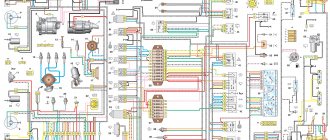

If you were unable to start your car and after checking the spark on the spark plug, it turned out that there was simply no spark, then you should check the entire ignition system of the VAZ 2106 and find a malfunction of a specific element.

In personal practice, I have had several cases that were accompanied by loss of spark. And then I will give them and talk about each in more detail.

Again, I will make a reservation that this is not a complete list of all the problems that can cause it, but I will try to list most of them. For experienced owners, you can supplement your thoughts by

One of the spark plugs is faulty

If, when checking a spark plug, a spark does not appear between the electrodes, then the first thing to do is check the spark plug itself. It is possible that this was the cause of this problem. Take a working spark plug (it’s better to always carry a spare one with you) and crank it a little with the starter. Observe the performance of the candle. If a spark appears, great; if not, you should look for the cause further. Also, you can see the problems that cause the spark to disappear here: https://atlib.ru/blog/164-net-iskry

Features of replacing the ignition switch

First of all, it is important to make sure that the problem is in the lock. Therefore, the spark plugs, distributor and ignition coil are inspected. Often these parts of the internal combustion engine become the reason for failures of correct operation. If breakdowns in them are excluded, then the ignition switch (IZ) should be replaced. Removal order:

- Disconnect battery.

- Remove the steering column.

- Mark the wires going to the 3Z contact area. Using a flat-head screwdriver, unscrew the bolts securing the switch to the steering column (left and right).

- Insert the key into position 0. By pressing the screwdriver, press the lock slightly through the hole (do not touch the key).

- Lightly pull the 3Z towards you and dismantle it. The ignition switch Niva 21213 is switched off according to the wiring diagram (the contact part is changed if required). To do this, be sure to remove the retaining ring with a screwdriver.

- Remove the key, install the contact part so that the wide protrusions of the body and the parts coincide.

- The remaining parts are assembled in the reverse order.

Failure of high-voltage spark plug wires or the central wire of the ignition coil

If there is no spark on any one cylinder, then try swapping the high-voltage wires. When after this the operation of the previous cylinder was restored, but the other cylinder, on the contrary, stopped working, this indicates a failure of the spark plug wire.

If a spark does not reach any of the VAZ 2106 spark plugs, then you should check the integrity and functionality of the central wire. This can be done in a similar way as I wrote in the last paragraph. Also, you should just try to stick the wire harder into the coil and the distributor cover. Perhaps the wire has just jumped out a little in one of these places and there is no necessary contact.

We change the distributor on our own | Repair of Niva VAZ 2121

In order to remove and subsequently replace the distributor on a VAZ 2121 Niva, we will need the following tool:

The procedure for performing work when replacing a distributor on a Niva VAZ 2121

First, we disconnect all the high-voltage spark plug wires from the cover, simply by pulling them up with a little force:

Then we immediately disconnect the hose from it, which goes to the carburetor, simply by grasping it with a little force and pulling it to the side:

After this, you can begin to unscrew the Niva distributor fastening nut, which is located at the bottom of the engine, as shown in the photo below:

Then we remove the metal plate that regulates the ignition by simply lifting it up with your hand:

And after all this, you can safely remove the distributor from its seat:

And don’t forget to use pliers or a 6mm wrench to unscrew the nut that secures the power cable. All this can be done after removal:

Now everything is definitely ready, you can remove everything and install the new part in place, in the reverse order of removal:

The entire work will take you no more than 15 minutes of time, I think everything was clearly shown and explained. If you have any questions, you can ask below in the comments.

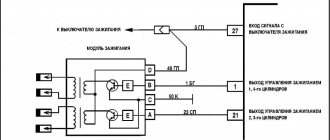

Failure of the switch or hall sensor and no spark

This item applies to owners of a VAZ 2106 with electronic ignition. If there is no spark, then these two elements can cause this disaster. It is necessary to diagnose the malfunction of these parts and replace them with new ones if necessary.

If you have a BSC installed on your VAZ 2106, then you can carry a hall sensor with you as a spare. Which, in fact, is the most common cause of malfunction. Or, as a last resort, do like me. Carefully fold the old contact ignition kit and let it lie in the trunk. It doesn't take up much space, but it can help you out a lot somewhere on the road. For example, if one of the BSZ elements burns out!

If any of the owners have encountered other reasons for the disappearance of the spark, then please share in the comments. I think that for many owners this information will be very useful!

Removing and sealing the distributor

It is necessary to remove the terminal from the battery and disconnect the high-voltage wires. You need to remember how the wires were located on the distributor.

Next action: disconnect the hose from the distributor. Next, you need to unscrew the nut holding the distributor power wire. This can be done using pliers or a No. 6 wrench. Using a No. 13 wrench, loosen and then unscrew the nuts that hold the distributor in a fixed position.

Installation of the distributor is performed in the reverse order.

We have already figured out how the distributor on the Niva should be installed; it is also recommended to carry out additional sealing. First of all, you should decide whether you need sealing. If you often spend time off-road, then you have encountered a situation where the ignition system is completely flooded. Before each ford, the driver thinks for a long time whether it is worth going there. Some motorists use special water-repellent compounds that should protect the system from liquid ingress. As numerous reviews say, there is no particular benefit from these mixtures.

You need to put a cut plastic bottle on the distributor. Next, you should prepare holes for the hoses of the vacuum corrector, ventilation and wires. All openings through which hoses and wires pass should be insulated with sealant.

To make working ventilation, you need to take an air hose and connect it to a snorkel, which is used for forced ventilation. The result looks like this: If you have extensive experience in repairing and modernizing the Niva, then try the complex method. The distributor is sealed as follows: The ignition system cover must be placed on the sealant. It is important that the glue is fresh, you need to completely isolate the ignition system. The junction with the drive should also be covered with this glue. The sealant should be applied along the edge of the connection . A fitting should be installed in the cover. Pressure must be created inside the Niva system, so an air supply must be made to the fitting.

Source

VAZ 21213 no spark on the center wire

Part two - the engine starts, but does not run satisfactorily.

Necessary preconditions: 1) the engine is in good working order; 2) the marks of the crankshaft and camshaft match; 3) gasoline and air enter the suction manifold from the carburetor; 4) there are no barriers to the escape of exhaust gases (no one’s “kind hand” stuck a potato into the muffler);

Step one: check for spark from the ignition coil. How to check it alone: 1. Gearbox in neutral; 2. pull out the central wire from the distributor and fix the metal tip of this wire at a distance of 5-7 mm from the ground (it is convenient to squeeze the insulating cap between the brake cylinder and the outlet tube); 3. turn on the ignition; 4. remove the block with wires from the starter relay and short-circuit the thick wires in it (perpendicular to each other) with a jumper - the starter will work; At this moment, a spark will (should) begin to beat rhythmically from the main wire. If there is no spark at all, read step two. If the spark is weak and begins to skip with a slight increase in the air gap (up to 10-12mm), read step six. In passing, I note that an indicator of the reliability of a starting spark is its continuity and length (and not color and thickness).

Repair of the ignition distributor sensor of a VAZ-2121 car

We remove the ignition distributor sensor (see the article on removing the distributor sensor).

Checking the distributor sensor can be found in the article - “Features of the ignition system”.

1. Using a screwdriver, unscrew the two screws securing the rotor.

2. Remove the rotor. When installing the rotor in place, the square protrusion should fit into the slot, and the round one into the hole in the support plate.

3. Using a thin beard, knock out the pin.

4. Remove the oil deflector and washer from the roller.

5. Remove the roller from the distributor body.

6. Using a thin screwdriver, remove the locking washer of the vacuum ignition timing regulator rod.

7. Remove the rod from the rotary plate pin.

8. Unscrew the two screws securing the vacuum ignition timing regulator

9. One of the screws has an extension to secure the sensor wiring.

10. Remove the vacuum regulator.

No spark on VAZ 2106

Sparking is an important process that ensures the startup and stable operation of the power unit, for which the ignition system is responsible. The latter can be contact or non-contact, but the essence of its work remains the same - to ensure the formation and distribution of a spark to the desired cylinder at a certain point in time. If this does not happen, the engine may either not start at all or run intermittently. Therefore, it is worth dwelling in more detail on what kind of spark there should be and what the reasons for its absence may be.

Checking the quality of the ignition switch installation

It is logical that errors are possible when connecting contacts or incorrect installation of the lock itself. Therefore, it is necessary to test the protection in the installed state. You will need an ohmmeter and a voltmeter. Performance diagnostics:

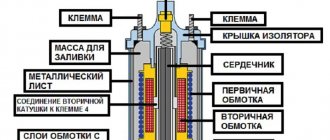

- Checking the resistance between the terminals of the secondary winding: connect the probes to cylinders 1 and 4, then to cylinders 2 and 3. The data should approximately match. An error greater than 100 ohms indicates damage to the secondary winding.

- The wiring is checked with a voltmeter. The first control - one probe is placed on contact A, the second - on ground. Start the engine and record the data. Turn off the car and repeat the procedure with contact B. The readings should be about 12 volts.

- In addition, if there is no voltage, check the fuse, the possibility of broken wiring or corrosion of the contacts.

The last case is especially unpleasant, since you will have to check almost all the wiring, contact elements, etc. If there are possible suspicions about the electrical network, it is better to take the car to a professional auto electrician. Repairing it requires a thorough knowledge of the circuit and experience in finding defects.

Troubleshooting

Troubleshooting in the ignition system of the VAZ “Six” should be carried out using the method of elimination, checking element by element sequentially. This is worth dwelling on in more detail.

Battery check

Since when starting a car, the power source is the battery, it is by checking this device that diagnostics should begin. Malfunctions with the battery appear when you try to start the engine. At this moment, the indicator lights on the instrument panel go out. The reason could be either poor contact on the terminals themselves, or simply a weak battery charge. Therefore, the condition of the terminals should be checked and, if you need to clean them, tighten the fastening. To prevent future oxidation, it is recommended to cover the contacts with a graphite coating. If the battery is discharged, it is charged using an appropriate device.

Spark plug wires

The next elements that require mandatory checking in case of problems with sparking are explosive wires. Upon external inspection, the cables should not show any damage (cracks, breaks, etc.). To assess whether a spark passes through the wire or not, you will need to remove the tip from the spark plug and place it near a ground (5–8 mm), for example, near the engine block, and crank the starter for a few seconds.

At this time, a powerful spark should jump. The absence of one will indicate the need to check the high-voltage coil. Since it is impossible to determine by ear which of the cylinders does not spark, the test should be performed one by one with all wires.

Video: diagnostics of explosive wires with a multimeter

Spark plug

Spark plugs, although infrequently, still fail. If a malfunction occurs, it is with one element, and not with all of them at once. If a spark is present on the spark plug wires, then to check the spark plugs themselves, they are unscrewed from the cylinder head of the “six” and an explosive cable is put on. The metal body of the spark plug touches the masses and turns the starter. If the spark plug element is working, then a spark will jump between the electrodes. However, it may also be absent from a working spark plug when the electrodes are filled with fuel.

Lada 4×4 3D Niva 96 › Logbook › BSZ distributors for engines 2106 and 21213

On the previous Niva, in the first year of operation, problems arose with the ignition (the contacts burned out, for some reason my engine was 2106). Cleaned it up and it worked. A trifle, of course, but it clearly had to happen again. Immediately on the Internet I came across an article “how to install contactless ignition in a classic car.” I read everything, I liked the idea and the expected bonuses, so I need to apply it to my car. It must be so. I took a pinch of money and wandered around the shops in search of the necessary ingredients. There were no problems with the purchase of wires and a switch, but there was a problem with the distributor; distributors for motors 21213 with the index 038.3706-10 are lying around on the shelves, but for the motor 2106 I need them with the index 038.3706. I had little understanding of what exactly the difference was at that time, so I simply relied on the competence of the seller, who, in response to my request for a BSZ distributor for the 2106 engine, with a deft movement, took out the distributor I supposedly needed from under the counter. Then, back in 2010, I touched the ignition with caution and didn’t really understand what and why, and as a result I installed what later turned out to be a distributor from engine 21213, somehow set up the UOZ and drove off somehow. The car seemed to be driving, but I didn’t come across other Nivas with a similar engine and BSZ to compare and understand that something was wrong in my car. The matter did not get much worse when I installed HBO. This is all an introduction, but the essence was revealed to my braking mind a couple of years later and problems that arose in the ignition system helped. While I was eliminating them “by scientific poking” (replacing parts one by one), I discovered a discrepancy in the markings of the installed distributor - mine was numbered 038.3706-10 from engine 21213!

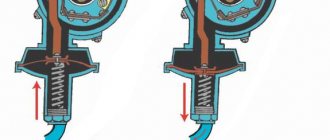

I went to the Internet for information and dug up final arguments for myself. The difference in distributors results from the difference in engines, and not so much due to the difference in volumes, but rather due to the compression ratio (2106 - 8.5 units, 21213 - 9.3 units). Hence, these distributors have different operating characteristics of centrifugal and vacuum regulators, which control the time of spark formation on the spark plugs. As can be seen from the graphs, the vacuum regulator 2106 has a maximum advance angle of 6 degrees (along the crankshaft)

The vacuum regulator 21213 has a maximum advance angle of 9 degrees (along the crankshaft)

The centrifugal regulator 2106 has a maximum advance angle of 15 degrees (along the crankshaft)

The centrifugal regulator 21213 has a maximum advance angle of 11 degrees (along the crankshaft)

The total ignition timing angle for the 2106 distributor is 21 g (along the crankshaft) The overall ignition timing angle for the 21213 distributor is 20 g (along the crankshaft) This is why I had a failure when pressing the gas pedal, there was a small ignition timing angle. Attempt number two, armed with knowledge, I went to buy the required distributor. Auto market. Lots of shops. A bunch of competent, cunning sellers. And all of them, in response to my request for a BSZ distributor for 2106, are trying to sell me a Niva. In response to my attempts to explain why I don’t want to buy what they give, they grinned sarcastically, saying that they take everything and don’t complain, and here you are being clever... and you don’t know what you’re looking for now. True, one seller listened to my explanation with interest and said that he had only seen such distributors on sale in the form of BSZ kits for classics and had not seen them separately, which upset me a little. But my stubbornness took its toll and in a normal store, from the first request they gave me what I asked for - a BSZ distributor with the index 038.3706 for the 2106 engine.

Checking the contact distributor

The need to check the distributor-breaker arises if problems arise with sparking, but during the diagnostics of the ignition system elements the problem could not be identified.

Cover and rotor

First of all, we inspect the cover and rotor of the device. The check consists of the following steps:

- We dismantle the distributor cover and inspect it inside and out. There should be no cracks, chips, or burnt contacts on it. If damage is found, the part must be replaced.

contact Group

The main malfunctions of the ignition distributor contact group are burnt contacts and incorrect clearance between them. In case of burning, the contacts are cleaned with fine sandpaper. If they are severely damaged, it is better to replace them. As for the gap itself, to check it it is necessary to remove the cover of the distributor-breaker and turn the engine crankshaft so that the cam on the distributor shaft opens the contacts as much as possible. We check the gap with a feeler gauge and if it differs from the norm, then we adjust the contacts by unscrewing the corresponding screws and moving the contact plate.

Capacitor

If a capacitor is installed on the distributor of your “six”, then sometimes the part can fail as a result of a breakdown. The malfunction appears as follows:

- problems starting the engine;

- sudden engine stop while driving.

You can check an element in the following ways:

- Control lamp. Disconnect the wiring coming from the coil and the capacitor wire from the distributor according to the figure. We connect a light bulb to the open circuit and turn on the ignition. If the lamp lights up, it means that the part being tested is broken and requires replacement. If not, then it's OK.

How to set the ignition on a Niva 21213 carburetor

I won’t go into too much detail about the advantages of a contactless ignition system over a conventional contact one. This has already been done well before me. Therefore, in order to avoid repetition of already known truths, I first suggest that you take a walk through the links below and read them carefully. Everything is quite complete and well presented there:

So, let's go to the store to buy components. At the same time, let’s carefully remember the number of the contactless ignition distributor for the “classic” indicated in the above links, or even better, write it down on a piece of paper so as not to forget. This number is indicated on the distributor body. Let’s not rely on the “competence” of sellers who can easily sell you a Niva distributor, assuring you that it must be installed on a six-wheel engine.

Also, when purchasing components, it is advisable to immediately take a spare switch and Hall sensor, since these devices have the unpleasant property of suddenly and for no apparent reason malfunctioning or breaking down, after which your car can only go further in tow. Remember that the commutator and Hall sensor are VITAL SPARE PARTS THAT MUST ALWAYS BE IN YOUR CAR! If you are a master yourself, then without much difficulty you can, if necessary, replace them, and if not, then someone who knows how to do this will replace them for you, for example the same “Angels”. But for this, the switch and sensor MUST BE AT YOUR HANDS, otherwise you will have to frantically rush around either looking for them or looking for the tractor.

When purchasing a Hall sensor, make sure that it matches the distributor you are purchasing. To do this, remove the distributor cover and compare the sensors. They must be absolutely identical. In addition, the “correct” sensor should have two ears on the sides for mounting screws, and not one in front - this is a sensor, in my opinion (I don’t know for sure), for 2108. It can also be adapted to the distributor, but the description of this work is beyond the framework of the present story.

The ignition coil must be taken for the VAZ-2108. Better than the regular type, oil-filled. I don’t presume to say for sure, but there seems to be an opinion that a “dry” type coil has a number of disadvantages, due to which the use of a conventional coil seems to be preferable.

It is also worth paying attention to the wiring harness. You need to get an ignition harness for the Niva - there are some on sale. The colors of the wires in it correspond to the colors of the wires indicated in the electrical diagram 21213, so in order to know what to connect and where, you need to have this diagram with you. When buying a harness, pay attention to how well the terminals hold in the sockets of the blocks, because when putting the blocks on the connectors of the switch and Hall sensor, the terminals, under the influence of the applied force, can jump out of the sockets and the car simply will not start. It is quite advisable to somehow better fix these terminals yourself before installing the harness.

Regarding high-voltage wires, we can say that their choice is quite large. More details about this can be found in this FAQ section. I used blue Tesla silicone wires and after replacing the engine I switched them over to it. I've been traveling with them for almost three years now.

There is no need to buy an electronic control unit for the forced idle economizer (EPHH), since the carburetor 2107-1107020 “Ozone”, which is equipped with the 2106 engine, does not have an electronic control system for the idle speed solenoid valve. This block may be required only if the carburetor 2107-1107020 “Ozone” is replaced on the engine of your car with the carburetor 21073-1107010 “Solex”, which is standardly equipped with the engine 21213, and you want to equip your car with this block, so to speak, for complete set. In my opinion, this need not be done, since this unit is mainly designed to meet the environmental safety requirements of the machine, and the fuel economy obtained thanks to it can rather be considered symbolic - about 0.5 l/100 km.

But the components have been purchased and now you can start installing them. Anyone who will not do this themselves and contact a car service center may not read further, since this article is intended mainly for those who will do all the work with their own hands.

What should you pay attention to when performing work? What's important here?

1. The negative terminal from the battery must be removed.

2. When working, as already mentioned, check the electrical diagram of the VAZ-21213.

3. The best place to install the switch is the inclined part of the wall of the engine compartment, behind the battery, next to the body number (the switch should not cover the number!). Holes are drilled in this wall for self-tapping screws that will mount the switch.

4. Before removing the old distributor, remove the cover from it and look at which cylinder the contact of the slider is directed towards. We install the new distributor with the cover removed and in the same position of this contact. If this is not done, then there may be problems with starting the engine, even to the point that the engine will not start at all.

5. The wiring harness (installed last), although it is believed to be for the Niva, the part that goes to the distributor is such a length that it would probably be enough for the engine compartment of a bus. Therefore, when laying the harness, we drag it behind the air supply box, and fold the excess part 2-3 times so that the harness can freely reach the distributor, fix this fold in several places with electrical tape and screw the entire harness in 3-4 places, again with electrical tape , to the spare tire support, from its lower side. When connecting the harness, you must try to connect the terminals so that the terminals fit tightly onto the connectors, otherwise there may be problems.

Checking the contactless distributor

If the “six” is equipped with a contactless ignition system, then checking elements such as spark plugs, coil, and explosive wires is performed in the same way as with a contact one. The differences lie in checking the switch and the Hall sensor installed instead of the contacts.

Hall Sensor

The easiest way to diagnose a Hall sensor is to install a known working element. But since the part may not always be at hand, you have to look for other possible options.

Checking the removed sensor

During the test, the voltage at the sensor output is determined. We determine the serviceability of the element removed from the machine according to the presented diagram by applying a voltage in the range of 8–14 V.

By placing a screwdriver in the gap of the sensor, the voltage should change within 0.3–4 V. If the distributor has been completely removed, then by turning its shaft, we measure the voltage in the same way.

Checking the sensor without removing it

The performance of the Hall sensor can be assessed without removing the part from the car, using the diagram provided.

The essence of the test comes down to connecting a voltmeter to the corresponding contacts on the sensor connector. After this, turn on the ignition and turn the crankshaft with a special key. The presence of voltage at the output, which corresponds to the above values, will indicate the serviceability of the element.

Video: Hall sensor diagnostics

Switch

Since the formation of a spark also depends on the switch, you need to know how to check this device too.

You can purchase a new part or perform the following sequence of actions using a control light:

- Unscrew the nut and remove the brown wire from contact “K” of the coil.

- We connect a light bulb to the resulting open circuit.

- Turn on the ignition and crank the starter several times. If the switch is working properly, the light will light up. Otherwise, the element being diagnosed will need to be replaced.

Video: checking the ignition system switch

The performance of the systems and components of the VAZ “six” must be constantly monitored. The occurrence of problems with sparking will not go unnoticed. Troubleshooting and troubleshooting does not require special tools or skills. A minimal set consisting of keys, a screwdriver and a light bulb will be quite sufficient for diagnostics and repairs. The main thing is to know and understand how a spark is formed, and what elements of the ignition system can affect its absence or poor quality.

How to disassemble the ignition distributor sensor of a VAZ 2121 Niva 2131

Disassembly of the ignition distributor sensor on a VAZ 2121 and Niva 2131 is carried out to repair it in order to replace failed elements. To carry out repair work, remove the distributor, wipe it thoroughly from dirt and dust, then place it on a workbench and begin disassembly. Prepare a standard set of tools and perform the following sequence of actions:

At this point, the repair work on disassembling the ignition distributor sensor on the VAZ 2121 and Niva 2131 has been completed. Make the necessary repairs, then reassemble in reverse order.

Setting the ignition

The last step that a car enthusiast can perform in setting up the ignition system after installing the lock. You can take the car to a specialist, but this fairly simple procedure is unreasonably expensive. Display instructions:

- Align cylinder 1 at top dead center when placing a mark on the crankshaft between marks 3 - 0 degrees.

- Remove the distributor cover and check the position of the slider (the direction should be towards the cylinder pin 1. Using a strobe light, set the torque and then connect the battery: ground to minus, positive contact to plus.

- The regulator clamp is connected to the high-voltage cable on cylinder 1. Mark the mark on the crankshaft pulley.

- Start the engine at speeds less than 800 rpm. Direct the strobe light at the mark on the pulley. If adjusted correctly, the mark should coincide with the middle one on the engine cover.

- If the marks do not match, turn off the engine and adjust the distributor mount clockwise or counterclockwise. Then repeat the procedure.

The final check takes place on the go. You will need to warm up the engine to 80 degrees. Then accelerate to 60 km/h (or go to 4th gear, as some experts advise). Press the gas pedal sharply. If the ignition is adjusted correctly, the engine may briefly detonate.

(2 ratings, average 5 out of 5)