already driven 6-7t.km. The vibration has increased and it’s not bad))) (by the way, the boot is still intact) I was thinking about a used drive unit, but if X-trails have this problem, then it makes sense to take a used one. I read on the Internet that the left front drive fits from Nissan Cefiro (A33), from Nissan Primera (P12) and, with minor modifications. I was more inclined towards the drive from the Nissan Cefiro (A33), because... The internal grenade will be stronger)).

But nowhere in Kurgan was there a used drive (((in other cities a used one from 5-7 t.r. immediately disappears. To order through the website www.japancar.ru/ it also costs about 5 t.r. and so on will come...unknown((In the end, I made up my mind and ordered Febest (0211-T30LH) 2860 rubles, I couldn’t continue to worry myself and those around me)) Only reviews about those who installed Febest were not found as a substitute((about the fact that Febest is complete shit..., this okay)) let’s see how long it lasts and if the vibration goes away))

As soon as it arrives, I’ll change it right away))

How to determine if a hinge is faulty? Diagnostics

At any service station, before repairs, they carry out diagnostics of the unit that is going to be repaired. Let's do it ourselves:

- Are there any strange sounds while driving your favorite car? One possibility could be a faulty CV joint.

- Most often, a CV joint in need of repair manifests itself during turns (not necessarily sharp ones). When turning the car, a sound comes from the hood, similar to metal jamming, the sound of metal breaking, metal grinding on metal.

- If such sounds appear even when driving straight, then the CV joint definitely needs to be changed!

Advice! Do not ignore sounds that occur when operating the vehicle. In some cases, this can cost the lives of the driver and passengers.

- After sounds similar to a malfunctioning grenade appear, it is necessary to diagnose the front chassis of the car in a pit or overpass, or, as a last resort, just in the garage.

- To do this, you need to lift the car using a jack. Raise the side from which the sound was heard. Don't forget to put wheel chocks under the rear wheels of the car.

- When the wheel can rotate freely, you should rotate it around its axis and listen for sound. If the sound does not appear, then you should turn the wheel in the direction of the turn at which it occurred.

- When a sound appears, it will become clear that the VAZ 2112 CV joint is faulty and requires replacement as soon as possible.

- If the sound still does not appear, then check the other side (the other wheel) in the same way. By the way, if the sound appears, check it anyway - you may have to change both grenades.

Why does the CV joint fail? Principle and working conditions

A torn boot is the cause of all troubles with grenades

- A car's wheel is its dirtiest part. The wheel is constantly in contact with the road, and the road is not always asphalt, but often dirt or sand.

- The outer grenade usually wears out much faster than the inner one, since it is closer to the wheel and is more subject to overload when driving on uneven surfaces.

- Anther breakage. One of the reasons for grenade failure is a violation of the integrity of the boot. This usually happens due to a torn boot clamp, a cut of its fastening, or a cut in the boot itself.

- It also happens that the boot loses its rubber properties over time and stretches. Then it does not fit tightly to the axle shaft.

- For all these reasons, dust gets inside the outer CV joint, and even worse, sand and dirt.

- If harmful substances get inside the grenade, the bearing fails - it collapses or jams.

If you notice a torn grenade boot, this means that on a VAZ 2112, replacing the CV joint is simply necessary for its further safe operation.