Why monitor your battery's condition?

A car battery consists of six batteries connected in series with a supply voltage of 2.1 - 2.16V. Normally, the battery should produce 13 - 13.5V. Significant discharge of the battery should not be allowed, since this reduces the density and, accordingly, increases the freezing temperature of the electrolyte.

The higher the battery wear, the less time it holds a charge. In the warm season, this is not critical, but in winter, side lights forgotten while turned on can completely “kill” the battery by the time it is returned, turning the contents into a piece of ice.

In the table you can see the freezing temperature of the electrolyte, depending on the degree of charge of the unit.

| Dependence of the freezing temperature of the electrolyte on the state of charge of the battery | ||||

| Electrolyte density, mg/cm. cube | Voltage, V (no load) | Voltage, V (with load 100 A) | Battery charge level, % | Electrolyte freezing temperature, gr. Celsius |

| 1110 | 11,7 | 8,4 | 0,0 | -7 |

| 1130 | 11,8 | 8,7 | 10,0 | -9 |

| 1140 | 11,9 | 8,8 | 20,0 | -11 |

| 1150 | 11,9 | 9,0 | 25,0 | -13 |

| 1160 | 12,0 | 9,1 | 30,0 | -14 |

| 1180 | 12,1 | 9,5 | 45,0 | -18 |

| 1190 | 12,2 | 9,6 | 50,0 | -24 |

| 1210 | 12,3 | 9,9 | 60,0 | -32 |

| 1220 | 12,4 | 10,1 | 70,0 | -37 |

| 1230 | 12,4 | 10,2 | 75,0 | -42 |

| 1240 | 12,5 | 10,3 | 80,0 | -46 |

| 1270 | 12,7 | 10,8 | 100,0 | -60 |

A drop in charge level below 70% is considered critical. All automotive electrical appliances consume current, not voltage. Without load, even a severely discharged battery can show normal voltage. But at a low level, during engine startup, a strong voltage drop will be noted, which is an alarming signal.

It is possible to notice an approaching disaster in a timely manner only if an indicator is installed directly in the cabin. If, while the car is running, it constantly signals about discharge, it’s time to go to the service station.

TMS device panel

This device is best suited for those owners who have a second battery built into their car. The device looks like an aluminum panel with a special voltmeter and a toggle switch for switching between batteries. The place of production is considered to be China, the cost reaches 1,500 rubles.

In stores you can find car battery indicators with a 12-volt charge level from the manufacturer Faria, located in the USA. But the cost for such devices is very high and ranges from four to five thousand rubles. For that kind of money it will be much easier to buy a new battery.

What indicators exist

Many batteries, especially maintenance-free ones, have a built-in sensor (hygrometer), the operating principle of which is based on measuring the density of the electrolyte.

This sensor monitors the condition of the electrolyte and the relative value of its indicators. It is not very convenient to climb under the hood of a car several times to check the condition of the electrolyte in different operating modes.

Electronic devices are much more convenient for monitoring the condition of the battery.

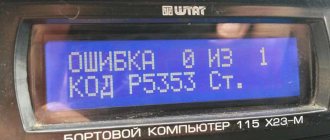

Generator faults

We began our story with the fact that the malfunction lamp on the instrument panel, which looks like a small red battery, came on and forced us to stop the car and diagnose the malfunction. We have determined when you can continue moving on your own and when you cannot do this. Now we have determined that it is the generator that is faulty. Let's consider possible options for the malfunction of this unit. Here is a complete list of what can fail in a generator:

- brush wear

- Regulator relay malfunction

- malfunction of the rectifier (diode bridge)

- rotor commutator wear

- broken stator or rotor windings

Most of these faults can be eliminated by replacing faulty parts with new ones. When carrying out repairs, it is imperative to pay attention to the condition of the generator bearings. It is better to carry out diagnostics of the generator on a special stand under load.

We have already complained more than once that today it is becoming more and more difficult for drivers to diagnose their own cars, especially while driving. The toolkit is constantly shrinking. Let's say that voltmeters have disappeared from dashboards like mammoths, and the driver learns about all problems with charging after the fact from a message from a laconic warning light. But even with the lamp, not everything is so rosy, they don’t talk about it in driving schools, in the instructions for the car there is only the phrase “contact the service center.” Most drivers roughly imagine that it is responsible for charging, but how exactly and what exactly it shows is something that not everyone understands.

Operating principle of the warning lamp

We have already written more than once about how the generator works; we would not like to repeat it. The operating principle of the control lamp is tied to the generator, although it is still a separate element. It's quite simple. Two electrical circuits are connected to the control lamp, which in a simplified form look like this:

1. The first circuit from the lamp runs through the fuse block to the ignition switch, from it to the generator and then to the battery.

2. The second circuit directly connects the generator and the test lamp.

The question arises - why are there two circuits and why are they both connected to the generator? That's the point. The control lamp depends on the current at both inputs; when the voltage is the same, the lamp goes out, when it differs, it lights up .

Imagine we turn on the ignition. In the first network, voltage came from the battery to the control lamp, but in the second it was empty, the engine did not work, the generator did not produce current, so the lamp lights up. And it will burn as long as the ignition is turned on.

But then we start the engine, the generator starts working and voltage appears in the second circuit; moreover, the first circuit also starts working from the generator. The same voltage is applied to the terminals of the control lamp, and it goes out. Some drivers believe that the warning light coming on before starting the engine is a diagnostic of the system, but in fact the car does not ring or check anything, it simply determines whether charging has started or not.

Types of battery charge indicators

Automotive stores sell many of these devices, differing in design and functionality. Factory devices are conventionally divided into several types.

By connection method:

- to the cigarette lighter socket;

- to the on-board network.

By signal display method:

- analog;

- digital.

The principle of operation is the same, determining the battery charge level and displaying information in a visual form.

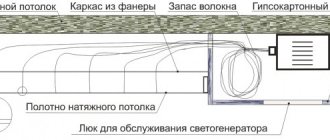

Schematic diagram of the indicator

VARTA battery – black eye

The Varta battery died the other day in the cold. The powercheck indicator began to glow black, according to the instructions - you need to charge the battery. I charged it, to no avail. The indicator is the same black, the battery itself does not oil well when starting. The battery is one year old. Maybe someone has the same problems?

These eyes are generally crap, the battery also died after a year, and the eye glowed green, like everything was fine. look at the electrolyte level and color; if it’s dark, it’s dead.

Yes, these Chinese guys are just dying on their way. If the battery doesn’t take a charge, it means it’s screwed

You can torture him in cycles, maybe he’ll come back to life

The essence of the problem is very simple. The maintenance-free Varta battery has some kind of cunning electronic design under the top cover; if you ever push it down to the “black eye,” the ability to charge is completely blocked. They don’t have such frosts there - :))

Is this Varta know-how? I dropped the Bosch Silver into zero and it froze. No problem, it thawed, charged it - then it went away for another 4 years.

Yes, these are apparently not the same Vartas, some Ketai ones, I also bought a BlueDynamic Vartu for 60 amps and never failed in 1.5 years, so I sold it with the old car.

you're wrong, there's no electronics there.

The “eye” on the lid - essentially a hydrometer - shows the density of the electrolyte (which allows you to judge the degree of charge), as well as a drop in its level below the minimum.

+1 and no electronics

as an option: at the topstarter this device broke and simply drowned in electrolyte.

+1 and no electronics

as an option: at the topstarter this device broke and simply drowned in electrolyte.

The peephole is a very useful feature. Only 0.5% of drivers look at it. In winter. When it sucks. No, it hasn’t broken – it has a high degree of sulfation. The author needs to perform desulfation. In the warmth. Day.

By the way. Here’s a question: Your battery is dead, and in your opinion it cannot be restored. And I will offer you, instead of purchasing a new battery, to restore the dead one for 30% of the cost. Do you agree?

How to make a battery charge indicator using LEDs?

There are dozens of different control schemes, but they produce identical results. It is possible to assemble such a device yourself from scrap materials. The choice of circuit and components depends solely on your capabilities, imagination and the assortment of the nearest radio store.

Here is a diagram to understand how the LED battery charge indicator works. This portable model can be assembled “on your knee” in a few minutes.

D809 - a 9V zener diode limits the voltage on the LEDs, and the differentiator itself is assembled on three resistors. This LED indicator is triggered by current in the circuit. At a voltage of 14V and above, the current is sufficient to light up all the LEDs, at a voltage of 12-13.5V VD2 and VD3 up, below 12V - VD1 .

A more advanced option with a minimum of parts can be assembled using a budget voltage indicator - the AN6884 (KA2284) chip .

Circuit of LED battery charge level indicator on voltage comparator

The circuit operates on the principle of a comparator. VD1 is a 7.6V zener diode, it serves as a reference voltage source. R1 – voltage divider. During the initial setup, it is set to such a position that all LEDs light up at a voltage of 14V. The voltage supplied to inputs 8 and 9 is compared through a comparator, and the result is decoded into 5 levels, lighting the corresponding LEDs.

How to perform diagnostics without a tool?

To independently diagnose the malfunction, you must turn off the engine, open the hood and perform an initial inspection. Particular attention should be paid to the generator drive belt. Very often, the reason why the battery icon on the instrument panel lights up is a broken drive belt. With such a malfunction, the generator does not rotate and does not produce current. In this case, it is necessary to determine what other units were driven by the broken belt.

If the generator drive belt drove only the generator itself or the generator and the power steering pump, then you can try to get to the repair site on your own. To do this, it is necessary to turn off all electrical consumers that are possible (headlights, air conditioning, interior heater fan, audio system) and that will not affect traffic safety. Provided that the battery is charged, you can drive from ten to fifteen kilometers. If this belt also drives the engine cooling water pump, then you cannot drive. It is necessary to replace the belt on site or tow the vehicle to the repair site.

Next, we will consider the situation when the generator drive belt has not broken and it is sufficiently tensioned. It is easy to check the belt tension by pressing it with your hand; it should bend no more than one and a half centimeters. It is necessary to inspect the wires that are attached to the generator. The malfunction may be that one of the fasteners is loose and there is no necessary electrical contact. It is also necessary to carefully inspect the battery terminals.

Oxidized battery terminals are also often the cause of poor battery charging. This completes all preliminary diagnostic steps that do not require a special tool.

Battery charging controller

To monitor the condition of the battery while the charger is operating, we make a battery charge controller. The device circuit and components used are as accessible as possible, while at the same time providing complete control over the battery recharging process.

The operating principle of the controller is as follows: as long as the voltage on the battery is below the charging voltage, the green LED lights up. As soon as the voltage is equal, the transistor opens, lighting up the red LED. Changing the resistor in front of the base of the transistor changes the voltage level required to turn on the transistor.

This is a universal monitoring circuit that can be used for both high-power car batteries and miniature lithium batteries.

Please rate the article. We tried our best:)

Did you like the article? Tell us about her! You will help us a lot :)

What do indicator colors mean?

Basically, the indicator has white, green and black colors. However, some batteries also have a red color. Each of them has its own name and helps the car owner to recognize what is what in his equipment.

- green (notifies that everything is in order);

- black (requires charging);

- red (the same as black, it signals to us that the battery needs to be charged);

- white (indicates a lack of fluid in the battery).

Something to remember! If the battery needs charging, it must be placed on it as soon as possible. Otherwise, in the future, such unfulfilled actions may lead to the failure of the battery.

Additional Information

Many motorists are faced with a problem when the battery is fully charged, but the red indicator does not change to green. There are three reasons why this could happen:

- The design uses special balls, and a situation often arises when they get stuck and cannot jump to the surface. In this case, you need to shake the battery and the indicator will show the desired color.

- The device has dirt from the plates, which prevents the correct transmission of information. This is due to the fact that the plates in any battery can crumble over time. Then the electrolyte becomes cloudy.

- It is possible that the device has malfunctioned and cannot charge properly. In this case, you need to contact specialists.

Is it possible to fix the problem?

The main thing is not to miss messages issued by the operating system , which also monitors battery performance. When problems arise with the battery, the OS sends a message about its damage - as a rule, it “crawls out” on the right. If the system does not produce such a message and “believes” that everything is fine with the battery pack, most likely there is a problem with the charger itself.

It is important to keep in mind that if the battery is damaged, it is no longer possible to repair it. In the best case, it will have to be either completely changed or a partial replacement of elements. About laptop battery repair →

The charger can simply be disassembled into parts and tested using a multimeter. Most likely, the wiring has frayed or the contacts have come loose - this problem can be fixed with your own hands. However, if the capacitor burns out, you will have to look for a new, suitable charger.