A differential is a transmission mechanism that distributes the torque supplied to it between the drive shafts and allows the wheels to rotate at different angular speeds. This is especially noticeable when the car goes through a turn. The differential ensures safe and comfortable driving on dry paved roads. However, if the car leaves its limits and continues to move over rough terrain, as well as in the event of ice (and other severe weather conditions), this mechanism may make it impossible for the car to move. What a differential is, how it works, what its harm is for SUVs and how to deal with it will be discussed below.

Differential as part of the transmission

A differential in a car is a mechanism that distributes the torque of the driveshaft of the transmission between the drive wheels of the front or rear axle (depending on the type of drive), allowing each of them to rotate without slipping. This is the main purpose of the differential.

Sectional view of drive axle with differential

During straight-line motion, when the wheels are loaded equally and have an equal angular speed of rotation, the mechanism works as a transmission link. If driving conditions change (turning, slipping), the load becomes uneven. The axle shafts need to rotate at different speeds, and, as a result, it becomes necessary to distribute the resulting torque between them in a certain ratio. Then the unit performs a second important function: ensuring safe maneuvering of the vehicle.

The differential arrangement depends on the type of vehicle drive:

- Front-wheel drive - gearbox housing.

- Rear-wheel drive - drive axle housing.

- All-wheel drive - front and rear axle housings (to transmit torque to the drive wheels) or a transfer case (to transmit torque to the drive axles).

The differential on cars did not appear immediately. The designers of the first “self-propelled carriages” were very puzzled by the poor maneuverability of their inventions. Rotating the wheels at the same angular speed while cornering led to one of them starting to slip or, conversely, completely losing contact with the road. Engineers remembered that the early prototypes of the first cars powered by steam engines had a device that prevented loss of controllability.

The torque distribution mechanism was invented by the Frenchman Onesiphorus Peccoeur. Pekker's device included shafts and gears. Through them, torque from the engine was supplied to the drive wheels. But even after applying Pöcker’s invention, the problem of wheel slipping when cornering was not completely resolved. The system's shortcomings were revealed. For example, one of the wheels at some point lost traction. This was most pronounced in icy areas.

Slipping in such conditions often led to accidents, so the designers spent a long time thinking about how to prevent the car from skidding. The solution was found by Ferdinand Porsche. He became the inventor of the cam mechanism, which limited the slipping of the wheels of the drive axle. The German differential device has found application in Volkswagen cars.

Service

Maintenance of a working differential comes down to changing the oil in the gearbox or transfer case. No adjustment or other service operations are provided, only repairs for wear and tear. On self-blocks, sometimes it will be necessary to restore the preload value by selecting a package of spring washers.

Typically, all limited slip differentials require the use of a special oil such as LSD (Limited Slip), but now the best universal oils already have similar properties, as indicated on the label.

In any case, it is better to follow the manufacturer's instructions for a particular product.

How does the differential work?

Schematic diagram of a differential

The unit operates as a planetary gearbox. The basic structure of the differential: the gears of the axle shafts (5) and satellites (4) are located in the cup (3). The cup (housing) is rigidly connected to the driven gear (2), which receives torque from the main gear drive gear (1). The housing transmits rotation through satellites to axle shafts that rotate the drive wheels. Different angular velocities are provided due to the operation of the satellites. The amount of torque remains unchanged.

Application of differentials depending on their types

The devices are used to transmit torque to the drive wheels and drive axles of a vehicle.

Trucks and cars of all types of drives have a cross-axle differential that transmits rotation to the wheels. A center differential, which distributes torque between axles, is used exclusively in all-wheel drive vehicles.

Based on the type of gear used, the following types of mechanisms are distinguished:

- conical;

- cylindrical;

- worm.

By the number of teeth of the axle gears:

- symmetric;

- asymmetrical.

Due to its property of proportionally distributing torque, an asymmetrical differential with a spur gear is installed between the axles of all-wheel drive vehicles.

Rear-wheel drive and front-wheel drive cars are equipped with a symmetrical bevel differential.

The worm gear, being the most universal, is used in all types of devices with all drives.

Automotive gearbox design

To familiarize yourself, you should consider the main components of this transmission unit.

The automotive gearbox includes:

- The body is made of high strength steel and a number of light alloys. It is used to protect the center differential from excessive external influences.

- Fastenings - they provide a strong connection between the body and the base; seals are seals. The latter prevent leakage of transmission fluid, which ensures the functioning of the differential and gears.

photo gearbox Hypoid gear

Differential operation diagram

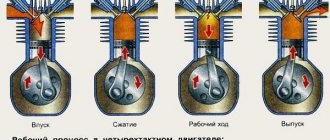

Let's consider the principle by which a symmetrical bevel differential operates, distributing torque between the wheels in three different conditions:

- straight motion;

- turn;

- slippage.

When moving in a straight line

Rectilinear movement is characterized by uniform distribution of load between the wheels of the car. They have the same angular velocity. The satellites placed in the housing do not rotate around their axes. They transmit torque from the main drive driven gear to the axle shafts through a fixed gearing.

Differential operation when turning and straight-line movement

When turning

When a vehicle turns, the drag forces and loads are distributed as follows:

- The inner wheel, which has a smaller radius from the center of rotation, experiences greater resistance than the outer wheel. The increased load forces it to reduce its rotation speed.

- The outer wheel, moving along a larger radius (larger trajectory), on the contrary, must increase the angular speed so that the car can turn smoothly, without slipping.

Thus, the wheels must have different angular velocities. Slowing down the rotation of the inner wheel axle shaft sets the satellites in motion. They, in turn, increase the rotation speed of the outer wheel axle shaft through a bevel gear. The torque received from the final drive remains unchanged.

When slipping

The wheels of a car, even moving straight on a slippery road or off-road, may experience different loads: one of them slips, losing traction; the other, becoming more loaded, slows down. The rotation pattern is repeated. Only now it causes harm: the slipping wheel can receive 100% of the torque received by the differential, and the loaded one will stop rotating altogether. The car will stop moving.

These disadvantages of the node operation are solved in various ways:

- manual or automatic locking;

- implementation of the exchange rate stability system.

Advantages and disadvantages

The main advantage of the differential is that it made it possible to make turns. The speed of movement of each wheel on the drive axle is adjusted to the road situation completely automatically, without driver intervention, so the safety and maneuverability of the vehicle have increased tenfold after the introduction of this mechanism. Today, a differential of one design or another is used in all types of automobile transport.

Another advantage is the fairly high reliability of the node. The planetary gear can withstand heavy loads, and the features of some types of differential further increase its power and wear resistance

The main disadvantage is the need to use a locking mechanism so that the car can move on ice and on difficult roads. Manual, automatic or electronic - any type of locking must be used, which means that there is an additional mechanism that can fail.

And, of course, we must not forget about monitoring the technical condition of the unit. This is another unit in which you need to change the oil, although not often, and monitor the wear of parts. And, by the way, many car owners forget about the need for this procedure.

Differential lock and stability control

Forced differential locking with a hydraulic drive

In order for the torque of the axle shafts to become the same again, it is necessary to block the action of the satellites or ensure its transmission from the cup to the loaded axle shaft.

This is especially true for off-road vehicles with 4X4 all-wheel drive. Not only because they are designed for driving in areas with difficult road conditions. If a car equipped with three differentials (two interwheel, one center) loses grip at least at one of the four points, the torque of the remaining wheels will go to zero, and the car will refuse to move.

Locking helps to avoid troubles, which can be either partial or complete (depending on the degree of redistribution of forces between the axle shafts), as well as either manual or automatic (depending on the degree of control on the part of the driver).

Self-locking differentials have proven themselves well, distributing torque taking into account its difference on the axle shafts or based on the values of angular velocities.

The most complex and perfect way to eliminate the shortcomings of the unit is electronic locking, implemented on the basis of the exchange rate stability system, the sensors of which monitor all the necessary parameters while the car is moving. Based on the data received, the vehicle’s operation is adjusted automatically.

Types of mechanisms

To get rid of slipping on slippery road surfaces or in off-road conditions, manufacturers equip vehicles with differential devices of the following designs:

- free-type mechanism with forced locking from the drive;

- partially locking limited slip differential;

- self-locking worm gear Torsen type.

In the first option, the gear unit discussed above is used, additionally equipped with a locking device. The system functions simply: if necessary, the driver activates the drive, which locks the satellites in a stationary state. The torque begins to be divided exactly in half, the axles rotate at the same speed and the vehicle successfully overcomes the problem area.

Forced locking of the center differential is activated using various drives:

- mechanical - from the transfer case lever;

- electric;

- pneumatic;

- hydraulic.

Similar drive elements are used to stop and hold the satellites of the front or rear axle.

Manufacturers equip expensive cars with a traction control system. It “deceives” the differential device in another way: based on a signal from a sensor that detects the rapid rotation of one wheel, the electronics gives the command to slow it down. Then the satellite gears begin to transfer more power to the other axle and the car stops “rowing” in place.

High resistance device

In addition to satellites, drive and driven gears, the limited slip differential includes the following elements:

- a housing rigidly attached to the planetary gear;

- a package of friction discs installed on each axle shaft;

- steel disks, whose protrusions are fixed in the body;

- a spacer spring inserted between the bevel gears of the axle shafts.

Steel and friction discs (similar ones are used in clutches) are installed alternately, the first rotate with the body, the second with the axles. The cone-shaped gear is put on the splines of the axle and is capable of moving a certain distance. The spring presses 2 opposite axial gears.

Partial differential locking occurs as follows:

- On a straight, dry section of the road, the satellites are stationary, and the disks rotate relative to each other.

- When one tire hits a slippery area, slippage begins. Thanks to the conical shape of the teeth, the gears on the side of the stopped wheel will begin to repel each other.

- The axle gear will move and compress the disc pack. A friction force will arise, causing the axis to rotate together with the body directly from the planetary gear, bypassing the satellites.

Such a device independently regulates the degree of blocking - the slower a tire with good grip spins, the more the disks are compressed and the more torque is supplied.

Torsen self-locking gears

The operating principle of these mechanisms is based on one feature of the worm pair: the gear is capable of transmitting rotation to the satellite, but the reverse action is impossible. All gears, including satellite ones, are made in the form of cylinders with oblique arcuate teeth. In total, the mechanism uses 3 pairs of worm gears installed around the axle gears.

A limited slip differential works like this:

- During linear motion, worm satellites behave similarly to cone gears - they do not rotate themselves, but rotate the axes from the main gear.

- When turning, the number of revolutions of one axle shaft will increase and it will give rotation to pairs of satellites - the power will begin to be distributed differently.

- Since each pair of satellites is connected to each other by a spur gear, slipping of one wheel is eliminated. The axis is capable of turning its satellite, which rotates the neighboring one, which can no longer turn the second axle axis. The mechanism is locked automatically.

The Torsen device is the most reliable and advanced, but too expensive, so it is installed on top-spec cars. The rest use more accessible high-friction mechanisms.

Among fans of extreme off-road driving, the simplest way to avoid slipping is known - locking the rear differential using welding. The satellites are tightly welded to the axles and are always stationary. True, such cars are intended only for driving on dirt and snow - operating them on hard surfaces is too inconvenient and expensive.

Safety first

The differential is designed to ensure safe, comfortable maneuvering on the highway. The disadvantages described above apply to driving in extreme conditions, as well as on rough terrain. Therefore, if your vehicle is equipped with a manual locking drive, it should only be used in appropriate road conditions. And highway cars, which are difficult to “persuad” to drive slower than 100 km/h, are generally impossible and even dangerous to operate without a differential. This is a simple, but infinitely important mechanism in the transmission.

Finding a New Differential

Despite the fact that a cross-axle or central differential is easy to find on the auto parts market, its cost is quite high (a new part can cost from hundreds to thousands of dollars). For this reason, most motorists rarely agree to a complete replacement of the mechanism.

A new mechanism or its individual elements can be found in the same way as regular auto parts. The easiest way is to go to the store and ask for a specific part for a given car. However, this applies if the car has not been modernized. Otherwise, the part is selected according to the unit code or the model of the car from which the spare part was removed.

It is best to search for a part using the vehicle data rather than the product code, since these symbols can only be found after dismantling the mechanism. This unit has many modifications. Even for the same brand of car, different differentials can be used.

Considering this point, it is extremely difficult to find an ideal analogue from another car. As for purchasing a differential on the secondary market, this is left at the car owner’s own risk, since no one will be able to disassemble and check the condition of the part. This increases the risk of buying a heavily worn mechanism.

To summarize, it’s worth saying that without a differential it is impossible to create a safe and efficient car, although those who like to spin pennies on dry asphalt will argue with this.