13.11.2019

| (Votes: 2, Rating: 5) |

Issues discussed in the material:

- Why does cylinder failure occur in an engine?

- What is the danger of cylinder failure?

- How to independently identify the cause of cylinder failure

While driving a car, did you feel that the power unit was vibrating, while its power dropped, and it began to consume more fuel? Does the car start only the second or third time? These signs indicate that a cylinder failure has occurred. In our article today we will look at how to fix this problem.

Why does the engine troit?

Some car owners do not know why the engine idles at idle. If you are an inexperienced driver, you need to identify this malfunction and then find the reason why it occurred.

Cylinder failure is a good reason for the engine to misfire. The cylinders may stop functioning alternately. Moreover, you don’t even need to search for a breakdown, because it will immediately become clear that a cylinder failure has occurred. The engine will shake and vibrate, the speed will begin to jump, it will be difficult to start the car, and the car will begin to consume more fuel. It is simply impossible to ignore such symptoms. For example, if one cylinder fails in an engine that has only 4 of them, the speed will drop by 25%. Even an inexperienced driver will notice this malfunction.

Tips for motorists

The VAZ-2114 passenger car (Samara-2) was discontinued last year, 2013. It was equipped with five injection engines, three of which (2111, 21114, 11183) had an eight-valve gas distribution mechanism (GDM), and two (21124, 21126) had a sixteen-valve timing mechanism.

Most often, drivers begin to notice that interruptions in engine operation appear at idle. Moreover, immediately after starting a cold engine, interruptions are not heard, but as soon as the engine warms up, it begins to “twitch” (twitch), and the Check Engine sign lights up on the instrument panel, requiring a diagnostic check of the engine. It is advisable to carry out diagnostics, since searching for a fault blindly may take a long time and be unsuccessful.

But it must be remembered that a possible cause of engine twitching at idle may be unadjusted timing valves, the thermal clearance of which must be checked every 20 thousand kilometers. There are cases that even on a new engine one of the valves turns out to be “pinched”, and the thermal gap will only be there while the engine is cold, but as soon as it warms up, the valve opens slightly and the engine begins to operate unstably at idle.

A possible reason for the intermittent operation of the engines (2111, 21114, 11183) of the VAZ-2114 car may be a malfunction of one of the spark plugs, poor contact of the high-voltage wire or its breakdown to ground. For engines (21124, 21126), failure of the spark plug or ignition coil. Malfunctions of spark plugs include the appearance of black carbon deposits on the insulator, as well as a large increase in the gap between the central and side electrodes.

Unstable operation of the engine can be caused by air leaks that enter the engine cylinders, bypassing the throttle assembly, which causes a lean mixture and a sharp decrease in crankshaft speed. Air leaks into the cylinders are possible due to a malfunction of the vacuum brake booster valve located in the flange to which the hose leading to the intake manifold is connected.

The injectors may also be involved in the same malfunction if the nozzle holes are completely or partially coked or, due to poor contact in its block, it does not fire every time. There may also be insufficient pressure in the fuel rail, which the fuel pump cannot create due to a clogged fuel filter or contamination of its intake chamber, the entrance to which is blocked by a fine mesh.

Signs of engine tripping

How to determine if a cylinder has failed:

- After a cylinder failure, the power unit will shake at idle speed. Unfortunately, an inexperienced driver is unlikely to notice this immediately after a breakdown. The fact is that this symptom occurs over time. And if you notice that the engine is shaking, it means that the problems started a long time ago. And after the cylinder failed, the engine worked for a long time and became worn out.

- The spark plug became dark, smoked, and carbon deposits formed. This sign indicates that the spark plug should be replaced. But this is at best, and at worst, such a symptom means that the machine is not working properly. Even though spark plugs can be used for quite a long time, they should not be sooted. A slight change in shade is allowed.

- The exhaust system began to sound differently. This also indicates a cylinder failure.

- If the car picks up speed poorly, both at low and high speeds, then the engine is not functioning properly. The reason could be either a cylinder failure or another engine failure.

- The car began to consume more fuel. In this case, you should definitely check the operation of the engine. This symptom indicates a serious problem with the motor.

We recommend

“The design of the clutch cylinder: a little theory for successful practice” Read more

- The engine speed “floats”, you can see this by the jumping arrow on the dashboard.

- When you accelerate or drive a car, it moves jerkily.

Unstable operation in cold conditions

From time to time, drivers encounter a problem: the VAZ 2114 engine stalls during a cold start, but as it warms up, the operation evens out. In this case, the reasons may be:

- large valve clearance;

- low compression, wear of compression rings;

- the mass air flow sensor is faulty;

- air leakage under the intake manifold gasket;

- poor quality fuel;

When the car shows signs of shaking, you should contact a service center for diagnostics. Diagnostics are carried out using special equipment, where a specialist can accurately determine the cause of the malfunction. Of course, if you have enough experience, you can figure out the reasons for the unstable operation of the engine yourself.

What does driving with an inoperative engine cylinder lead to?

When a cylinder fails, the fuel mixture entering it does not burn. The fuel is mixed with oil, removing it from the cylinder bore. The mixture will then penetrate into the crankcase. Due to the fact that the surface of the cylinder is dry, scoring occurs on it. In addition, oil mixed with fuel does not lubricate healthy cylinders well.

As a result of the failure of the first cylinder, the others will also stop working normally. Where will all this lead? The car owner will be forced to spend a large sum on boring the cylinder block or even on lining.

The next problem that will happen if the cylinder fails is that the engine will overheat. The change in its operating temperature is due to the fact that the lubricant does not perform its functions. And, as you know, motor oil not only lubricates surfaces, but also removes heat.

All of the above is sufficient reason to declare: under no circumstances should you operate a car after a cylinder failure!

Checking the fuel supply

The next step is to check the injectors. For this:

- disconnect the electrical connector;

- on the tester, set the measurement limit to 200 ohms;

- measure the resistance by touching one probe to the common wire (pink with a black stripe), and the other to each of the other contacts. It should be 11.5-15.5 ohms.

You can check it another way. First, with the engine running, touch the injector: it should tremble. If there is vibration, but suspicions remain, then:

- turn off the engine;

- disconnect the power connectors from all injectors, and connect 2 wires to the “suspect” one and connect them directly to the battery terminals;

- turn on the ignition: if there is a spray of fuel, the injector is working.

How can you tell if a cylinder has failed?

To do this, disconnect the wiring from the spark plugs one by one. In the case where there is no spark, you will understand that the slave cylinder is vibrating. During the test, you must be extremely careful so that you do not get an electric shock.

In addition, when diagnosing a carburetor engine, the switch or distributor can be broken. To prevent this from happening, put the spark plug wire on a regular bolt, so the spark will work without interruption.

Carrying out diagnostics on injection-type engines is easy and safe. After all, such a power unit uses a direct fuel injection system into all cylinders.

How do you know if the injection engine is faulty? First of all, turn off the fuel supply to the injectors. If you feel that the car has become worse, it means that the cylinder has failed.

We recommend

“Replacing the clutch cylinder: process and recommendations for choosing a part” Read more

To carry out diagnostics on a diesel engine that idles at idle, you should remove the nuts from the high-pressure fuel pipes one by one. They are attached to the nozzles.

Be extremely careful when performing this work. The fact is that when the nut is unscrewed, diesel fuel may begin to flow out under high pressure. Pay attention to the speed. Haven't they gone down? This means you have detected a cylinder failure.

Featured Posts

povsklada

Cylinders 2 and 3 do not work, it stalls in neutral, but not always. I did computer diagnostics, there are no errors, I checked the timing marks, everything is ok. Changed all spark plugs and wires. could it be the ignition or valve module?

VAZ 2115i mileage 130000

The first thing you need to do is measure the compression.

povsklada

If compression is normal then is it the module? and if there is no valve?

First replace the MH.

At a minimum there should be misfires.

We need to measure and not guess.

Modified on April 25, 2012 by Samen

Exactly, how can diagnostics fail to show errors?

Elementary! “Old” ECUs do not record misfires cylinder by cylinder until a certain number is reached! A motor tester will help here!

Modified April 25, 2012 by user 111

Well, the diagnosticians don’t know about this. Drive and they should appear.

Diagnosticians should announce such incomplete official duties.

Not all diagnosticians have the necessary equipment and, most importantly, experience!

Let them do it for free then.

povsklada

I checked the compression. in the second and third, 4 each. The master says that this is a gasket, supposedly the module cannot. Then why did she stall while driving?

VMSP

In fact, it won't make you any easier, gasket, plane or valve.

Cylinder head for removal, and then repairs on site.

the module will need to be checked after repairing the cylinder head

How did she even drive?

Nekto59

Perhaps they measured it “well”... they measured it for me the same way, the first time pots 3 and 4 were 7 and 6 respectively, after a while they measured it became 5 and 11, then it became 10 and 10. In short, you need to measure normally.

povsklada

yes, it seems like a guy with experience, and not a little one at that

povsklada

That’s right, the gasket on the block and head burned out. I declare the topic closed)))

Modified on April 29, 2012 by povsklada

Where to look for the cause of cylinder failure

Important!

You will have to look for the cause of engine cylinder failure in a garage. There are two possible ways here: check the mechanics or the electrical, that is, the ignition. Let's start with the simplest thing and diagnose the electrical system.

- Spark plug . Let's use a proven method to check their functioning. Look at the side electrode and insulator, their color should be light brown, not black. There should also be no soot. If there is soot, it means the mixture is over-enriched or there is oil on it. Now let's start checking sparking. Place the spark plug on the high-voltage wire, and then bring it to the cylinder block, the distance between them should be 1-2 cm. Turn the starter. Did the spark travel that distance? This indicates that the spark plug is working properly, otherwise it should be replaced.

- BB wires . They may be damaged. How to check this? Pay attention to the tip of the high-voltage wire. Did you see a light gray coating on it? This means he is operating at the limit. Use a special multimeter to check the resistance of the high-voltage wire. Please note that depending on the motor, the wire length and resistance may vary. When there are no additional instructions, 20 kOhm is taken as a constant resistance value. If this value is exceeded, then the problem is in the high-voltage wire.

- Ignition distributor . When the spark plug does not work properly, a breakdown occurs in the ignition distributor cap. In this case, it is necessary to diagnose the ember; stretching the spring will also help.

- High voltage wires are mixed up . If a cylinder failure occurs, the cause may be in the explosive wires.

We recommend

“The injector is pouring into the cylinder: causes and solutions to the problem” Read more

Now we check the mechanics.

- Injector . A malfunction in its operation may be one of the reasons for the failure of the cylinder. For example, an injector is broken, or the injector is clogged with a poor quality fuel mixture. Note! Damage can result from the use of the latest fuel purifiers, which can be purchased at any specialized auto store. It is best to diagnose and clean the injectors at a trusted service center.

- Gas distribution mechanism . The fuel mixture enters the cylinders in the wrong quantity and quality. This can happen for various reasons. For example, the timing belt was installed incorrectly, the tensioners or oil seal became unusable. The camshaft may also break, or the hydraulic lifters may need to be replaced.

Because the engine constantly overheats, the cylinder head gasket may burn out. This happens because the car owner does not monitor the antifreeze level or drives the car at high speed.

All of the above can cause the cylinder to fail. By the way, not everything that can lead to such a breakdown is listed here. Only by understanding why one cylinder in the engine failed will you be able to eliminate the problem. You can do this yourself or by visiting a specialized service center.

Vehicle characteristics

In 2001, the line of the VAZ automobile concern was replenished with the five-door hatchback VAZ 2114. The platform for creating the model was the VAZ 2109. Basically, the car was equipped with 4 cylinder 8 valve engines. The power system consists of an injection mechanism and an electronic control unit.

Engine operation is controlled by special sensors that inform the central module about engine performance. The module processes information and sends an impulse to the devices that need to be activated at the moment:

- prepares the required mixture quality depending on the speed and engine speed;

- distributes the spark among the cylinders in a certain sequence.

During production, the model was equipped with different engines.

| Parameter | Meaning | ||||

| Engine | 2111 | 11183 | 21124 | 21126 | 21114 |

| Configuration | L4 | L4 | L4 | L4 | L4 |

| Volume, l | 1499 cm3 | 1596 cm3 | 1599 cm3 | 1597 cm3 | 1596 cm3 |

| Number of valves per cylinder | 2 | 2 | 4 | 4 | 2 |

| Piston stroke | 71 mm | 75.6 mm | 75.6 mm | 75.6 mm | 75.6 mm |

| Cylinder diameter | 82 mm | 82 mm | 82 mm | 82 mm | 82 mm |

| Compression ratio | 11,5 | 9.6 — 10,0 | 10.3 | 11 | 9,6 |

| Gas distribution mechanism | OHC | OHV | OHV | OHV | OHV |

| Rated power | 77 l. With. at 5400 rpm min. | 82 l. With. at 5300 rpm min. | 89 l. With. at 5 thousand rpm min. | 98 l. With. at 5600 rpm min. | 81.6 l. With. at 5200 rpm min. |

| Max. torque | 116 Nm, at 3 thousand rpm. min. | 125 Nm, at 3 thousand rpm. min. | 131 Nm, at 3700 rpm. min. | 145 Nm at 4 thousand rpm. min. | 125 Nm, at 3000 rpm. min. |

| Supply system | injector | injector | injector | injector | injector |

| Maximum speed, km | 160 | 167 | 172 | 182/175(automatic transmission) | 175 |

| Acceleration time from 0 to 100 km/h, s | 15 | 13,2 | 12,4 | 11,2/13,1 | 12,5 |

| Fuel | AI 93 | AI 95 | AI 95 | AI 95 | AI 95 |

| Claimed gas mileage | 7.6 l/100 km combined cycle | 7.8 l/100 km combined cycle | 7.0 l/100 km combined cycle | 7.2 l/100 km combined cycle | 7.2 l/100 km combined cycle |

Diagnostic methods

When you find out that the motor is not working, you should diagnose it. This is the only way you can find out which cylinder failed and why. You can do this yourself, or go to a car service center. There the engine will be checked using a computer. However, most often you will be able to find out on your own why the engine is tripping. However, if there is a cylinder failure, and the reason is a decrease in compression, you should find a competent specialist who will solve your problem.

Act one. We find the cylinder that failed. To do this, we diagnose the engine after it starts. Be extremely careful when performing this work. Turn the ignition key, the hood should be open. Let's listen to the sounds coming from the engine compartment. Pay attention to how the engine works. Now, one by one, we disconnect the explosive wires that go to the spark plugs.

If you disable a cylinder that is working properly, the engine will run rough. If a cylinder fails after the spark plug is disconnected, the power unit will operate without changes.

How else can you perform diagnostics? We do not touch the explosive wires. We simply turn off the chips one by one that control the fuel supply from the injectors to the cylinders. If you disconnect the chip, but the motor runs without changes, it means that this cylinder has failed.

Act two. We carry out diagnostics of explosive wires, as well as spark plugs. First of all, you should disconnect the wire and carry out an inspection. Is the insulation damaged? This indicates that the problem is in the BB wire. Then we check whether the conductive core is intact. Did you find that it has kinks or is burnt out? This means that a breakdown or internal resistance may occur. To measure it, use a multimeter. The data obtained must satisfy the acceptable readings. Otherwise, current will not flow normally to the spark plug.

Did you find out that everything is fine with the wire? Then we unscrew and diagnose the spark plug.

Is the spark plug base or its electrodes deformed or do they have carbon deposits on them? A new spark plug needs to be installed. If everything is fine with it, then the reason for the engine tripping is not a cylinder failure.

Act three. We determine how much air penetrates the cylinder. If it is not enough, then the fuel mixture will be over-rich, which means the engine will start to stall. The air supply system must not be depressurized. To check whether this is so, you should shut off the intake pipe, and then use a compressor to supply air into the cylinder through a vacuum hose. Supply pressure 0.5–0.7 atmospheres. Pay attention to the sounds you hear when doing this. Is there a hissing sound? This indicates that the air supply system is leaking.

How else can you diagnose the engine for breakdowns? Examine the air filter. When it becomes clogged, no air can enter the cylinder. We inspect the throttle sensor, as well as the mass air supply sensor. To carry out such diagnostics, you will need a computer; it should be connected to a special connector.

Act four. We find out what volume of the fuel mixture enters the cylinder. For this purpose, you will need to measure the pressure in the fuel system (no more than 7 atmospheres). Use a pressure gauge. It must be connected to the injector ramp. To find out the pressure, you will need to measure it in four different operating modes of the engine: when you turn on the ignition, then at idle speed, at operating speed, when the tube is removed from the pressure regulator and the check valve tube is pinched.

Have you discovered that your blood pressure is insufficient? Most likely, the fuel pump or pressure valve in the fuel system has broken down. Is the pressure normal? Then, perhaps, the injectors are faulty or dirt has accumulated in them. At the end of the test, we diagnose the functioning of the fuel system using special equipment. Most likely, you will find errors in the electronic control unit.

Act five. Using a compression meter, we find out what the compression is in the cylinder. This device should be inserted into the spark plug hole of the cylinder that has failed. Then turn the ignition key and increase engine speed. Record the received data 2-3 times. Did you notice that the compression decreased by 15%? This means that the piston in the cylinder has become unusable. The problem may also be in the piston rings or valves. To determine the cause, you will need to disassemble the motor.

Misfires of cylinders 2 and 3 VAZ 2114

Guys, tell me what the problem is.

The 2nd and 3rd cylinders are not working, I changed the explosives, I changed the ignition module, I changed the spark plugs, I changed the brains, I changed the sensors, the compression in each cylinder is 14 points, the injectors are spraying, I can’t give any help for a week now. The timing belt is on marks.

How are things going with the valves in these cylinders?

georgiy63, April 10, 2022, 16:35, #3

How are things going with the valves in these cylinders?

SeVeN_7, April 10, 2022, 16:26, #1

compression in each cylinder 14 points

SeVeN_7, April 10, 2022, 17:22, #6

Are the armored wires worn correctly? on the MH there is a marking for each output

SeVeN_7, April 10, 2022, 17:22, #6

them... change everything, etc. if there is even a spark.

It would be better to measure the fuel pressure...

How is it determined that the gaps are at 2 and 3?

and if you consider that the spark is supplied in pairs... then it’s still worth digging into the ignition, the signal from the DPKV

what happened to the motor, what was the background of the malfunction, what was done or not done the other way around??

Flying, 10 April 2022, 17:16, #5

On the classic, after running in 50 km, it was 15-15.5, and for the “chisel” it was engine. normal meanings.

Flying, 10 April 2022, 17:39, #10

. what happened to the motor, what was the background of the malfunction, what was done or not done the other way around??

The TS should have written this in the first message. Because... They come in for a couple of minutes, “throw a die,” and you lay out the cards and guess. Everyone here is psychic.

There was a recent incident on Chirik; a small problem manifested itself in this way for a long time when it was cold. “thumped” into the muffler. Once it warms up to 50. everything is fine. in the summer it’s basically unnoticeable, but in the cold in the winter. 5-7-10 minutes each. it was so loud. in general. I skated like this for a couple of years. and then it began. troits, the car completely loses power. twitches. then everything is fine, and then again. We started moving the “braid” of the injectors with our hands. On the 3rd cylinder, engine performance either improves or deteriorates again. Corrected the contact on the force. Everything has been fine for about a month: it works immediately when cold, and in other modes without failures.

GENACL, April 10, 2022, 17:41, #11

I think on the classic after running in 50 km it was 15-15.5, and for the chisel it was engine. normal meanings.

if you measure compression according to the rules and on a working engine, then it should be 1.25 (1.2. 1.3) * compression ratio. in other cases, it was either measured incorrectly or there was a malfunction, for example, a lot of oil on the cylinder walls increases the compression value.

Well, or the compression gauge is lying.

georgiy63, April 10, 2022, 5:46 pm, #12

The TS should have written this in the first message. Because... They come in for a couple of minutes, throw a dice, and you lay out the cards and guess. Everyone here is psychic.

I can't help but agree. have to pull it out)))

and in 95% of cases it’s not a matter of the “bobbin” at all, but simply .

Flying, 10 April 2022, 19:11, #15

I can't help but agree. you have to pull it out))) and in 95% of cases it’s not a problem with the reel at all, but simply .

Flying, 10 April 2022, 19:10, #14

if you measure compression according to the rules and on a working engine, then it should be 1.25 (1.2. 1.3) * compression ratio. in other cases, it was either measured incorrectly or there was a malfunction, for example, a lot of oil on the cylinder walls increases the compression value. Well, or the compression gauge is lying. This is according to science if. )))

I know the difference in engine conditions with dry and oil compression. And if we talk about the rules for measuring compression, then they say that measurements need to be carried out on a warm engine, and people usually have problems with a cold engine in the winter in the morning. So it turns out that on a problem engine when measuring on a hot one. on the same classic, the neighbor’s seems to be 12, but on a cold one... only 7. I think it’s in any condition. 14 it seemed at that point in time. Also. It has long been known that both a separate engine has all the cylinders and a single cylinder. It may say the same 14 bar of compression. But in one case, in 3-4 piston strokes. Or maybe in 6-8. and this will be a different compression, and a different state of the engine, which means. and the performance characteristics of the car as a whole will be different.

Gennady, well, everything is already in a heap. Compression is measured on a warm engine. The rate of compression rise is also taken into account. You also tell me to measure by connecting the starter to 24V. here it generally jumps to 20. in 4 turns..

No, there are conditions for measuring compression - EVERYTHING. Based on them, conclusions are drawn. What's there for the cold, what's for the hot, etc. We’re not talking about what’s at our neighbor’s, and even on a problematic one. If it's 7 when cold, then you need to figure it out.

But for the best, it seems to me that a more complete picture is obtained if you measure it when it’s cold, measure it when it’s warm, there are a couple more options.

It’s not clear from your speech. measure compression whether cold or hot. and again. measure for the sake of measurement or for the sake of analyzing the condition of the motor. And this is not a bunch of stuff, these are practical notes that allow you to understand exactly the state of the internal combustion engine unit. yet again. There is a lower limit of values in the working tolerance range, but the upper limit is not limited as far as I understand this compression term. That's why. if the KShM and CPG are “dense”. There's nothing wrong with that. there will be more operating time before the cap. all other operating conditions being equal. And as an example, I know many drivers whose oil pressure on a warm engine is below 1. They have been working for many years. Yes, and compression... this is a rather relative value. without accompanying other measurements...the same pneumatic test. and other quantities. she will not be able to answer more “deep” problems in the car. its motor, and on superficial requests it’s quite easy.

and what ensures density, even in quotes. in the sense that there is a fully serviceable cylinder and timing gear, they provide the required compression of 12.5 units,

what can “compact” it and why.

with a certain relativity, not of magnitude, but of its interpretation, you probably talked about this too, I agree. nothing prevents you from continuing to operate the engine with a compression of 11 units. But when there are already serious failures and operational problems, then we decide what to do next.

those. By and large, there is not much difference in how we interpret this and other diagnostic data, and with what nuances for ourselves, the main thing is that they lead to reliable conclusions..)))

Professionals usually have only one parameter in determining the health of the motor. “it doesn’t burn oil”, but in determining the performance of the entire car: “the radio is screaming properly.” and the mechanic has a degree of understanding of a working CPG. “there is no shoulder at TDC of the piston” when checking for it with your finger. And for many people it even works. and they have their own clients, followers, students, colleagues, etc.. In general.” whoever is able to enter the TEMPLE OF KNOWLEDGE will find his TEACHER there!”

How to prevent the engine from stalling

After you check the motor and find out why it is misfiring, you should fix the problem. When spark plugs or explosive wires fail, it will be easy to solve the problem: just replace them. We take exactly the same actions if the ignition coils or switch are broken. However, when the fuel or air system is clogged, it will not be possible to quickly eliminate the breakdown. To clean the injectors, you will have to use a cleaning compound, such as Injection System Purge. It may also be necessary to replace the lambda probe, because it most likely functions incorrectly.

Have you cleaned the injectors, but this did not help fix the problem and the fuel mixture is flooding the spark plugs? Then we replace them. If the engine fails, the fuel pump and other components of the fuel system should be removed and new ones installed. It is not recommended to repair or install old elements. It may also be necessary to replace the air filter and parts of the air supply system if depressurization occurs.

At the very end, we remove errors in the electronic control unit; this may also be the reason that the motor is not working.

Checking the control unit

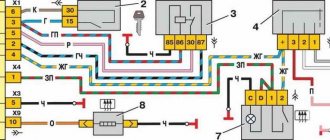

If the VAZ 2114 does not have a spark in cylinders 1 and 4, and the spark plugs, armored wires and ignition module are working properly, then the last reason remains - a breakdown in the electronic control unit.

This is easy to check - just connect to the unit using a light bulb with two wires. If the light blinks periodically, then the unit is working; if not, then the problem lies with it. In this case, you should disconnect the unit, open its case and remove the board, then carefully inspect it. Very often the breakdown of this device is the burnout of the transistors (they look like the largest electronic components with three legs). If one of them looks burnt, it should be replaced.

For this you will need:

- tester;

- soldering station or hair dryer;

- tweezers (preferably with ceramic tips);

- low-melting solder.

First you need to check the transistor using a multimeter. If it shows no signal, then the element will need to be unsoldered, and in its place soldered a new one - similar or similar in its properties (transistors can be purchased in stores for radio amateurs or ordered from China, for example, from Ali. In the latter case, they will cost less than 15 rubles).

Transistors should be desoldered and soldered using a soldering station or a single hair dryer, since they are made in chip design

If soldering is carried out with a soldering iron, then it should be done extremely carefully and using low-melting solders

After the transistor is replaced, the electronic unit will need to be assembled and installed in place, and then try to start the car. If all 4 cylinders work properly, then the problem has been resolved; if not, then you should continue your search and check all other electronic components of the device with a tester. If additional parts are found to be faulty, they should also be re-soldered.

If such a check does not show results or the task of finding burnt elements turns out to be too difficult, you will need to replace the unit with a new one - similar or similar in characteristics.

True, if an immobilizer is installed on the car, then the burnt-out unit should be replaced exclusively with exactly the same one (installing even a close analogue will lead to the fact that the car simply will not start).

The instrument panel backlight has disappeared, what should I do?

Therefore, it is worth understanding that if the instrument panel does not light up, then this problem must be eliminated immediately, but not all car enthusiasts are capable of this.

It is worth understanding that if the backlight disappears, then the problem lies somewhere in the electrical circuits. This is where you need to look for the problem. This will require design knowledge of the vehicle's on-board circuit, a tester and related tools, such as electrical tape, a soldering iron or more. Of course, it is not always possible to eliminate the problem locally, and faulty products have to be replaced completely.

Causes of malfunction

Where does the problem lie? As mentioned earlier, it is worth looking for problems in electrical circuits. Let's look at the main locations where problems may be hiding:

- Fuse.

- Backlight bulbs and their electrical circuit.

- Wiring.

- There is a fault in the fuse box.

- Damage to the board.

Solutions

So, when all the main reasons are, so to speak, “in the face,” you can try to determine the exact location of the breakdown, and also fix it yourself. As always, it is worth noting that if a motorist does not know the design of the car or is not confident in his abilities, then it is recommended to contact a specialist car service center.

Fuse

General view of a blown fuse

This is where you should start troubleshooting. To find out which fuse is responsible for the instrument lighting, as well as its location in the mounting block, you should refer to the technical documentation. Also, on the fuse cover it is written which element should be checked. If the fuse is found and replaced, but the problem does not go away, then you should look for the source in another place.

If you look at the dashboards of cars that were produced 60-70 years ago, you can see a very simple combination of them. This is a speedometer, indicators for coolant temperature, oil pressure, fuel in the tank, ammeter and 2-3 warning lights.

Today everything has changed dramatically. Modern cars are equipped with powerful engines and reach high speeds, so designers equip cars with a large number of passive and active safety systems. Their operation is monitored by indicator lamps installed on the instrument panel, and on some models by LEDs or LED strips.

Instrument panel for VAZ 2114, 2115, 2113