Rating

Rating of the most popular car tires according to users

Look

Popular article

What is rolling resistance coefficient

2

Home › Articles

Almost every car owner responsibly begins to choose winter tires, since they play an integral role in the safety of the driver on the road. High-quality tires guarantee your safety for several years to come.

Today we will look at Velcro winter tires and tell you what they are. Tires of this type are not very common yet, but soon more and more people will want to buy them. In another way, such tires are called friction tires. You may need to mention this scary word when purchasing.

- How Velcro tires work

- Advantages and disadvantages

- Review of the best tires

- Photo

- Conclusion

- Useful video

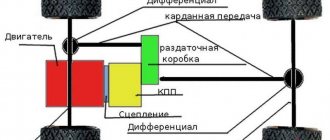

Principle of operation

A friction tire or “Velcro” is a class of winter tire that can cling to the ice surface without metal inserts. If in studded tires the interaction between the slippery coating and the tread consists of friction of the rubber and adhesion by the studs, then in friction tires only the friction force is used. The grip of a wheel on the road largely depends on the tread pattern. The greater their number and the total length of the edges in the contact patch, the better the wheel will handle the winter road. When accelerating, the rear edge of the tread block is used, and when braking, the front edge is used.

A heated winter tire can melt the ice structure. This is clearly evidenced by tread marks on the icy surface. The principle of operation of the Velcro protector is to remove (absorb) a thin film of water that forms between the icy surface and heated rubber, resulting in dry or semi-dry friction. The thickness of the water film is affected by air temperature and ice structure, so the traction properties of a tire depend entirely on climatic conditions. The lower the temperature drops in winter, the more effective the use of friction rubber is.

There is only one drawback, but a very significant one.

However, friction rubber also has its disadvantages. Velcro is intended for hard surfaces only. On soft and slippery surfaces, such as ice and packed snow, they are noticeably inferior to winter spikes. “Black ice” that forms at near-zero temperatures is especially dangerous for friction tires. It has a very low coefficient of adhesion and is sometimes covered with a microscopic layer of water, which, when mixed with snow and ice chips, instantly clogs the lamellas and reduces the adhesion properties of the rubber. The car can skid unpredictably even in a slight turn. Moreover, it will be extremely difficult to stop its chaotic movement. It is precisely because of the unpredictability of behavior on smooth ice that drivers traveling long distances in winter do not trust Velcro and try to use studded wheels. In such situations, studs allow you to better control the car and cope with possible skidding.

In general, friction rubber with a large number of sipes rides best on asphalt and is designed for life in large cities with good road infrastructure. She has no equal here.

Features of the Velcro splint

The functional features of Velcro are provided by the special properties of rubber and the special texture of the tire surface:

- a large number of lamellas;

- softness of materials;

- porous structure;

- abrasive microparticles.

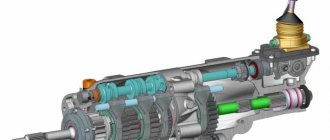

All friction tires are connected by an increased number of lamellas. The lamella is a thin strip of rubber into which the tread is divided. This separation increases the pressure on the coating, resulting in improved adhesion. The following types of lamellas are distinguished:

- transverse;

- diagonal;

- zigzag.

The Velcro protector is equipped with lugs, like any other self-cleaning protector. The difference lies in the increased density of the arrangement, which has a positive effect on mileage, allowing the use of a larger number of lamellas. It is the edges of the tire sipes that cling to the surface, and in combination with the large tread depth, a stable and large contact patch is formed.

Under the weight of the car, the lamellas in the tread blocks diverge, which literally sticks to the surface of the snow-covered road surface. When leaving the contact zone with the road, the sipes converge and the tire self-cleans, displacing crushed ice and snow. But the lamellas are far from the only important condition. No matter how many of them are provided, maximum adhesion efficiency can only be ensured by the porous structure of the rubber. It is this that will absorb water when hitting the road surface.

The composition of the Velcro rubber includes a cryosilane mixture with silica, so it does not become rough at low temperatures, and a large number of micropores remove the water film. At the molecular level, each pore of the tire interacts with the road surface according to the suction cup principle, which provides not only an effective traction function, but also a short braking distance. At the same time, many manufacturers claim the addition of solid microparticles of inorganic and organic origin to the rubber mixture. Such abrasives perform the function of unique mini-spikes, which only enhances the friction properties.

Review of the best tires

First, you need to divide tires into three segments: premium, medium, and budget. Below is an analysis of the best models from each segment:

- Premium.

- Bridgestone Blizzak VRX . The main difference between this Japanese tire is its high service life. Thanks to the asymmetric tread pattern, road traction improves significantly, thereby increasing cross-country ability. The central part has special checkers that have cross sections. They improve traction on loose snow;

- Goodyear UltraGrip Ice 2 . These tires are designed for high snowy and icy roads. Their distinctive property and main feature are special treads and sipes, which allow the tires to be used much more efficiently even during the harshest winter. The rubber composition has been changed, due to which, with a sharp drop in temperature, the properties of the tires do not change;

- Nokian Hakkapeliita R2 SUV . These Finnish tires cannot be confused with any others thanks to their special tread. It helps you accelerate quickly and brake confidently on icy roads. Such tires are no worse than studded tires.

- Average.

- Hankook Winter I*Cept IZ2 W616 . The tread pattern is V-shaped notches. This car Velcro rubber is also well suited for use in harsh conditions. In the middle there is a special rib necessary for the stability of the wheel. There are diamond blocks on the side parts. They are designed to remove moisture.

- Budget.

- Barum Polaris 5 . This relatively inexpensive tire is suitable for both crossovers and cars. Its main advantage is good handling on ordinary clean and asphalt roads. These tires also significantly reduce fuel consumption. The fifth revision of this model has improved handling;

- Nexen Winguard Ice . On snowy and icy roads, handling results remain at a good level. There are a lot of lamellas on the surface of the tire. The tread has sharp-angled additional edges. The car's stability is good both on ice and asphalt. Skidding on such wheels is rare.

May be interesting : Tire storage

Types and features of friction tires

Depending on their performance characteristics, friction tires are divided into Nordic and European. This is a conditional division; there is no such marking on the tire. Velcro of the Nordic type differs from the “European” type by the following features:

- A large number of deep slats. Compared to European friction rubber, the sipes are cut to almost the entire tread depth. Thanks to this, the tread blocks open and simulate the tire sticking to the surface.

- No tenon/tenon hole.

- Low speed index. “Scandinavians” are less stable at high speeds due to the dense cutting of the sipes and deep tread. As a rule, the speed limit varies between 160-190 km/h.

- The soft composition of the rubber compound ensures that elasticity is not lost at extremely low temperatures.

- Nordic friction tires are designed for cold winters with frequent snowfalls, while “European” tires do not tolerate frost and require more gentle conditions - clean roads treated with deicing agents.

Rubber - Velcro: why is Velcro better than spikes?

In recent years, many motorists, when choosing winter tires, are faced with the fact that stores offer them two types of tires - winter tires with studs or winter tires without studs, the so-called “Velcro tires”, or friction tires.

If you don’t listen to the manager’s admonitions, then for many the question arises: what kind of tires should you choose, studs or Velcro? How is Velcro better than spikes?

From this article you will learn:

- What are studless winter tires?

- Pun

- How to drive in winter

- What to choose?

If with studded tires everything is more or less clear - soft rubber and a deep pattern for driving on snow, and studs for driving on ice - then motorists have many questions about Velcro and friction tires.

Firstly - What is Velcro rubber?

Secondly, what operating conditions are Velcro tires intended for?

Thirdly, how can Velcro “stick” to the road and how strongly can it “stick” to an icy surface?

What are studless winter tires?

Velcro rubber is a winter tire without studs. Initially, winter tires without studs were invented in Europe specifically for comfortable European winters with slight frosts.

Roads in Europe are maintained in good condition at all times of the year, ice on the road is rare, and studded tires are in most cases not needed for driving on European roads in winter.

Moreover, in most European countries, such as Germany, France, Great Britain, Czech Republic, Poland, etc. The use of studded tires is prohibited.

And for these countries, so-called friction tires were developed (from the word “friction” - friction), which received their second name - “Velcro”, which are ordinary winter tires without studs, adapted for driving in any winter conditions, including on the ice.

Pun

If the name “friction tires” comes from the scientific term “friction” - friction, then the name “Velcro”, in turn, was invented by tire sales specialists specifically for countries with cold climates, such as Russia, where buyers have long been accustomed to studded tires. tires, and are reluctant to buy winter tires without studs.

When a buyer sees the name “Velcro Rubber,” he understands that he is buying tires whose properties differ from those of “regular winter tires without studs,” and therefore these tires deserve attention.

How to drive in winter

Today, operating a car in winter in a big city is very different from how it was used 20 years ago.

Today, in big cities in winter, tons of special reagents are poured onto the roads, which melt snow and ice, but at the same time form a greasy film on the asphalt.

When driving on asphalt covered with such a film, a car on studded tires feels quite insecure - the metal studs slide, noticeably increase the braking distance and interfere with stable movement.

In turn, a car on friction winter velcro tires that gets onto asphalt covered with a greasy film feels much more confident, because there are no slippery metal spikes in the contact patch, and the tire itself has increased frictional properties.

It is also worth saying that at very low temperatures, Velcro often behaves better than a studded tire, due to the fact that in severe frost the water film, which is the main reason for slipping, forms much more slowly. In this regard, the absence of unnecessary interference in the form of studs improves the traction properties of the tires.

For these reasons, today's motorists, who drive their cars most of the time on city streets cleared of snow and generously flavored with reagents, increasingly prefer Velcro to regular studs.

What to choose?

Spikes or friction rubber-Velcro? The answer to this question for today's motorist will depend on two points: how often he plans to travel outside the city in winter, as well as on the climate in which he operates his car.

Features of the use of Velcro

The legal requirements for the winter class of tires are the same for both studded and friction tires. Between December and February, vehicles must be equipped with winter tires bearing a mountain peak icon with a snowflake and the lettering "MS", "M&S" or "M+S". In this case, the remaining tread height should be more than 4 mm. The requirement for a vehicle to have a sign with the letter “Ш” does not apply to friction tires.

It is important that this technical regulation prohibits the use of studded tires in the summer, but there is no direct ban on the use of Velcro during the same period. However, this does not mean that the tire can be considered all-season: its characteristics are designed for the winter period, and operation on hot asphalt will lead to a loss of adequate controllability and accelerate wear. It is worth remembering that during the first 100-150 km the friction tires are broken in. This distance is enough to erase the film of lubricant that was applied before vulcanization. The optimal speed during the break-in period is no more than 80 km/h. The slats will sharpen in the direction of travel, so you should not brake sharply or make other sharp maneuvers. Otherwise, damage to the tread is inevitable.

During further operation, such sharp maneuvers are also undesirable: the rubber of friction tires is soft and therefore wears out quickly. Installation of the old set for the next season should be carried out in compliance with the direction of rotation that was previously.

Advantages and disadvantages

No type of tire can be called ideal. Below we will list both the disadvantages and advantages of friction tires. Pros :

- comfortable and soft ride;

- preservation of properties in the cold;

- good road handling;

- Possibility of use in the off-season;

- effective self-cleaning;

- improved water removal;

Minuses:

- poor handling on packed snow;

- disproportionate wear;

- need for break-in.

Attention! During the first kilometers, the car must be driven carefully, without making sudden maneuvers.

Useful to read : Monitoring tire pressure

Buy correctly, don't get confused

In conclusion, I would like to note that many of us confuse the friction tire with the so-called EUROZIN , and then tell everyone that this “Velcro doesn’t work at all,” but this is not entirely true. EUROZIMA is designed for a very mild climate, literally for several days or weeks of not so low sub-zero temperatures, and its operation is also recommended on cleared and well-maintained roads - THIS IS A COMPLETELY DIFFERENT RUBBER. Don't confuse it with real winter!

Now let's watch a short video of the work.

I’ll finish this, I think the article and video were useful to you. Sincerely yours, AUTOBLOGGER.

Similar news

- How are wheels made? Let's analyze an ordinary car + detailed video

- Unwelding. What is it, main pros and cons. How to make a s…

- How to choose winter tires for a car. 8 right steps! Pl...

Add a comment Cancel reply

Where to use Velcro?

And now we come to the most important thing, now in megacities it is better to use Velcro when there is snow porridge. The thing is that it removes moisture much more efficiently, and also does not make noise on the asphalt, it simply has nothing to do with it (there are no metal elements in it).

YES, it can also cope with ice and snow, but it also has its disadvantages.

Snow cover - on snow cover it is practically in no way inferior to its studded counterpart; it also has a high profile that bites into snowdrifts and overcomes them. REMEMBER, in the snow, spikes are not entirely necessary (the main thing here is the profile), unless, of course, you have polished the wheels to the bottom coating - ice.

Ice covering – this is where Velcro loses a little; nevertheless, the spikes pierce the ice and cling to it like claws. Velcro does not have this, it has a special coating - friction, which does not slide over the surface, but tries to cling to it. Let's just say it's not always effective! Up to – 18, – 20 degrees Celsius, Velcro loses a little; if we translate into percentages, its ability to grip on ice is 15, 20% worse than that of spikes.

However, after -20 degrees, the characteristics of winter tires are practically comparable, the whole point is that at such temperatures the ice becomes very strong, the studs are not able to “pierce” it, they scratch it, trying to cling to it, and the rubber is on studded tires rougher. But the Velcro remains just as elastic, clinging to the surface.

So how does it do this, how does it work on ice and snow?