Lada 4×4 3D BadboY › Logbook › Steering — Part 3 — Installing power steering in Niva 21213

Greetings to all!

Today we finally managed to post some material on installing the power steering in the field, the process is going slowly due to lack of time, then one thing or another, in general, a blockage also complicates the matter of designing a bracket for the power steering pump, let me remind you that the power steering pump will be located on a free place on the right, after moving the generator upstairs! So the path is somewhat thorny))) And so we take all the details that I described in detail in the first part, lock ourselves in the garage and begin installation) Stage one. Installation of the steering gear.

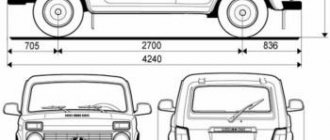

Initially, it is necessary to make an enlarged hole for the gearbox, since it is much thicker and extends into the cabin through the engine shield! Many who encounter this, to mark the boundaries of the hole, download a template from the Internet that has been tested by many people, adjust it in size and scale and print it on paper, then apply it to the engine shield and already cut out a hole, all the holes and irregularities that have arisen between the shield and the gearbox are simply covered up sealant! But since I was able to get hold of the original steering gear boot and the pressure plate of this boot, which quite accurately follows the contours, then by applying it and being guided by the spar, we trace its inner contour with a marker and get a template according to which we need to cut!

Next, we cut it out, in terms of access, of course, there is still fun even with a small grinder, ideally, of course, you need a reciprocating saw! We grind and trim the hole... we get approximately the following result

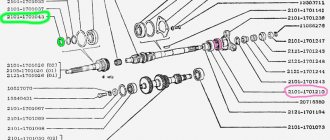

We put the gearbox in its rightful place. Slight subtlety, the original gearbox mounting bolts turn out to be a little short, we use Shniva bolts M10x170x1.25 orig number 21230-3401155-108, 170 mm long. The boot fits perfectly; you need to drill two holes under its pressure plate in order to pull it to the engine shield and clamp the boot.

Stage two. Manufacturing the power steering pump bracket. Pump installation.

Since the transfer of the generator was done when the power steering was not yet planned, and I didn’t want to redo such a huge job, and on the left side there is a very dense layout with an oil filter and a fuel pump, and the distributor is now also a generator with a bracket, and on the right there is empty space generator, it was decided to install the power steering pump not according to the standard, but on the right to make a bracket for it from scratch and select hoses and a belt! The entire bracket is attached to 4 studs, 3 studs on which the generator bracket was attached, and a 4th stud in the pump body on which the generator tension bar was previously attached. Thus, the attachment points are shifted relative to each other, which will strengthen the bracket torsion. In the photo everything is bolted on, this is temporary for adjustment.

For the base for the bracket, a 70th Sovdepovsky corner with a wall thickness of 6 mm was taken. Holes for fastening with 3 bolts were marked and drilled into the area where the generator bracket was attached; in the corner itself, a chamfer was filed along almost the entire length of the corner, since the engine pan protrudes and the corner, without filing, presses on the pan and becomes skewed. The corner has received a weakening which will subsequently be reinforced by scarves when turning the corner.

Next, we prepare another piece of corner to weld two corners into a U-shaped bracket. Also, due to the fact that the bracket is turned upside down in a mirror order and is very different from the factory, the factory so-called sickles for attaching the pump to the bracket are also not suitable, and they are flimsy, so we cut out new sickles for the power steering pump from a 5 mm steel sheet.

Next is the process of welding, alignment and adjustment, which simply was not photographed...

In the end, we got something like this design, the place where the corners are welded is reinforced with a cross member, the pump stands in place, the alignment with the KV pulley can be adjusted by placing or removing washers under the lower fastenings of the pump sickles, the sickles from below are welded with a sleeve, the top of the sickles is free so that the pump is not pinched between them and it was easily dismantled. At the top there will be tension bars, also floating on bolts. With this design, the Continental Contitech AVX10x750La toothed V-belt was selected minimally, but the size range was approximately 825 mm for the belt. The belt tension will be done using the adjusting bolt.

Top view of the bracket. The attachment to the pump, as well as the cutout of the corner at the top, have not yet been photographed, but everything is ready and this will be the subject of the next post with a photo of the bracket processed and prepared for painting.

The fundamental difference between the new power steering

The fundamental difference between the new power steering (model 21.3400012) and the now obsolete ZF8052 is a rotary-type spool valve (manufactured by ZF) instead of a rotating spool valve. A similar design has been successfully working in the ZF8070 model on many European machines since the mid-90s. The spool-type rotary distributor significantly increases steering sensitivity because it reduces the free play of the steering wheel.

Another feature of the new product is that the steering gear housing, when installed on a Niva, requires virtually no changes to the car itself. In the future - amplifiers with an electronic control system that changes the gain depending on the speed of the car, and spools with increased force in the center (see figure).

Probably everyone knows how the standard Niva steering mechanism works and works. Over the 33 years of the “classics” existence, it has remained virtually unchanged. A little more about the new product - a steering mechanism with built-in power steering.

Its task is to catch the driver’s intention to change the direction of the car and turn the wheels to the desired angle. In fact, the driver can only move the spool with the steering wheel, and it, directing the flow of fluid from the pump, controls the movement of the piston. The piston, also known as the rack, is in mesh with a gear sector on the bipod shaft and rotates it to the right or left as needed. If the hydraulic force is not enough, the driver’s muscles will come into play - there is a thread inside the piston, and in it a screw rotates on balls, connected through a torsion bar to the steering column shaft. The same thread allows you to maintain control of the machine even when the amplifier is not working. Oil driven by the piston will be pumped through the valve, bypassing the pump.

Lada 4×4 3D › Logbook › Installation of power steering and steering column from Chevrolet Niva in 21213

I matured on power steering for a long time. Last winter, this is where I twisted the steering gear

It’s not legible in the photo, but I bought a complete set from shnivy: gearbox, pump, steering column, steering wheel, steering column switches, casing. This whole epic cost me 12 thousand everwood.

Also originally purchased: 1. Power steering pulley for the crankshaft + spacer sleeve + nut 2. Steering gear boot for the engine shield from 21214 3. Power steering reservoir bracket 4. Gearbox bolts M10*1.25*160 5. Dextron 3 - 2 liters

Since there was no way to install it myself, my garage is very cramped and cold, so I went to troshin1 in Remzon 4x4 for installation. A proven person, he always does things efficiently and conscientiously. I don’t trust my field to anyone anymore.

The gearbox was removed, completely dead

The engine shield was not cut out according to the template circulating on the Internet, but it was perfectly cut according to the boot.

From the inside, everything was immediately reinforced with a plate and boiled

The second task was to strengthen the bushings in the spar. They picked out the spar, but it was all sick. I had to perform an execution on him

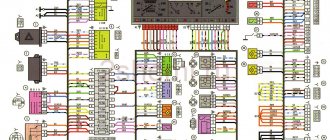

Because I have to move the generator, and in general, in order to separate the generator/pump and power steering pump to different belts, it was decided to install the pump in the regular place of the generator. To do this, I had to invent a bracket and order a custom high-pressure hose. We ordered a length of 1450mm (center-to-center from fitting to fitting) according to the murzilka from Niva-FAQ

The belt was selected according to the fact. This one came up

To install the steering column, we had to splice the old mounting platform from 21213 with the platform 2123, and also install a telescopic driveshaft. No photo unfortunately.

I took a ride. ***. How did I live without power steering? 31 Silvera, with tea leaves, and with one finger? Cool! Thanks to Alexander for the work. Without removing it, this installation took 3 working days!

It remains: 1. Buy a reinforced pendulum. I'm leaning towards the product from Dima-Nivovodets. Can anyone else recommend travel products? 2. Reinforced steering rods. Vlad Bochkov has powerful ones, but the price is of course wow. I read somewhere a topic about tips from Hilux (by the way, Vlad has a line of ends similar to them + powerful bushings) Or is it stupid to install a hexagon and ends from 2101? Who can recommend something smart?

Source

Story

I have already said many times that I do not do tuning or modifications for the sake of the process. Only if there are problems. In this case, it all started with the “collective farmers” of AvtoVAZ. For a very long time, the plant installed German ZF power steering pumps on the assembly line, and then suddenly the Russian version came into use. As usual, the plant was not going to give any explanations, so I had to turn to another source, the manufacturer ZF.

A technical seminar was held in St. Petersburg, organized by this company, and I asked the German a question about this situation. Directly at the lecture (that is, the official position), the German specialist said that this is a trade secret. And during the lunch break, when I addressed him in German, he straightened up and said the following. Quote.

Along with the supply of pumps, we gave a recommendation to AvtoVAZ on what SHOULD be poured into the system. At first, the plant filled in an approximate analogue of the liquid that we recommended, and then suddenly it began pouring green Pentosin. The result was not long in coming - leaks and a humming sound when turning. But the funny thing is that all these “supposedly” warranty cases were transferred to the shoulders of ZF.

Communities › VAZ: Repair and Modification › Blog › Installing power steering on a Niva

I hope it will be useful to someone. I immediately want to calculate how much money the power steering cost me:

- steering gearbox 2000 rubles - power steering pump (2 liters of juice) 100 rubles - high pressure hose (2 liters of juice) 100 rubles - pulley 650 rubles - barrels 150 rubles - hydraulic fluid 500 rubles - hose meter and clamps 150 rubles

TOTAL: 3650 rubles

No power steering - somehow very out of date. Especially in the future the installation of wheels of non-standard size. Therefore, immediately after purchasing the car, it was decided to install power steering. I didn’t consider the EUR because my steering gearbox (hereinafter referred to as RR) was leaking oil, and was not playing like a child, and generally had to be replaced. A new RR costs 2500 rubles plus the EUR from Priora (at disassembly 5-6 thousand rubles) total: 7500-8500 rubles... a little expensive. I called for disassembly: - you need a RR Chevy Niva, do you have it? -Yes, manufactured in 2006. cost 2000 rub. Come and get it. -OK.

The next day I bought a RR, and for 2 liters of Multifruit juice I took a power steering pump from a Mitsubishi Galant (80s) from one very good person.

That same day in the evening I came across an article on the Internet about installing such a RR in 2121, which contains a template for cutting a hole in the engine shield for this RR (since it is slightly larger than the original one). The template, by the way, is not life-size, so I had to draw it again.

Since I work in an advertising agency, I printed a template on self-adhesive film and stuck it on the engine shield.

I cut it out using a small grinder and a drill. (use disks with a thickness of 0.8 or 1 mm, although they grind down faster than thick ones, they are a pleasure to cut, they cut very quickly)

Operating principle of the hydraulic control system

How does power steering work? Its main element is a pump, which, using a belt from the crankshaft, sucks in oil and pumps it into the distributor. The latter, in turn, monitors the force applied to the steering wheel and, using a torsion bar (follower device), helps turn the drive wheels. When moving in a straight line, the torsion bar does not twist, so the distributor channels are blocked and the oil drains back into the reservoir.

Power steering is most often useful when parking and turning, making the work of your hands three times easier. We can also say that the mechanism weakens the transmission of microshocks from the road surface to the steering. The mechanism is also useful in case of a sharp drop in tire pressure. The disadvantages of power steering include the fact that it interferes with “feeling the car”, so designers need to achieve a compromise between informativeness and tightness of the steering wheel.

Foreign manufacturers conduct a lot of research in order to make the hydraulic booster light at low speeds and elastic at high speeds. To do this, German hydraulic boosters from ZF are equipped with pressure modulators, which limit the oil pressure in the operating circuit as speed increases. In addition, circuits with power steering driven by an electric motor are acceptable, which makes it possible to change the pump performance in accordance with the rotation of the electric drive. Sometimes the gear ratio is also changed.

Lada 4×4 3D VYATSKAYA GUN › Logbook › Installing power steering on the Niva.

Like all the spare parts that I install on my car, I had an almost complete set of power steering for 3 years, but I couldn’t get around to installing it. And if on a car without a winch, due to my physical abilities, I could turn the wheels almost without problems, then with a winch everything became more complicated, I didn’t have enough hands to operate the winch, steering wheel and gear shift at the same time