There is one of the indicators on the dashboard of cars that informs the driver about a decrease in oil pressure in the engine unit. The so-called oil pressure light in the form of an oil can signals a critical condition of the engine - insufficient amount of lubricant. On the panels of VAZ “classic” cars (six, seven, nine) there is also such an indicator. And if it suddenly lights up while driving or at low speeds while parked, this is a signal that there is a malfunction in the engine.

Why does the oil pressure light come on in a VAZ classic?

The first step is to distinguish cases when an icon in the form of an oil can is suddenly displayed. It is completely safe for the icon to light up for just a few moments in the following cases:

- when there is a strong roll of the car on a sharp turn;

- when starting in winter;

- after a long period of parking on uneven ground.

As a rule, in such situations, oil flows from one part of the engine to another, which is why the oil pressure sensor is triggered. However, after some time, the working fluid is evenly distributed, and the signal about a drop in pressure in the system stops. The situation is similar when starting the engine unit in the cold season: at low temperatures, the working fluid thickens, accordingly, it is necessary to warm up the engine properly in order to create the necessary pressure in the system.

In all other cases, the appearance of an oil can on the instrument panel indicates the presence of failures or malfunctions. So for what reasons can the oil pressure light come on in classic VAZ models?

- First of all, due to a lack of oil in the engine.

- Due to an exhausted oil filter.

- The oil pressure sensor or its wiring is to blame.

- Wear of the liner on the crankshaft.

- The oil pump has failed.

Any of these reasons can affect the oil pressure level in the engine unit. Therefore, the car owner will first have to find the source of the problem and only then begin troubleshooting.

The oil level control device is located separately

This is interesting: How to increase engine power - truly effective ways

Reasons for the indicator to light up

It should be noted that the oil pressure light may come on intermittently in some situations without presenting any danger to engine operation. Such situations include:

If the light comes on while driving or at idle, and does not go out after a while, then appropriate measures should be taken. The oil pressure indicator indicates the occurrence of failures and malfunctions. Such problems occur not only in the engine, but also in the electronic part. Some of the main reasons why this indicator lights up include:

In certain cases, it is necessary to stop and determine the presence of oil in the engine using a dipstick. If the level is normal, then you should get to the nearest station or home, and then determine the reason for the light coming on. If there is no oil, then continuing to move under your own power is strictly prohibited, because this may cause the motor to jam.

If the pressure indicator lights up, you should make an emergency stop and turn off the engine. After this, a number of steps should be taken to determine the cause of such consequences.

Checking the lubricant level

After stopping, you need to open the hood and remove the dipstick. The measuring scale of the dipstick should be wiped, then reinsert it into the hole, and then remove it and make sure there is a sufficient level of lubricant. If the dipstick shows a minimum fluid level, then you should top it up, but then try to find out the reasons for the decrease in level. Often the reason for a drop in oil level is its leakage through the seals, which need to be changed periodically.

After the oil is added to the engine, the indicator will not light up, which indicates that the cause has been correctly eliminated. Low oil pressure in the engine can also be determined using a special dial-type indicator, which displays information for the driver about the state of oil pressure. However, on VAZ 2107 cars such indicators are not installed from the factory, although some motorists install them themselves.

Oil filter malfunction

If the lubricant level is in order, then the cause of such consequences may be a faulty filter. If you recently changed the oil and filter, and after some time the light comes on, then there is a high probability that you have received a defective filter. Under such circumstances, you will need to replace not only the filter, but also the lubricant in the system. Such cases, although rare, are all appropriate.

Checking the health of the sensor

The malfunction may consist of a breakdown of the sensor itself or a short circuit in the supply wiring. To check the health of the sensor, there are two ways:

In the first case, the pressure in the system must be at least 0.35 kgf/cm2. The value on the pressure gauge is not lower than the specified one, indicating that the system is working properly and the sensor is faulty. In the second case, the test involves connecting the multimeter probes to the sensor terminals. In this case, the device should show zero resistance. Now you need to pump using the pump, as a result of which the multimeter readings should change and it will show infinity. In order to check the integrity of the wiring suitable for the sensor, you should test it using a multimeter. Replacing the sensor is not particularly difficult, so even a beginner can cope with this task.

Checking the quality of the lubricant

If all of the above methods have been tried, but the icon continues to light, then you should check the quality of the oil. To do this, you need to inspect the dipstick, with which you can easily determine the presence of signs of antifreeze or gasoline in the lubricant. To do this, you need to dip the dipstick in water and see if streaks appear on the surface, then the reason is that foreign liquid has entered the motor.

In such a situation, a complete flush of the engine, as well as major repairs, cannot be avoided. It is necessary to eliminate the cause of gasoline or antifreeze getting into the engine compartment.

From the above, it should be noted that in order to avoid unpleasant situations, when the oil pressure light comes on, you should immediately stop and find the cause.

Source

How does the oil sensor work and why can it fail?

Now let's consider the situation if you are on the road and the low pressure indicator has triggered.

The very first thing you need to do is stop the vehicle and turn off the engine. As soon as it cools down, you will have to check the lubricant level in the system. There is a special dipstick under the hood for this purpose. It is wiped dry and immersed in its original place. It is quite possible that the level will be below the minimum level. This means that somewhere there is a leak or depressurization of connections. You can set off again only after adding oil to the engine. If the lamp continues to light after starting and does not go out subsequently, it makes sense to think about towing the car to the nearest service station or to a trusted auto mechanic. The matter may turn out to be quite serious, so it is advisable to conduct the examination in a calm environment. Since we have already said that the causes of low pressure may be associated with a faulty sensor, it would be useful to understand the principle of operation of this device. There are certain contacts inside it. Until the ignition is turned on, there is no pressure in the system, so the contacts are closed. When you turn the key and turn on the ignition, but before the starter starts, the warning lamp should be on. If this does not happen, then there may be some kind of malfunction. Maybe the light bulb itself simply burned out, or maybe the contacts were broken or the sensor itself failed. As soon as we start the engine, the contacts open, leading to the light bulb going out.

The thermostat is the boss

Not a very pleasant breakdown, especially if it happens on the road. And if the engine is boiling due to a faulty thermostat, then there is only one way out - to change this element of the system. True, at first you can slightly “reanimate” him; for this you need to apply several sharp blows to his body with something heavy.

But such a “rough” solution may not always help. There will be much more trouble if liquid leaks out of the tank. The thermostat allows the system to switch the circulation of liquid between two circles - large and small. These circles differ in that in the first one a radiator is connected to the cooling process. And if it does not connect, then the liquid boils.

On VAZ 2107 cars, and indeed on all cars of this manufacturer, the thermostat fails in such a way that the antifreeze continues to circulate in a small circle. And even if you turn on the radiator fan with the button, this will not save the situation.

The car still drives poorly, the antifreeze boils, and you won’t be able to immediately understand why this is happening. And the answer is very simple - to increase the life of the thermostat, do not pour running water into the system. Use any antifreeze, in particular antifreeze. The water leaves a large amount of scale, which interferes with the movement of the thermostat element.

Special malfunctions of VAZ engines

These problems are common to almost all types of engines used in cars, including domestic ones.

POPULAR WITH READERS: Do valves bend on Renault Sandero?

But there are also specific faults that occur only on certain cars.

On classic models VAZ-2106, 2107, the pump is driven from the timing chain via a drive gear and a drive roller.

A common problem in the malfunction of the lubrication system is wear of the gear sector on the gear or shaft. Replacing these elements allows you to get rid of problems.

As for modern cars, from the VAZ-2108 to the VAZ-2115, they have a direct pump drive, from the crankshaft gear.

The absence of intermediate elements in the design has increased the reliability of the drive, so the problems that arise in the engines of classic VAZs do not occur in modern cars.

Location and appearance of the device

The sensor installed on classic VAZ 2106 models consists of the following parts:

- an element in the form of a round metal barrel with one terminal for connecting a wire (factory name - MM393A);

- the second part is a membrane switch in the form of a nut with a contact at the end (designation MM120);

- a steel tee into which the above parts are screwed;

- sealing bronze washers.

The sensor includes 2 meters screwed to one tee.

The large “barrel” MM393A is designed to measure pressure, the “nut” with the MM120 terminal fixes its absence, and the tee is a connecting element screwed into the engine. The location of the sensor is on the left wall of the cylinder block (if you look in the direction of movement of the car) under spark plug No. 4. Do not confuse the device with the temperature sensor installed higher in the cylinder head. Wires leading inside the cabin, to the dashboard, are connected to both contacts.

The gauges are located on the left wall of the cylinder block, next to it there is a coolant drain plug

About additives and properties of oils for increasing pressure in the system

Some car enthusiasts are interested in whether there is motor oil that increases the pressure in the system. Rather, we are talking about special additives that improve its characteristics. The main result from the use of such compounds (for example, SUPROTEC) can be called the restoration of the previous parameters of operating processes in the engine. The surfaces of working parts and mechanisms of the piston group, worn out by constant friction, are partially restored, and their oil-holding capacity increases. As a result, fuel combustion efficiency increases and engine compression improves. Many oils contain special additives that are aimed at reducing engine lubricant consumption.

Sincerely, blog author Andrey Kulpanov

Place for contest advertising

Device and connection diagram

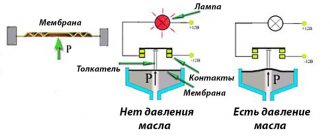

The task of the membrane switch, made in the form of a nut with a terminal, is to promptly close the electrical circuit with the warning lamp when the lubricant pressure drops. The device consists of the following parts:

- metal body in the form of a hexagon;

- contact Group;

- pusher;

- measuring membrane.

The glow of the indicator depends on the position of the membrane, which is stretched under the pressure of the lubricant.

The element is connected to the circuit according to the simplest circuit - in series with the indicator. The normal position of the contacts is “closed”, so after turning on the ignition the light comes on. When the engine is running, there is a pressure of oil flowing to the membrane through the tee. Under the pressure of the lubricant, the latter presses the pusher, which opens the contact group, as a result the indicator goes out.

When one of the malfunctions occurs in the engine, causing a decrease in the pressure of the liquid lubricant, the elastic membrane returns to its original position and the electrical circuit is closed. The driver immediately sees the problem by the flashing “control”.

The design of the second element, the “barrel” called MM393A, is somewhat more complicated. The main role here is also played by an elastic membrane connected to an actuator - a rheostat and a slider. The rheostat is a coil of high-resistance chromium-nickel wire, and the slider is a movable contact that moves along the turns.

As the lubricant pressure increases, the rheostat reduces the chain resistance, the needle deviates more

The electrical circuit for connecting the sensor and pointer is similar to the first one - the rheostat and the device are in series in the circuit. The operating algorithm is as follows:

- When the driver turns on the ignition, on-board voltage is supplied to the circuit. The slider is in its extreme position, and the winding resistance is maximum. The instrument needle remains at zero.

- After starting the engine, oil appears in the channel, flowing through the tee into the “barrel” and pressing on the membrane. It stretches and uses a pusher to move the slider along the winding.

- The total resistance of the rheostat begins to decrease, the current in the circuit increases and causes the indicator arrow to deviate. The higher the lubricant pressure, the more the membrane stretches and the less resistance of the coil, and the device notes the increase in pressure.

The sensor reacts in the reverse order to a decrease in oil pressure. The force on the membrane decreases, it is thrown back and pulls the slider with it. He turns on new turns of the rheostat winding in the circuit, the resistance increases, and the instrument needle drops to zero.

According to the diagram, the sensor is connected in series with the indicator located on the instrument panel

Machine diagnostic procedure

There is a known homemade method that will help you find out if there are problems with blood pressure:

- Start the engine and warm up the car well (drive 5-6 km).

- Depress the brake and clutch at the same time.

- Engage the gear and gradually release the clutch (hold the brake).

- If the tachometer shows below 500 rpm and the lamp does not light up, the pressure is normal.

If there is a problem, you can look for the breakdown yourself. Then at the service center you will spend less time on diagnostics, pointing out to the mechanic the most likely cause of the malfunction. The check is carried out according to the following algorithm:

- Open the hood of the car and check for oil leaks. If they are, there is a leak in the system.

- Inspect the oil filter. If there are smudges, try tightening the part clockwise. Perhaps the problem will go away.

- Inspect the crankcase (located on the bottom) for leaks. If they are identified, you must urgently contact the service center, having first provided “first aid” - plug the gap using dry welding, fabric or a special rubber gasket.

You should start checking after the car has warmed up and stopped for ten minutes.

Consequences of ignoring the problem

Stopping the engine when the pressure lamp lights up is a mandatory measure. Ignoring the signal can result in very serious problems:

- As a result of “oil starvation”, the contacting surfaces of components and mechanisms will begin to work “dry”, which will lead to their intense wear and high heating. If you take a crankshaft, the main and connecting rod bearings will begin to melt and “wrap” around the journals, which will lead to jamming of the crankshaft;

- Lack of lubrication will lead to intense wear of the camshaft “bed”;

- Wear products - small metal shavings - will spread through the channels of the lubrication system, which can lead to their clogging. Also, chips can cause jamming of the pressure relief valve and damage to the oil pump gears.

Elimination of such malfunctions is only possible through a major overhaul of the power plant.

More - no less

Many people mistakenly think that the maximum mark on the dipstick is just a warning mark, and that filling a little more won’t cause anything terrible.

If you overfill the oil, excess pressure is created in the oil lines, which helps squeeze out the oil through all possible gaskets, pipes, but most often the oil seals.

Plus, a paradox appears - the more oil, the worse it lubricates and leads to accelerated wear of parts. But the fact is that if there is an excess of oil, it begins to foam intensely and it loses its lubricating properties. And this already leads to a major overhaul of the engine, which will cost a tidy sum.

Why does the oil pressure light come on at idle when the engine is warm?

Most Zhiguli owners are faced with the problem of indicating a drop in oil pressure at idle speed. There may be several reasons for this:

- malfunction in the oil pressure sensor;

- the oil pump is clogged or faulty;

- low-quality oil is poured;

- severe wear of the splines;

- a faulty oil filter is used.

Video: reasons for the oil pressure sensor to operate and troubleshooting methods

Thus, the pressure sensor signals the presence of problems in the engine unit. If the owner does not have the necessary experience in diagnostics and repair, then it is better to entrust the identification of the true cause of the problem to a specialist. In addition, when the oil can icon lights up, it is not recommended to drive the car - there is a high probability that the rubbing parts of the engine will jam. In this case, the motor will practically not be restored.

VAZ cars of classic models are equipped with outdated, but fully functional mechanisms. The same oil pressure sensor, which signals the driver about problems with the lubrication of engine elements, performs its functions quite successfully: at the right moment the device is activated, which allows the driver to take timely measures. The most important concern of the car owner should not be repair work, but preventive procedures. Only vigilant monitoring of the condition of the engine unit and the selection of proven working fluids and filters will allow you to delay costly major repairs as much as possible.

Copywriter, needlewoman, traveler

Home →

Maintenance and Repair →

Engine →

Radiator fan

As you understand, the engine operates in a variety of modes. Sometimes he pulls the car along the highway at high speed, and sometimes through a traffic jam. And in the latter case, the speed is lower than that of pedestrians.

What's the difference? And the fact is that the radiator on a VAZ 2107 car is blown in these two modes with different amounts of air. In the first case, the flow is enough to maintain the temperature balance, but in the second it is not enough

And it doesn’t matter whether it’s an injector or a carburetor, the radiator must be blown normally

You have to create an artificial flow using an electric fan. In earlier VAZ 2107 cars (and indeed in the “classic” series) impellers were used that were mounted on the axis of the liquid pump. With the help of these mechanisms, the radiator is subjected to airflow. An electric fan may not perform its functions for the following reasons:

- The impeller has been destroyed.

- The sensor responsible for turning on the fan has failed.

- The motor winding burned out.

- Destruction of electrical wiring (breakage, contact failure, oxidation).

- Failure of a relay, fuse, button (if these elements are present in the design).

The last point applies mostly to VAZ 2107 cars, in which the fan switching circuit has been modified by installing a button in the passenger compartment. With its help, the driver can forcefully start the fan.

If it doesn’t start even from the button, you need to find out the reasons. To do this, connect the wires from the fan to the battery terminals. If it doesn’t work, the motor winding is damaged.

Please note: for better airflow, use a diffuser! This is a small plastic element that will force more air to flow to the radiator. And if there are no breakdowns in the fan, then be sure to install a diffuser, the radiator will thank you

Engine injection mechanism

Regardless of the power supply system, pressure is created for all units by a specially designed pump. The main parts of this pump are gears that rotate during engine operation, thereby creating pressure and ensuring its supply to all parts of the unit.

If the oil pump does not operate properly, so-called oil starvation may occur, when the lubricant is not able to move along the internal walls of the engine and evenly lubricate its parts, thereby reducing their level of friction. Starvation can also occur due to a simple lack of necessary oil volume.

If such a situation occurs, a red light of a certain configuration lights up on the dashboard.

Problems with oil pressure may be indicated by increased noise from a running engine. If you do not stop the car and then carry out work to eliminate the problem, you can provoke the following problems:

- camshaft wedge;

- block head damage;

- formation of scoring on the surface of the cylinders;

- turning the liners.

How to identify and eliminate the causes of low lubricant pressure?

Low oil pressure in a car engine can significantly shorten its service life. And all due to insufficient mitigation of friction of moving elements. Therefore, at the first signals from the pressure gauge, you must try to eliminate the malfunction.

The most common reasons that lead to unpleasant consequences are:

- engine overheating;

- initially low oil level;

- low lubricant viscosity coefficient;

- clogging of the oil receiver;

- pressure reducing valve malfunction;

- extreme wear of crankshaft bearings.

Diagnostics should begin by checking the temperature in the engine. If it is increased, it means that the lubricant becomes very viscous. As a result, the sensor erroneously registers its low level. Owners of a VAZ 2106 car are well familiar with this problem.

If this is the cause of low pressure, you should pay attention to the following list of possible malfunctions that will need to be eliminated:

- leakage of coolant followed by the formation of an air lock;

- problems with the cooler switch on in the engine or with the fan itself;

- incorrect ignition adjustment;

- radiator clogged;

- increased formation of soot in the combustion chamber.

The latter was especially common in domestically produced cars, for example, in the VAZ 2106 model.

Low oxol levels in the crankcase drainage passages can occur due to severe wear on the piston rings or a leaking radiator. If you have, for example, a VAZ 2106, then the leak can be eliminated by simply replacing the pan gasket. And piston wear can be determined by black smoke coming out of the muffler. Its presence means the need to check the mechanisms on a compression meter and replace them with new ones.

Nuances of the cooling system

Much also depends on the coolant used. For example, there is no need to pour water even into old cars; it is better to buy inexpensive antifreeze, there will be fewer problems. However, modern engines require high-quality cooling. The manufacturer indicates in the manual the recommended brands of coolant. It is advisable to follow these tips and not dilute the antifreeze if you do not have a concentrate.

Modern coolants have different service life and boiling points. For example, G12 boils later than G11, and G12++ has an increased resource, but it is also more expensive. In any case, to avoid engine boiling, it is recommended to fill only high-quality coolant.

How to determine the quality of the auto chemicals used?

The quality of a lubricant is determined by its viscosity. The unit of measurement is centistokes. For each car, the manufacturer recommends its own optimal oil viscosity. For VAZ 2106, it is recommended to use oxol 0W or 5W in winter, and 20W and 30W in summer. If suspicion arises and inspection is not possible, the lubricant should be replaced.

This procedure is carried out as follows:

- 10 minutes after the engine has been turned off, you need to unscrew the plug and completely drain the lubricant.

- Screw the cap back on and fill in the appropriate product.

- Start the engine and let it run at minimum speed for 2 minutes.

- Stop the engine and wait 5 minutes.

- Check the lubricant level and top up if necessary.

How do you know which oil is suitable? First, follow the manufacturer's recommendations. And secondly, trust only well-known, well-established brands.

If the oil receiver is clogged, then it is not difficult to guess why the lubricant pressure drops. There simply won’t be enough of it supplied to the pump. If the valve breaks, the situation is different. Here, on the contrary, an increased bypass of oxol will be observed. The reason must be sought by the method of sequential elimination. First, check whether the strainer is in normal condition. If clogged, it is washed in gasoline and replaced. A valve malfunction in a VAZ 2106 car most often occurs due to a failure of the spring, which has to be replaced with a new one.

Pressure in the lubrication system of domestic and foreign cars

Each car model has its own pressure in the lubrication system. Below are some examples:

- VAZ 2106 - at idle speed 0.2 kgf/cm 2. At 4500 rpm - 4.5 kgf/cm 2;

- 16 valve VAZ 2109 and Priora - at idle 0.1 kgf/cm 2. At 5000 rpm – 6 – 6.4 kgf/cm2;

- On cars with a ZMZ 405 engine, idle speed is 0.4 kgf/cm 2. With loads of 2 kgf/cm2 or more;

- 8 valve Renault Logan - at idle 0.3 and at 5000 rpm 4 - 4.6 kgf/cm 2, respectively.

- Mercedes Vito with a 2.2 liter diesel engine - at idle - 0.3 kgf/cm 2, under load of 3 and above.

- Chevrolet Lacetti 1.4 – idle – 0.6 kgf/cm 2, at 3000 rpm – from 3 and above.

What is normal oil waste

Before looking for the reason for the high oil consumption and the need for constant periodic topping up, it is worth understanding what value of waste is considered normal. And only then figure out why the engine began to consume oil.

Additives that reduce oil consumption

If oil consumption is high, it is necessary to repair the engine or replace the oil caps, but if the oil consumption is insignificant, special additives will help. To reduce the amount of engine oil "waste" use Hi-Gear OIL Treatment, Liqui Moly Oil Additiv or Read more

The oil burn rate depends on the type and condition of the engine. Let's start the review with naturally aspirated gasoline engines. For new engines, the rate of oil loss is about 5...25 grams per thousand kilometers, that is, approximately 0.005%. 0.025% per 100 liters of fuel burned. Occasionally you can find models in which a similar value is up to 30...40 grams (for example, V6 or V8 engines). As for normally worn engines, their natural consumption is considered to be 0.025%. 0.1% per 100 liters. That is, about 25.100 grams per 1000 kilometers. If the gasoline engine is very worn, the value increases to 0.4%. 0.6% per 100 liters, that is, 400.600 grams. The critical level is considered to be 0.8%, that is, 800 grams per 100 liters of gasoline. This engine needs a major overhaul!

Now a little about turbocharged gasoline engines. If the engine is new, then it will consume about 80 grams per 100 liters of fuel (conditionally per 1000 kilometers). As for worn-out units, the critical value is 2 liters of oil per 100 liters of fuel.

As for diesel engines, their waste consumption will be higher than that of atmospheric gasoline engines. So, it is believed that the norm is about 30.50 grams of oil per 100 liters of fuel. The critical value is 2 liters per hundred liters of diesel fuel. In this case, urgent repairs are necessary. Delaying it can lead to irreversible consequences.

Important points

- all the recommendations mentioned above are valid for almost the entire family of classic VAZ cars - from VAZ 2105 to VAZ 2110;

- Completely draining the oil from VAZ engines, which was discussed above, is practically impossible. This is hampered by the very design of these motors, which has many holes, cavities, and channels. The old oil remains in all this. This problem can be partially solved by placing the machine on an inclined surface (or jacking up one or two wheels) to facilitate the flow of oil to the drain hole. But even such measures will not lead to complete cleaning of the engine from the so-called waste, so that for the next 20 thousand km the car will run on a mixture of new oil and waste;

- if to check the indicator in the car you need to install another, known-to-be-good sensor, but the required model is not at hand, then you should remember that the oil pressure sensor from the VAZ 2106 can be installed on other classic models of this family, in particular, on the VAZ 2107 and VAZ 2109. But it will not be possible to install sensors from these models on the VAZ 2106.

So, the car owner will have to solve the problem of the burning oil pressure indicator on VAZ cars by the method of elimination. Logic dictates that first you should check the most obvious options that do not require serious intervention in the design of the machine: check the oil, check the sensor itself, assess the condition of the oil filter. Well, if a solution has not been found, you can proceed to inspecting the electrical wiring and removing the oil pump.