On Monday there was a little misfortune. I was driving around town on business and the car just stalled. The starter oils as it should and that's all. I immediately thought of only one thing - the ignition coil or the distributor cap, there’s usually nothing else that can break.

They pulled the car into the nearest yard. I removed the distributor cover and everything became clear. I don’t know where or how, but moisture often gets under the distributor cap. Possibly condensation, because I no longer see where else it can get in, because... Even when driving through puddles, water does not pour into the engine compartment. This is the second such problem and always occurs during a thaw, on days with fog and high humidity. The first time was about 3 years ago, also at the same wet time. In general, the central graphite contact that is retracted into the center of the slider is stuck in the cover; apparently the spring has rusted and remains in a compressed state. And the contact that goes to the high-voltage output of the coil was not only stuck, but also broke off, then the circuit was opened, before that it somehow drove like this, with stuck contacts, apparently a spark struck. But due to poor contact with the coil, the output from it was even slightly burnt. In short, I ordered the trampler cover and reel yesterday, picked it up today, 15 minutes and I’m back on wheels. Our coil is located inside the distributor, under its cover, remove the cover, 3 8mm bolts, coil with 4 bolts for a figured screwdriver + 2 bolts for 2 wires and it is removed. I'm not attaching any photos, because... I did everything on the field, in the city center.

There is a ventilation hole on the distributor cover, but it doesn't help at all along the way. The lid was also sitting on the sealant, I installed it after the first time, but still moisture appeared in it. I don’t know what to do with this, I’ll have to check it periodically, a couple of times a year. These are the pies.

On all carburetor cars produced in Tolyatti, a distributor-distributor is installed in the ignition system; there is no electronic control unit in the electrical circuit. Although the electronics are quite simple and reliable, breakdowns still occur.

Repairing the distributor on VAZ cars is necessary when its parts wear out, but if the damage to the device is too serious, it is not practical to repair the distributor; it is easier to replace it.

Distributor VAZ-classic

The breaker-distributor (CD) on rear-wheel drive VAZ cars is designed to interrupt the current in the primary circuit and distribute high voltage across the cylinders. On VAZ 2101-07 cars there are contact and non-contact distributors. Contact PR VAZ model 30.3706 consists of the following main parts:

- housings;

- roller with cams;

- centrifugal regulator with weights;

- contacts;

- runner (rotor);

- covers;

- vacuum ignition timing.

A capacitor is installed on the contact distributor, which improves sparking and protects the contacts from premature burnout. In a contactless system, interruption occurs due to a Hall sensor, which is installed instead of contacts.

VAZ classic distributors differ in shaft length - on engines 2101/21011 a distributor-distributor with a short shaft is installed, on engines 2103/2105/2106/21213 - with a long shaft.

Contactless ignition VAZ 2106

Some VAZ 2106 owners replace the contact ignition system with a contactless one. To do this, you have to replace almost all the elements of the system with new ones, but as a result, ignition is simpler and more reliable.

In a contactless ignition system there is no breaker, and its function is performed by a Hall sensor built into the distributor and an electronic switch. Due to the lack of contacts, nothing gets lost or burns here, and the resource of the sensor and switch is quite long. They can fail only due to power surges and mechanical damage. Apart from the absence of a breaker, a non-contact distributor is no different from a contact distributor. There is no gap setting on it, and setting the ignition timing is no different.

A contactless ignition kit will cost approximately 2,500 rubles. It includes:

- distributor with Hall sensor;

- an ignition coil whose design differs from that of a coil for contact ignition;

- electronic switch.

All these parts can be purchased separately. In addition, new spark plugs (with a gap of 0.7–0.8 mm) will be required, although old ones can be adapted. Replacing all elements of the contact system will take no more than an hour. In this case, the main problem is finding a seat for the switch. The new coil and distributor are easily installed in place of the old ones.

Preparation stage

Diagnostics of how the ignition module and each individual coil operates is carried out using a special device called a multimeter or ohmmeter. Its functional task is to show the voltage value supplied by the ignition module. As a result of diagnostics, it is possible to identify the source of current loss in the circuit and, accordingly, the nature of the malfunction. To facilitate painstaking work, it is recommended to dismantle the module outward before starting the process.

Distributor malfunctions

The distributor on VAZ cars may fail:

- due to mechanical damage;

- due to wear and tear of parts;

- due to moisture entering the device.

Main breakdowns in the distribution switch:

- cracks appear in the distributor cover, or the contacts in it burn out (central or side);

- the slider burns out;

- The Hall sensor stops working;

- shaft bearings wear out;

- the sensor contact breaks;

- the diaphragm of the vacuum ignition timing regulator breaks through.

The contact distributor may also have a faulty capacitor or burnt contacts.

You can identify a faulty distributor by the following signs:

Distributor purpose

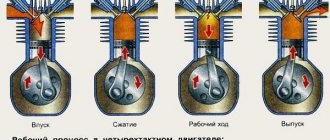

The distributor is a unique mechanism designed to determine the moment when high-voltage pulses begin to form in the ignition system. This device is used to distribute electric ignition among the cylinders of two types of gasoline internal combustion engines - injection and carburetor.

The distributor, by its nature, differs from other components in that its structure has a fairly large number of parts that wear out quickly. But the condition of this mechanism has a direct impact on the efficiency of the engine, as well as its starting characteristics. In addition, how efficiently the distributor works also affects the overall dynamics of the car and the toxicity of the exhaust.

As for the functions of this mechanism, there are two main ones:

- Interruption of the primary ignition circuit - in this way, the distributor provides current fluctuations in the primary winding of the coil, as a result of which a high level voltage appears in the primary part.

- Distribution of energy between the cylinder spark plugs in the required quantity and sequence.

The described mechanism is also indispensable because in its structure it has a number of mechanisms whose task is to change the ignition timing, which depends on the operating mode of the engine.

It should be noted that some cars, namely those with glow, diesel and compression engines, do not need a distributor for the simple reason that they have a different principle of ignition of the fuel-air mixture.

The key to high-quality circuit testing

Non-contact ignition system checks for short circuits

First, pay attention to the coil winding. To get started, connect a multimeter, which determines the resistance value

There is a recommendation regarding the lubrication of the tip of a high-voltage wire: a special product for the VAZ 2107 or technical petroleum jelly is used here.

The coil itself is diagnosed as follows:

- the module is disconnected from the tips;

- one terminal of the device is connected to the central contact, which has a coil;

- the other terminal of the device is connected to ground.

If the display of the infinity device implies that there is no short circuit, then the coil is in order

Important: unchanged display indicators when ringing the circuit will indicate infinity

Checking the primary ignition circuit involves installing a multimeter to its left and right contacts, which are assigned the ignition function. This setting of the ohmmeter should cause a change in readings. If this is not observed, you can prepare not only to replace the coil, but the entire device. Here they focus on the norm, which is 3-3.5 ohms.

The process of checking the secondary windings of the module includes:

Disconnecting wire tips from it. Level position in front of you. Installing the module to the right outputs of the upper and lower locations

Repair of VAZ 2106 distributor

On older VAZ 2106 cars, a contact distributor is installed, but such a system is not very reliable - due to malfunctions in the contact group (CG), various problems often arise:

- due to burnt contacts, the engine may not start;

- too large a gap in the CG affects engine power - the engine stops developing speed;

- If there is a small gap in the contacts, the motor jerks and works unstably.

- rotate the crankshaft until the marks align;

- we pull off the tips of the high-voltage wires from the spark plugs;

- unclip the two latches of the distributor cap and see what position the slider is in. If it is directed to the fourth cylinder, we make another full turn of the crankshaft. Usually, with correctly set marks, it should be located as in the picture below;

replacing the support bearing in the distributor

Actually, in order to change it, do you need to press it out somehow, or can you change it with a support? I’ve just never encountered a replacement for it, I know that it exists, but who the hell knows how it exists.

Denz, it is necessary as I understand. The shaft cannot be removed without removal.

NikVE, how much does a new distributor cost? About 1000r. Maybe? What if a new bearing costs a couple of tens? Perhaps then it makes sense.

NikVE what? should I buy a new tram? what for? the bearing with the support costs less than the stolnik, plus I’ll change the breaker contact at the same time. in total it will be less than 2 hundred. and the tram costs almost 7. Or maybe Omsk is a city of millionaires?

Because Zheka is talking nonsense, she advises me to replace my absolutely good distributor for some reason, the bearing is just a little loose. Judge for yourself why the hell should I change it entirely?

No, not nonsense! You often don’t value your time! And the tram doesn’t cost 7 tr! I took it for 700 rubles (approximately, I don’t remember exactly) for BKSZ. If you don’t have time or work, then yes, you can poke around until you lose your pulse!

NikVE is about 700, my tram is in 49 and I don’t need a car to change the bearings and contacts. Now I’ll go buy everything and change it. Why are you suggesting that I take my absolutely serviceable tram to the trash heap and buy exactly the same one?

Yes, it doesn't take long to change the bearing. but it’s better to buy a BSZ - there’s less climbing and adjusting. my opinion (because I will find time for repairs, but I don’t want to spend it on periodic adjustments).

The main components of the distributor and a description of its operation

VAZ classic distributor device

Device

The distributor is assembled in a housing. Inside it, a contact group is mounted on a bearing: moving and fixed contacts or a Hall sensor (for contactless ignition). To correct the advance angle, the vacuum regulator can rotate the contact group at a small angle relative to the housing. The capacitor is attached to the bottom of the case with screws. A drive roller is mounted on bushings in the center of the body. Its bottom has splines with which it engages with the drive gear. In the upper part of the roller there are contact drive cams (for contact ignition) or a steel cup with four slots - a screen (for contactless ignition). At the very top, on a steel platform, two weights and two springs of the centrifugal ignition regulator are installed. A plastic housing with a moving contact and noise suppression resistance of the high voltage distributor (slider) is screwed onto the top with two screws. The entire structure is closed with a lid on two spring latches. The body and cover have a tongue and groove so that they fit together in only one position. The cover contains contact terminals for high voltage wires from the spark plugs and from the ignition coil. The distributor is secured to the engine block using a stud, nut and pressure washer. To adjust the ignition timing, the housing can be rotated relative to the block.

Job

Removing the replacement part

Be sure to remove the terminal from the battery! After this, we disconnect all kinds of wiring from the coil, the main high-voltage wire. Now remove the cap from the distributor.

We must try to set the slider so that it is at an angle of 90 degrees towards the engine.

Draw a mark in advance (most conveniently on the cylinder block) so that you screw the new part to its original location.

Unscrew the nuts from the old distributor and remove it.

Distributor VAZ-classic

The breaker-distributor (CD) on rear-wheel drive VAZ cars is designed to interrupt the current in the primary circuit and distribute high voltage across the cylinders. On VAZ 2101-07 cars there are contact and non-contact distributors. Contact PR VAZ model 30.3706 consists of the following main parts:

A capacitor is installed on the contact distributor, which improves sparking and protects the contacts from premature burnout. In a contactless system, interruption occurs due to a Hall sensor, which is installed instead of contacts.

VAZ classic distributors differ in shaft length - on engines 2101/21011 a distributor-distributor with a short shaft is installed, on engines 2103/2105/2106/21213 - with a long shaft.

About the drive mechanism

To transmit torque to the distributor shaft on the “six”, a helical gear is used, rotated by a timing chain (in common parlance – “pig”). Since the element is located horizontally and the distributor roller is vertical, there is an intermediate element between them - the so-called mushroom with oblique teeth and internal grooves. This gear simultaneously drives 2 shafts: the oil pump and the distributor.

More information about the design of the timing chain drive: https://bumper.guru/klassicheskie-modeli-vaz/grm/kak-vystavit-metki-grm-na-vaz-2106.html

The distributor transmission consists of two helical gears

Both transmission links - the “hog” and the “fungus” - are designed for a long service life and are modified during engine overhauls. The first part is removed after disassembling the timing chain drive, the second is pulled out through the upper hole in the cylinder block.

The VAZ 2106 distributor, equipped with a contact switch, is a rather complex unit consisting of many small parts. Hence the unreliability of operation and constant failures of the ignition system. The non-contact version of the distributor creates problems much less often, but its characteristics are still inferior to modern ignition modules, which have no moving parts.

Distributor malfunctions

The distributor on VAZ cars may fail:

- due to mechanical damage;

- due to wear and tear of parts;

- due to moisture entering the device.

Main breakdowns in the distribution switch:

- cracks appear in the distributor cover, or the contacts in it burn out (central or side);

- the slider burns out;

- The Hall sensor stops working;

- shaft bearings wear out;

- the sensor contact breaks;

- the diaphragm of the vacuum ignition timing regulator breaks through.

The contact distributor may also have a faulty capacitor or burnt contacts.

You can identify a faulty distributor by the following signs:

Repair of VAZ 2106 distributor

On older VAZ 2106 cars, a contact distributor is installed, but such a system is not very reliable - due to malfunctions in the contact group (CG), various problems often arise:

- due to burnt contacts, the engine may not start;

- too large a gap in the CG affects engine power - the engine stops developing speed;

- If there is a small gap in the contacts, the motor jerks and works unstably.

- rotate the crankshaft until the marks align;

- we pull off the tips of the high-voltage wires from the spark plugs;

- unclip the two latches of the distributor cap and see what position the slider is in. If it is directed to the fourth cylinder, we make another full turn of the crankshaft. Usually, with correctly set marks, it should be located as in the picture below;

- pull off the hose from the vacuum regulator;

- unscrew the nut number 13, which holds the distributor, and dismantle the distributor.

Now the PR should be disassembled, perform the following operations:

The disassembly is now complete, all that remains is to troubleshoot and replace worn parts.

Installing a new spare part

We disconnect the cap from the new distributor, set the slider at an angle of 90 degrees, and only then begin installing the part.

Now we match the marks and tighten the distributor.

Having attached the cover, we connect the spark plug wires and the main wire of the ignition coil itself.

After this, we begin to change the ignition coil. Remove every single wiring from the old part, unscrew the bolts, dismantle it.

We connect the wiring (including high-voltage) from the distributor to the spark plugs to the new spare part.

We will connect two brown wires to the first contact, usually designated “K”, and two blue wires to the other (contact “B”).

A connector with three contacts must be inserted into an empty socket that has a distributor.

To install the switch, you will need to make a couple of holes and attach it with self-tapping screws. We recommend placing it next to the washer barrel and the left headlight.

We plug the most important connector into the switch, twist the wires into a bundle, and attach them side by side so that they do not interfere.

After these steps, you can safely start the VAZ 2107 car and hit the road.

Repair of VAZ 2107 distributor

First of all, we inspect the distributor cover:

- there should be no chips or cracks on its surface, both outside and inside;

- the coal on the spring should move freely, without jamming;

- there cannot be burnt contacts on the cover, and the internal contacts must not show signs of wear.

If the condition of the cover is in doubt, it is better to replace the part immediately, especially since it is very inexpensive.

The runner must also be visually intact, without external defects. We check the performance of the part using a multimeter, measure the resistance of the conductive part (resistor) - it should be in the range of 5 to 6 kilo-ohms.

The condition of the contact group is determined by external inspection - the contacts must close tightly, without gaps, and not have signs of burntness or severe wear. If the contacts are slightly burnt, we smooth out the unevenness on them with a file; a badly burnt CG needs to be changed.

The weights on the shaft should move easily, without jamming, and return to their place under the influence of springs. If jamming is observed in the mechanism, the moving joints should be lubricated with machine oil.

The shaft itself should not show signs of wear, and if there is wear on it, it needs to be replaced.

The distributor bearing should not bite, rotate as desired, or have any play.

Repairing the VAZ 2107 distributor is easy to do yourself; besides, distributor spare parts are always available in auto stores, and they are very inexpensive.

Repair of VAZ 2108 distributor (replacement of the vacuum regulator)

The ignition timing regulator can be replaced on site without removing the distributor:

Replacing the VROZH can also be done by removing the distributor, which will even be more convenient. Remove the distributor as follows:

- disconnect the high-voltage wires from the PR cover;

- use a thin screwdriver to hook the retaining springy wire on the connector and remove the plug going to the distributor from the bottom left;

- we pull off the hose from the VROZH, make a mark on the PR body or notice how it stood;

- unscrew the three nuts that secure the distributor itself, and then remove the breaker - distributor.

Reinstalling the distributor is simple - the camshaft spline has a groove shifted to one side, and therefore the PR is installed in only one position, it is impossible to make a mistake here. During installation, you need to pay attention to the rubber O-ring - if the rubber has hardened, the part must be replaced. And in any case, the seal should be coated with an oil-resistant sealant, in which case oil leakage will be almost 100% avoided.

Setting the angle of the closed state of the breaker contacts

The angle of the closed state of the contacts of the switch (UZSK) is, in fact, the space between the contacts of the switch. Due to constant loads, it is lost over time, which leads to disruption of the ignition process. The UZSK regulation algorithm is as follows:

- Disconnect the high voltage cables from the distributor cap.

- Unscrew the two fasteners that secure the lid. Remove the cover.

After adjusting the UZSK, the ignition timing is always lost, so it should be installed before assembling the distributor.

Video: setting the gap between the breaker contacts

Repair of VAZ 2109 distributor

One of the most common problems with the VAZ 2109 distributor is failure of the Hall sensor. If the sensor is faulty, the engine stops starting; we replace this part as follows:

- remove the distributor from the engine;

- unscrew the cover (two screws);

- dismantle the vacuum regulator;

- unscrew the screw holding the sensor connecting block;

- unscrew the fasteners of the upper bearing holder, it is secured with two screws;

- remove the bearing assembly with the sensor, remove the Hall sensor from the holder (two screws);

- we install a new part, assemble the distributor, and put it in place.

After repairing the VAZ2109 distributor, you may need to adjust the ignition; it is done very simply: