What is a Kalina oil pressure sensor (DPM), many car enthusiasts imagine only in general terms. Often, Kalina owners, without reading the booklet that comes with the car when purchasing it at a car dealership, do not even always know which icon on the dashboard means what. Although it is quite possible to guess this without reading the instructions.

But for beginners this can be difficult. Therefore, if the Lada Kalina is your first car, then it is better to read the instructions very carefully. In this case, it is advisable to be near the car.

Oil leak from oil pressure sensor

The second common failure is an oil leak from under the sensor.

In this case, the exhaust manifold of the 1st cylinder, the upper part of the pump, and the left side of the engine protection will be in oil. The sensor itself and the wire leading to it will also be covered in oil. If you find oil leaks in the area of the first cylinder, make sure that it is not the camshaft or crankshaft seal, it is not leaking from under the valve cover gasket, or, which is much worse, the cylinder head, then in 99 cases out of 100 the fault will be a broken oil pressure sensor.

We wipe off all the drips, install a new DDM and observe. If there are no more leaks, you did everything right.

PS, when installing a new sensor, do not tighten it with too much force, you can overdo it and break the thread on the head of the block, which will not please you.

What is an oil pressure sensor (OPS)

Not all motorists know; as a rule, acquaintance with it occurs after the oil pressure indicator lights up on the dashboard and does not go out for a long time. Then any conscious car owner has a lot of unpleasant questions and premonitions. Some people prefer to immediately contact a service station, while others begin to look for the cause on their own. If you belong to the second type of people, this article will be useful to you, because in it we will talk about how to check the oil pressure sensor, as well as how to replace it using the Lada Kalina as an example.

First of all, you should not fall into despair and draw hasty conclusions; the emergency oil pressure light really indicates a critical oil level in the system and a drop in pressure, but it is not a fact that this is the reason. It happens that the sensor itself fails and simply “lies”. If you don’t notice this in time and don’t find out who is right and who is wrong, you can really do some serious “things.”

How does the oil sensor work and why can it fail?

Now let's consider the situation if you are on the road and the low pressure indicator has triggered.

The very first thing you need to do is stop the vehicle and turn off the engine. As soon as it cools down, you will have to check the lubricant level in the system. There is a special dipstick under the hood for this purpose. It is wiped dry and immersed in its original place. It is quite possible that the level will be below the minimum level. This means that somewhere there is a leak or depressurization of connections. You can set off again only after adding oil to the engine. If the lamp continues to light after starting and does not go out subsequently, it makes sense to think about towing the car to the nearest service station or to a trusted auto mechanic. The matter may turn out to be quite serious, so it is advisable to conduct the examination in a calm environment. Since we have already said that the causes of low pressure may be associated with a faulty sensor, it would be useful to understand the principle of operation of this device. There are certain contacts inside it. Until the ignition is turned on, there is no pressure in the system, so the contacts are closed. When you turn the key and turn on the ignition, but before the starter starts, the warning lamp should be on. If this does not happen, then there may be some kind of malfunction. Maybe the light bulb itself simply burned out, or maybe the contacts were broken or the sensor itself failed. As soon as we start the engine, the contacts open, leading to the light bulb going out.

Speed sensor

The DS is intended to measure the speed of a vehicle, with subsequent transmission of the received data to the ECU. The speed sensor is a small part; it is located in the upper part of the clutch housing, near the front wheel on the right. Its malfunction is usually directly related to a breakdown of the speedometer. However, the sensors installed on Grants are distinguished by fairly high quality and durability.

By the way, initially three types of speed sensors were installed on Grants: VAZ-2170 PEGAS, 2190 AVAR Russia and 21700-3843010-02.

More details about the speed sensor on Grants.

If the DS malfunctions, the electric power steering most often stops functioning, and at the same time the instrument panel begins to display error P-0501. As a rule, the steering wheel fails precisely because the car detects a breakdown of the speed sensor; the DS itself may show zero speed.

If the sensor fails, the following symptoms of failure are noted:

- the speedometer needle stops at the zero mark; often the speedometer operates only periodically;

- when the engine is running idle, interruptions are observed;

- the speedometer readings diverge from the actual speed of movement;

- fuel consumption standards are increasing;

- craving worsens.

These parts have their own markings, their price ranges from 300 to 600 rubles.

Anti-drainage valve as a reason

The so-called “anti-drainage valve” maintains the oil pressure inside the filter; it is this that “locks” the lubricating component inside. If this valve fails or is made of low-quality materials, then it will not work! Here's the reason.

But what is it, what does it consist of? Guys, essentially the valve is a banal rubber band, or now it’s just ordinary silicone

However, rubber (silicone) also comes in different qualities, and the assembly of the product also plays an important role.

It happens that immediately after changing the oil, a long extinguishment of the pressure lamp appears. This means either there is simply no rubber band (valve), or it has fallen off or torn (from “high” quality). THIS FILTER NEEDS TO BE CHANGED IMMEDIATELY! BECAUSE THE QUALITY IS SIMPLY “BELOW BELOW PINBOARD”, IT IS STILL NOT CLEAR WHAT IS THERE WITH THE FILTER PAPER.

It is also not uncommon for the light to start to light up after a certain mileage, say after 1000 - 3000 km. This also tells us that the anti-drainage valve is of poor quality, that is, the rubber has become “stiff” (or baked) from the high temperatures of the oil, and no longer holds it inside. It is also worth getting rid of such an element.

Kalina, misfires on cylinders 1 and 4

Hi all. KALINA-1.6,8V 11183-1411020-22, I201CO57. January 7.2 E2 suffered all day, cylinders 1 and 4 do not work. No reaction at all on these cylinders, as if they were not there at all, when removing the spark plug wires from these cylinders, zero reaction .Compression is 11 in cylinders 1 and 4, and 2 and 3 are 10 atm each. Valve regulation is in order, fuel pressure is 3.8, spark plugs, wires, oil pump are in order. Of the errors, of course, there are leaks in cylinders 1 and 4. I checked the air intake , no leaks. The spark plugs for 1 and 4 are black, there are no short circuits in the injector wires, I checked them separately from the ECU for each injector. I changed the DPKV. The client claims that all this happened after replacing the clutch disc, i.e. The gearbox was also removed. And also errors according to EMUR MAKHACHKALA.

It’s strange, there’s compression, there’s a spark, the valve adjustment is fine, there’s no air suction, the injectors are controlled, there’s no difference between cold and hot, :bezpo:

Modified November 27, 2022 by Qena

§

I haven’t worked with a postograph, but I’ve studied its functionality; to be honest, the settings are a little unclear. In principle, something simpler, like Osa, is enough, because if you’re not going to diagnose everything using an oscillator, including tire pressure :), then the Postolovsky is not needed at all, it’s expensive, and basically it will lie on the shelf. For example, it’s easier for me to look at the marks on the belts visually, more reliably, and faster than hanging the engine with wires every time and fussing with the settings, and a compression gauge it’s easier and faster to stick it into the cylinders than hemorrhoids with a pressure sensor. For diagnosing the secondary, and not only there is a good thing from ACELab for 8 tr, I’ve been using it for the second year or so, it’s quick to use, auto-tuning and all sensors can also be checked, and for the secondary there are two types of probes, for wires and individual coils, take a closer look at it, it’s definitely worth the money, and to check the coils I additionally use a Chinese RLC meter for 3 tr, in the mode of checking the quality factor of the coils, I read somewhere on the sites, I bought it and use it, using the coils I calculate 100% using these two gadgets

Computer diagnostics

The most effective methods are those using sophisticated computer technology.

What does this method provide? First of all, it allows you to control the entire internal combustion engine. The diagnostic accuracy is exceptional. Errors that may arise as a result are automatically eliminated using special programs.

Types of work:

- stationary – with the device connected directly to the car’s ECU (PC, laptop, scanner);

- remote – via Bluetooth or Wi-Fi (tablet, smartphone).

Computer data processing is carried out by introducing “software” (programs) into the processor of the device, focused on:

- comprehensive diagnostics (engine, suspension and steering systems, brakes);

- ICE;

- electronics.

How to do it? Drivers usually use the services of a car service center. This is not the only option. With some preparation, it is possible to diagnose a car yourself.

Description of the procedure:

- Basic equipment: - computer; — “K-Line” adapter with a cable on Olb2 and Usb connectors (for a fixed connection) or Elm327 adapter with Bluetooth (remote testing); — diagnostic programs and drivers;

- installation of the necessary “software” and “chip” (driver) on the computer platform;

- “firmware” (adaptation) of the ECU (provides communication between the controller and the computer and transfers to it all available vehicle parameters.

The state of the required systems is determined by gradually scanning each node. Defects that cannot be eliminated by the intervention of electronic correctors are eliminated during minor, medium or major repairs.

Why does the light stay on after the oil has been changed?

Yes, there are times when even after changing the oil, the driver still detects the same signal indicating a failure in the system. The red “oil can” is a reason for both simple and complex problems.

Let's consider a situation where the lamp flashes immediately after turning on the car's ignition. The lack of oil in the engine is to blame here. Measure the level and add, if necessary, the required amount of lubricant.

If low-quality oil or filter was used, the lamp will also get on your nerves with its light. We advise you to choose only those filters recommended by the car manufacturer. It happens that, saving on parts, we often play around with operating the car and then pay several times more for repair work. A defective filter will not be able to contain the oil, so sooner or later you will have to change it. Everyone understands that high-quality components are the key to long-term operation of any unit, including a car engine.

Expert answer

To get a more accurate answer to the question posed, you need to specify the make of the car, year of manufacture, and engine type.

There are several methods for assessing the performance of the listed sensors without the use of special equipment and computer diagnostics.

Let's start with the oxygen sensor. It is installed on the exhaust manifold. If this sensor is faulty, fuel consumption increases by 30 - 40 percent. Moreover, if the sensor heater is working properly, then the check will not light up at the time of start-up. The sensor heater circuit can be tested with a multimeter; the resistance will be in the range from 2 to 10 ohms. The multimeter is connected to the thicker wires of the sensor.

You can check the oxygen sensor by connecting a voltmeter to the thin terminals of the sensor. When over-gassing (enriched mixture), the voltage at the sensor terminals should be more than 0.7 Volts; when the mixture is lean (idling, you can artificially create a suction into the intake manifold), the voltage drops to 0.2 Volts. If the voltmeter readings are different, the sensor should be replaced. Washing and cleaning will have no effect. The sensor on the Toyota model is not cheap; you can install a universal lambda probe, including from Lada.

If the mass air flow sensor (flow meter) is faulty, an incorrect fuel/air ratio is formed, which can also lead to an increase in fuel consumption by 10 - 20%. In this case, there are difficulties with starting, uneven engine operation. The check is easy to do. If, after disconnecting the sensor connector, the engine continues to run as before, the sensor is most likely faulty. Washing the sensor with a carburetor cleaner sometimes works, especially if the sensor is contaminated with crankcase gases from a “rotating” engine. The flow meter is usually located after the air filter in the pipe.

The EGR valve also affects fuel consumption if it does not turn on the exhaust gas recirculation system. It can be checked by “continuity” using a multimeter (resistance from 10 to 100 Ohms).

Source

Burns and doesn't go out

To be honest, I already wrote about the reasons - when the lamp does not go out at all, read here, it is very useful. But this should not be confused with our case, when the lamp does not go out at all, here either breakdowns or your oversight are already occurring, the main reasons are:

- The oil pressure sensor is faulty

- Poor lubrication (not changed for a long time)

- Insufficient lubrication, low level

- Wrong oil, doesn’t fit the specifications

- Antifreeze or antifreeze getting into the oil

- The oil pump is faulty or clogged

- Excessive engine wear

BUT these are completely different reasons for which the lamp will constantly burn, today we will look at why it lights up for a while and then goes out.

Let's sum it up

An oil pressure light that comes on while driving is almost guaranteed to promise serious problems for the car owner. The easiest problem that is possible in this situation is problems with the electrical system or failure of the oil pressure sensor. Otherwise, repair work will become a rather expensive and very lengthy process. This is especially true in cases where the car owner drives for a long time with the pressure light on.

Indication of any problems in your car deserves due attention. It is dangerous to continue driving a car with almost any problem, because you can damage the vehicle. Modern sensors in cars rarely break down and cause any problems to car owners. Therefore, often the culprit for a light that comes on is an oil problem. Have you ever experienced situations where the oil pressure light came on while driving?

On the instrument panel in the interior of any car there are light bulbs, the purpose of which is to signal the driver about the presence of certain malfunctions. Each of the indicator lights is connected to its own sensor, which transmits data about a problem or failure that has arisen. In this way, the driver is informed about the occurrence of failures and breakdowns in various vehicle systems. The oil pressure sensor is responsible for the level of lubrication of the rubbing parts of the engine unit. However, for what reasons the oil pressure light may come on and what needs to be done in a particular case, not every driver knows.

Why does the sensor work?

The reasons for this can be very different:

- insufficient oil level;

- problems with the lubrication system;

- damage to the engine oil pan;

- poorly performed overhaul of the power unit or its untimely and improper maintenance.

To determine the cause of the operation, first of all, it is important to note exactly when the oil pressure light came on, immediately after starting or while driving, and how exactly it lights up. Does it blink or not, if it blinks, does it depend on the crankshaft speed, does it go out as the engine warms up or with an increase in crankshaft speed, etc.

About additives and properties of oils for increasing pressure in the system

Some car enthusiasts are interested in whether there is motor oil that increases the pressure in the system. Rather, we are talking about special additives that improve its characteristics. The main result from the use of such compounds (for example, SUPROTEC) can be called the restoration of the previous parameters of operating processes in the engine. The surfaces of working parts and mechanisms of the piston group, worn out by constant friction, are partially restored, and their oil-holding capacity increases. As a result, fuel combustion efficiency increases and engine compression improves. Many oils contain special additives that are aimed at reducing engine lubricant consumption.

This is where we will end today’s material. There are many interesting articles ahead of us in the field of engine maintenance and car maintenance in general. Therefore, subscribe to our updates to receive useful newsletters in the future. Bye!

On the dashboard of the car there are light indicators that signal problems in the operation of one or another mechanism of the car. One of them is the oil pressure lamp.

Many drivers have encountered a situation where the oil pressure indicator (OP) lights up and does not go out. This often happens at idle, after starting the car. Next, we will look at what reasons could cause the indicator llama to turn on and how to troubleshoot possible problems?

Pump

The pressure level in the system is provided by the oil pump. If it fails, the supply of lubricant to many engine parts is stopped. You cannot drive with a faulty part. This will lead to camshaft failure, as well as problems with the operation of the piston group.

Oil pump diagnostics can be done in several ways, depending on your capabilities:

- Installing a known good part. This method is only suitable for domestic cars, as well as some budget foreign cars. The test will provide guaranteed accuracy, but it is not always possible to buy a second pump without knowing for sure whether it will be useful;

- Testing at the stand. This is a fairly reliable method. But, it can only be carried out in a car service center. There is no point in purchasing or assembling a stand for a single test;

- Pump disassembly and visual inspection. The most difficult method, which also requires some experience to carry it out.

If you have identified a pump malfunction, it is better to replace it. Of course, if you really want to, you can restore the old one, and this usually works out. But this solution is temporary; soon the problems may begin again.

What to do if the oil pressure sensor lights up on any hot engine: initial diagnosis

Oil emulsion level

It doesn’t matter whether the oil pressure light is on at idle or at rpm, the first step is to check the oil level in the crankcase. Its deficiency can cause reduced pressure in the oil system, and the sensor records exactly this

This suggests that lubrication starvation is experienced by such important components as:

- Crankshaft bearings.

- Supports for the camshaft and turbocharger rotor.

- Hydraulic compensators.

- Phase regulators.

- Hydraulic belt tensioners.

There is no need to delay refilling. Critical wear and jamming of shafts can occur quickly, and the amount of repair costs will unpleasantly surprise you.

Electrical connections

The level is fine or has been restored, but the oiler is still on - a reason to inspect the functionality of the sensor. But first the wiring. Diagnostics is simple - remove the terminal from the sensor, the lamp on the tidy should go out. If it blinks or lights up, we perform an additional test:

- Select a long piece of single-core wire.

- Remove the supply block of the oil pressure meter.

- Connect the “plus” of the battery and the wire suitable for the sensor.

After the actions have been performed, the icon blinks/is lit, there are definitely questions about the condition of the wiring. It is quite possible that one of the wires has frayed. The indicator goes out - let's move on.

Lada Granta Take me to Techno › Logbook › Oil pressure lamp - got it!

Hello everyone! I changed the oil at 7000 km, I was planning to do it earlier, but I still didn’t have time, about 5000 of them were driven on the highway. I decided to pour shell 5w40 synthetic oil, as in all previous cars, I never had any problems with it. I was looking for the filter as it came from the Livna factory only with the LADA marking, I didn’t find anything like that, I bought an original blue Lada, like in the photo, only higher

I changed everything, in the morning I started the car, the oil can was on for 3-4 seconds and the buzzer beeped, I immediately suspected the filter, since there was no such problem before the replacement, I went to the store and bought a black Livny filter

When I unscrewed the LADA filter, it was empty, the valve did not hold oil at all, I installed Livny, and started it in the morning. the same song, when I removed the filter, it was full of oil, that is, the check valve was working, why then did the lamp constantly burn when it was cold? I went to buy another filter, chose the vaunted MANN, in all respects it is similar to the original

In the morning I start the car, the light is on for about a second, well, it’s better, but it’s still annoying, I drove for a week, the light began to burn longer, so I’m thinking about changing the oil, although there’s a verification code on the canister, I entered it on the website, it says it’s original, I don’t know how much this information is reliable

Today I decided to change the oil pressure sensor, it was white, I bought a black one, changed it and nothing changed, except that the car took longer to start, before it was half a kick, and after replacing the starter I had to turn for 3 seconds. In general, I threw out this black sensor, installed back white, started starting as before

In general, that’s all for our authority, I’ll drive like this until the next oil change, although maybe I’ll change the filter once more) All the best!

UPD: The problem is solved, I changed the oil, filled it with Lukoil Lux 5w40 synthetic, now the lamp goes out as it should.

Source

Check light is on, video diagnosis) — Lada Kalina Hatchback, 1.6 l., 2010 on DRIVE2

Please help, the check light comes on, full description:

There is a viburnum on a cable with a 1.6 16kl engine. From Priora with Bosch M7.9.7+ controller.

Initially, the car began to have trouble starting in cold weather and the check light came on.

At that time it was still under warranty, I went to the PSSS, they diagnosed one of the injectors as dirty, I did not agree with them, I always filled in good gasoline.

In general, after discussions, we carried out another diagnostic and found the ECU filled with antifreeze, they changed it and the problem went away. But a few days later the check light came on again, there was no longer a guarantee, I went to the diagnostician and they counted errors:

0300 Random or multiple misfires detected 0301 Cylinder 1 misfire detected

0302 Misfire detected in cylinder 2

The errors were cleared, I was advised to change the spark plugs, it turned out the officials screwed in 3 different types of spark plugs

candles that were replaced by the officials

I installed NGK BCPR6E -11, changed the oil, all filters, the mesh in the fuel pump, it was quite clean

fuel pump mesh

and everything worked perfectly, everything was clean in the gas tank too)

gas tank

I didn’t drive the car for a couple of days, and the problem repeated itself, the check light came on, you can see everything in the video. If you warm up the car, it can work perfectly without a check.

Can anyone advise me to check or see what?

Thanks in advance to everyone who responded!

## the problem has been solved, more details here: www.drive2.ru/l/660985/

Mileage: 45000 km

Page 2

Please help, the check light comes on, full description:

There is a viburnum on a cable with a 1.6 16kl engine. From Priora with Bosch M7.9.7+ controller.

Initially, the car began to have trouble starting in cold weather and the check light came on.

At that time it was still under warranty, I went to the PSSS, they diagnosed one of the injectors as dirty, I did not agree with them, I always filled in good gasoline.

In general, after discussions, we carried out another diagnostic and found the ECU filled with antifreeze, they changed it and the problem went away. But a few days later the check light came on again, there was no longer a guarantee, I went to the diagnostician and they counted errors:

0300 Random or multiple misfires detected 0301 Cylinder 1 misfire detected

0302 Misfire detected in cylinder 2

The errors were cleared, I was advised to change the spark plugs, it turned out the officials screwed in 3 different types of spark plugs

candles that were replaced by the officials

I installed NGK BCPR6E -11, changed the oil, all filters, the mesh in the fuel pump, it was quite clean

fuel pump mesh

and everything worked perfectly, everything was clean in the gas tank too)

gas tank

I didn’t drive the car for a couple of days, and the problem repeated itself, the check light came on, you can see everything in the video. If you warm up the car, it can work perfectly without a check.

Can anyone advise me to check or see what?

Thanks in advance to everyone who responded!

## the problem has been solved, more details here: www.drive2.ru/l/660985/

Mileage: 45000 km

www.drive2.ru

The oil pressure light comes on at idle: ways to check

Now let's talk about the case when the low oil pressure warning light comes on while the engine is idling. Below we present available methods for identifying malfunctions, which will generally be useful in diagnosing the condition of the engine lubrication system and engine oil pressure.

- If the oil pressure light comes on, then you should check the engine oil level in the engine and its condition. If the level drops, add oil. A suspicious condition of the oil (black color, excessive thickness) will require thorough flushing of the oil system and subsequent oil change. The smell of gasoline/diesel, an emulsion on the oil filler cap, or severe dilution of the engine oil will indicate problems with the CPG or cracks in the cylinder head/cylinder head. On a working engine, the combustion chambers should be sealed, fuel and antifreeze from the cooling system should not enter the lubrication system.

- The oil pressure lamp may come on at idle immediately after changing the oil during the first start. In this case, the warning light may remain on for 10, 15 or even 20 seconds. If after the specified period of time the low oil pressure lamp does not go out, then you should check the oil filter. The product may be of poor quality, poorly screwed (oil leaks are noticeable in the area where the filter is attached) or defective.

- Check the oil pressure sensor. The oil pressure level at idle speed at around 800 - 900 rpm should not be less than 0.5 kgf/cm2. It is also worth noting that emergency oil pressure sensors on different engines may have different response ranges, which on average range from 0.4 to 0.8 kgf/cm2. This means that if there is a sensor designed to operate at 0.7 kgf/cm2, already during a pressure drop to 0.6 kgf/cm2 the sensor will turn on the emergency oil pressure lamp. This is done for conditional notification of a decrease in pressure in the line of the internal combustion engine lubrication system.

The initial check of the sensor should be done by slightly increasing the crankshaft speed (1000-1100 rpm). In other words, if the oil pressure light goes out when you press the gas, then the following options are possible:

- idle speed is too low (the light blinks at idle);

- low oil pressure in the lubrication system;

- malfunction of the oil pressure sensor;

- engine malfunction;

To accurately measure the oil pressure in the engine, you need to unscrew the sensor and install a pressure gauge in its place. Also, one should not exclude false alarms of the oil pressure sensor at idle speed, which may occur due to contamination of both the device itself and the engine oil channels. In this case, you will need to clean the sensor and clean the lubrication system channels.

As for engine breakdowns that lead to a decrease in oil pressure, indirect signs are increased consumption of fuel and engine oil, the engine emits blue or bluish smoke. In such cases, the oil pressure lamp lights up at idle, taking into account the warmed-up engine. This occurs due to the fact that the heated lubricant liquefies and flows freely through the gaps between various parts (liners, shaft journals, etc.).

As you know, at idle the crankshaft speed is minimal. At the same time, the oil pump also develops a minimum pressure. As a result, a relatively small deviation can lead to the oil pressure lamp coming on at idle, while when the speed rises and the oil pressure in the lubrication system increases, the problem of the low oil pressure warning lamp on the dashboard coming on may not appear.

Engine oil pressure: what it depends on, how to measure it correctly. What is the oil pressure on different engines in idle mode and under load.

Why there may be low oil pressure in the engine, the oil pressure light blinks at idle or under load. Fault diagnosis and repair.

Why does fuel get into the engine oil, what could be the consequences of a malfunction for the internal combustion engine. Gasoline gets into the oil: diagnostics and repair.

Foaming of engine oil in the engine: in what cases and why is this dangerous for the engine. Main causes of malfunction, diagnostics.

Purpose of the diesel engine lubrication system. Components, oil pump performance, cooling function. Malfunctions and prevention.

Causes of oil leaks in the oil filter area: oil flows from under the filter, through the housing, in the area of the fitting, etc. Available diagnostic and repair methods.

Source

When to change engine oil

The oil change in the Kalina engine, as recommended by the manufacturer AvtoVAZ, should be done every 15 thousand kilometers.

However, experienced owners of these cars argue that the oil change in the Lada engine should be done more often in order to extend the life of the Kalina engine without repairs and replacement of oil rings. This procedure must be performed every 8-10 thousand km. Of course, this depends on the operating conditions of the car.

You can change the oil yourself. First you need to buy the appropriate oil filter and know what kind of oil to pour into the system. It needs about 4 liters. There are usually 5-liter canisters on sale. But there should always be a reserve.

The filter for Kalina 2 can be used the same as for the VAZ 2108, or you can purchase an imported one. The choice of suitable filters is quite large.

Experienced owners of VAZ cars say that the best choice of oil for Kalina is synthetic. As a last resort - semi-synthetic. But if another engine oil was previously poured into the engine, then it is better to replace it not yourself, but in a car repair shop, where the engine will be washed with a special compound before adding new lubricant.

tweet

back Why the Kalina gearbox lever rattles and how to fix this problem

Next How is the oil changed in the Lada Kalina gearbox?

Tagsensor, oil pressure sensor, replacement

If the oil pressure lamp lights up with a warm engine at idle speed

This situation often confuses drivers, because the engine is in a warm state, and in this case it cannot be attributed to the fact that the oil is cold or thick. This state of affairs most likely indicates:

- about contamination of the oil receiver, in which dirt often settles;

- about oil pump failure or wear;

- about a short circuit in the system or a sensor malfunction;

- about wear of the crankshaft liner.

To be honest, all of the above reasons indicate the car owner’s negligence towards the car. A caring driver can predict such breakdowns and prevent them in a timely manner.

The light only comes on at high speeds

High speed is achieved at 4000 rpm, which corresponds to a speed of 145 km per hour. This speed requires increased oil consumption; if the driver is a fan of fast driving, then much more oil will be required. Such a load for the engine is considered to be increased, and the use is considered to be maximum.

The sensor lamp can often light up at high speeds, and this indicates a lack of oil. It must be taken into account that a sudden transition to increased speed can disable the oil pump. It will have to be replaced immediately, and it is best to seek the help of professionals.

How to reset a check on Kalina yourself

It is not recommended to reset errors yourself if the Lada Kalina check engine light is on. The error information will disappear. In a car service, if something happens to the engine after the reset, they will not be able to determine what kind of malfunction caused the engine to stop working. This means that you will have to completely disassemble the motor. It's an expensive endeavor.

However, if the car owner is sure that the wires were simply shorted after washing the car (this happens), then he can do the following at his own peril and risk:

- Turn the ignition key, but do not start the engine.

- Open the hood and remove the terminal from the positive terminal of the battery.

- Wait about 5 or 10 minutes.

- Reinstall the positive battery terminal. Close the hood.

- Turn off the ignition and turn it on again. Now start the engine and get ready to start driving.

The check lamp should disappear from the panel.

Lada Kalina engine check light comes on and does not gain speed

| Forum V Kalina > Technical section > Engine and its systems |

| The check light comes on and does not gain momentum |

| Engine and its systems Engines, cooling system, power supply, ignition and engine control, exhaust system. |

| Page 1 of 2 | 1 | 2 | > |

__________________ Do nothing, be nothing, say nothing, and then you can avoid criticism

Sasha_sd

, How much mileage and how real it is. Was the check blinking or on?

Has the fuel pressure been checked? The best thing to do is to connect the scanner and see what lights up the check

__________________ Do nothing, be nothing, say nothing, and then you can avoid criticism

__________________ Do nothing, be nothing, say nothing, and then you can avoid criticism

Sasha_sd

, If after starting the engine the check mark flashes, then you should not operate it, if it just lights up, but everything works fine, or if the check mark goes out, then you can operate it. It is not worth removing the terminal from the battery, so as not to erase errors from memory, it will be easier to understand. It is advisable to turn out the spark plugs. If they are black, or with a lot of soot, then you shouldn’t use them either.

Added after 1 minute 15 seconds

Sasha_sd

In order to make a decision whether it is possible or not, you need to know exactly the reason. If the phase sensor fails, for example, you can drive, if the second lambda fails, the same is possible, but if there is a double failure, the lambda is no longer worth it.

__________________ Do nothing, be nothing, say nothing, and then you can avoid criticism

Sasha_sd

, if the injectors are clogged, then you won’t get away with blowing. It is necessary to remove the fuel pump, change the mesh on it, the fine filter, wash the injectors, and flush the fuel line

Added after 2 minutes 41 seconds

I've encountered clogged injectors. Inexplicable interruptions in engine operation, its traction capacity is slowly but surely falling. The engine stops spinning above a certain speed. It can also be diagnosed by turning off the injectors one by one and observing changes in engine operation. If everything is always different, then there is a chance. Spark plugs need to be looked at immediately after an unknown refueling

__________________ Do nothing, be nothing, say nothing, and then you can avoid criticism

Source

Repair work after driving without oil

When an engine is running without good lubrication, the unit has very little chance of survival. Within a few minutes, the wear of the piston group reaches the maximum possible level. Gaining speed in this state of the engine will mean an almost guaranteed loss of vital activity of the unit. It is better to carry out repairs after the car has been evacuated, as soon as the light starts to burn. In this case, you can often get by with little expense. If the unit operates without oil, the problems can increase significantly:

- new problems will be added to existing problems to repair the engine due to its wear;

- the piston group is almost guaranteed to be replaced, which will make repairs unrealistically expensive;

- the entire oil supply system will most likely also be replaced at enormous expense on the part of the owner;

- the repair will have to be carried out at a professional station, because disassembling the engine is not an easy process;

- the use of low-quality parts will not work in this case, since the machine will completely lose reliability;

- A clear computer diagnosis is needed to help identify the affected nodes.

Diagnostics at the service center after a long trip without oil will truly surprise you with its scope. For inspections alone you will have to pay a very impressive amount of money. However, after such a situation, it is imperative to perform a good check of the car and obtain information about the damage caused. Often, after such adventures, it turns out to be much more profitable to purchase a new engine or contract power unit than to look for any solution to this problem. We invite you to look at self-diagnosis of a domestic car when the oil light is on:

Failure of the fuel tank, failure of the neutralizer

When the check engine light comes on, the owner of a Lada Kalina with an 8-valve engine first of all aims to find faults directly in the engine. However, the reason can sometimes “lurk” elsewhere. The glow of the symbol is caused by a loss of tightness in the fuel circuit. Even a loose tank cap can cause this situation.

Depressurization of the system involves the penetration of an additional portion of air into the circuit. In this case, a symptom such as an increase in fuel consumption appears, and the correct functioning of the engine itself is also disrupted.

When the owner of a Lada Kalina does not detect any extraneous sounds in the engine or other deviations in its operation, but the lamp on the dashboard still continues to glow, then the first step is to make sure that the gas tank cap is tight. Quite often there are situations in which drivers, in a frantic rush, forget to check that the cap is correctly and securely seated after refueling.

If after such a check the lamp on the dashboard “refuses” to go out, then you need to continue searching for other reasons. What to do when the catalyst “announces” its malfunction? This important component of the exhaust system serves to neutralize the flow of exhaust gases. It is no secret that a huge number of substances harmful to the surrounding atmosphere accumulate in the exhaust system during engine operation. Due to the presence and functioning of the neutralizer, the level of their emissions is reduced significantly.

Among the main signs of a breakdown of the catalyst in Lada Kalina, 2 experts highlight the factor of reduced engine power. This also manifests itself in worsening dynamics.

As already noted, a common reason for the neutralizer to become unusable is the breakdown of the lambda probe in the Lada Kalina 2. Also, worn-out spark plugs can significantly shorten the “life” of the exhaust circuit element considered here.

As a result of the influence of these factors, a significant decrease in the effect of gas neutralization is observed. Oxides accumulate inside the component, which over time leads to overheating and the risk of catalyst destruction. Operating a car with such a breakdown is undesirable, since incorrect operation of the engine will not allow the unit to develop the declared characteristics. Over time, a neutralizer that has become unusable can cause damage to the power plant, so timely replacement of this component is a more rational and cheaper measure compared to engine overhaul. To replace it, you will need to contact a service center, since it is unlikely that you will be able to carry out the repair procedure yourself.

Let us remind you that the keys to a long service life of the neutralizer are:

- timely replacement of spark plugs;

- use of high-quality fuel;

- correct operation of the lambda probe.

Another factor if the check light is on is the failure of the sensor responsible for the mass flow of air sucked into the intake manifold. This malfunction is characterized by a decrease in the engine power level and the failure of the unit to start smoothly when cold.

Why can the mass air flow sensor fail? One of the reasons for this annoying situation is the untimely replacement of the filter element in the air intake circuit. The motor itself is unlikely to suffer from a faulty state of the sensor, other than the indicated loss of power parameter. However, the owner will refuel more, due to the increase in consumption provoked by this fact. The price of the mass air flow sensor is not exorbitant, so it is not advisable to delay replacement. The repair procedure itself is not difficult to perform. This can also be done at the service center during scheduled maintenance.

What to do if the oil pressure light does not go out immediately

As mentioned above, the oil pressure burns for a long time when starting the engine due to the fact that the lubricating fluid leaves the filter element when the engine is idle. This is due to the quality of the oil filter, or more precisely, to the anti-drainage (non-return) valve. An oil filter consists not only of a housing and a filter element, it also has a special gasket called an anti-drainage valve, and its task is to retain oil inside the element.

During operation, or due to poor manufacturing, the check valve may fail. In essence, it is an ordinary rubber band that can crack, tear under pressure, or fly off. Replacing this rubber is not expected, and if the oil pressure burns for a long time, replacing the oil filter will be the solution to the problem.

Please note: The oil filter is often changed at the same time as the oil. If, after the first start of the engine, a problem immediately appears with the pressure lamp fading for a long time, the filter should be replaced

Most likely it was performed poorly, which is why the anti-drainage valve flew off or broke when oil passed through it. Operating such a filter is extremely dangerous for the engine.

Often the problem with the anti-drainage valve occurs on non-original filter elements of low quality. Sometimes it immediately fails to cope with the functions assigned to it, in other situations, after several thousand kilometers the rubber band “sticks”, which is why it stops coping with its tasks.

In order for a car engine to last as long as possible, it is necessary to lubricate it during operation, and even a few seconds without lubrication after the engine starts will significantly speed up the need for major repairs.

Some of us, those who do maintenance ourselves, may encounter such a problem - after starting the engine, when it is cold (say, after night), the oil pressure lamp is on for a certain period of time. Maybe 3, 5, or even 10 seconds. Why does this happen, what are the reasons? Is this dangerous for the car and in particular for the engine and what should I do? Useful information, as well as a video version, read, watch...

What I want to say at the beginning is that guys, when the pressure lamp is on, it’s no longer good! After all, it cannot light up just like that, and must go out immediately after starting. That is, the engine started, the lamp went out and there shouldn’t be any 3 – 10 seconds! THIS IS ALREADY A DEVIATION FROM NORMAL OPERATION.

Currently commenting:

Are the front fenders from the top suitable for a regular w124

Russia has enough fools for a hundred years. Answer why North Korea is now pla

However, when he died, the whole country mourned. How many people do you think will pay

Is there no error message?

Good day. Such a problem. Priora 2008 release. I arrived yesterday evening and

Under Stalin there was nothing at all. Destroyer of the people.

Oka stalls - very informative. It seems to me that with this approach it is better to push it to the autoserver

I’m creating a topic to discuss general and technical issues about Oka, so that everything is in one place

By the way, the engine is still running rough, I changed the spark plugs, new wires, no effect either.

Oil pressure monitoring

Such emergency measures are explained by the fact that the engine is the most expensive component of a car. The oil supply system performs the most important functions in its stable operation:

- lubrication of rubbing parts of rings, pistons, crankshaft, liners, valves;

- partial heat removal from the ignition chambers of the fuel mixture;

- washing off the chips and transporting them to a pallet;

- creating a film to protect metal surfaces from corrosion.

These and many other functions of the oil system are fully performed only when normal pressure is maintained inside the power unit. The light indicating the oil pressure does not light up or blink at idle speed.

There are a number of reasons why the oil pressure decreases and it burns. This situation is considered an emergency, since a running engine is subjected to unacceptable loads, heat dissipation is reduced, the cylinder block may overheat, and the entire piston group may fail.

What to do if the oil pressure light comes on

If on the road you notice that the light with the image of an oil can periodically lights up or starts to shine constantly, you should first stop the car and turn off the engine. The problems can be very different, so it is better not to start the power unit until the problem is investigated. When the car is turned off, you should not immediately run and check the lubricant level, because this way you will not get reliable results. It is worth following a fairly simple algorithm of actions that is available to every driver without exception:

- completely stop the car, turn off the engine to prevent serious problems;

- wait a few minutes until the oil cools slightly and flows into the crankcase through the parts of the power unit;

- remove the dipstick from the crankcase and wipe it with a dry cloth to avoid incorrect level readings;

- check the oil level by inserting the dipstick into place and removing it again, noticing the actual fluid level;

- if necessary, add oil to the crankcase to the normal level (between min and max, closer to max);

- try to start the power unit, and if the light does not go out after starting, immediately turn off the engine;

- call a tow truck or take the car in tow and transport the car to the nearest service station;

- perform detailed diagnostics, find the problem and be sure to completely eliminate it.

This is a simple procedure to follow if the oil pressure light starts to light up or blink. The most common problem with this indication is insufficient oil level. This is especially true for those cars that, for technological reasons, consume a certain amount of motor oil. Do not forget to add fluid to properly lubricate all engine parts. Operating the unit without a sufficient amount of oil is fraught with the most unexpected and unpleasant consequences.

where is the DDM light located and why is it on?

Checking the Priora oxygen sensor The Kalina oil pressure sensor is a fairly reliable device and rarely breaks down, but sometimes it fails. The article is dedicated to this device: what it is, where it is located, how to check its serviceability. Instructions for replacement are provided.

What you need to know about DDM?

A modern car has a large amount of electronics installed, based on the readings of which the electronic control unit issues the appropriate commands. One such device is the oil pressure sensor (OPS).

Purpose and location

The purpose of the DDM is to monitor the oil level in the power unit; as soon as the amount of lubricant drops below the permissible level, the corresponding indicator light lights up on the instrument panel.

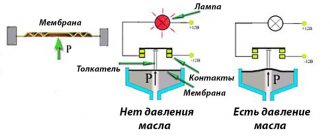

The operating principle can be described as follows. Lubricant is supplied to all components of the system under pressure. The system includes a DDM, inside of which there is a membrane indicated by arrow 4. If the pressure is low, then the membrane is not deformed, the contacts numbered 3 are closed and the lamp indicated by arrow 2 is on.

When the engine starts, the pressure increases, the membrane is deformed and acts on the pusher that is installed on it. In this case, the contacts open and the light goes out.

The DDM is located on the cylinder head on the right, when viewed in the direction of travel, on the back side of the engine. It receives power through a wire with a plastic terminal, which makes it easy to detect.

Diagnostic features

If the indicator on the dashboard is constantly on, you should first check the oil level using a dipstick and the condition of the oil filter. It is also necessary to check for oil stains on the power unit housing. If the level is normal, you should check the device itself. The simplest test option is to install a known-good device instead of the device being tested.

You don’t have to buy a new one, you can ask your neighbor in the garage. True, the sensor should be exactly the same. If, after installing a working device, the indicator stops lighting, then the removed one is faulty.

In addition, using a multimeter, the power supply to the device is checked to see if there is an open circuit. If you have a pressure gauge, you can check the oil pressure. To check, you need to screw the pressure gauge into the DDM seat and start the engine. At idle, the pressure value should be above 0.65 kgf/cm2.

If you don't have a pressure gauge, there is another way to check. To do this, the sensor is unscrewed, and then the starter is cranked without starting the engine. If, when the starter rotates, oil splashes from the seat of the removed device, we can conclude that the device is faulty.

What does a burning oil pressure light indicate?

If the DDM indicator light on the instrument panel is constantly on, this indicates that the Lada Kalina oil pressure sensor is broken or the circuit is broken.

If after diagnostics it turns out that the device is faulty, it must be replaced (the author of the video is Alexander Skripchenko).

It is recommended to unscrew the old device before purchasing and take it with you so as not to make a mistake when choosing a new one. To replace it, it is better to purchase an original or a high-quality analogue. You should not buy a cheap product trying to save money on it, since a low-quality product will quickly become unusable and will have to be replaced again. If the DDM pad is in poor condition, it is worth replacing it too.

FakeHeader

Comments 12

That's it, guys, the problem is solved. There was condensation in the oil receiver, and this condensate froze. We drained the oil, removed the filler, warmed up the oil receiver, filled in oil, started the engine, heated the engine to 80 and drained the oil, then poured in new oil. Now everything seems to be fine.

Drain the oil, my sump and change the oil receiver, a friend did this on a viburnum and the machine came to life.

I don’t think it’s anything serious, maybe the oil is frozen. Another option is to check the wire that goes to the sensor with a tester; if the light does not light, it means there is an open circuit, this happens in cold weather

I had this happen with a couple of Kalinovodovs as well. Condensation. It appears if you go on short trips in winter. Then it freezes in the car along with the oil in severe frost. I warmed up the pan and changed the oil. I switched to 5v40 Mobile. Before this, the owner supposedly had zero .Thank God this didn’t happen again!

The Kalina oil pressure sensor is a fairly reliable device and rarely breaks down, but sometimes it fails. The article is dedicated to this device: what it is, where it is located, how to check its serviceability. Instructions for replacement are provided.