For correct diagnostics and repairs, it is necessary to know the structure and operating principle of the heater in order to diagnose a breakdown or carry out repairs at the first sign of a malfunction, preventing failure of the entire unit as a whole. Most faults can be predicted by indirect signs and their progression can be prevented. To do this, you need to know and understand what each element is responsible for and what the principle of its operation is.

Heater Gazelle business principle of operation.

Business Gazelle Heater is a good parody of foreign car heaters, but only at first glance. The heater is controlled by buttons and knobs on the electronic unit located on the control panel. The air in the heater, as in all Gazelles, is sucked in by an electric fan through the grilles under the windshield and, passing through air ducts and deflectors, enters the cabin.

The coolant is supplied to the heater radiator through a tap that opens and closes electrically. It differs from similar taps of previous models by the presence of an additional fitting. When the valve is closed, the liquid is redirected to the cooling system.

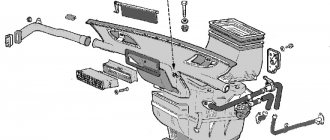

Heater Gazelle business device.

The valve is automatically controlled by the heater controller depending on the selected temperature. In addition, the temperature of the air supplied to the cabin is regulated by a central damper, which directs the air flow or part of it through the radiator or bypassing the radiator.

In addition to the central door, there are a number of dampers that redistribute the air flow. The Gazelle heater dampers, unlike previous models, are controlled by geared motors rather than cables. Control is carried out by the heater control unit. The heater fan is located inside the housing and to access it the entire heater must be removed and disassembled. Despite the fact that the fan motor is imported, this arrangement completely negates all the advantages of the heater.

The speed of the electric motor is easily adjusted by turning the knob on the control unit, thanks to the electronic regulator located on the heater body. To access it, as well as to access almost all elements of the heater, you must completely remove the front panel. The only thing that can be changed without removing the panels is the heater core. To change it, simply remove the glove box.

Quick replacement of the engine speed controller for the gazelle business stove

The problem and matter is installing a stove for a gazelle.

The stove does not work on a gazelle business

I found the reason for the failure of the internal heating motor.

Diagnostics

If the speed control unit fails, then you need to understand which of the elements of the entire circuit has failed. The control of the Gazelle stove is electronic, and all drives are electric.

- To begin with, with the engine turned off, we try to turn the temperature regulator. When you turn it, you should hear clicks from the gear motor. If there are no clicks, then you need to check the power in the block that comes to the tap opening motor. This can be done using a test lamp or a multimeter.

- If the fan speed controller does not work, you need to check its operation in all positions. If it does not work in all positions except the last one, then the reason is a faulty rheostat. If operation is not heard in any of the positions, then you need to check the power supply to the fan block. If power comes in, then it is broken.

- If the stove adjustment works correctly, but the display does not light up, then the display itself or the backlight is faulty.

Heater Gazelle business troubleshooting.

What to do if something goes wrong with the heater? Due to the design of the heating element, it is difficult to diagnose it if its parts fail. First, as always, you need to check the fuse.

Checking gearmotors.

The gear motors of the windshield fans and deflectors can be controlled without completely removing the panels. It is enough to remove its lower part. The main damper motor is accessible from the driver's side. To check the gearmotor, you need to disconnect the connector of its electric motor, the connector with a latch and connect a tester to it in voltmeter mode or a test lamp. With the ignition and heater on, press the button that controls this shock. In this case, the control lamp should light up. If the light is on and the gear motor does not work, it must be replaced.

If you're on the road, you don't have the option to replace the blown glass shutter actuator, so you can remove the rod from the driver's side shutter lever and manually turn it, locking it in the open position. To open the flap on the passenger side, you will need to unscrew the fastening screws of the gearmotor and, by rotating its housing, fix it in the same way.

Checking the electric motor and speed controller.

To check the heater fan motor and the reasons for its failure if the fan does not work, you will need to remove the air intake in the engine compartment. Inside the open OK you will see two wires with a connector. To check the power supply, connect a test lamp to the connector terminals and, with the ignition on, turn the heater speed control to full speed. In this case, the control lamp should burn strongly. When turning the knob to the minimum speed, the brightness of the lamp should decrease. This indicates the functionality of the speed controller.

If the control lamp is on and the fan does not rotate, its electric motor is faulty. To check, measure the resistance between the motor terminals in the connector. Motor malfunction may be caused by hanging brushes. In this case, you can try knocking on the heating element body. In this case, the operation of the fan can be restored until the next time it is turned off, possibly longer, but you can get to the service center in a warm place.

If the warning light does not come on during the power test, the cruise control is faulty. If the cruise control malfunctions, you can temporarily connect the positive wire on the connector to the fuse near the battery with a wire. This will allow you to get to the garage or service in the winter.

How to remove a Gazelle heater and disassemble it due to its high labor intensity cannot be described here, but you can download detailed instructions with photographs from the Gazelle heater.

Below is a schematic diagram of connecting a Gazelle heater and ventilation.

Where are the dampers located?

If the problem situation is related to the dampers of the GAZelle stove, they will need to be dismantled or repaired. In most cases, when it comes to mechanical malfunctions and breakdown of the unit, replacement is provided. It's not difficult to carry it out.

It is not difficult to understand the peculiarities of the operation of the stove dampers on a GAZelle. But they can be the main reason for the poor operation of the heating system if the electric fan and other main components, including the stove radiator, are working properly.

The dampers are located directly inside the heater. If you are from the driver's seat, the flaps can be seen on the right side of the electric fan housing. To get to it you will need to remove the large glove box on the passenger side. But this does not guarantee full access to the node.

To carry out more serious repair and restoration work, it is better to get to the electric fans of the heating system and carry out the repair in comfortable conditions.

Design of the cooling system for UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

To increase energy efficiency, improve fuel efficiency, reduce toxicity and noise, models with an integrated microprocessor injection and ignition control system have been developed based on the YuMZ-421 carburetor engine: the YuMZ-4213 engine for UAZ cars and the YuMZ-4216 for GAZelle cars. The design of the cooling system on the UMZ-4213 and UMZ-4216 is slightly different, since it has differences in the connection diagram of the expansion tanks and heating radiators.

General design of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

The cooling system is liquid, closed, with forced circulation of liquid and an expansion tank, with liquid supply to the cylinder block. Includes a water pump, thermostat, water jackets in the cylinder block and cylinder head, radiator, expansion tank, fan, connecting pipes and radiators for body heating.

For normal operation of the YuMZ-4213 and YuMZ-4216 engines, the coolant temperature must be maintained within plus 80-90 degrees. Short-term operation of the engine is allowed at a coolant temperature of 105 degrees. This mode may occur in hot weather, when the vehicle is driven with a full load over long hills, or in urban driving conditions with frequent acceleration and stopping.

Design of the UMZ-4213 engine cooling system on a UAZ vehicle.

Design of the UMZ-4216 engine cooling system on a GAZelle car.

Operation of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

Maintaining normal temperature of the coolant is carried out using a two-valve thermostat TS-107-01 with solid filler. When the engine warms up, when the coolant temperature is below 80 degrees, a small circle of coolant circulation is turned on. The upper thermostat valve is closed, the lower valve is open.

Coolant is pumped into the cooling jacket of the cylinder block by a water pump, from where, through holes in the upper plate of the block and in the lower plane of the cylinder head, the liquid enters the cylinder head cooling jacket, then into the thermostat housing and through the lower thermostat valve and connecting pipe to the water pump inlet. In this case, the radiator is disconnected from the main coolant flow.

For more efficient operation of the internal heating system when circulating liquid in a small circle, and this situation can persist for a long time at negatively low ambient temperatures, at the liquid outlet there is a throttle hole with a diameter of 9 mm, a channel through the lower thermostatic valve. This throttling leads to an increase in the pressure drop at the inlet and outlet of the heating radiator and more intense circulation of liquid through this radiator.

In addition, throttling the valve at the fluid outlet through the lower valve of the thermostat reduces the likelihood of overheating of the emergency engine in the absence of a thermostat, since the shunting effect of the small fluid circulation circle is significantly weakened, so a significant part of the fluid will pass through the cooling radiator.

In addition, to maintain the normal operating temperature of the coolant during the cold season, UAZ vehicles can have shutters installed in front of the radiator, with which you can regulate the amount of air passing through the radiator.

When the fluid temperature rises to 80 degrees or more, the upper thermostat valve opens and the lower valve closes. The coolant circulates through the radiator in a large circle.

For proper operation, the cooling system must be completely filled with liquid. When the engine warms up, the volume of liquid increases, its excess is displaced by increasing pressure from the closed circulation volume in the expansion tank. When the fluid temperature drops, for example, after stopping the engine, the fluid from the expansion tank returns to a closed volume under the action of the resulting vacuum.

On UAZ vehicles with a UMZ-4213 engine, the expansion tank is directly connected to the atmosphere. The regulation of liquid exchange between the tank and the closed volume of the cooling system is regulated by two valves, inlet and outlet, located in the radiator cap.

Gazelle stove diagram

How the stove works in Gazelle Business

For correct diagnosis and repair, it is necessary to know the structure and operating principle of the heating element, so that at the first sign of a malfunction, it diagnoses a breakdown or makes repairs, preventing failure of the entire unit as a whole. Most faults can be predicted by indirect signs and their development can be prevented. To do this, you need to know and understand what each element is responsible for and what the principle of its operation is.

Car cooling system

In Gazelle Business the stove is an integral part of the engine cooling system. When the engine is running, a large amount of heat is generated that must be removed. Heat is created by combustion of fuel and friction of surfaces. If the heat is not removed, the engine will very quickly overheat and fail. The cooling system consists of two circuits (large and small), separated by a thermostat. When the liquid is cold, it circulates in a small circle, and when it warms up, it circulates in a large circle. This allows you to quickly reach operating temperature without overheating. During the hot season, heat is removed from the atmosphere, and with the beginning of the cold season, part of the heat is used to heat the interior.

Heating

Having figured out how the cooling system works, you can move on to heating the interior. The heater circuit on the Gazelle car is identical to the heaters on other cars with a liquid-cooled engine. Fluid can circulate through the heater core whether the thermostat is open or not. For better heating, the furnace fluid comes from the hottest part of the engine (from the head). Therefore, on an engine that has not yet reached operating temperature, hot air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the radiator or drains it back. And the temperature of the air leaving the dampers depends on how open they are. The valve position is adjusted from the heater control panel. The crane is equipped with an electric drive that changes the position of the shock absorber. You can also change the intensity and direction of tightening from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the puff.

Changing the position of the dampers changes the direction of the air flow (on the face, on the legs, on the chest, on the glass). The coolant heated by the engine flows through the lines into the heater radiator, which causes it to heat up. At this time, air blown by a fan passes through it. Then it passes through air ducts, the dampers of which are open. Warm air then enters the car interior and heats it up. To repair or diagnose a malfunction of this equipment, there is a connection diagram that shows all the components of the electrical devices. And in the event of a breakdown or incorrect operation of the devices, it is necessary to read it in detail in order to understand where the device is powered from and what regulates the faulty device.

When you know the principle of operation and the device, it is much easier to navigate in the event of a breakdown. After all, to successfully complete the repair, it is important to understand the cause of the malfunction, otherwise the repair will not be completed successfully. To make a correct diagnosis, it is also important to understand the algorithm of operation of the entire mechanism as a whole. Currently, the driver does not need to know how to repair a car; there are gas stations that perform repairs of any complexity. But it happens that you are caught in a breakdown along the way, and there is no opportunity to use the services of specialists. That’s when knowledge about the structure of a car and its mechanisms will come in handy. Knowing how the Gazelle stove works, if a malfunction occurs on another machine, it will be easier to navigate during repairs or diagnostics, since they are almost the same in all machines, with the exception of minor nuances. And you can easily diagnose the problem.

Repair

Repair of the control unit will directly depend on the cause of the malfunction:

- If the power check shows that there is no “+” on the gear motor, then there is a malfunction in the heater control system. It needs to be dismantled and either repaired or replaced with a new one. For repairs, it is better to use the services of specialists, and if you have experience in this work, you can try to solve the problem yourself. To dismantle it is necessary: remove the top drawer for documents; unscrew the front panel (two screws on top and two on bottom); remove the decorative trim; pull out the entire panel so that all terminals can be numbered; disconnect the terminals; then take out the control element itself. Then reassemble everything in reverse order.

- To replace the resistor, you need to either remove the entire dashboard, or cut a hole under the box for documents, after first removing the box itself. To replace the fan, it is necessary to dismantle the entire instrument panel along with the stove. Then disconnect the stove from the dashboard, “halve” it and remove the resistor. If there is no power to the fan block, then the reason must be sought in the heater control system. To do this, you need to check it with a multimeter. Pinout of contacts of the Gazelle Business heater control unit:

- reserve;

- motor-gearbox (MR) feedback, heat-cold;

- access to the BRS;

- reserve;

- 5V, power supply for external temperature sensor;

- tap closing signal;

- tap opening signal;

- coolant heating sensor input;

- external temperature input;

- interior temperature sensor input;

- reserve;

- external temperature sensor housing;

- feedback, MR, glass - legs;

- MP heat – cold “+”;

- MP heat – cold “-”;

- MP recirculation “+”;

- MP recirculation “-”;

- MR glass – chest “+”;

- MR glass – chest “-”;

- MR glass – legs “+”;

- MR glass – legs “-”;

- feedback MR glass – legs 1;

- output of the heated glass and mirrors relay “+”;

- air conditioning relay output “-”;

- frame;

- feedback MR heat – cold 2;

- on-board network.

- To repair the display, you need to dismantle the entire heater adjustment element (as described in point No. 1) and repair or replace the entire assembly unit. If you repair it yourself, you can change the handle illumination diodes to a different color or change the brightness.

The stove is a very important element in a car. It affects not only the driver’s comfort, but also the safety of driving (since if the windows fog up in cold weather, driving becomes difficult). And it’s better to do all the work in a warm garage or parking lot than to do it on the road.

Design of the cooling system for UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

To increase energy efficiency, improve fuel efficiency, reduce toxicity and noise, models with an integrated microprocessor injection and ignition control system have been developed based on the YuMZ-421 carburetor engine: the YuMZ-4213 engine for UAZ cars and the YuMZ-4216 for GAZelle cars. The design of the cooling system on the UMZ-4213 and UMZ-4216 is slightly different, since it has differences in the connection diagram of the expansion and heating radiator tanks.

General design of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

The cooling system is liquid, closed, with forced circulation of liquid and an expansion tank, with liquid supply to the monoblock. It includes a water pump, a thermostat, water jackets in the cylinder block and cylinder head, a heater, an expansion tank, a fan, sections of connecting pipes and even batteries for heating the body.

For proper operation of the UMZ-4213 and YuMZ-4216 engines, the coolant temperature must be maintained in the range of more than 80-90 degrees. Short-term operation of the engine is allowed at a coolant temperature of 105 degrees. This mode may appear in the hot season, when the car is moving with a full load along long slopes or in city traffic with frequent accelerations and stops.

Design of the UMZ-4213 engine cooling system on a UAZ vehicle.

Design of the UMZ-4216 engine cooling system on a GAZelle car.

Operation of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

Maintaining normal coolant temperature is carried out by a two-valve thermostat TS-107-01 with a solid filler. When the engine warms up, when the coolant temperature is below 80 degrees, a small circle of coolant circulation is turned on. The upper thermostat valve is closed, the lower valve is open.

Coolant is pumped into the cooling jacket of the cylinder block by a water pump, from where through holes in the upper plate of the block and in the lower plane of the cylinder head, the liquid enters the cylinder head cooling jacket, more in the thermostat housing and through the lower thermostat valve and a piece of pipe that connects to the inlet of the water pump. In this case, the heater is disconnected from the main coolant flow.

For better operation of the internal heating system when circulating liquid in a small circle, and this situation can persist for a long time at low negative ambient temperatures, there is a throttle hole with a diameter of 9 mm in the channel, the liquid exits through the bottom valve of the thermostat. This limitation leads to an increase in the pressure drop between the inlet and outlet of the heating radiator and a more saturated circulation of liquid through this heater.

In addition, throttling the valve at the fluid outlet through the bottom valve of the thermostat reduces the likelihood of emergency overheating of the engine in the absence of a thermostat, since the effect of deflecting the small circle of fluid circulation is significantly weakened, because of this, most of the fluid will pass through the cooling radiator.

In addition, to maintain the normal operating temperature of the coolant during the cold season, UAZ vehicles may have curtains in front of the heater, thanks to which you can regulate the amount of air passing through the heater.

As soon as the fluid temperature rises to 80 degrees or more, the upper thermostat valve opens and the lower valve closes. The coolant circulates through the heater in a large circle.

For proper operation, the cooling system must be completely filled with liquid. When the engine warms up, the volume of liquid increases, its excess is displaced by increasing pressure from the closed circulation volume in the expansion tank. When the temperature of the liquid decreases, for example, after stopping the engine, the liquid from the expansion tank, under the influence of the resulting vacuum, returns to a closed volume.

On UAZ vehicles with a UMZ-4213 engine, the expansion tank is specially connected to the atmosphere. The control of liquid exchange between the tank and the closed volume of the cooling system is modified by two valves, inlet and outlet, located in the heater cover.

Which radiator is better

When studying the design of the stove for passenger or cargo Gazelles, many owners wonder: which radiator copes better with its functions - aluminum or copper. Let's look at the main advantages of each of these options:

- Aluminum. It has an affordable cost, which can be 2 times lower compared to its copper counterpart. This is precisely the main reason why such products are distributed throughout the globe by manufacturers. Their main drawback is their lower thermal conductivity. The appearance of corroded areas can cause problems with the functioning of the entire heating and cooling system. They cannot be repaired - you have to throw them away and replace them with a new one.

- Copper. They have high thermal conductivity, and this directly affects the quality of interior heating. Copper is easy to solder, and therefore such radiators are repairable. The soldering is smoother and there are no oxides. The disadvantage is the higher selling price.

Experienced mechanics recommend installing a radiator made of copper after a major overhaul. Such a product will last longer, however, dirt particles can get into it, clogging the system. If there is no information about how dirty it is, then you can save money and install aluminum, which is simply washed during use.

Gazelle stove diagram

How the stove works in Gazelle Business

For proper diagnosis and repair, it is important to know the structure and operating principle of the heating element, so that at the first sign of failure it either leads to a malfunction or carries out repairs, preventing failure of the entire unit as a whole. Most failures can be predicted by subtle signs and their development can be prevented. To do this, you need to know and understand what any of the components are responsible for and what the meaning of its work is.

Car cooling system

In Gazelle Business, the stove is considered an important part of the engine cooling system. When the engine is running, a lot of heat is generated that needs to be removed. Heat is created by combustion of fuel and friction of surfaces. If the heat is not removed, the engine overheats quite quickly and fails. The cooling system has 2 circuits (small and large circle), they are separated by a thermostat. When a liquid is cold, it moves a little, and when it warms up, it moves in a large circle. This allows you to quickly reach operating temperature and not overheat. During the hot season, heat is removed from the atmosphere, and when it becomes cold, part of the heat is used to heat the interior.

Once we understand how the cooling system keeps working, we can move on to supplying heat to the cabin. The heater circuit on the Gazelle car is similar to the heaters on other cars with a liquid-cooled engine. Fluid can circulate through the heater coil whether the thermostat is open or not. For better heat transfer, the furnace fluid comes from the hottest part of the engine (from the head). This ensures that pleasant air, which has not yet reached operating temperature, is still released from the engine dampers. The heater has a valve in its design that either allows liquid to flow into the heater or drains it back. And how open it is depends on the ambient temperature at the outlet of the deflectors. The valve position is adjusted from the heater control panel. The crane is equipped with an electric drive that changes the position of the shock absorber. You can also change the intensity and direction of tightening from the control panel. The intensity is controlled by a motor with an impeller, the speed of which changes the intensity of the puff.

Changing the position of the dampers changes the direction of the air flow (on the face, on the legs, on the chest, on the glass). The coolant heated by the engine flows through the line into the stove, from which it heats up. At this time, air blown by a fan passes through it. Then it passes through air ducts, the dampers of which are open. The hot air then enters the car interior and heats it up. To carry out repair work or diagnose a breakdown of this equipment, there is an electrical diagram that shows all the components of the electrical devices. And in the event of a breakdown or incorrect operation of devices, it is necessary to read it in detail in order to understand where the device is powered from and how to replace the failed device.

When you know the principle of operation and the device, it is much easier to navigate in the event of a breakdown. After all, to successfully complete a repair, it is necessary to understand the cause of the breakdown, otherwise the repair will not be carried out correctly. To make a correct diagnosis, it is also necessary to understand the mode of action of the entire mechanism as a whole. Now the driver does not need to know how to repair a car; there are service stations that carry out repairs of varying complexity. But it happens that the problem catches you on the road, and there is no opportunity to use the services of professionals. That’s when knowledge about the automobile device and its mechanisms will come in handy. When you know how the Gazelle stove works, if it breaks down on another car, it will be easier to navigate during repairs or diagnostics, since in all cars they are almost the same, with the exception of small unnoticeable moments. And the gap can be easily identified.

Design

On the Gazelle Business, the control of the interior heating system is combined and is carried out both manually using levers and using push-button control from the instrument panel.

The heating operation scheme is standard - air enters through the frontal air intakes by being sucked in by a fan with an electric motor, after which it passes through a system of deflectors and enters directly into the car cabin.

Coolant flow into the heater radiator

is controlled by a damper, the angle of which is driven by an electric motor. The electric motor of the damper drive is Italian-made, which does not at all guarantee against its breakdown, which often happens to it on this Gazelle brand.

Engine control

The damper tap is operated in automatic mode and depends on the set air temperature at the outlet. The design of the stove also includes a damper, which is controlled by an electrically driven gearmotor and can direct part of the air flow bypassing the radiator.

This is one of the main differences between the heater of the Business model and later Gazelles, on which the angle of the dampers was changed using a cable system.

The imperfection and ill-conceived design of the heater leads to the fact that when the stove on a Gazelle Business does not heat, it takes a long time to look for the cause of the malfunction. If the car is under warranty, the best option would be to contact a service station.

Heater Gazelle business