October 28, 2015 Lada.Online 237 629 112

In 2013, AVTOVAZ decided to modify the manual transmission (manual transmission 2180). A cable replaced the gear shift drive with rods. The design of the box was modernized, and the following serial number was added to the name (manual transmission 2181). Let's look at the features of a cable gearbox.

REQUIREMENTS AND SUGGESTIONS

The new product, which is installed on the “Norma” and “Lux” versions, is based on the same gearbox that appeared on the VAZ-2108 and, with minor upgrades, has survived to this day. Its weaknesses are well known: difficult activation, large lever strokes, smeared switching pattern, low vibration comfort.

Figuring out what and how we could improve, we agreed on one thing: not to touch the gear part, namely the shafts, gears, and synchronizers. Otherwise, huge financial costs will be required to launch a new gearbox into production - without high-precision equipment, it will not be possible to ensure the proper quality of engagement, operation and synchronization.

So what's new in the box with the VAZ-2181 index?

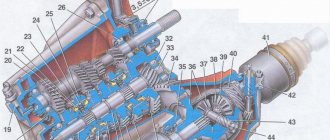

Main elements of the VAZ-2181 gearbox:

Gearbox selection

All types of gearboxes on the Lada have their advantages and disadvantages, but even the domestically assembled Grant gearboxes do not cause very big problems for car owners.

If we do not take into account the slight noise of the mechanical part of the transmission, then we can say that the “robot” and “mechanics” are quite reliable, without pronounced characteristic “diseases”.

For those who like a leisurely drive and comfortable driving, an automatic transmission is best; there is only one drawback - increased gas consumption.

Although the manual transmission whines, the noise does not particularly affect its service life; during normal operation, it can travel about two hundred thousand kilometers without problems.

The electronics in the robotic box sometimes malfunction, and you need to get used to the specifics of driving a car with AMT.

Which transmission to choose for the Lada Granta is a personal matter for each motorist; a lot here depends on the preferences of the driver himself.

1_no_copyright

1 - main gear drive gear;

2 - secondary shaft;

3 - input shaft;

4 — fifth gear fork;

5 — fork for selecting third and fourth gears;

6 — reversing light switch;

7 — clutch housing;

8 — gear shift mechanism;

9 - central lock.

==Disassembly of differential ==

We clamp the driven gear of the main gear in a vice with soft metal jaw linings.

Using a 17mm socket, unscrew the eight bolts securing the gear to the differential box. Leaning the driven gear of the main gear onto the jaws of a vice (with jaw linings made of soft metal)…

...using a hammer with a plastic tip (or a soft metal tip) we knock the differential box out of the driven gear.

By inserting a blunt chisel into the gap between the end of the inner bearing ring and the differential box, we strike the chisel, increasing the gap.

Then, installing two mounting blades into the resulting gap...

...press the bearing with them.

Remove the speed sensor reference ring.

During subsequent assembly, the tabs of the drive ring must be installed in deeper grooves at the end of the differential box.

By turning, we remove the wheel drive gears from the differential box.

Using circlip pliers, remove the circlip from the pinion axis.

We take out the pinion axle and pinion gears from the differential box.

SYNCHRONIZER

So, the gear part remains the same. Almost the same: in first and second gears, we still had to install multi-cone synchronizers. Firstly, for the sake of reliability: the second stage is the most loaded, and the multi-cone will undoubtedly extend its life. Secondly, to reduce the effort when shifting gears. In addition, they plan to install the VAZ-2181 gearbox on models with more powerful engines. Therefore, a clutch with a larger diameter (215 mm) is required, which naturally has a larger moment of inertia. This is an additional argument in favor of a multi-cone synchronizer. A more powerful clutch required a different housing, because the previous one accommodated a maximum of 200 mm disc. The starter also had to be moved; now it is located not along the box, but along the engine.

The first samples were equipped with a three-cone synchronizer. But calculations have shown that double-cone, cheaper ones, can withstand the required torque with a margin (see pictures). Among other advantages, they made it possible to get rid of the problematic cone on the gears of the first and second gears, which is in contact with the synchronizer ring and requires high precision in manufacturing. The ring set now creates two friction surfaces for smooth and efficient synchronization. In addition, the German manufacturer (Ho¨rbiger) applies an additional coating to the intermediate ring, which reduces wear and ensures stable operating parameters, including the required coefficient of friction.

To make shifting easier, the bevel angle of the synchronizer teeth was reduced (from 125 to 100º) and the preload force (from 150 to 70 N). If the developers had kept the same single-cone assembly with these changes, it is possible that a crunch would have appeared when the second stage was quickly implanted (especially at low temperatures) - the so-called synchronizer breakdown. This will not happen with a multi-cone due to the larger working surface.

Structure of VAZ-2110 (A) and -2181 (B) gearbox synchronizers:

Step-by-step replacement instructions

Let's assume that we will change the oil in the VAZ 2181 gearbox in an ordinary garage, which does not have a pit or a lift.

- Using a knife, cut out the side surface of the canister.

Canister with cut side surface

- Before starting work, we properly warm up the VAZ 2181 gearbox. That is, you must first warm up the engine, and then drive ten kilometers so that the gears have time to disperse the oil throughout the entire transmission.

- We raise the right side of the VAZ 2181 car using a jack. We put a stand or some reliable and durable block and then lower the car. Under no circumstances should you work under a car that is supported by only one jack.

Car raised with a jack

- If the floor is cold, you can put a sheet of plywood under the car.

- If crankcase protection is provided, then it must have a cutout under the oil plug. The plug is located on the left flange of the gearbox from the bottom; if it is missing, you will need to remove the engine protection. Clean the cork with a metal brush. Wipe the surface around it with a rag. Using the “17” key, unscrew it, after placing the canister under it. The liquid that drains should be warm, not hot. We wait approximately 10-15 minutes for complete drainage, and then tighten the plug.

Location of the plug on the gearbox flange

- Using a knife, cut out the bottom of a plastic bottle.

Plastic bottle with the bottom cut off

- The air filter must be removed along with the intake pipe. To do this you need to remove the terminal from the air flow sensor.

Removing the air flow sensor terminal

- Unscrew the clamps at the throttle body and pipe and remove the intake unit completely.

- Remove the oil dipstick from the gearbox. It is located at the top.

Probe location

- We place the neck of a 1.5 liter plastic bottle to the hole for the cork. Using the bottle as a funnel, fill it in (a little less than 3 liters). Let's see if oil is leaking from the plug under the car. To do this you need to wait about ten minutes.

Use of a plastic bottle for filling liquid

- Having made sure of the tightness, we install the engine protection (if it had to be removed), and lower the car from the stand. Next, you need to top up to the “MAX” level using the dipstick. In total, the box should contain 3.2 liters.

Unscrewed dipstick

- We install the inlet pipe with filter.

It is necessary to check the oil in the gearbox of a VAZ 2181 every 15,000 km. The level is checked only when the gearbox has cooled down, with the engine turned off, and the vehicle position must be strictly horizontal.

To make it easier, you may have to remove the engine air filter. In order to find out how much fluid is needed in the VAZ 2181 gearbox:

- take the dipstick;

- wipe it with a rag and then insert it into the crankcase hole;

- Pull out the dipstick again and check the level.

It is imperative that the fluid level in the gearbox must be between o and “MAX”.

SWITCH MECHANISM

In the old box it is located at the bottom and bathes in an oil bath. After spending the night in the cold, the oil thickened, making it difficult to change gears for the first few kilometers. In addition, at the bottom of the box there were clamps for the rods and reverse forks, a reverse light switch, and a gear selection seal - all of these are potential sources of leakage. Sealants and other materials, of course, helped, but the problem was radically solved only by moving the mechanism upstairs.

The new mechanism is a separate module. It can be installed last and removed if necessary without disassembling the box. This is technologically advanced not only in production, but also in repair. Already at the concept stage developed by the VAZ team, a selector grill appeared in it, clearly repeating the gear shift pattern and setting the lever stroke when selecting gears. The mechanism includes a lock against accidental reverse gear, which is only accessible from neutral.

Having embodied the concept in metal and made it work correctly, the unit was sent for fine-tuning to the German company (Scha¨ffler), which has long been engaged in the engineering and production of engine, transmission and chassis parts. One of the most interesting changes proposed by foreign experts is the so-called three-dimensional central plate instead of several return springs and locks. Its spatial shape is calculated by a complex computer program, and the manufacturing equipment requires high precision. After all, the central locking ball walks along this plate, and it is this plate that sets the necessary forces when turning on and selecting speeds.

The characteristics of the mechanism were selected on the original simulation stand. The tester sits down on the seat and begins to go through the gears, while the automatic system imitates the shift pattern, forces and lever strokes implemented on a specific production car. You can also upload your own settings. Don't like an overly tight lever? A couple of taps on the keyboard and the effort is reduced. So, step by step, we selected the optimal settings for the “eighty-one”. The computer processed the data and produced parameters for constructing an accurate mathematical model, according to which those very tricky central plates were made.

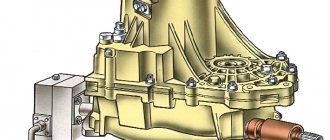

Automatic transmission

“Automatic” was installed on the car of the Togliatti Automobile Plant from July 2012 to March 2015 - this is 4 speed. Automatic transmission from Japanese manufacturer Jatco.

Grant's four-speed automatic transmission - model JF414E, classic type, with a torque converter; similar units are equipped in Nissan, Mitsubishi, and Suzuki passenger cars.

This type of transmission on Granta is paired only with the 98-horsepower VAZ-21126 power unit.

The gearbox is highly reliable; with careful operation and timely maintenance, it can run up to 200 thousand km.

It is necessary to replace the transmission fluid every 60 thousand km; the manufacturer recommends filling with Nissan branded ATF EJ-1 or Matic-S oil.

Automatic transmission problems.

The quality of the Lada Granta automatic transmission does not cause any major complaints; if the transmission requires repair, it is mainly due to the fault of the driver:

- as a result of slipping, the clutches burn out;

- after overheating, gaskets and seals begin to leak;

- When you hit an obstacle, the automatic transmission pan breaks through, and then a thorough repair is definitely required.

Car owners have more complaints about the performance characteristics of an automatic transmission - increased fuel consumption, sluggish acceleration of the car, jerking during gear changes during dynamic driving.

ROPE DRIVE

Despite the simplicity and low price, almost all manufacturers abandoned the rod drive, like on the old box. Today, designs of several rods with complex scenes are used to dampen vibrations on the lever, or a more expensive and convenient cable drive. AVTOVAZ experimented with the latter back at Samara, purchasing parts from. But with the switching mechanism located at the bottom, the performance of such a circuit is problematic, and the price of components was scary at that time. Work on the cable-driven gearbox continued as part of other projects, but the production model could only be realized now.

Service

The only way to maintain the 2181 gearbox on a Grant is to change the oil in a timely manner. The replacement interval is 70 thousand km.

Manual transmission service

The oil change procedure looks like this:

- Find a place where you can access the bottom of the car - an overpass, a lift, a hole in the garage.

- Drive the car, secure the car with the handbrake.

- Prepare a container of at least 3 liters and gloves. Waste oil is harmful to the skin.

- Open the drain cap and wait until all the oil drains into the container. You also need to open the filler plug, so the oil will come out faster and more evenly.

- Fill in 0.5 liters of mineral oil to flush (a little more is possible), put the gearbox in neutral and idle for five minutes, then turn it off.

- Drain off what you washed with and add fresh oil.

Oil change for Lada Granta

For “mechanics” it is very advisable to wash the box when changing the oil, this way it will live longer.

Clutch Drive Maintenance

The clutch drive does not need to be serviced; it is simply easy to maintain. Chafing of the cable and damage to the drive itself can lead to increased noise when the clutch is disengaged and to its incomplete engagement.

It is very advisable to lubricate the cable, and if it is worn out, replace it. Periodically, the clutch needs to be adjusted and the pedal travel monitored.

Maintenance and adjustment of the cable drive (gear selection system)

It also needs lubrication and supervision. There is no way to adjust the cable drive on the Grant purely technically, because the engineers did not provide for such a possibility. Craftsmen try to simply tighten the cables or move the fastening ears, but the method is not very effective.

If the cable drive is worn out, it must be replaced. According to the plan, they are replaced every 100 thousand km. If the car is still under warranty, the easiest way is to contact the authorities. The Granta gearbox cable repair kit will also help you.

4_no_copyright

The single-rod gear shift drive was replaced by a cable. The unpleasant vibrations on the lever are gone, there is less play, and shifting is clearer.

It is curious that in the clutch drive, on the contrary, they planned to abandon the cable in favor of hydraulics. Unfortunately, for economic reasons, they left the previous design, although the hydraulic drive has better characteristics. In particular, the clutch pedal works more logically and clearly with it. The advantages in the layout are also obvious: it is easier to lay tubes and hoses. But the cable for the new box had to be lengthened. These are unnecessary mechanical losses, which means additional effort on the pedals and worse information content.

Results of the modernization of the gearbox on the Lada Granta

The box turned out to be ambiguous. On the one hand, the transition to cables made it more reliable, quiet, and clear in switching. Most automakers are now switching to cable-based transmission designs.

However, the first revision of these boxes was a failure. Many owners have them break. The vibrations became much quieter, but the box began to howl. Bad metal also made itself felt in the form of licked gears. The design of the gearbox was promptly modified at the factory, and everything is fine on modern cars, but the owners were left with an unpleasant aftertaste.

7_no_copyright

1 — gear selector levers;

2 — selector grid pin;

3 — selector grid;

4 — reverse locking mechanism;

5 - central three-dimensional plate.

However, the developers are not delaying documentation on the hydraulic drive and plan to launch it into series. As well as other improvements, by the way, which for various reasons were not implemented this time. For example, a multi-cone synchronizer in third gear and an equally interesting solution that makes the transition to the fourth and fifth stages clearer and more enjoyable. Not otherwise, appetite comes with eating. By the way, the food turns out delicious - I tried it myself. The main thing I would like to wish to the developers is not to be late with changing dishes. And to consumers - bon appetit!

Thank you for your help in preparing the material.

developers of the VAZ-2181 box

Mikhail Votinov, Vladimir Petunin, Sergei Ishchenko, Dmitry Gorev.

New gearbox "Grants" and "Kalina": traction to the cable

Regulations for changing gearbox oil from AvtoVAZ

It is necessary to change the oil in the gearbox-2181 in one case - if the mileage exceeds 200,000 km.

In theory, the entire service life of the car is indicated here, and the numbers are taken from the regulations.

The first two dismantling steps

The thin clamp that secures the expansion tank hose is also removed (see photo).

The video shows how to change the oil

do it yourself in the gearbox

with cable drive

LADA Granta

Liftbek.

Changing the gearbox oil on a Lada Granta

Change of oil

with your own hands.

Disconnect a couple of connectors: the mass air flow sensor and the adsorber valve connector. The first of them is oval (photo below). And the second one is turned off like this: tighten the tongue, remove the terminal block.

Down with all terminal blocks!

The filter housing can be moved to the side in the final step. There is no need to disconnect it from the corrugation.

Rubber fasteners can be defeated this way: the rubber band is held with pliers, and the body is pulled back (to the left, forward). Start with the right front support.

Reconnaissance in force

We are trying to remove the reverse switch. We look for a plastic connector on the crankcase (see photo) and immediately disconnect it.

View of the gearbox housing from under the hood

Using a 22mm round wrench, try to unscrew the switch housing. Cancel the replacement if nothing can be done - neither unscrew the “top” plug, nor remove the switch.

When the switch is returned to its place, the threads are treated with sealant. The tightening torque should be 28-45 Nm.

Detailed algorithm for changing the oil in a CABLE gearbox

The oil from the Lada Granta gearbox is drained through the “bottom” plug. It is unscrewed with a 17 key.

The simplest thing is to drain the oil

You need to unscrew the cap like this: make 1-2 turns with the key, then substitute the container. And then unscrew the plug by hand.

When the liquid flows out, wipe the surface of the crankcase. We tighten the plug back (torque – 29-46 Nm). Getting ready to refuel.

Hose and funnel are ready for use

conclusions

It becomes clear that the cable-driven gearbox of the Lada Granta has become better than its younger brother with rigid rods. Modernization of components has improved performance, reduced vibration and improved gear shift quality. At the same time, many car owners still express dissatisfaction with increased wear and frequent breakdowns, although the plant promises to correct this deficiency.

Lada Granta 2016

According to the manager of the car dealership where I bought the car, a new gearbox with a cable drive instead of a rocker was installed with the grant. and it is more reliable and there will be no problems with it! I’ll tell you honestly, it’s complete crap, in fact, it would be better if they left the backstage!

at a mileage of 14,000, when switching to 3rd gear and accelerating to the floor, the gearshift knob began to tremble, and only in 3rd gear! I went to the salon and explained the situation to them, they told me it’s a disease they have, it can be solved without any problems! We took the car to the service center and “started disassembling it.” I’ll tell you why I wrote it in quotation marks. I sat down in front of the TV in the recreation area and began to wait! Exactly 2 hours have passed and a cheerful serviceman comes out and says everything is done. I leave the service first - 40 km, throw it on the second - 70 km, throw the gas to the floor on the third and the same situation - the gearshift knob rattles! and here I have a thought: maybe they didn’t do a damn thing. I drove back and asked for a recording from the service cameras and imagine that the car was driven into the corner of the service from the moment the manager got out of my car, nothing happened to this car, it just stood stupidly at the end of the hall in the corner for exactly 2 hours! cursed out all the service personnel and the director of this car dealership. I wrote a complaint to AvtoVAZ, they didn’t even deign to answer! this is half the trouble, a week later I stopped at a traffic light at idle, I wanted to hear a knocking sound in the gearbox, when the clutch is depressed the sound disappears! When you release the clutch the sound appears! I called another car dealership and signed up for service! set a day and time. I arrived there, they took the car to the service center, they took it apart, dismantled the gearbox and saw a picture, the bearing was crushed, the oil was covered in metal shavings, the gearbox was replaced under warranty. AVTOVAZ what are you doing? How did it happen? After all this, my only opinion about your cars is this: you don’t know how to do anything. You have no engines, no gearboxes either! The paintwork is okay, we checked the car with a device, the front doors on top show 110 microns, on the bottom 170, what's that? You can’t even set up your equipment in such a way that the paint you use on your car is applied evenly. The sills are all peeling off, the hood is all chipped! and all this on a mileage of 14,000. The plastic in the cabin is rattling! for 437,000 the owner of the car gets hemorrhoids! but I just wanted to buy a car and drive without problems for at least 100 thousand!

Manual transmission 2190

A manual transmission that started its journey on the assembly line together with the release of the Lada Granta. In terms of its ideology, it is almost a complete clone of previous manual gearboxes from Lada, however, there are differences from the old models and the assembled gearbox from the tens or nines will not fit. Firstly, Granta has its own gearbox housing, which some craftsmen call the “bell”. Secondly, the principle of placement of the speed sensor is different; in old gearboxes there was a shaft for the speed indicator, but since with the arrival of the Lada Grant on the assembly line, AvtoVAZ began to switch to a different car control bus and the speed sensor 2190 is already built into the gearbox and only an electrical contact comes out.

Otherwise, in terms of its internal parts, the mechanism is completely identical. Despite its excellent reliability, it has a number of fatal drawbacks: low vibration comfort, poor selectivity of gear selection, large lever strokes.

At the moment, it is not used on Lada cars; it has been replaced by manual transmission 2181, which will be discussed further.

Manual transmission 2181

Unlike its predecessor, the new gearbox has received a lot of innovations. This box was the first for AvtoVAZ to undergo computer modeling; a similar approach to production and engineering made it possible to optimize the design and make it more reliable. The oil sump of the new gearbox has changed from 3.3 liters to 2.2 liters and the oil used is not outdated “mineral water”, but good “semi-synthetic” whose service life is designed for the entire life of the car, namely 5 years or 200 thousand kilometers .

But, undoubtedly, the most important and significant change was the introduction of gear shift cables instead of metal rods. This solution made it possible to completely remove vibration from the gearshift lever, qualitatively increase the clarity of gear engagement and their selectivity, and reduce the lever strokes.

The filling of the new box has also changed. The gear part, namely the primary and secondary shafts, remained unchanged; new multi-cone synchronizers were introduced in first and second gears. Unlike classic synchronizers, the new type of synchronizers are much more reliable, and since, according to statistics, the first and second gears are the most loaded, this solution made it possible to increase the reliability parameter of the new unit. Also, synchronizers of this design simplify gear shifting, making it even smoother. In addition, the car plant’s plans include installing this gearbox on more powerful engines, which means a clutch with a larger diameter is required. Unlike its predecessor, the new clutch has a size of 215mm (approx. It was 200mm), this entailed changing the clutch housing and relocating the starter.

The next change will be especially noticeable at subzero temperatures. In old-type boxes, the gear selection mechanism was located at the bottom and was in oil. When the temperature dropped below zero, the oil thickened and engaging gears until the oil warmed up was difficult. In the new model gearbox, the gear selection mechanism is a separate module located outside the gearbox - this solution made it possible to get rid of the problem of difficult shifts in cold weather during the first kilometers of the journey, and also in the future greatly simplifies the process of repairing and servicing the gearbox. There is protection against erroneous engagement of reverse gear, which can only be engaged in neutral.

Through an integrated approach to the development of a new gearbox, engineers managed to achieve a level of gearbox operation no worse than that of competitors in the price segment. AvtoVAZ plans to introduce multi-cone synchronizers in third gear, as well as switch to a hydraulic clutch drive.