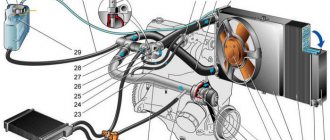

The engine lubrication system involves supplying engine oil to loaded parts and components under a certain pressure, which is created by the oil pump. At the same time, a decrease in lubricant pressure for one reason or another is a critical malfunction that can quickly damage the power unit.

The driver is informed about this decrease in oil pressure by a warning light located on the instrument panel. In some cases, the light may be constantly on, in others the oil light blinks at idle and low speeds, only on a cold or warm engine, etc.

In this article we will talk about why the oil pressure comes on after the engine warms up, what causes and problems in the engine or lubrication system lead to this, and what the driver should do if the oil pressure comes on “hot”.

Causes

If we are talking about oil pressure, then naturally the problem is in the engine, namely in some components and parts. To determine the causes, it is necessary to know the structure and operation of the power unit, since without this it will be impossible to eliminate malfunctions. So, let’s look at the reasons why such a warning light may appear on the instrument panel:

- There is a malfunction in the sensor and wiring.

- The oil level has dropped below normal (see “how to check the oil level”).

- Signal to change the oil.

- The oil pump has failed.

- The malfunction is hidden in the cylinder head or directly in the cylinder block itself.

When all the reasons have been considered, it is necessary to move on to a consistent definition of the problem and options for eliminating it.

In order to eliminate an engine malfunction, you will need a set of tools, as well as knowledge of the structure of a car engine. So, let's look at how to fix the problem.

Oil pump pressure reducing valve failure - repair or replacement?

Repair work begins with disassembling the pressure reducing valve. Removing the cover and removing the spring is not difficult, but removing the valve itself usually becomes difficult. In order to do this, you will need the following tools:

- anchor bolt M8 (length 90 mm);

- nut for wrench 10;

- open-end wrench.

The anchor must be inserted tightly into the plunger, and then the nut must be screwed onto it. After this, take the wrench and continue tightening the nut. After some time, the piston will break off and you can remove it.

To disassemble the mechanism you need to remove the cover, remove the spring, and then the valve itself.

In the absence of the above tools, some craftsmen come up with their own ways of dismantling the valve.

Video: how to remove the valve using a wooden stick

The repair of this mechanism itself depends on the cause of the breakdown. If the problem was low pressure, you should replace the spring

It is very important to find the same part that was before

Please note that the sizes of pressure reducing valves and their components differ for different car models. We recommend that you consult with a specialist before purchasing a part, and come to the store with a disassembled mechanism

The spring for the pressure reducing valve must be sufficiently elastic

If the valve becomes clogged and stops reducing pressure inside the oil pump, carry out the following procedures.

Clean the part thoroughly, paying particular attention to the oil passages. Wash the mechanism in gasoline. Lubricate the dried part. Place the valve in its place. Now you need to check the pressure. A regular pressure gauge is used for this.

The hose with a threaded fitting must be screwed into place of the standard pressure sensor, and then start the engine. You need to find out the values acceptable for your car in the engine manual. For most cars they range from 1 to 4.5 kg/cm2 at medium speeds.

After installing the valve, be sure to check the pressure with a pressure gauge

Typically, experts recommend replacing the valve if major repairs have been carried out before. It is believed that ordinary cleaning and rinsing cannot cope with small chips. It is also worth replacing if you find mechanical damage on the surface of one of the valve components.

Repairing and replacing the pressure relief valve affects the overall performance of the vehicle. And this is not only clearly visible, but also clearly audible while the engine is running.

Video: differences in engine sounds before and after replacing the pressure relief valve

Before disassembling the oil pump and its pressure relief valve and carrying out any work on them, make sure that you are confident in your own abilities. Inaccurate actions can lead to final failure of parts. It will be especially disappointing if the problem was not in the valve, but in other elements of the system, and you have to change a working part. If in doubt, it is better to seek the help of specialists at a car service center.

Oil level

The root cause of such a malfunction may be a simple lack of oil in the engine. If its level drops below normal, it must be topped up and this indicator checked. If the light went out, that was the reason. Don't forget to change and refill it on time.

If the problem appeared after replacing the old oil with a new one and the problem did not disappear after 20 seconds after starting, then the reason lies in a non-working fuel filter, or the oil viscosity does not meet the manufacturer’s recommendations.

[custom_ads_shortcode2]

Main set of sensors for 16-valve VAZ-2112 engines

The ECU must control many parameters at once. The most important information will be the position of the crankshaft. You can turn off all sensors except the DPKV, and this will not lead to the engine stopping.

Sensors connected to the ECU

Let's list all the elements one by one:

- 15 – DTOZH. A resistor screwed into the thermostat housing. The temperature of the antifreeze is determined;

- 17 – DPRV, also known as DF (phase sensor). The operating principle is the Hall effect. The position of the camshaft is controlled. Check it out here.;

- 20 – TPS. Resistor fixed to the throttle assembly 19. The angle of deflection of the throttle valve is measured;

- 21 – Mass air flow sensor. Sensor connected to the filter housing. Controls air flow; the main signs of its malfunction are discussed here;

- 22 – IAC. Not a sensor, but a regulator (electromagnet). Used in idle mode. About its testing and diagnostics here. About replacing the IAC here.;

- 24 – lambda probe or oxygen sensor (see above);

- 25 – speed sensor. Fixed in the gearbox slot. Operating principle – Hall effect;

- 26 – DPKV. Electromagnetic sensor. The position of the crankshaft is controlled;

- 27 – DD (knock sensor). A piezoelectric element mounted on the outer wall of the cylinder block.

Let's take a look at how all the elements look in real life. Shown are pictures of VAZ-2112 sensors (16-valve internal combustion engine).

Each element will be easy to find under the hood

Everything said above is true for two engines at once - for units 21124 and 21120 (1.6 and 1.5 l).

You cannot unscrew the DTOZH sensor without draining the coolant. And to disconnect the sensor means to disconnect the connector, but not to dismantle the sensor itself.

Where is which sensor located - engine compartment diagram

Let's look at another picture.

Engine compartment and engine 21124

It is important to understand where the following elements are located:

The location of the phase sensor is indicated in the previous chapter.

Never unscrew the speed sensor. It will be difficult to install it in a way that maintains a seal.

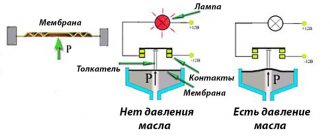

Oil pressure sensor

Another reason that may be observed is the oil pressure indicator. You can check its functionality by visual inspection or by shorting the ground wire to the engine. Do not rush to replace the oil pressure sensor with a new one, since the cause of the malfunction of the old one may be contamination of the channels. If the circuit is working properly, connect a working, new or cleaned sensor to the system in advance and connect the power. The lamp continues to light, which means you need to read below.

Crankshaft bearings

The pressure in the system may also drop due to severe wear of the main or connecting rod bearings of the crankshaft. This phenomenon occurs on engines that have traveled more than 200 thousand km without major overhaul. Such a malfunction can only be detected after disassembling the engine.

Worn bearings allow more oil to pass through, which affects the pressure in the system

Video: causes and consequences of pressure drop in the lubrication system

Diagnostics of the lubrication system is a rather complex and time-consuming process. But you can’t do without it, especially since the car itself gives you a distress signal. It’s better to waste a day looking for a minor problem and try to fix it than to carry out a major engine overhaul later.

Home →

Maintenance and Repair → Engine →

The light comes on during the cold season

The cause of the low oil pressure warning light on VAZ engines can also be negative ambient temperatures, but this is a completely normal phenomenon. This happens because the oil drains from all channels overnight and inevitably thickens. When the engine warms up, the warning light should go off. Therefore, during a “cold” start, the engine needs to fill all the lines and create the necessary pressure (what to do if there is no pressure in the engine?). Since the oil reaches the most important parts much earlier than the oil pressure sensor, wear on these parts is eliminated. During winter startup, the light can remain on for up to 3 seconds continuously.

All VAZ-2112 sensors 16 valves and their location: diagram and description

The efficient operation of the injection engine is ensured by a set of sensors. They all connect to the ECU. Lada hatchbacks of the 2112 family were produced only with injection engines, and two varieties of these internal combustion engines are 16-valve. We will talk about them further. All VAZ-2112 sensors, their location and appearance will be shown in the photo.

The excess oil pressure sensor, which is not connected to the ECU, is shown in the video.

Tips and tricks

Please note that if no leaks are visible, and the oil level and its condition are normal, then before starting complex operations to disassemble the engine, experts recommend accurately measuring the oil pressure in the engine at the initial stage.

Quite often it happens that there is actually nothing wrong with the pressure, and the faults that lead to the warning light coming on are directly related to the wiring and the oil pressure sensor.

The contacts may oxidize over time, and the sensor may also fail. It is quite obvious that these elements also need to be checked first and foremost as part of diagnostic procedures.