Quite often, drivers wonder how to inject cardan crosspieces.

This is one of the common questions that beginners ask, but this work needs to be done quite often. At the same time, injecting is not a complicated action; it can be done in any garage, but you will need a tool. And despite the ease of repair, many people are simply afraid to touch the driveshaft themselves; for some reason it is believed that any work with the transmission requires high qualifications. This approach is justified if it is necessary to overhaul the automatic transmission, but the lubrication of the crosspieces can be done independently. How to inject cardan crosspieces is a simple question. To do this, there are a number of devices that make the task easier. It is much more difficult to correctly determine the time when this needs to be done. Here the task is complicated by the need to determine whether the crosspiece needs to be replaced completely, or whether it is enough to simply lubricate it. Below we will look at all these points.

KIA Sportage Grand › Logbook › A tale about injection of universal joints - do it yourself

I really want to tell you (once again to cry about what kind of comrades work in the service) about how I myself went the way of injecting universal joints)))))

In short, the story is this:

for the entire time that I have been the owner, among all the other work that was done at the service, I asked 4 times to have the cardans injected

did, as it turned out, never...

As it turned out, I read the forum, drive and in several places I came across similar opinions that injection is better done with an internal combustion engine oil change (7-9 thousand depending on the load), and I just changed the oil.

I think I won’t go to the service center for injection anymore, since I changed the oil, I’ll go and do the injection myself, because earlier in one service center the master checked everything and did not consider it necessary to do the injection (but they didn’t take the money then), in another they didn’t they were able to, because they didn’t have a syringe (!), the third SC did something, but the lubricant scattered all over the bottom, at first I didn’t understand why this was so, but after I did everything myself, now I know that they didn’t do a damn thing then They did it, but they took the money.

here I won’t continue to push for manhandling again (apparently, for some reading this it’s like a sickle on the fingers) just the text:

So, to carry out high-quality (in my opinion) injection you will need:

1. buy lubricant for crosspieces: LIQUI MOLY — Mehrzweckfett

2. buy lubricant for splines: YES - YES! (again according to Galygin) - it turns out that when injecting, 2 different lubricants are used! so fucking different that they are EVEN DIFFERENT COLOR!

LIQUI MOLY — CV joint grease with molybdenum disulfide LM 47 Langzeitfett + MoS2 400 ml

3. I bought 2 plunger syringes to insert these tubes into; the kit included flexible hoses for ease of fitting into the grease fittings of the crosspieces.

then, on occasion, there was a visit to the service center, where, while the machine was hanging, I asked for free, out of great friendship, to show how to insert the tube into a syringe and how to syringe. Please don’t laugh here - it’s better to see it once...

so what did I see? how to insert and pump grease into a flexible hose is half the job (for which special thanks), then the following happens - since it’s a little dark under the car, the technician found the oiler by touch in the rear crosspiece of the rear universal joint, easily tucked the head of the hose onto the oiler, pumped it a couple of times, Fresh grease immediately came out (from the oiler side). That's it, he says, see if the lubrication has gone?

I think to myself, what’s wrong - the fresh lubricant should squeeze out the previous lubricant through the rings, which should even be of a different type - worn out.

Because they didn’t take any money for it, I went home from them, and the next morning I had an early start to Belarus. I took the syringes with me - I think I’ll figure it out at my leisure.

there he crawled under the car and started looking.

Firstly, there were rubber caps on the oil nipples! and judging by the lubricant that fanned out, it did not go inside the cross, but came out under pressure from the syringe fitting in front of the cap:

Such caps appeared on all crosspieces.

however, on the oiler, which is splined - there was no cap - apparently lost:

so, first we put the syringe fitting on the oilers without caps))))), pump it, we see that the black slurry is squeezed out from under the rings (though not from under all of them) between the cross and the cardan (more precisely, the U-shaped part of the cardan - I don’t know how it's called), just as a lot of clean lubricant falls to the ground, as it gags famously past the oiler - apparently, a low-quality syringe (300 rubles) or incompatibility of the fitting and the oiler ((((

there were no problems with the rear driveshaft - it’s a pity that a lot of grease gets squeezed past ((everything excess that didn’t get into the crosspiece, but densely filled the space between the joints around it - we wipe it with a rag or, like me, with toilet paper that was at hand))

Next, we take off the protection and plastic boots, and similarly inject the front driveshaft. I still have the Belkardovsky one. last year it was disassembled and cleaned, I skated for a year without problems - when necessary, the PP was connected and there were no questions about the operation of the cardan.

However, not all so simple. The fitting turned out to be a bit thick in diameter and did not want to get close to the oiler. I accidentally turned the oiler with my finger - for some reason it easily spun inside the crosspiece and it was difficult to fit the fitting onto it. pumped it up, the song repeated itself - a little black slurry came out, and not from all the rings, a kilogram of good lubricant was gone.

Then the dancing with the tambourine began - the syringe fitting did not want to come off the oiler.

I pulled and twisted the cardan shaft, and the oiler with a hose, and took out a screwdriver - so that, like a lever, sliding it under the fitting, I could squeeze it out of the oiler... in short - the word is fucked - the easiest thing)))))

In general, almost tearing off the hose, he pulled it off. ... cursed everything! (maybe that’s why no one injected the cardan?)

Because stopping there is not my topic - there was a similar pandemonium with the second cross. except that I quickly used a screwdriver to pry off the fitting when I took it out

I also decided to remove the rubber corrugation from the slot and see what happened there over the year:

sad, but not a disaster

marked the joints, took off the cardan (the nuts came off easily), cleaned everything, changed the tubes in the syringe, pumped it so that the previous lubricant came out and pushed it heartily into the spline

assembled, installed, checked that there was some play (the plastic connection was knocked out last time), drove on asphalt with PP - beating and vibration appeared after 80 km/h, assembled the protection and finally, since there was already spline lubrication in the syringe, pumped the lubricants into splined rear cardan.

Comparing lubricants for servicing kingpins

EFELE MG-212

1

place

EFELE MG-212

/100

RATING

100

EFELE MG-212 is the best grease for king pins. It contains high-quality mineral oil thickened with lithium soap, as well as extreme pressure additives and molybdenum disulfide. Operating temperature range from -30 to +120 °C.

In addition to kingpins, the material is used in chassis components of transport equipment operating in harsh conditions.

Suitable for equipment components in the woodworking, polymer industry, metallurgy and other industries, as well as heavily loaded bearings of general industrial machines, bearings of electric motors and fans.

EFELE MG-212 is resistant to water washout, provides excellent protection against wear and corrosion, and can withstand impact loads. It has proven itself positively when working in damp and dusty environments, and also serves as an anti-emergency lubricant.

This lubricant has the highest performance characteristics among all presented materials and an affordable price.

Molykote BR2 Plus

2

place

Molykote BR2 Plus

/100

RATING

100

Molykote BR2 Plus is a lithium mineral oil based grease. Provides long-term lubrication of components of various machinery and industrial equipment Operating temperature range from -30 to +130 °C.

In addition to pins, it can be used in other elements of the chassis of lifting and transport machines and friction units of industrial equipment.

The material is characterized by high load-bearing capacity, high anti-wear and anti-corrosion characteristics, works in conditions of moisture and dust, and has the properties of an anti-emergency lubricant. It is not washed out by water, prevents stick-slip, fretting corrosion and has a long service life.

Mobilgrease XHP222

3

place

Mobilgrease XHP222

/100

RATING

100

Mobilgrease XHP 222 is an extended life blue grease. Made from mineral oil thickened with lithium soap. Operates at temperatures up to +150 °C, lower limit not specified.

It has proven itself well for servicing kingpins, as well as other components of industrial equipment and various equipment: construction, marine, agricultural, etc.

The material can withstand exposure to water and high temperatures, has high extreme pressure and anti-wear properties, protects against corrosion, and has high adhesion to surfaces

According to the characteristics of Mobilgrease XHP 222, it is not inferior to previous materials only in terms of heat resistance. Otherwise, it is inferior to the first two materials in terms of characteristics.

Litol-24

4

place

Litol-24

/100

RATING

100

Gazpromneft Litol-24 is an anti-friction lithium lubricant based on mineral oil. Operates at temperatures from -40 to +120 °C.

Used for servicing various rolling and sliding bearings, hinges, gears, etc. in industrial equipment, wheeled and tracked vehicles, electrical machines, etc.

The material withstands exposure to water, protects against wear and corrosion, and is mechanically, chemically and colloidally stable. It adheres well to surfaces and ensures performance even in heavily worn mechanisms.

Litol-24 is one of the most popular lubricants in Russia and the CIS countries. It can be used in kingpins, which is what many car owners do, but the characteristics of this material do not entirely satisfy the requirements of this unit. The quality of the lubricant is much inferior to previous materials.

TAD-17

5

place

TAD-17

/100

RATING

100

Automotive transmission distillate oil. It is produced on the basis of mineral oils, depressants and sulfur-phosphorus additives.

This material is very widely used for servicing king pins. This is due to its cheapness and availability.

It protects against corrosion, reduces friction and wear, and prevents pitting and seizing. The operating temperature range is from -25 to +130 °C.

Despite the positive aspects of using gear oil, the disadvantages still outweigh. This includes low quality raw materials, unstable characteristics, and the need for too frequent lubrication. Therefore, it is much more advisable to use greases that last longer and have more optimal properties.

How to properly lubricate driveshaft crosspieces

From trucks and SUVs to compact cars and sedans, your vehicle's powertrain system helps keep you on the road.

Also called the driveshaft, the transmission is responsible for shifting your vehicle from idling to driving. A bad or faulty driveshaft can make your vehicle difficult to control. And the main cause of breakdowns is the lack of lubricating mixture in its connections.

Common topics

Meetings, rides and events of the Land-Cruiser.ru club

Trips, meetings, events, competitions organized by the site Land-Cruiser.ru

Events of other clubs

Announcements about events of other clubs

Congratulations, funny jokes and other offtopic

Auto tourism

Trips. Cards. Tracks reports.

We sell, buy, exchange.

Car sale

Please place advertisements for car sales here

What kind of lubricant should be used for crosspieces?

Manufacturers of oils and lubricants sell a fairly large assortment of materials intended directly for both universal joints and having general positive characteristics for various parts of a car or other equipment. To make the best choice, you need to pay attention not only to the cost of the lubricant and the manufacturer, but also to its main performance characteristics. You can get all the necessary information from your car's owner's manual or from your mechanic.

If we talk directly about the cardan, then a suitable mixture for it should have the following properties:

- high anti-corrosion and water-repellent properties;

- the lubricant must be designed for use over a wide range of temperatures and pressures (resistance to high temperature and pressure is required);

- should be thick and sticky; this way it can remain in place even with high vibration or intense rotation of parts;

- must be safe for human health;

- mineral lithium compounds are used to lubricate components and parts of the suspension and transmission, so the lubricant for the cross must be combined with them;

- the characteristics of the composition should extend the service life of the driveshaft components, increasing the range of its replacement;

- the density of the composition should not increase with decreasing temperature;

In a word, the mixture must have high mechanical and chemical properties, maintain density and composition under different extrusion conditions, and also withstand the effects of external aggressive factors.

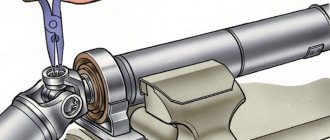

Types of pullers

Replacing the driveshaft crosspiece of a VAZ 2107

Pullers of certain designs can be used for different tasks and specific situations. Therefore, in order to figure out which crosspiece puller is best to use, you need to understand its types and purpose.

There are several types of pullers:

1. Hydraulic - they are designed for dismantling various parts and assemblies (pulleys, gears, bushings) that have an interference fit. In this category, devices with the following types of design are most often used:

- two-grip (for working in confined spaces);

- three-grip (to create a reliable grip).

2. Mechanical ones are used for dismantling parts that are installed with tension, in the case when little effort is needed to remove them. The puller jaw locking mechanism allows you to adjust or change the gripping points by simply rotating the locking nut.

3. “Clamps” are used for dismantling gears, bearings, wheels, couplings, impellers, pulleys and other parts that are pressed into place, which can be damaged when removed with conventional pullers. The design of the clamp provides a secure grip only when the shape of the part does not allow the use of a conventional puller.

4. Universal crosspiece puller - designed for dismantling parts installed with tension, such as gears, wheels, couplings, impellers, as well as thin-walled parts installed in holes (clips, bearings), which can be damaged when removed with conventional pullers. The Universal Puller is a unique combination of a clamp puller, a combined (external/internal) grip puller and a hollow rod jack that can be removed and used separately.

Since these are the best-selling pullers, let’s consider their types:

- Universal crosspiece puller JTC-5571 (cost RUB 7,800)

- Crosspiece puller Universal Autom 11210 (cost 760-1000 rub.)

- Crosspiece puller Universal Autom-2 (price 800 rub.)

There are also puller designs for internal and external gripping of the part. The cost of crosspiece pullers of all types varies from 500-7900 rubles. In the video presented, you can familiarize yourself with how to use the puller.

Using a puller to remove and install the driveshaft spider

How often should lubrication be carried out?

Manufacturers regulate the frequency of injecting crosses in the operating instructions. You can also contact an authorized service center, where specialists can check the condition of the transmission and recommend lubrication and frequency of maintenance of the driveshaft.

It is generally accepted that the life cycle of a driveshaft spider is about 500,000 km. And this is only if you comply with the care and maintenance requirements, including changing the lubricant. Depending on the nature of driving, terrain and operating conditions, the lubricant must be changed every 10-20 thousand kilometers. Most experts recommend doing this at a service center during maintenance.

However, there are a number of signs when it is necessary to lubricate the driveshaft crosspieces as soon as possible. Here are the main ones:

- When the crosspiece begins to crunch for no apparent reason.

- The crosspiece vibrates strongly, especially when accelerating to speeds above 50 km/h or when starting the car from a standstill.

- Noise, whistling or grinding, as well as hum or clicks coming from the crosspiece.

If you notice one or more of the following symptoms in your vehicle, be sure to contact a mechanic or have your driveshaft joints lubricated as soon as possible.

General technical questions

Issues of operation and maintenance of automatic transmissions on Toyotas and not only. Because the boxes of many models overlap

Tuning, styling, interior, car audio and theft protection

“Non-power” body kit, trim and restoration of the interior, car audio, sound insulation, anti-theft, etc. for all models of Toyota SUVs.

Other related Toyota issues.

Life of Toyota 4x4 - problems and solutions are common to all platforms.

Technical non-Toyota questions

Any car from Acur to UAZ, if it has a steering wheel, wheels and it’s not a Toyota

What is used for lubrication

In order to lubricate the driveshaft crosspieces, you will need a set of special tools. The equipment and materials for this will depend on which method you use. You can lubricate the crosspieces by dismantling the driveshaft or without doing so.

To lubricate the parts of the driveshaft when dismantling it, you will have to put in much more effort. However, when dismantling the cardan, you will be able to perform the operation more efficiently, checking the complete penetration of lubricants and the density of filling voids. If you decide to lubricate the cardan without removing it, you risk doing it not so carefully, since it is impossible to control the penetration of the lubricant into the voids of the parts.

The procedure for lubrication of cardan crosspieces is carried out in an inspection pit or using a lift - most often this can only be done on the territory of a service station.

So, to lubricate the driveshaft crosspiece without removing it, you will need the following tools and materials:

- lubricant;

- a special syringe with a container for lubricant;

- syringe adapter - necessary if the lubricant container is inconveniently located.

If you decide to fully lubricate the universal joint crosspieces and remove it from the car, in addition to the above, you will need special tools - keys, screwdrivers, etc. With their help, the part will be dismantled.

The driveshaft is an important part of your car, and it is best to have it removed by a qualified mechanic who will do everything correctly and in compliance with safety regulations.

Car manufacturers equip driveshafts with grease nipples designed to fill them with oil. Usually they are located directly on the crosspieces, but their placement may vary depending on the brand of car. If you are unsure, be sure to check the instruction manual.

Necessary tool

So, you have established that it is necessary to lubricate the cardan cross once again.

It is worth considering that this work cannot be done without a special tool, so you will have to prepare for the process in advance. First of all, purchase a special syringe for lubricating cardan shafts; it is inexpensive and will last quite a long time. For this work, a lever-plunger type syringe is used. Please note that different models have different holes for lubricant supply, oil seals or nipples may be used, so check this nuance and purchase the appropriate nozzle.

Another point is the choice of lubricant

. Here it is worth familiarizing yourself with the manufacturer's recommendations. In many cases, modern cars use a specialized lubricant that is designed for a specific brand. The result of mixing it with other types of lubricant is quite difficult to predict. Therefore, if the manufacturer accurately indicated a specific brand of grease, it is better to use that particular one. If there are no clarifications on this matter, then you can use any option designed for such an application.

Lubrication procedure

Let's look at the correct procedure for lubricating the crosspieces without removing the shaft.

- Clean the crosspieces. These shaft parts are in a very corrosive environment, so they are likely to become heavily contaminated. For a thorough cleaning, it is best to use engine or carburetor cleaner. At the end of the procedure, wipe the crosses dry.

- Prepare materials for lubrication. After cleaning the crosspieces, prepare lubricants. To do this, unscrew the cap from the syringe and the plastic cover from the lubricant cartridge. An iron cap will appear under the latter.

- Assemble the syringe. Place the syringe into the hole in the cartridge and unscrew the iron cap.

- Lubricant injection process. Place one end of the syringe into the hole in the cleaned oil can and begin pumping the lubricant. At the same time, make sure that the syringe handle is squeezed all the way. This will ensure full penetration of the lubricant into it.

- Lubricate all points of the part. In total, the shaft has 3 such points. Two of them are on the crosspieces, and another one is on the spline joint.

Old grease will begin to come out from the opposite side of the crosspieces. Continue the procedure until fresh appears from there. You can distinguish it from the old one by color and density (the new grease will be red). That's all!

Consequences of ignoring a fault

Ignoring the lubrication of crosspieces can lead to the most disastrous consequences, including complete failure of the spare part and breakdown of your car. In this case, you risk not only your life, but also the lives of passengers.

If you do not carry out the procedure, you risk facing the following consequences:

- Vehicle vibrations. Worn seals or bushings can cause the driveshaft to vibrate. Failure to properly lubricate spiders, joints, or bushings can cause further damage to other transmission components. Note that tire problems can also cause vibration problems, but they are easy to tell apart. Vibrations caused by tire balance problems are speed sensitive, but driveshaft vibrations are not.

- Difficulty when turning. If you are having trouble turning, it may be due to a problem with the driveshaft. A faulty driveshaft can prevent your wheels from turning correctly, making your vehicle difficult to control.

- Loud noise. If you hear a loud noise when your car shifts gears, this is another sign of driveshaft damage. The likely culprit is worn crosspieces.

- The car shudders when accelerating. If you experience a shudder when accelerating from a stop or at low speeds, a loose weld or a bad center bearing may be to blame.

- Creaking noise. An annoying squeaking sound at low speeds can be caused by a lack of lubrication on the spiders. The lubrication procedure will get rid of it.

- Clicking or knocking sound. May indicate a worn or faulty driveshaft. Contact your mechanic.

As you can see, in order to ensure long-term and stable operation of your car, in addition to standard maintenance, you must carefully monitor the lubrication of the cardan crosspieces. If you have already encountered the procedure, tell us about it in the comments below the article.

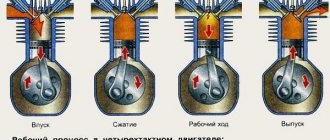

Design features

The driveshaft consists of 2 elements (in some types of equipment there are 3 elements), this allows you to transfer force from the gearbox to the axle with minimal losses. The elements are connected to each other by a cross. This hinge connection allows for optimally secure fastening between the nodes. At the same time, minimal wear of the associated elements is ensured.

The crosspiece requires constant lubrication

, so it is tightly stuffed with a plastic substance at the factory. This allows you to avoid problems during operation. But, unfortunately, there is not enough lubricant for the entire service life, so it must be added.

For process continuity, manufacturers have provided the ability to supply lubricant directly inside the crosspiece, without dismantling the cardan. This makes operational work easier. Also, thanks to this, it is possible to quickly perform injection if necessary.

If you do not lubricate the part, it will fail much faster. It is also worth considering that the crosspiece is almost constantly exposed to sand, dirt and reagents. Therefore, only the proper amount of lubrication can avoid many problems with this structural element.

How to lubricate a universal joint without an oil can

quote: take a needle from the system, dilute the lithol with a small amount of transmission fluid and repeat the process, No?

quote: Everything there that is not injected is, like, for the entire service life. #3

There is one idea - select the crosspiece to size, drill out the old one and make a key so that the new one does not fall out. You just need to see if there is room for the key.

quote: Firstly, the cardan is not eternal

quote: there is one idea - select the crosspiece according to size, drill out the old one and make a key so that the new one does not fall out. You just need to see if there is room for the key.

quote: Originally posted by pf:

The problem is precisely to accurately align the crosspiece in the ears. Well, balance the cardan. Otherwise there will be a beating like hell.

quote: If the crosspiece is pressed evenly, then no balancing is necessary.

quote: I inserted bushings to fit the size, protruding slightly beyond the ears and grabbed them.

quote: Originally posted by almost anonymous:

change the cardan? have you seen the prices?

quote: Originally written almost anonymously: Suzuki Jimny. intermediate shaft with a cross without a nipple for injection. The crosspiece is pressed tightly. It's sour, it's beating. Somehow I applied liquid oil through the seals with a medical syringe, but it lasts for a month, then it dries out again. What should I do?

Get rid of the trough

quote: Originally posted by almost anonymous:

What should I do?

quote: Originally posted by pornographer:

see above - this is what they usually do. insert nickels according to size and cook. sometimes, when the cardan is reaching its last days, they cook a glass of the cross without a nickel. and the problem is precisely to position the crosspiece exactly before it is fixed. This is almost impossible to do on your knees.

How to lubricate a universal joint without an oil can

Reputation: 0 Registered: 09/11/2008 Messages: 29 From: Kyiv

Groups

| Andrey34 |

| strateg |

| almost anonymous |

| strateg |

| Cossack-bereg |

| pornographer |

| fur dictator |

| strateg |

| USSR Moscow |

| pornographer |

| Cossack-bereg |

| [ CL "Longnomer" ] |

|