VAZ 2121 - do-it-yourself body repair

The Niva VAZ 2121 became the first comfortable Soviet SUV.

Before it left the factory in 1977, off-road vehicles were used primarily for military purposes. For a Soviet citizen, an SUV was, in principle, inaccessible, and they were not available for open sale. There was an opportunity to buy decommissioned UAZs, but they were not very comfortable. The Niva revolutionized the concept of an SUV for the semi-wild inhabitants of the country of the Soviets - no one had ever seen such comfort as in a six, with the cross-country ability of an UAZ, but at first the consumer was stopped by the rather high price, and later they got used to it. Niva has become an active rural worker and city dweller - in terms of performance indicators, it is in no way inferior to the VAZ classic.

The bottom of the Niva 21213 can be partially repaired. To do this, individual places are changed or patches are installed. In this case, you will definitely need a welding machine. Semi-automatic is best. If you are replacing a separate part of the floor, you will additionally have to take a drill. She drills the rivets. No welding required.

Scheme of sequential actions:

- Raise the car on a lift or turn it over.

- Remove the rusty, holey area.

- Install the repair panel.

- Tack the panel by welding or attaching it with rivets.

Among the models of the domestic automobile industry, the VAZ 2121 stands out somewhat from the general range not only due to its excellent cross-country ability, all-wheel drive and monocoque body, but also due to the fact that the Niva is the first independent VAZ development to reach serial production. The car began serial production at the beginning of 1977 and immediately began to enjoy great success among the population not only in the Soviet Union, and later in Russia, but also in many countries both near and far abroad.

In its class, an SUV from Russia is considered the most successful model. It found its consumers in France, Portugal, Spain and Canada. And although Niva cars equipped with the French Peugeot diesel engine are in great demand, cars with the domestic 1.6 are also selling quite well.

Body replacement

In Russia, several companies are engaged in the sale of metal bodies for domestic cars, either assembled or in separate parts. Having familiarized yourself with the assortment of these products, you can see that such stores offer a wide range of colors, which allows the car owner to quickly choose the appropriate option.

You may be interested in: Design, diagnostics and repair of the rear suspension of the VAZ-2106

As a rule, bodies intended for Niva cars, equipped with three doors, were painted at the factory in several standard colors. All of them are listed below:

- Snow white (factory code 202).

- Nessie (factory code 368).

- Jasper (factory code 140).

- Baltika (factory code 420).

- Glacial (factory code 221).

- Nice (paint serial number - 328).

- Snow Queen (paint serial number – 690).

- Quartz (paint serial number – 630).

- White cloud (paint serial number – 240).

You may be interested in: Hyundai Porter: body dimensions, technical specifications, engine, photo

The VAZ-2121 car with five doors was painted at the factory in three color options:

What problems may arise

The fact is that to replace the engine on a VAZ-2121, you can choose almost a dozen different engines, but they are all from foreign cars. But the main problem is that you will have to do some additional work during installation, for example, install or change fasteners, add new parts. Because of this, it is not so easy to find a budget replacement option. The choice is significantly narrowed down to just a few options. In order for an engine to be suitable for installation, it must meet several conditions:

- The engine from a foreign car must be freely placed in the Niva engine compartment. This is one of the most important criteria to pay attention to. If you have to add new parts, adjust old ones, or change the shape of the body, it’s better to discard this option. The cost of such a replacement is too high to be profitable.

- The new internal combustion engine should not be inferior or significantly exceed the power of the old version. The maximum permissible excess power is 10-20 hp, that is, from 90 to 110 hp. In this case, the maximum power limit is a critical value, and parts with this indicator are not recommended to be installed at all.

- The replacement must provide some benefit, otherwise it will be useless.

Which engine should you consider first?

Like many brands of cars, the body deteriorates the most during use. Main “sore spots”:

- rust under the headlights;

- lower parts of wings;

- thresholds;

- arches;

- the bottom under the driver's feet.

And also interesting: VAZ 2130 engine | Characteristics, problems, tuning

I would like to talk about the last problem in more detail. The bottom under the driver's seat of the Niva deteriorates due to constant contact with water. In winter it is melted snow, in other seasons it is rainwater. The liquid impregnates the sound insulation and the metal is rubbed to holes. It is also worth paying attention to the place where the transfer case is attached to the bottom. Cracks form there.

Repair of VAZ 21213

Despite the fact that the VAZ-21213 is considered one of the most successful developments of the Volga Automobile Plant, like all mechanisms, it is prone to breakdowns. Moreover, the more mileage a car has, the more actively it begins to break down - this is typical not only for Niva, but also for all other representatives of the domestic automobile industry. Therefore, a dilemma very quickly arises - constantly contact service centers or learn how to repair the VAZ 21213 yourself. With sufficient skills and “direct” hands, doing the latter is not as difficult as it seems - the main thing is to have all the necessary tools and components on hand.

The most common breakdowns and malfunctions

The most common problems that require VAZ 21213 Niva repair are:

- Carburetor clogged;

- Engine overheating;

- Failure of timing chain tensioners and dampers;

- Wear of the elastic coupling of the shaft;

- Failure of the gearbox;

- Increased vibration;

- Wear of CV joint boots;

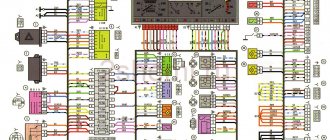

- Oxidation of electrical wiring contacts;

- Stove tap leaking;

- Body corrosion.

Some of the problems can be fixed yourself. For example, you can clean the terminals from oxidation or install a new boot on the CV joint in your garage. With certain skills, you can also clean the radiator. But it is better to fix more serious problems with specialists - this requires certain knowledge, tools and equipment.

Engine problems - what you need to know

The main disease of the VAZ-21213 engine is the carburetor. When using low-quality fuel - and this problem occurs regularly at our gas stations - the carburetor constantly becomes clogged. If the fuel lines and filters become clogged, simply clean them and, if necessary, install new filters. But if you do not pay attention to this problem for a long time, then very soon the fuel pump will fail and then you will have to change it.

Another problem, which can hardly be eliminated, is engine overheating. The reason for this is the poor design of the cooling system, or rather the blowing system. This is especially noticeable on engines that have undergone major overhauls, since due to boring of the cylinders, the partition becomes thinner and heat transfer increases. It can only be combated by upgrading the blowing system and installing either an additional fan or replacing it with a more efficient one. But you can’t ignore this problem - even novice motorists know the consequences of prolonged engine overheating.

Vibrations and transmission

Another problem that requires VAZ 21213 repair is vibration. Its cause is the failure of one of the transmission elements. There may be several reasons:

- Disturbance in the alignment of the transfer case;

- Souring of the cardan shaft crosspiece;

- Biting the CV joint of the shaft;

- Wear of the elastic coupling of the shaft;

- Failure of suspension elements.

As long as all transmission and chassis components are adjusted, vibrations are unnoticeable. But if even one of the parts fails, you can immediately feel it.

Among other things, the VAZ-21213 has a characteristic disease - failure of the fifth gear gears. The fact is that this box is a modernized version of the old four-speed gearbox. There is a big flaw here - the ill-conceived design of the lubrication system leads to oil starvation of the fifth gear gears and they wear out much faster than others - literally after 30-40 thousand kilometers.

Body

There is a joke that the body of a Niva begins to rust even before it is purchased. This is, of course, an exaggeration, but there is simply a problem with the anti-corrosion treatment of metal - it really starts to rust very quickly, especially in those places where there is active contact with water: thresholds, rear door, bumper mounting points, fenders, and so on.

In order to delay the appearance of holes in the body as much as possible, it is necessary to carry out anti-corrosion treatment every year. Considering how we deal with icy roads in winter, the bottom can literally rot in a year if it is not treated.

Also, carefully monitor the drainage and ventilation holes - if they become clogged, moisture and condensation begin to accumulate inside.

If you can repair the VAZ 21213 with your own hands, then reinforce the floor with an additional metal plate in the place where the transfer case is attached - due to increased vibration, this area is subject to increased loads and may simply fall off.

Video about body and engine repair of VAZ 21213 https://www.youtube.com/watch?v=ANMDnRcrz5g

Improved Niva

The injector installed on the Niva, although it reduces fuel consumption, is still not the most economical option in urban conditions with traffic jams and other delays. On the highway and during long trips outside the city, this is not felt so much, since the car works without stops and downtime.

Due to the unprofitability of cars in urban environments, drivers are thinking about a good and effective replacement for the old injection-type engine in their car. The best option would be a diesel engine for the Niva. It has approximately the same power characteristics, but its fuel consumption is comparatively lower. Also, diesel is less capricious in terms of fuel quality. What options from this category of motors are worth detailed consideration?

The first and most worthy candidate is the XUD 9 SD from Peugeot. This engine was used to create a modified version of the Niva - model 212151 with a French engine. It can be installed on the Niva without any problems - the fastenings of the parts and the assembly are identical, the motor fits perfectly in size, and in addition, there are some advantages from its installation.

In fact, this is the only option that suits all parameters.

Is it worth changing the body to a new one?

The body of the VAZ-2121 is the most expensive part of this domestic car. You should take good care of it and carry out cosmetic repairs. You should also cover the thresholds with anti-gravel protection, promptly remove rust from the metal, and wash the car as often as possible, especially in the winter, because that is when reagents are actively used on the roads, corroding car body parts and rubber seals.

If the body has fallen into disrepair, is heavily rusted, or has large holes formed on it that cannot be repaired, the easiest way is to replace it with a new one. However, remember that a radical replacement of the body can result in problems when meeting with traffic police officers. You should come to the registration point in advance and register the changes made to your car.

If the body of the VAZ-2121 has undergone minor corrosion, the best option for the owner would be local cosmetic repairs of metal parts, as well as strengthening of some components of the car.

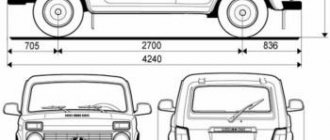

Description of the design of Niva 2121 and 21213

Both cars have high cross-country ability. This is inherent in their design. Niva 2121 and Niva 21213 belong to the class of light SUVs:

- body type - station wagon;

- number of doors – 3 pcs.;

- drive - four-wheel drive;

- gearbox – 4 or 5-speed;

- ground clearance size – 220 mm;

- wheelbase - 2.2 m.

Thanks to these parameters, the car can be used in off-road conditions. Niva 21213 has similar parameters. The appearance of the car has only improved. The power unit was also replaced.

Modified options

Since it is not always possible to supply an engine of a certain foreign car, it is worth considering imported production options that require a little modification:

- The first candidate will again be the French engine from Peugeot XUD 11 series. Since the power of this unit is higher than that of the previous model, some changes will need to be made to the design of the Niva - replacing the gearbox. An acceptable option is a gearbox from Fiat Polonez. In addition, a good solution would be to replace the front supports of the power plant fasteners, pan and exhaust system. It is also worth replacing the drive elements with similar parts from the Chevrolet Niva.

- There are options from the Japanese concern Toyota - 3C and 3CT. You won't have to change the transmission, but you'll have to tinker with the fastenings. Another acceptable option with modifications is 2JZ. It will be necessary to install an automatic transmission and update almost all parts of the exhaust system and engine compartment, since the model is too powerful for the standard Niva design.

- Engines from BMW models M42-M43. To install, you will have to use a few tricks and buy a few additional parts, but the final effect will please many car enthusiasts.

Also interesting: Characteristics of the NIVA 2121 engine - Shop of auto parts and accessories for Niva and NIVA-Chevrolet cars

Preparation for repair

It is quite possible to carry out repairs to the bottom of any Niva model yourself. Before welding a complete bottom or installing patches, dismantle the interior.

- Remove the seats.

- Remove the carpet.

- Remove the old sound insulation.

- Move the electrical wiring to the side to avoid touching the wires during repairs.

Tools you will need:

- hammer;

- welding machine;

- screwdrivers;

- electric drill;

- Bulgarian.

After removing the sound insulation, the metal is thoroughly cleaned and wiped dry. Problem areas are cleaned with a grinder. It can be replaced with fine-grained sandpaper. Then the metal surface is degreased and treated with an anti-corrosion agent.

Welding work

The first step is to remove rusty metal and corrosion. It is advisable to carry out this work with a grinder. Hard-to-reach places are cleaned using a gas welding machine. Then the metal patches are cut out. This is done with special scissors. This way you can make correct, even workpieces without torn edges.

It will be easier for two people to weld a new floor, since you will have to fix the patch and weld it at the same time. Basic rules for welding the bottom:

- The patch is stuck at 3-4 points, and then completely scalded.

- Short sutures are used to correct small defects. Length – 3 cm.

- The patch is applied as tightly as possible. In gaps, corrosion quickly forms again.

- To increase the strength of the seams, they are hammered.

After repairs, be sure to check the work done in a well-lit room. If necessary, weld the seams on the Niva again. Only after this can the seam beads be cleaned.

Bottom repair without welding

Niva flooring can be repaired without a welding machine. This is done in two ways:

- Installing a sheet metal patch. Rivets are used to secure them.

- Application of composite materials. They contain polymer resins, reinforcing filling and a curing reaction accelerator. This material restores the mechanical strength of the area and reduces the risk of rapid rust.

Installing patches is suitable for large-scale damage. If corrosion has pinpointed the bottom, it is easier to seal the hole in the Niva with a special mixture.

How to choose a part: average prices

When choosing spare parts for Niva, look at the article number. The part must fit exactly your car model. Don't take the bottom from a Chevrolet Niva. It has different dimensions, which means the part will have to be trimmed.

When buying a new spare part, remember that the factory bottom does not have a number of elements:

- hairpins;

- fastening elements;

- bracket for the hand brake cable.

They will have to be moved from the old flooring. If you are not sure of their safety, it is better to immediately order all the related parts. The average price of the bottom in the capital is 5,000 rubles. If you want to buy a spare part cheaper, contact a VAZ car dismantling center.

Repairing the bottom yourself requires patience and time. Spare no effort in processing the metal and cleaning it from rust. Poor preparation and careless attitude towards post-repair work will negatively affect the service life of the new body element.

Strengthening other areas of the car

The metal body of the Niva car has several more places that need strengthening over time, since they can no longer withstand increased loads during operation of this vehicle. All of them are listed below:

Major body repair

Buying a VAZ body is a great chance to save money on expensive major repairs or buying a new car. It has long been proven that it is more desirable to immediately send a decrepit body for scrap than to periodically repair it in services where they charge quite a lot of money for services of this kind.

And also interesting: Engine VAZ 21213 Niva | Niva engine tuning and repair

To protect himself from problems, a caring driver uses preventative measures. These, in addition to anti-gravity treatment and other procedures, include strengthening.

All operations related to strengthening and restoration of the car body are very complex, take a lot of effort and time, but give an excellent result.

When it comes to upgrading the body, strengthening the side members comes first. It is often carried out using a steel sheet up to 3-4 mm thick. At the same time, the suspension fasteners are strengthened.

Let us immediately note that strengthening the side members in front is more important than ever if stiffer shock absorbers, springs and larger wheels are installed on the Niva. It is also recommended to do this after installing power bumpers and winches.

Body repair of a VAZ 2121 consists of several types of work.

Due to the specifics of its operation and design, the VAZ 2121 requires increased attention, namely increased monitoring of the condition of the body. In general, if you are the owner of a used Niva, and you intend to use it for its intended purpose for at least another couple of years, carefully examine the condition of the VAZ 2121 body, the repair of which and the strengthening of its individual elements is more a necessity than a precaution. Problem areas that you should pay special attention to are:

- The bottom, namely its corrosion and through holes in the floor (very often the car overcomes water obstacles without subsequent proper drying);

- Spars, namely for the presence of cracks (consequences of impacts with corresponding metal fatigue).

Cracks in side members usually occur in the area of the fastenings:

- Steering gear;

- Pendulum;

- Engine beams;

- Front shock absorber upper bracket;

- Rear shock absorber mountings;

- Long jet rods to the very bottom of the floor;

- “House” of “Ponara” traction.

The photos below clearly show the repair of the body of a VAZ 2121, which was in use for only five years.

Restoration of the rear part of the front spar

Rear arch before repair

and after renovation

Front spar before repair

New, shiny - just like the real thing

Cracks in the most unexpected places

Complete loss of body parts

and car suspension elements

Since the work associated with restoring and strengthening the body is very labor-intensive and takes a lot of time and effort, the restoration of a car from an economic point of view can be considered profitable only when it is done with one’s own hands. This means that when buying a rotten car, even when its price is mere pennies, it is necessary to take into account the considerable future costs of restoring it. Reinforcement and replacement of parts of the floor and side members are usually carried out with patches of sheet metal 3-4 mm thick.

Ready-to-install spar patches/reinforcers

Ready-made car floor with reinforced side members

Instead of Ponar thrust

A - shaped lever

Device VAZ-21213, -21214 operating and repair manual

Removing the spring We hang up the front of the car and remove the wheel. We disconnect the lower mount of the shock absorber and the clip of the stabilizer bar cushion from the spring cup. Unscrew the lower arm axle nut a few turns. Place the stop under the lower arm and disconnect the ball joint from it. We reduce the height of the adjustable stop or, with a rigid stop, raise the car. We lower the lever and remove the lower coil of the spring from behind the protrusion of the cup. Remove the spring with the upper support cup and the insulating gasket. Remove the support cup and insulating gasket from the upper coil of the spring. Remove the plastic insulating gasket from the protrusion of the lower support cup.

Technical parameters of Cable AVBbShv 4x95. . Electronic ballast 1x36 electronic ballast choke.

To remove the lower support cup of the spring, use a 17mm socket to unscrew the nut of the cup mounting bolt, holding the bolt from turning with a wrench of the same size. We take out the bolt. Unscrew and remove three more cup mounting bolts. Remove the lower spring support cup. We install the removed parts in reverse order. We finally tighten the nuts of the lower arm axle and the bolt of the lower shock absorber mounting in the “car on wheels” position.

Inspections Inspect the springs carefully. If deformations are found that may cause malfunction, replace the springs with new ones. To check the spring settlement, press it three times until the coils touch. Compress the spring along the axis of the spring; The supporting surfaces must correspond to the surfaces of the supporting cups on the vehicle suspension. Then apply a load of 6276 Nm (640 kgf) to the spring. According to the length of the springs under the specified load, they are divided into two classes: class “A” - length more than 192 mm and class “B” - length equal to or less than 192 mm. Class “A” springs may be unmarked or marked with white paint on the outside of the coils; class “B” springs are marked with black paint.

Install springs on the front suspension of the same class as those installed on the rear suspension. In exceptional cases, when class “B” springs are installed on the rear suspension, but there are no springs of this class for the front suspension, it is allowed to install class “A” springs on the front suspension. But it is not allowed to install class “B” springs on the front suspension if class “A” springs are installed on the rear suspension. Check the technical condition of the insulating gaskets and replace them if they are damaged.