Engine oil is required to continuously lubricate moving parts, but for this to happen, it must be supplied under pressure. Thus, a drop in oil pressure in engines, including the VAZ-2101-2107 (classic), will lead to catastrophic consequences for it. Therefore, the car owner must know the normal value of engine oil pressure and what to do if it drops critically.

Radiator fan

As you understand, the engine operates in a variety of modes. Sometimes he pulls the car along the highway at high speed, and sometimes through a traffic jam. And in the latter case, the speed is lower than that of pedestrians.

What's the difference? And the fact is that the radiator on a VAZ 2107 car is blown in these two modes with different amounts of air. In the first case, the flow is enough to maintain the temperature balance, but in the second it is not enough

And it doesn’t matter whether it’s an injector or a carburetor, the radiator must be blown normally

You have to create an artificial flow using an electric fan. In earlier VAZ 2107 cars (and indeed in the “classic” series) impellers were used that were mounted on the axis of the liquid pump. With the help of these mechanisms, the radiator is subjected to airflow. An electric fan may not perform its functions for the following reasons:

- The impeller has been destroyed.

- The sensor responsible for turning on the fan has failed.

- The motor winding burned out.

- Destruction of electrical wiring (breakage, contact failure, oxidation).

- Failure of a relay, fuse, button (if these elements are present in the design).

The last point applies mostly to VAZ 2107 cars, in which the fan switching circuit has been modified by installing a button in the passenger compartment. With its help, the driver can forcefully start the fan.

If it doesn’t start even from the button, you need to find out the reasons. To do this, connect the wires from the fan to the battery terminals. If it doesn’t work, the motor winding is damaged.

Please note: for better airflow, use a diffuser! This is a small plastic element that will force more air to flow to the radiator. And if there are no breakdowns in the fan, then be sure to install a diffuser, the radiator will thank you

Bleeding the system

On VAZ 2107 cars and its analogues (models 2101-2106), you can remove the traffic jam very simply. It is enough to remove the pipe that goes to the carburetor to heat the damper. If an injector is installed, then remove the pipe going to the throttle assembly.

Then fill the radiator with antifreeze. And do not forget that the stove tap must be opened. When it is full, you need to squeeze all the pipes with your hands (or rather, the top and bottom). The antifreeze should go away.

Add the missing amount and start the engine. Warm it up and carefully monitor the level, sometimes add antifreeze. You will have to add about three liters. And watch when fluid comes out of the tube connected to the carburetor.

When this happens, you need to put it in place and tighten the clamp. Of course, if you stop there, you won’t be able to get rid of the breakdown. The antifreeze still boils, the temperature rises. And why does this happen? Do a few more procedures and everything will return to normal.

Put on a glove and continue to slowly crimp the pipes. In this case, you need to install a plug on the radiator, and there should be antifreeze in the expansion tank between the two marks. That's all, there is no air, circulation occurs normally.

One small piece of advice: when refueling the system, it is advisable to position the car so that its front is higher than its rear. This will ensure that the system is completely filled. As a result, the antifreeze does not bubble or boil, the car runs like a watch.

What is normal oil waste

Before looking for the reason for the high oil consumption and the need for constant periodic topping up, it is worth understanding what value of waste is considered normal. And only then figure out why the engine began to consume oil.

Additives that reduce oil consumption

If oil consumption is high, it is necessary to repair the engine or replace the oil caps, but if the oil consumption is insignificant, special additives will help. To reduce the amount of engine oil "waste" use Hi-Gear OIL Treatment, Liqui Moly Oil Additiv or Read more

The oil burn rate depends on the type and condition of the engine. Let's start the review with naturally aspirated gasoline engines. For new engines, the rate of oil loss is about 5...25 grams per thousand kilometers, that is, approximately 0.005%. 0.025% per 100 liters of fuel burned. Occasionally you can find models in which a similar value is up to 30...40 grams (for example, V6 or V8 engines). As for normally worn engines, their natural consumption is considered to be 0.025%. 0.1% per 100 liters. That is, about 25.100 grams per 1000 kilometers. If the gasoline engine is very worn, the value increases to 0.4%. 0.6% per 100 liters, that is, 400.600 grams. The critical level is considered to be 0.8%, that is, 800 grams per 100 liters of gasoline. This engine needs a major overhaul!

Now a little about turbocharged gasoline engines. If the engine is new, then it will consume about 80 grams per 100 liters of fuel (conditionally per 1000 kilometers). As for worn-out units, the critical value is 2 liters of oil per 100 liters of fuel.

As for diesel engines, their waste consumption will be higher than that of atmospheric gasoline engines. So, it is believed that the norm is about 30.50 grams of oil per 100 liters of fuel. The critical value is 2 liters per hundred liters of diesel fuel. In this case, urgent repairs are necessary. Delaying it can lead to irreversible consequences.

Special malfunctions of VAZ engines

These problems are common to almost all types of engines used in cars, including domestic ones.

But there are also specific faults that occur only on certain cars.

On classic models VAZ-2106, 2107, the pump is driven from the timing chain via a drive gear and a drive roller.

A common problem in the malfunction of the lubrication system is wear of the gear sector on the gear or shaft. Replacing these elements allows you to get rid of problems.

As for modern cars, from the VAZ-2108 to the VAZ-2115, they have a direct pump drive, from the crankshaft gear.

The absence of intermediate elements in the design has increased the reliability of the drive, so the problems that arise in the engines of classic VAZs do not occur in modern cars.

VAZ 2107 jerks on a cold engine

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Hi all. I have a VAZ-2107i. I began to notice that when you drive with a cold engine (even in summer), the car jerks, it feels like the engine torque is constantly changing. Especially when overclocking

There is no problem. Any car with a cold engine will jerk like this, regardless of whether it has carburetor power or injection. Don't fool yourself.

Any car with a cold engine will jerk like this, regardless of whether it has carburetor power or injection.

Well, I grabbed it. At -27 I warmed up the cold engine for one minute, the needle didn’t even begin to rise - and off I went. And nothing twitched, but I have a carb.

So, does it also twitch in neutral, or only under load?

For me personally, it works great in neutral. It twitches a little when starting, and I only noticed it a few times.

When starting off there are jerks, it's the clutch you're looking at, not the engine. You don’t know what to expect from our machines

A friend's seven came from the factory with the check engine light not connected, he didn't even change the Enegels spark plugs, he thought everything was fine. And the car was shaking at the beginning of the drive due to the fact that when starting, out of habit (after switching from the carb), he pressed the accelerator. The spark plug controller was flooded and at least one did not work until you drove about five hundred meters and cleaned the spark plugs. He went there to straighten the red plastic (he says it askance), and discovered this nonsense. In general, it starts, the SE lights up, after a while it goes out, the accelerator doesn’t touch - the SE doesn’t light up and everything is ok.

The light is always on when you turn the key and goes out when the engine starts, but you can’t touch the accelerator pedal when you start it, it’s all written in the manual

By the way, I didn’t change the spark plugs from the factory and everything seems ok.

Source

The thermostat is the boss

Not a very pleasant breakdown, especially if it happens on the road. And if the engine is boiling due to a faulty thermostat, then there is only one way out - to change this element of the system. True, at first you can slightly “reanimate” him; for this you need to apply several sharp blows to his body with something heavy.

But such a “rough” solution may not always help. There will be much more trouble if liquid leaks out of the tank. The thermostat allows the system to switch the circulation of liquid between two circles - large and small. These circles differ in that in the first one a radiator is connected to the cooling process. And if it does not connect, then the liquid boils.

On VAZ 2107 cars, and indeed on all cars of this manufacturer, the thermostat fails in such a way that the antifreeze continues to circulate in a small circle. And even if you turn on the radiator fan with the button, this will not save the situation.

The car still drives poorly, the antifreeze boils, and you won’t be able to immediately understand why this is happening. And the answer is very simple - to increase the life of the thermostat, do not pour running water into the system. Use any antifreeze, in particular antifreeze. The water leaves a large amount of scale, which interferes with the movement of the thermostat element.

Important points

You can read more about common causes of lamp fires in VAZ 2110 cars here: https://vazweb.ru/desyatka/dvigatel/vaz-2110-gorit-lampa-davleniya-masla.html

So, the car owner will have to solve the problem of the burning oil pressure indicator on VAZ cars by the method of elimination. Logic dictates that first you should check the most obvious options that do not require serious intervention in the design of the machine: check the oil, check the sensor itself, assess the condition of the oil filter. Well, if a solution has not been found, you can proceed to inspecting the electrical wiring and removing the oil pump.

What problems arise from oil leaks?

It is important to understand that any leaks cause the engine oil level to drop. If there is insufficient lubrication in the engine, the loaded friction pairs are subject to severe wear

As a result, the engine life is noticeably reduced, and parts may break and jam.

Let us also note that normally, engine oil may well be consumed (waste consumption), but such consumption must be within certain limits determined by the engine manufacturer itself. If you add to this even a minor oil leak, then the risks of a critical decrease in pressure in the oil system and a drop in the lubricant level increase significantly.

Also, if there is a leak, the driver has to constantly monitor the lubrication level and add oil to the engine. At the same time, it is necessary to remember that for topping up you cannot use oils that do not meet the tolerances, mix products from different manufacturers, etc. To put it simply, you have to buy oil that is recommended by the engine manufacturer and is often not cheap.

Let us also add that oil leakage pollutes the engine and engine compartment. As a result, a thick layer of dust and dirt mixed with lubricant adheres to the motor. Such contamination is dangerous because heat exchange is disrupted, the load on the cooling system increases, and the engine may overheat.

Also, heavy oiling of the internal combustion engine can cause a fire. By the way, this layer of dirt and oil is difficult to remove from the engine surfaces (regular and thorough engine washing with Karcher, steam, etc. is required).

Separately, it should be taken into account that a leak can lead to oil accumulating in the spark plug wells. This leads to engine malfunctions, engine tripping, and misfires. Also, grease can damage the insulation of wires under the hood, get on the clutch, soften rubber cushions, seals, interact with plastic parts, etc.

How does the oil sensor work and why can it fail?

Now let's consider the situation if you are on the road and the low pressure indicator has triggered.

The very first thing you need to do is stop the vehicle and turn off the engine. As soon as it cools down, you will have to check the lubricant level in the system. There is a special dipstick under the hood for this purpose. It is wiped dry and immersed in its original place. It is quite possible that the level will be below the minimum level. This means that somewhere there is a leak or depressurization of connections. You can set off again only after adding oil to the engine. If the lamp continues to light after starting and does not go out subsequently, it makes sense to think about towing the car to the nearest service station or to a trusted auto mechanic. The matter may turn out to be quite serious, so it is advisable to conduct the examination in a calm environment. Since we have already said that the causes of low pressure may be associated with a faulty sensor, it would be useful to understand the principle of operation of this device. There are certain contacts inside it. Until the ignition is turned on, there is no pressure in the system, so the contacts are closed. When you turn the key and turn on the ignition, but before the starter starts, the warning lamp should be on. If this does not happen, then there may be some kind of malfunction. Maybe the light bulb itself simply burned out, or maybe the contacts were broken or the sensor itself failed. As soon as we start the engine, the contacts open, leading to the light bulb going out.

Why does the VAZ 2107 engine consume oil?

Re: About oil consumption

Unread message Topor » Tue Aug 10, 2010 18:35:00

Why is the compression in cylinder 4 generally excellent, but the spark plug is dirty? And in cylinders 2-3 the spark plugs are more or less dead.

And is it worth continuing to pour expensive synthetics into the engine, or fill it with some luxoil and let it eat to its health? Since the rings are...

Re: About oil consumption

Unread message Buiny » Tue Aug 10, 2010 18:53:55

Re: About oil consumption

Unread ErPA message » Fri Aug 13, 2010 10:09:28

Re: About oil consumption

Unread message vit84 » Fri Aug 13, 2010 10:13:13

Re: About oil consumption

Unread message guest » Fri Aug 13, 2010 10:20:55

Re: About oil consumption

Unread message by Zayec » Fri Aug 13, 2010 10:44:27

Re: About oil consumption

Unread message vit84 » Fri Aug 13, 2010 11:22:43

Re: About oil consumption

Unread message guest » Fri Aug 13, 2010 11:27:05

Re: About oil consumption

Unread message Alex » Fri Aug 13, 2010 11:42:54

Re: About oil consumption

Unread message Topor » Sun Aug 15, 2010 7:20:30 AM

Re: About oil consumption

Unread message yurecgod » Sun Aug 15, 2010 9:11:41 AM

In my case, the valve seat of the 2nd cylinder burst and smoked heavily.

I thought the seals or bushings took off the head, everything was ok, but the ring probably burst. scattered the motor rings like new

I reached my head. and lo and behold, the valve seat burst

Trouble-shooting

A faulty oil pressure indicator system can lead to very serious consequences. Therefore, problems of this kind should be resolved immediately.

Necessary tools and devices

To carry out repair work you will need:

- new wiring;

- light bulb;

- set of screwdrivers;

- pressure gauge;

- multimeter;

- new oil pressure sensor.

In some cases, it will be necessary to replace the oil pressure sensor

The list of mandatory work includes replacing the light bulb in the instrument panel, checking the DDM, measuring the pressure and oil level in the system.

Replacing a light bulb

Often the light bulb itself is faulty. Its replacement on the dashboard of a VAZ 2109 car is carried out as follows.

- Using a screwdriver with a wide blade, the buttons for dimensions, low beam and emergency signals are removed from the dashboard. The connectors are disconnected from the buttons.

- Use a Phillips screwdriver to unscrew the screws securing the instrument console trim.

The screws securing the instrument console trim are unscrewed using a Phillips screwdriver. - The car radio is pulled out and all connectors are disconnected from it.

- The metal latches around the perimeter of the visor are pressed out, and the visor is pulled out.

- The panel itself is bent or completely removed.

- The oil pressure light is replaced with a new one.

Oil pressure light on the dashboard number 21

Diagnostics and replacement of the oil pressure sensor

The oil pressure sensor is usually located on the rear of the engine block. A more precise location can be found in the vehicle's operating manual. When diagnosing a DDM, it is first recommended to carry out an external inspection of it - check the integrity of the case and contacts. Then the connector is disconnected from it and, after cleaning, reconnected. Often this is enough for the sensor to work.

The DDM connector of some cars has a protective rubber cap, which expands due to heat during long-term use. Often this is what explains why a light bulb blinks and lights up for no reason.

A protective rubber cap on the sensor may cause it to not work correctly.

If you find such a cap, you should simply remove it and throw it away as a completely non-functional element.

The VAZ 2106 oil pressure sensor does not have a rubber cap

If traces of oil appear on the DDM, this indicates that the sensor is leaking oil and should be replaced immediately.

The functionality of the DDM can be checked by removing the wire from it and attaching it to the car body. If the light starts flashing and works normally, the sensor is faulty and must be replaced.

To check the functionality of the DDM, the wire is removed and connected to the car body

You can check the DDM using a multimeter. This is done as follows.

- The wire is removed from the sensor.

- A multimeter measures the resistance between the DDM contact and the motor surface.

- If the resistance is close to zero, the sensor is working. Otherwise, it must be replaced with a new one.

Such diagnostics can be carried out using a regular 12 V light bulb with wires. One wire is connected to the battery positive, the other to the DDM contact. If the light comes on, the sensor is working.

Replacing the sensor is extremely simple - remove the old DDM and install a new one. It is better to replace the faulty wiring entirely.

Video: checking the oil pressure sensor

Oil pressure measurement

If the DMM is working properly, you should use a special pressure gauge to measure the oil pressure as follows.

- The engine starts and warms up to operating temperature.

- The engine stops.

- The DDM is removed, and a pressure gauge is connected in its place using an adapter.

Oil pressure is measured using a special pressure gauge - The engine starts again. If the car is equipped with an automatic transmission, it is set to P or N mode.

- The pressure is measured and compared with the indicators regulated by the car's operating manual for idling.

- Pressure is measured at high speeds (up to 4–5 thousand rpm).

The obtained values are again compared with those specified in the instructions. Oil pressure indicators must match the values regulated by the manufacturer

Low pressure is usually associated with low oil viscosity and antifreeze or fuel entering the engine crankcase. With increased pressure, the oil begins to turn into an emulsion, and antifreeze consumption increases. If the measurements showed a pressure value that does not correspond to the technical characteristics of the car, the DDM should be replaced.

The oil pressure lamp is on at idle speed VAZ 2107 injector

I actually had this kind of garbage on 06, it was most likely the oil pump that went bad. While the car is cold, the oil is thick, and then it warms up and becomes thinner. the pump gears are worn out, the gaps in the gear pair have increased, and at speed the centrifugal force increases and the pressure in the system increases.

As the engine warms up, the oil pressure light comes on at idle.

This happens when the oil receiver grid is clogged. The explanation is very simple. When the engine is turned off, large particles of dirt (that’s what we’ll call them) gradually sink to the bottom of the crankcase. When the engine starts, the oil begins to circulate and the pressure is normal. Gradually, large particles of dirt stick to the oil receiver mesh and make it difficult for oil to enter the oil pump. The pressure drops. If you accelerate, the pump sucks in more oil due to the speed and the pressure is restored briefly. This is one of the likely reasons. Good luck!

To begin with, you don’t need to change anything, but you need to measure the oil pressure on a cold and hot engine.

To begin with, you don’t need to change anything, but you need to measure the oil pressure on a cold and hot engine.

_________________ you can have whatever beliefs you want as long as they do not disagree with ours.

I will leave the bliss of paradise for the poor; the poor in spirit must have a king and a god.

There is a whole discussion here, but urgent measures need to be taken. You can’t drive like that. 1-pressure. 2-mesh oil intake. 3 - oil on the finger - presence of soot. 4 - gasoline pump - there may be more gasoline in the crankcase than in the tank.

3 - oil on the finger - presence of soot.

Which engine parts suffer the most from lack of pressure? I opened the oil filler cap and it gurgled.

Z.Y. By the way, where did the author of the post go? I would really like to know how things are going with him.

Z.Y. By the way, where did the author of the post go? I would really like to know how things are going with him. [/quote]

3 - oil on the finger - presence of soot. 4 - gasoline pump - there may be more gasoline in the crankcase than in the tank.

The oil darkens as it should after changing, it doesn’t look like soot at all. I changed the fuel pump a week ago, it was wet on the outside, but the oil didn’t smell like gasoline. The oil pressure sensor was also replaced.

So after all, what suffers primarily without pressure at low speeds?

So after all, what suffers primarily without pressure at low speeds?

The crankshaft is the first to suffer. I already asked the masters.

I'll take the pan off and clean the oil pan.

The oil receiver mesh, especially around the edges, is very difficult to clean; the funnel gets in the way. IMHO it is more advisable to replace the oil receiver with a new one, it does not seem expensive. Good luck!

More - no less

Many people mistakenly think that the maximum mark on the dipstick is just a warning mark, and that filling a little more won’t cause anything terrible.

If you overfill the oil, excess pressure is created in the oil lines, which helps squeeze out the oil through all possible gaskets, pipes, but most often the oil seals.

Plus, a paradox appears - the more oil, the worse it lubricates and leads to accelerated wear of parts. But the fact is that if there is an excess of oil, it begins to foam intensely and it loses its lubricating properties. And this already leads to a major overhaul of the engine, which will cost a tidy sum.

What pressure should be in the system?

The sensor serves only to determine the pressure drop, but it does not indicate the exact indicator of this parameter. Therefore, a conventional 10 bar dial pressure gauge is used for measurement.

For measurements, you can use any device, adapting it to the engine or using a pressure gauge specially designed for this.

To use a conventional pressure gauge, you will have to improve it a little so that it can be connected to the motor. To do this, you will need the pressure gauge itself, a piece of thick-walled rubber tube, clamps and a threaded fitting for the hole for installing the pressure sensor.

We connect all this into one structure, and securely clamp the joints of the tube with the pressure gauge and fitting with clamps.

With a special pressure gauge for measuring oil pressure on engines, such a procedure is not required, since it is already equipped with a fitting and adapters for connecting to the engine.

Measurement is performed using the following technology:

- Disconnect the wire and unscrew the pressure sensor;

- We screw the pressure gauge into the sensor seat and tighten it well (but do not overdo it, since the thread in the hole is aluminum and breaks easily);

- We briefly start the engine (a short period of engine operation will not cause any damage);

- We look at the device readings.

If the pressure gauge shows pressure above 1 Bar, the lubrication system is functioning normally and the cause should be sought in the sensor or wiring.

https://youtube.com/watch?v=3uc4G3f31_A

What builds up the pressure?

Regardless of the type of power system and timing system, on all internal combustion engines a special pump is involved in this process. It is located in the area of the engine crankcase. This mechanism is driven by gears that rotate the motor during operation.

As a result, the lubricant begins to move through the channels to the right places. This is the camshaft, crankshaft, piston system and much more. It is the pump that is responsible for the oil pressure in an internal combustion engine. What happens if his work stops? We will talk about this below.

Engine oil leak: how to find the cause

Let's start with the fact that the lubrication system of an internal combustion engine is closed. The lubricant circulates through special channels in the BC and cylinder head under a certain pressure, and oil is also supplied to some parts by splashing or by gravity.

At the same time, it is necessary to constantly maintain a strictly defined level of lubricant in the oil system, which should not be lower than the minimum or higher than the maximum. It is quite obvious that oil leakage from the engine is a serious malfunction, which in some cases can damage the power unit.

Next, we will look at what the driver should do if the engine is in oil, what is the cause of such a malfunction, and also how to find an oil leak from the engine in cases where it is not possible to quickly localize the problem area or element.

What to do if there is no oil pressure

If the oil pressure disappears, this is not a good sign. It is not difficult to find out about this - the corresponding red lamp will light up on the instrument panel. In this case, you need to immediately turn off the engine and figure out the reasons why the oil pressure lost?

The required amount of pressure inside the engine is created by a special oil pump, which is driven by the engine crankshaft. The tightness of the system is ensured by a system of oil seals and seals. Based on this, the reasons for the decrease in oil pressure can be identified in the list below.

What to look for when the lubrication level is high

It turns out that a high level can arise as a result of a banal overflow of oil into the engine. Also, possible mistakes should not be ruled out, especially among novice car owners:

- when replacing or adding lubricant, the car was not placed on a flat horizontal platform;

- the lubricant was added, then the dipstick was immediately removed to check the level, without taking into account that it was necessary to wait for the time during which the residues still flowed into the pan;

- the level was checked “hot” immediately after stopping the internal combustion engine, etc.

In this case, excess lubricant must be removed immediately, which will avoid foaming, oil squeezing out through oil seals, gaskets and seals, oiling of the turbocharger, and penetration of lubricant into other systems and components.

Let's move on to the second reason. To understand why the oil level in the engine increased in this case, it is enough to evaluate the operation of the engine, as well as the condition of its power system

We will not consider outdated carburetor internal combustion engines separately, focusing on injection power units. However, a number of problems may be common to both types

If we add to this that the engine itself may be worn out (low compression, stuck rings, damage to the cylinder bore, obvious smoke from a grayish exhaust, etc.), then the total amount of fuel in the oil often turns out to be quite large.

In this case, the oil smells like gasoline, becomes highly flammable and dilutes greatly, which can be reliably determined during testing. Also, with such diluted lubricant, the engine runs very noisily, knocking noises may occur, and the unit itself will quickly fail.

In this case, fuel in the oil is only a consequence of breakdowns, and the root causes of the engine malfunction itself can be different. For example, problems with mixture formation (the mixture becomes over-rich in gasoline and loses its ability to ignite), lack of spark on the spark plugs, low compression, leaking injectors (when closed injectors “pour” fuel), etc.

In any case, the engine cannot be operated with such a problem, since the lubricant loses its protective, antifriction and other properties. The power unit must be repaired immediately, eliminating the main cause or a whole set of problems due to which fuel enters the engine crankcase.

Finally, the third reason. In this case, working fluid from the cooling system enters the engine oil. This is indicated by a decrease in the coolant level in the expansion tank, an increase in the oil level, as well as a water-oil emulsion under the oil filler cap.

The danger of mixing oil and antifreeze is that the result is not only a loss of oil properties, but also the formation of sediment. This deposit is the result of a chemical reaction between the additives in the base engine oil and the component package in the coolant.

The emulsion clogs the oil passages, and solid particles significantly increase wear on the crankshaft bearings and other elements. Ultimately, the engine becomes severely damaged and begins to knock as it suffers from oil starvation, to which is added the damage from the above-mentioned particulate matter.

It is also advisable to reduce the subsequent replacement interval for fresh lubricant by 50% in order to eliminate the negative impact and premature aging of the oil after contact with the remnants of the emulsion and flushing oil that are not drained from the internal combustion engine.

What you need to know about the VAZ 2106 oil pressure sensor: device, testing methods and replacement

The performance of the engine of any car depends on the presence of engine lubrication and the pressure created by the oil pump. So that the driver can control these important parameters, a corresponding indicator and an emergency lamp flashing red are installed on the instrument panel of the “classic” VAZ 2106. Both indicators receive information from one element built into the engine - the oil pressure sensor. The part is simple and can be easily changed with your own hands if necessary.

Purpose of the oil pressure control sensor

All moving and rubbing parts of the power unit are constantly washed with liquid lubricant supplied by a gear pump from the engine sump. If, for various reasons, the supply of lubricant stops or its level drops to critical, the motor will face a serious breakdown, or even more than one. The result is a major overhaul with replacement of the crankshaft bearings, cylinder-piston group, and so on.

To protect the car owner from these consequences, classic Zhiguli models provide two-level control over the engine lubrication system, operating according to the following algorithm:

- After turning the key in the lock and turning on the ignition, the red warning lamp lights up, indicating a lack of oil pressure. The pointer needle is at zero.

- In the first 1-2 seconds after starting the engine, the indicator continues to light. If the oil supply is normal, the lamp goes out. The real pressure created by the pump is immediately shown by the arrow.

- When the engine turns off, a large amount of lubricant is lost, or a problem occurs, the red indicator lights up immediately.

- If the lubricant pressure in the motor channels decreases to a critical level, the light begins to flash periodically.

Malfunctions leading to a drop in pressure - breakdown or wear of the oil pump, complete wear of the crankshaft liners or breakdown of the crankcase.

The main role in the operation of the system is played by the sensor - an element that records the oil pressure in one of the main channels of the engine. The indicator and pointer are just a means of displaying the information transmitted by the pressure meter.

Location and appearance of the device

The sensor installed on classic VAZ 2106 models consists of the following parts:

- an element in the form of a round metal barrel with one terminal for connecting a wire (factory name - MM393A);

- the second part is a membrane switch in the form of a nut with a contact at the end (designation MM120);

- a steel tee into which the above parts are screwed;

- sealing bronze washers.

The large “barrel” MM393A is designed to measure pressure, the “nut” with the MM120 terminal fixes its absence, and the tee is a connecting element that is screwed into the engine. The location of the sensor is on the left wall of the cylinder block (if you look in the direction of movement of the car) under spark plug No. 4. Do not confuse the device with the temperature sensor installed higher in the cylinder head. Wires leading inside the cabin, to the dashboard, are connected to both contacts.

In later models of the “classic” VAZ 2107, the indicator arrow on the dashboard is missing, only a warning lamp is left. Therefore, a stripped-down version of the sensor is used without a tee and a large barrel.

Device and connection diagram

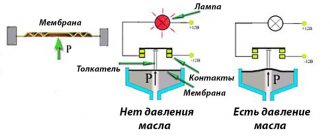

The task of the membrane switch, made in the form of a nut with a terminal, is to promptly close the electrical circuit with the warning lamp when the lubricant pressure drops. The device consists of the following parts:

- metal body in the form of a hexagon;

- contact Group;

- pusher;

- measuring membrane.

The element is connected to the circuit according to the simplest circuit - in series with the indicator. The normal position of the contacts is “closed”, so after turning on the ignition the light comes on. When the engine is running, there is a pressure of oil flowing to the membrane through the tee. Under the pressure of the lubricant, the latter presses the pusher, which opens the contact group, as a result the indicator goes out.

When one of the malfunctions occurs in the engine, causing a decrease in the pressure of the liquid lubricant, the elastic membrane returns to its original position and the electrical circuit is closed. The driver immediately sees the problem by the flashing “control”.

The design of the second element, the “barrel” called MM393A, is somewhat more complicated. The main role here is also played by an elastic membrane connected to an actuator - a rheostat and a slider. The rheostat is a coil of high-resistance chromium-nickel wire, and the slider is a movable contact that moves along the turns.

The electrical circuit for connecting the sensor and pointer is similar to the first one - the rheostat and the device are in series in the circuit. The operating algorithm is as follows:

- When the driver turns on the ignition, on-board voltage is supplied to the circuit. The slider is in its extreme position, and the winding resistance is maximum. The instrument needle remains at zero.

- After starting the engine, oil appears in the channel, flowing through the tee into the “barrel” and pressing on the membrane. It stretches and uses a pusher to move the slider along the winding.

- The total resistance of the rheostat begins to decrease, the current in the circuit increases and causes the indicator arrow to deviate. The higher the lubricant pressure, the more the membrane stretches and the less resistance of the coil, and the device notes the increase in pressure.

The sensor reacts in the reverse order to a decrease in oil pressure. The force on the membrane decreases, it is thrown back and pulls the slider with it. He turns on new turns of the rheostat winding in the circuit, the resistance increases, and the instrument needle drops to zero.

Video: what pressure should a working device show?

How to check and replace an element

During long-term operation, the internal parts of the sensor wear out and periodically fail. The malfunction manifests itself in the form of false readings on the indicator scale or a constantly burning emergency lamp. Before drawing conclusions about power unit failures, it is highly advisable to check the functionality of the sensor.

If the control light comes on while the engine is running and the indicator drops to zero, your first action is to immediately turn off the engine and do not start it until the problem is discovered.

When the light comes on and goes out in a timely manner, and the needle does not deviate, you should check the serviceability of the oil sensor - the MM393A pressure meter. You will need a 19 mm open-end wrench and a pressure gauge with a scale of up to 10 Bar (1 MPa). A flexible pipe with a threaded tip M14 x 1.5 must be screwed to the pressure gauge.

The verification procedure is as follows:

- Turn off the engine and let it cool to 50-60 °C so you don’t have to burn your hands while working.

- Disconnect the wires from the sensors and unscrew them with a 19 mm wrench along with the tee. Please note that during disassembly a small amount of oil may leak out of the unit.

On the road, it is more difficult to check the VAZ 2106 oil sensor, since there is no pressure gauge at hand. To make sure there is lubricant in the engine channels, unscrew the element, disconnect the main ignition wire and rotate the crankshaft with the starter. If the pump is working properly, oil will splash out of the hole.

If the arrow on the instrument scale shows normal pressure (in the range of 1-6 Bar), but the red lamp is on, the small MM120 membrane sensor has clearly failed.

When the light signal does not light up at all, consider 3 options:

- the light bulb burned out;

- broken wiring;

- The small sensor in the form of a hexagon has become unusable.

The first 2 versions can be easily checked by testing them with a tester or multimeter. The serviceability of the membrane element is tested as follows: turn on the ignition, remove the wire from the terminal and short it to vehicle ground. If the lamp lights up, feel free to change the sensor.

Replacement is done by unscrewing the large or small sensor with a wrench. It is important not to lose the bronze sealing washers, since they may not be included with the new part. Remove any leaks of engine lubricant from the hole with a rag.

Both meters cannot be repaired, only replaced. Their metal cases, capable of withstanding the oil pressure of a running engine, are hermetically sealed and cannot be disassembled. The second reason is the low price of VAZ 2106 spare parts, which makes such repairs pointless.

Video: how to check lubricant pressure with a pressure gauge

Video: replacing the VAZ 2106 sensor

Pointer functions and operation

The purpose of the device, built into the dashboard to the left of the tachometer, is to display the engine oil pressure level, guided by the sensor. The principle of operation of the pointer resembles the operation of a conventional ammeter, which responds to changes in current strength in the circuit. When the mechanical rheostat inside the measuring element changes resistance, the current increases or decreases, deflecting the needle. The scale is graduated in pressure units corresponding to 1 Bar (1 kgf/cm2).

The device consists of the following main elements:

- round body;

- pointer mechanism with permanent magnet and windings;

- a control light connected to the corresponding sensor by a separate line;

- scale with backlight;

- compensation resistor;

- connecting wires with connector.

Zero readings of the device correspond to a circuit resistance of 320 Ohms. When it drops to 100-130 Ohms, the needle stays at 4 Bar, 60-80 Ohms - 6 Bar.

The Zhiguli engine lubrication pressure indicator is a fairly reliable element that breaks very rarely. If the arrow does not want to leave the zero mark, then the culprit is usually the sensor. When you doubt the functionality of the indicating device, check it using a simple method: measure the voltage at the connection contacts of the MM393A oil sensor with the engine running. If voltage is present and the needle is at zero, the device should be changed.

The VAZ 2106 oil pressure monitoring system with two sensors and a mechanical indicator is simple and reliable in operation. Despite the outdated design, car enthusiasts often buy and install these meters on other, more modern cars, equipped from the factory with only a control indicator. Examples are the updated VAZ Seven, Chevrolet Aveo and Niva.

Reasons for a drop in oil pressure - how to eliminate them?

- Oil pump malfunction. It manifests itself as a mechanical component, such as jamming or breakage of individual elements or its clogging. The fact is that such a pump has very thin tubes for oil circulation, which can easily become clogged due to small foreign particles.

- Violation of the tightness of the system is the most “capricious” malfunction, which is quite difficult to identify, but possible. First of all, this concerns the oil seal, which suddenly began to leak and leak a certain amount of oil out. As the oil level drops, the pressure created inside also decreases. The most visible malfunction associated with low pressure is a broken engine sump, which happens when driving carelessly on “bad” roads.

Be that as it may, the problem needs to be solved. Therefore, depending on the reason, we will try to tell you what to do if the pressure is low.

So, you saw a red light on the instrument panel. First of all, you need to check the oil level. To do this, open the hood and pull out the oil dipstick. If the level is normal, then measure the oil pressure using the methods mentioned above. If the pressure is normal, then the fault lies in the sensor, which simply shorted. Replace the sensor and check everything again. In most cases, the malfunction disappears. However, if the pressure is reduced, then it is time to remove the oil pump, clean it or repair it.

If the oil level has dropped, check the engine for leaks. If the pan is broken, it needs to be replaced. Change the gasket along with it. However, under no circumstances should the engine be started in this condition until the work is completed.

Leaks can also come from the seals

For example, it is worth paying attention to the condition of the crankshaft oil seals. If they are worn, you will see corresponding traces of oil in place from the installation

Just change the seals and pour new oil into the engine.

The last reason is oil consumption. This happens when the cylinders and oil rings are faulty. In this case, you will find an engine repair that is not the most pleasant, but worth it. As a temporary measure, move the breather down and constantly monitor the oil level.

That's all that can be done for the engine if the oil pressure suddenly drops. As you can see, the problem is not that complicated.

In this material, we will pay attention to the light bulb that notifies you of a decrease in oil pressure in the engine of VAZ 2107 cars. This indicator is located directly on the dashboard and looks like an oil can.

If it lights up, it makes it clear that the oil pressure in the engine has decreased. Further operation of the VAZ 2107 is contraindicated until the causes of this phenomenon are eliminated.

What should the oil pressure be and how to check it

Oil pressure is a very important value, because the quality of lubrication of engine parts will depend on it. If the pressure is insufficient, the oil will not be able to get into small holes, and if there is excess pressure, it will squeeze out the seals and cause increased leakage. That is why it is important to know and be able to maintain oil pressure at the proper level.

For example, for a VAZ 2107 engine, standard values are set at which the oil pressure is within normal limits. The normal level starts from 0.2 kgf/cm2 . At the same time, the contact contacts of the oil pressure sensor are open and the lamp indicating insufficient oil pressure does not light up. When the engine is warmed up, the oil pressure can reach 4.5 kgf/cm2 . Moreover, these values are typical only for idle speed. As their number increases, the pressure increases in direct proportion.

As for checking the oil pressure, only VAZ 2106 cars of their classic family are lucky here, since they have a sensor for monitoring oil pressure. There is simply no such device in the VAZ 2107 panel. Therefore, we will measure pressure directly on the engine itself.

To do this, you will need a working pointer from the car. One of the pointer contacts must be connected to ground, and the other two to positive, which must be taken from the car’s ignition switch. The last wire goes to the sensor contact, which is not connected to ground. Start the engine and check the gauge readings. If everything is connected correctly, the device will give you accurate values.

Of course, there are devices that are simply screwed in instead of the old sensor and, after starting the engine, give more accurate readings, but the previous method has long been time-tested and has helped out more than one car enthusiast.

How to determine the quality of the auto chemicals used?

The quality of a lubricant is determined by its viscosity. The unit of measurement is centistokes. For each car, the manufacturer recommends its own optimal oil viscosity. For VAZ 2106, it is recommended to use oxol 0W or 5W in winter, and 20W and 30W in summer. If suspicion arises and inspection is not possible, the lubricant should be replaced.

This procedure is carried out as follows:

- 10 minutes after the engine has been turned off, you need to unscrew the plug and completely drain the lubricant.

- Screw the cap back on and fill in the appropriate product.

- Start the engine and let it run at minimum speed for 2 minutes.

- Stop the engine and wait 5 minutes.

- Check the lubricant level and top up if necessary.

If the oil receiver is clogged, then it is not difficult to guess why the lubricant pressure drops. There simply won’t be enough of it supplied to the pump. If the valve breaks, the situation is different. Here, on the contrary, an increased bypass of oxol will be observed. The reason must be sought by the method of sequential elimination. First, check whether the strainer is in normal condition. If clogged, it is washed in gasoline and replaced. A valve malfunction in a VAZ 2106 car most often occurs due to a failure of the spring, which has to be replaced with a new one.

Oil pressure in the VAZ 2106 engine

The need for a technical inspection arises when the VAZ oil pressure is lost. Often a breakdown occurs while driving or after an overnight stay. To determine its cause, you will need to examine the “iron horse”. There is no point in waiting for the problem to resolve itself. As the oil gauge continues to light, the vehicle's technical condition will gradually deteriorate.

Formation of a fault

Absence or insufficient oil pressure leads to rapid wear of engine parts. Even under light loads, the motor elements do not receive the required amount of lubricant. There are many reasons for such a malfunction, but most often it is the deformation of the oil pan that is to blame. This can happen even with a new car, so there is no need to refuse preventive examinations.

It is not difficult to damage the mentioned unit while crossing artificial uneven surfaces or when driving on a bumpy road. A few hits on the oil pan are enough for the engine to develop a problem with oil pressure. Further developments depend on the severity of the damage:

Regardless of the degree of breakdown, experienced drivers focus on an important aspect. Under no circumstances should the lubricant pressure level in the system be allowed to drop to 0. As soon as the arrow crosses the indicated value, irreversible changes will begin in the engine. If a breakdown occurs while driving, you must stop immediately and turn off the engine.

The same should be done if, as a result of a breakdown, the oil pressure level in the system has increased many times over. Otherwise, its excess amount will come out of all holes. Excessive lubrication will not benefit engine components.

Fault Diagnosis

Constant monitoring of the engine condition will help reduce the likelihood of a sudden breakdown even when driving carefully.

A sensor on the dashboard can determine what pressure is in the system. It is constantly in the driver's field of vision, otherwise expensive repairs cannot be avoided. At the same time, its meaning should not mislead the owner of the “iron horse”.

It happens that a short circuit in the sensor lamp circuit leads to incorrect readings. It's easy to check. It is enough to connect the wire from the sensor directly to the engine (to ground). If after this manipulation the light does not go out, you need to replace it. An extinguished light will indicate that the oil pressure in the system has indeed lost.

Further troubleshooting involves inspecting the oil sensor itself. Ideally, the device should be in oil; if this is not the case, you should continue to look for the problem below. The oil filter valve located below often malfunctions. The problem is eliminated by replacing the gadget, the cost of which is low. If this does not help get to the bottom of the truth, they continue to look for the problem at idle speed of the car.

The pan and oil receiver are inspected for mechanical damage. It would be a good idea to inspect the oil pickup ring. It should not show signs of abrasions or mechanical damage. The list of possible malfunctions that lead to incorrect display of the oil level in the system ends with a breakdown of the pressure reducing valve. If you have a classic or premium version of a VAZ, a similar malfunction may occur. Eliminated during engine overhaul.

A drop in the lubricant level in the system is a dangerous breakdown that can damage individual engine components or the entire engine. That is why you should constantly pay attention to the oil level sensor. At the slightest deviation, a preventive examination is carried out.

Reasons for the indicator to light up

It should be noted that the oil pressure light may come on intermittently in some situations without presenting any danger to engine operation. Such situations include:

If the light comes on while driving or at idle, and does not go out after a while, then appropriate measures should be taken. The oil pressure indicator indicates the occurrence of failures and malfunctions. Such problems occur not only in the engine, but also in the electronic part. Some of the main reasons why this indicator lights up include:

In certain cases, it is necessary to stop and determine the presence of oil in the engine using a dipstick. If the level is normal, then you should get to the nearest station or home, and then determine the reason for the light coming on. If there is no oil, then continuing to move under your own power is strictly prohibited, because this may cause the motor to jam.

If the pressure indicator lights up, you should make an emergency stop and turn off the engine. After this, a number of steps should be taken to determine the cause of such consequences.

Checking the lubricant level

After stopping, you need to open the hood and remove the dipstick. The measuring scale of the dipstick should be wiped, then reinsert it into the hole, and then remove it and make sure there is a sufficient level of lubricant. If the dipstick shows a minimum fluid level, then you should top it up, but then try to find out the reasons for the decrease in level. Often the reason for a drop in oil level is its leakage through the seals, which need to be changed periodically.

After the oil is added to the engine, the indicator will not light up, which indicates that the cause has been correctly eliminated. Low oil pressure in the engine can also be determined using a special dial-type indicator, which displays information for the driver about the state of oil pressure. However, on VAZ 2107 cars such indicators are not installed from the factory, although some motorists install them themselves.

Oil filter malfunction

If the lubricant level is in order, then the cause of such consequences may be a faulty filter. If you recently changed the oil and filter, and after some time the light comes on, then there is a high probability that you have received a defective filter. Under such circumstances, you will need to replace not only the filter, but also the lubricant in the system. Such cases, although rare, are all appropriate.

Checking the health of the sensor

The malfunction may consist of a breakdown of the sensor itself or a short circuit in the supply wiring. To check the health of the sensor, there are two ways:

In the first case, the pressure in the system must be at least 0.35 kgf/cm2. The value on the pressure gauge is not lower than the specified one, indicating that the system is working properly and the sensor is faulty. In the second case, the test involves connecting the multimeter probes to the sensor terminals. In this case, the device should show zero resistance. Now you need to pump using the pump, as a result of which the multimeter readings should change and it will show infinity. In order to check the integrity of the wiring suitable for the sensor, you should test it using a multimeter. Replacing the sensor is not particularly difficult, so even a beginner can cope with this task.

Checking the quality of the lubricant

If all of the above methods have been tried, but the icon continues to light, then you should check the quality of the oil. To do this, you need to inspect the dipstick, with which you can easily determine the presence of signs of antifreeze or gasoline in the lubricant. To do this, you need to dip the dipstick in water and see if streaks appear on the surface, then the reason is that foreign liquid has entered the motor.

In such a situation, a complete flush of the engine, as well as major repairs, cannot be avoided. It is necessary to eliminate the cause of gasoline or antifreeze getting into the engine compartment.

From the above, it should be noted that in order to avoid unpleasant situations, when the oil pressure light comes on, you should immediately stop and find the cause.

Source

Results

Finally, we note that it is better to start looking for the reason for the oil pressure warning light to start with something simple - checking for leaks and the oil level.

Then the sensor itself and the filter are checked. You can then use a pressure gauge to determine the actual pressure in the system, which may give you a clue as to where to look for the problem.

For example, if even at medium and high speeds the value on the pressure gauge does not increase, then most likely the pressure relief valve is jammed.

Removing the pan to get to the oil intake, pump and pressure relief valve is the last thing to do.

Source

Nuances of the cooling system

Much also depends on the coolant used. For example, there is no need to pour water even into old cars; it is better to buy inexpensive antifreeze, there will be fewer problems. However, modern engines require high-quality cooling. The manufacturer indicates in the manual the recommended brands of coolant. It is advisable to follow these tips and not dilute the antifreeze if you do not have a concentrate.

Modern coolants have different service life and boiling points. For example, G12 boils later than G11, and G12++ has an increased resource, but it is also more expensive. In any case, to avoid engine boiling, it is recommended to fill only high-quality coolant.

Let's sum it up

So we figured out why there is pressure in the engine cooling system, why it can be excessively high or, conversely, low. There is often nothing complicated about checking it yourself, although a lot depends on the car. For example, it happens that the coolant temperature sensor fails. It can provide incorrect data to control devices, thereby misleading the driver. It can show both a high temperature of the power unit and, conversely, a low one. But this will not mean that the system is not working correctly.

If there are any breakdowns in the cooling system, they must be repaired as soon as possible. It is advisable not to operate a vehicle with a stuck cover or thermostat. After all, for some engines overheating is fatal, and major repairs are not cheap at all. In general, it is worth regularly checking the coolant level in the system to ensure that there are no leaks or other defects. It is also recommended to periodically clean the radiators from dirt, as this can cause increased engine temperature.

Didn't find the information you are looking for? on our forum.

The oil pressure light comes on at idle and when the engine is warm

To make it easier for drivers to monitor the operation of the power plant, the engine systems are equipped with control sensors. Their task is to monitor the operation of the system and, if a malfunction occurs, immediately alert the driver about it.

Control sensors are connected to warning lights and instruments installed on the dashboard in the cabin. This allows the driver to immediately notice a malfunction.

One of the most important warning lights, the lighting of which should alarm any driver, is oil pressure.

Before starting the engine, after turning the ignition key, this indicator always lights up, indicating that there is no pressure in the system. But after starting the engine, it should go out and not light up again until the power unit is stopped.

The operation of the control sensor is quite simple - while there is no pressure in the system, it closes the contacts, causing the lamp to light.

After starting the engine and increasing the pressure to a certain level, the contacts open and the lamp goes out. In a fully functional engine, it goes out no later than 1-2 seconds after starting.