Today we will look at the design and diagrams of ignition systems for VAZ cars of all major models. Since carburetor versions of VAZ are practically history, we will dwell in detail on the ignition systems of injection cars. Their ignition system is based on an electronic ignition module. We also recommend that you carefully consider the choice of spark plugs and the quality of high-voltage wires, because the quality of the spark and, accordingly, the operation of the ignition system as a whole will depend on them. The information is intended as a reference guide for self-repairing a car.

Pinout, connection diagram and check of the VAZ ignition coil

Today we will look at the design and diagrams of ignition systems for VAZ cars of all major models. Since carburetor versions of VAZ are practically history, we will dwell in detail on the ignition systems of injection cars. Their ignition system is based on an electronic ignition module. We also recommend that you carefully consider the choice of spark plugs and the quality of high-voltage wires, because the quality of the spark and, accordingly, the operation of the ignition system as a whole will depend on them. The information is intended as a reference guide for self-repairing a car.

The main reasons for the lack of spark

General view of the engine 10-12 series 16 valves

Not all motorists know the reasons for the loss of spark, much less methods for diagnosing and troubleshooting problems. So, it is worth identifying the main reasons, and then deciphering why exactly they become the cause. Finally, you need to consider ways to eliminate the defect. So, what reasons could cause the spark to disappear:

All the reasons have been found and it is worth moving on to the process of eliminating this malfunction.

Are you giving me a spark? Troubleshooting!

First of all, it’s worth noting that you don’t need to rush to check right away. As practice shows, there is a certain sequence of actions and malfunctions that could lead to loss of spark on a 16-valve engine.

Fuel pump

Fuel pump made by Bosch

Ignition is not the first reason for the ignition failure on a car. Before getting into the electrical part of the car, it’s worth delving into the mechanics, so to speak. Turn on the ignition and listen to see if the gasoline pump is working. If it is silent, then you need to check whether gasoline is entering the cylinders.

It is worth starting the diagnostic procedure by checking the fuses for serviceability. Of course, you can only view the one that is responsible for the fuel pump (in this case, when you turn on the ignition, the pump will not pump), but it is recommended to diagnose everything for integrity. If at least one fails, it must be replaced.

The fuses are located to the left of the steering wheel under the light mode switch

If the previous procedure did not help, then we turn directly to the pump itself. For diagnostics, you will have to remove the entire module, which is located under the rear sofa, and disassemble it.

Spark plug

Location of spark plugs on the engine

The candle becomes the second boundary, which may cause the spark to disappear. We unscrew the elements and carry out visual diagnostics. If everything is clean and beautiful outside, then you need to measure the resistance and check the gap. Of course, you can check the performance of a spark plug on a special spark plug stand, but not everyone has one in their garage. Therefore, we do everything the old fashioned way.

When performing this operation, you should be extremely careful, since the voltage that enters the spark can be fatal. Thus, we check all the spark plugs for the presence of a spark.

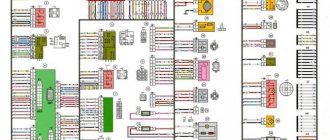

Pinout and diagram of the VAZ ignition coil

Pinout of ignition coil modules for various car models of the VAZ family:

Ignition VAZ 2101

1 – generator; 2 – ignition switch; 3 – ignition distributor; 4 – breaker cam; 5 – spark plugs; 6 – ignition coil; 7 – battery.

Ignition VAZ 2106

1 – ignition switch; 2 – fuse and relay block; 3 – EPHH control unit; 4 – generator; 5 – solenoid valve; 6 – microswitch; 7 – spark plugs; 8 – ignition distributor; 9 – ignition coil; 10 – battery.

Ignition VAZ 2108, 2109

Ignition VAZ 2110

Ignition VAZ 2111

Ignition VAZ 2112

Ignition VAZ 2114

Diagram of a non-contact ignition system: 1 – non-contact sensor; 2 – ignition distributor sensor; 3 – spark plugs; 4 – switch; 5 – ignition coil; 6 – mounting block; 7 – ignition relay; 8 – ignition switch.

How to check the ignition coil of a VAZ

If the ignition coil is faulty, the engine will not start. A characteristic sign of a faulty coil is its increased temperature when the ignition is turned off. This is easy to determine by touch.

Signs of a faulty ignition module may include the following:

- hesitant engine starting or failure to start;

- failures during sudden changes in speed;

- high fuel consumption;

- two cylinders do not work, the engine is feverish;

- lack of dynamics;

- a sharp drop in power;

- drop in power and thrust after warming up.

These symptoms may not only be caused by the ignition module. To determine the malfunction, it is enough to spend a few minutes diagnosing spark plugs, high-voltage wires and caps. This will eliminate the remaining elements of the ignition system and make sure that it is the ignition module that is faulty.

Checking the ignition coil is performed in one of 2 ways. The simplest one is to remove the central wire from the breaker-distributor, bring it to the motor housing and turn it with the starter, and a running spark should appear. After this, we check the energy supply to a separate spark plug, for which we unscrew the working spark plug, bring its contact to ground and attempt to start the engine. In this case, the spark should come from the wire to ground. If it is absent, the reason will be a malfunction of a system element such as the ignition coil.

To check the module in the second way, we only need a multimeter, then follow the step-by-step instructions:

- We check the power supply and the presence of pulses supplied from the ECU. We check the power between the central terminal (15) of the wire block connected to the module and the engine ground. When the ignition is on, the voltage should not be less than 12 V. Otherwise, either the battery is dead or the ECU does not work.

- We check the pulses from the ECU on the wiring block. We install one tester probe on connector 15, the second on the far right, then on the far left. The assistant cranks the engine with the starter, and at this time we record short-term voltage surges with a tester. If there are no impulses from the ECU, it is he who is to blame.

- We check the resistance on the secondary windings of the coils. We put the tester in resistance measurement mode and measure it at the high-voltage terminals of the module cover. Between pins 1 and 4 and pins 2-3, the resistance should be 5.4 kOhm. Otherwise, the module must be replaced.

- We check the resistance of the primary windings between contacts 15 and the rightmost, then the leftmost terminals. Nominal - 0.5 Ohm. Deviation is not allowed.

- Check the module for a short circuit. In ohmmeter mode, install one multimeter probe on the central terminal, the second on the metal body. There shouldn't be any resistance. If the device detects at least some resistance (other than unity or infinity), the module must be replaced.

Let's sum it up

As you can see, the VAZ 2110 ignition module is a fairly simple device consisting of contacts, coils, boards and wires. However, only contact connections can be repaired. Other elements are beyond repair and need to be replaced.

At the same time, before starting repair work, it is necessary to properly test the module. To do this, you should adhere to the general rules, and also take into account the subtleties and nuances discussed above. As a result, diagnostics of the VAZ 2110 ignition module allows you to quickly identify certain problems and eliminate problems.

Symptoms of a problem

It is extremely rare for two built-in coils to fail at once, so it is more likely to be possible to start the engine with a faulty unit. However, even an inexperienced driver will immediately suspect something is wrong. The malfunction will appear as follows:

- unstable (floating) idle speed;

- the engine has difficulty picking up speed;

- characteristic sound of the engine (triple);

- jerking when accelerating (while moving).

Operating a car with such a breakdown is possible (you can drive to a garage or car service station), but it is not advisable unless absolutely necessary.

Similar signs of unstable engine operation are possible with a number of other ignition or fuel supply faults. To differentiate possible breakdowns, the performance of the ignition unit should be determined. It would be useful to check the contacts of the wires coming to the device, as well as their integrity.

Methods for diagnosing device performance

The simplest method that will help determine the performance of the coil is to replace it with a similar working device. This is possible if there is somewhere to get it. Please note that the module must match the parameters of the device under test. If the engine with a working coil works as before the breakdown, the ignition module is definitely faulty.

The main testing method involves using a multimeter. It consists in determining the resistance of the secondary windings of the coils built into the ignition module. The method is simple and does not require additional skills. The device does not need to be removed for testing. The check is done with the engine turned off.

This is how you check the resistance of the secondary winding with a multimeter

- High-voltage wires are removed from the module sockets.

- The tester switch is set to the 20 kOhm position.

- The multimeter rods are placed in turn in the recesses of the corresponding contact pairs (1 and 4, 2 and 3).

- With an intact secondary winding, the performance in both cases is the same. Normally, the resistance should be about 5.4 kOhm (in some models the indicators differ, which needs to be clarified). If the resistance is much greater, then there is a winding break. The resistance is much lower - a breakdown. The coil is faulty and cannot be repaired.

Video: How to check the secondary winding with a multimeter

When is there an option to repair?

If during testing both secondary windings show integrity and serviceability, the reason for the inoperability of the coils may be a break in the soldering of the switch wires. Such damage is detected when the rear cover of the module is removed. If you have a soldering iron and know how to use it, you can restore the integrity of damaged contacts, while at the same time strengthening the rest. This, unfortunately, is the only failure of the ignition module that can be repaired.

Testing the ignition module can be done using simple do-it-yourself instruments. Based on our advice, you will be able to fully check both the module itself and other elements of the mechanism that may be the cause of the breakdown. We wish you success in this matter!

Read with this

Connecting and replacing VAZ short circuit

The procedure for removing and installing the ignition coil on old VAZ models:

- First, disconnect the central high-voltage wire leading to the distributor (ignition distributor).

- Disconnect all power wires from the coil contacts. Since they are fastened with nuts, you will need an 8 wrench for this.

- If you don’t know which wires to connect to which connector later, it’s better to immediately remember or mark them somehow, so that later during installation you can connect them correctly.

- Unscrew the coil housing. It is attached to a clamp (clamp), which is pressed to the car body with two nuts.

- After the work has been done, you can remove the ignition coil and replace it if necessary.

For new type VAZ cars:

- We remove the “minus terminal” from the battery.

- Remove the top protective cover of the engine. If the engine volume is 1.5 liters, then this part is missing and this step is skipped.

- We remove the high-voltage wires from the coil.

- Now, using a 13mm wrench, unscrew the two fasteners.

- Using a 17mm wrench, loosen one bolt securing the coil.

- We take out the module.

- Use a hexagon to unscrew the coil from the holder.

- Assembly is carried out in reverse order.

Particular attention should be paid to the connection, since high-voltage wires must be located in the strict order provided for by the design. If this is not done, the car will stall or the engine may not start at all.

Replacing the ignition coil on a VAZ is quite simple. Even a novice motorist can do this in his garage, and if everything seems too complicated, contact a car service center. Particular attention should be paid to the choice of product, since this will determine how well the engine and ignition system will work.

Method of using a spark gap for checking spark plugs

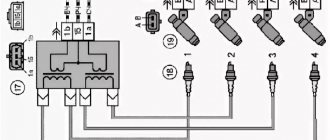

If the spark is lost on a VAZ 2112 injector 16 valves, then you can diagnose the breakdown using a spark gap made by yourself. The drawing shows a diagram for checking the presence of a spark simultaneously for 4 conductors,

and the photo shows a device for testing 2 wires.

Having installed the spark plugs in the spark gap, you need to turn on the ignition and observe the occurrence of an electric arc. If it appears on only one of the two spark plugs when the current is distributed simultaneously to 2 spark plugs, this indicates that the conductors or windings of the ignition module have been pierced to ground. If there is no spark on two spark plugs at the same time, the cause should be found in a malfunction of the controller or ignition winding. It is quite possible that this is caused by a broken wire. To determine the integrity of all electrical cables, their resistance is measured - as a rule, it should be identical in all wires of one electrical circuit. Check the serviceability of the coils using controller diagnostics for errors. If the module cannot be verified, then it is better to simply replace it with a new one (or a used one, but in good working order) and repeat the test again. In the case when there is still no spark on the VAZ 2110 injector 8 valves, you need to diagnose the controller and the electrical wiring connecting it to the coil. If there is no current in all cables, you need to check the power supply to the coil and the presence of a minus. If the wires turn out to be in good condition, then it is necessary to check the functionality of the sensor responsible for the location of the crankshaft. This must be done as follows. Turn off the ignition and the fuel pump stops working. Now, if we start cranking the crankshaft and the pump turns on, then the sensor is in working condition. However, it should be remembered that some models of controllers turn on the pump only when a certain crankshaft speed is reached. If the spark on the VAZ 2110 injector is lost due to a controller malfunction, then in most cases this is caused by a breakdown of the transistor. For this reason, modules also fail. If the module is in compound, the controller must be repaired. To carry it out, basic electrical skills and the ability to use a soldering iron are enough, so you can do it yourself. The sensor breaks very rarely, and if there is no spark in the VAZ 2114 injector, then most likely the contact in the sensor’s power supply is simply broken. This may be caused by dirt, oil, or improper installation of electrical wiring after repairs. If after cleaning all the connecting elements the problem does not disappear, proceed to more specific diagnostics.

We check the ignition module on the injection VAZ-2110 8 valves with our own hands

At different times, different engines were installed on the VAZ-2110 car, both carburetor and injection. However, regardless of the type of power system and the number of valves (8 or 16), all engines are assembled on the unit base of the old engine 21083 and 21093. The most progressive of these engines is the 16-valve 1.6-liter VAZ 21124 engine with a power of 89 horsepower. Today we will touch on the ignition module for 8-valve engines 2111 and 21114 (1.6 l), check its performance and find a suitable replacement for the failed module.

The engine won't start?

If, as a result of the check, it became clear that the spark hits the spark plugs, but the VAZ 2110 injector engine still does not start, then it is also necessary to diagnose it. The faults that cause this problem can be serious or not very serious.

At the same time, it is sometimes possible to cope with their solution without anyone’s help:

- It is necessary to purchase a spark gap and a Hall Sensor, which is inexpensive, but has an irreplaceable purpose. With their help, you can find out about the presence of a spark in the candles;

- Check the spark plugs to see if they are OK. A spark gap can be used for this purpose. However, you need to remember that the controller will be broken if candles are placed on its body;

- Perform fuel pump diagnostics. When you try to start a VAZ 2110 car, a characteristic sound will appear from under the rear seat. If there is no sound, then you need to check the fuses and the main relay. In a VAZ 2110 car they are located behind the side cover of the driver's seat.

If, after diagnostics, problems were identified with one of these elements, then you can fix them yourself. Usually the spark plugs begin to work after proper wiping, although this does not always happen, so they have to be replaced.

Version of the module on the 8-valve VAZ-2110

The top ten was equipped with two 8-valve engines of different sizes - 1.5 (2111) and 1.6 liters (21114). The ignition modules for these engines are different.

- The one and a half liter engine has a module with article number 2112-3705010,

- and the 1600 cc engine is equipped with module 2111-3705010.

A module for a 1.5 liter engine costs about 1500-2100, and the second one is 500 rubles cheaper.

Which is better?

SOATE devices manufactured in Stary Oskol have proven themselves to be the most reliable ignition modules.

Module structure

The module consists of two ignition coils and two high-voltage switch switches.

The coil generates a high voltage pulse, and it is a simple transformer with two windings, primary (induction voltage about 500 V) and secondary (induction voltage at least 20 kV). All this is assembled in a single housing, on which there is a connector for signal wires (from the engine control unit) and four terminals for high-voltage wires.

The module operates on the principle of an idle spark - it distributes sparks in pairs to cylinders 1-4 and 2-3 according to impulses transmitted from the ECU.

Design

The design of the ignition module is quite complex, since it combines technology and electrics. The device serves to create high voltage transmitted to the spark plugs. It is this supplied current that is the basis for ignition.

The operation of the module ensures fuel combustion and, accordingly, engine operation. In very simple terms, the car won’t go anywhere without the module.

For VAZ models, the use of two types of ignition modules is provided:

- Separate;

- Block.

Block ones differ in that the coils operate one per pair of spark plugs. These are the devices that are installed on the “fourteenth” model of the domestic automaker.

The coil distributes power to two candles at once, and its design includes the following elements:

- High voltage wires;

- Low voltage terminals;

- Secondary and primary winding;

- Core.

Separate modules, where the coils supply a separate circuit to each of the 4 sections, are distinguished by the output of high-voltage wires through a spring contact. Block ones are easier to check, they are easy to remove and return to their place.

It is noteworthy that with a size of 11x11x7 centimeters, this block weighs about 1.5 kilograms.

Signs

- If one of the module coils completely fails, then two cylinders do not work. This is clearly visible even to the naked eye - the engine is feverish at idle, starting is difficult, fuel consumption is sky-high, loss of dynamics.

- To eliminate all other components of the ignition system, make sure that the spark plugs are in working order. To do this, unscrew them and check the spark on each of the spark plugs by cranking the engine with the starter and placing the spark plug with the high-voltage wire on the head so that the body (threaded part) of the spark plug touches the engine mass. If there is no spark or it is weak, replace the spark plug with one that is known to work.

- If this does not lead to anything, check the high-voltage wires. Thus, we will exclude spark plugs, caps and high-voltage wires from the list of non-working elements. Next we will check the ignition module.

How the device works

Instead, an ignition module is used, consisting of high-energy control electronics and two coils. The advantage of the new system is that it does not require regular maintenance and maintenance, since there are no moving elements. Also, no special adjustment of the system is required. The reason lies in the presence of a controller. is the one responsible for setting up and adjusting.

How to check the ignition module?

- First of all, we carefully inspect the module body. There should be no chips, burns or cracks on its surface. A module with a damaged casing is replaced without any hassle.

- If the spark is unstable only on cylinders 1-4 or 2-3, one of the module coils is probably damaged. In any case, we will conduct a comprehensive check of the device. For this we will need a regular multimeter.

Nothing happens when I turn the key in the lock.

If the starter does not turn, then the spark has disappeared between the ignition switch and the starter. This most often happens when the battery is low or faulty. When checking with a voltmeter, a normal battery should show at least 11.8 V, and when diagnosing with a hydrometer in each jar during measurements, the data should not be lower than 1.22.

Other causes of problems with engine starting may be breakdowns:

- The ignition lock cylinder makes itself known the moment you insert and turn the key. If this happens too easily or, on the contrary, you feel difficulties, then the problem is in the lock. It needs to be replaced with a working one.

- The starter or ignition relay is located under the instrument panel. Only a qualified auto electrician can check the functionality of these units. On your own, you can simply replace the relay with a working one.

- The starter’s “retractor” often jams; in this case, the spark could disappear right along the way. Experienced car enthusiasts recommend hitting the starter in the field with a key or something heavy, but just be careful with the force. If you managed to get to the garage, you can check the starter using the battery. Ideally, when you press the starter housing at the zero phase, and stretch the wire with the “crocodile” from the positive to the “retractor”, the unit should “come to life”. If nothing happens, then the problem is in the “retracting” part. If the relay is working, the problem may be in the brushes; it makes a loud noise and the starter does not turn if the bendix is faulty.

- Often the spark disappears at the point of power supply to the starter. The circuit can be checked using a multimeter. In this case, you need an assistant who will turn the key at the moment when you begin to take measurements.

The spark in the VAZ-2110 often disappears for another reason - banal oxidation of the contacts. We have already mentioned cleaning them from oxidation; if servicing the ECU did not help, then you should look at other wires. For example, trace the course of a mass conductor. The most vulnerable places on it are where it contacts the body and approaches the battery terminal. If a fault is found at the terminal, replace the wire. At the point of contact with the body, it is enough to simply clean it with a metal brush.

Diagnostic procedure

The diagnostic procedure can be as follows:

- Disconnect the connector with signal wires from the module.

- Turn on the ignition and check the voltage at terminal 15 (central) of the control wire block. The rated voltage is 12 V. A drop or absence of voltage when the battery is charged indicates that the engine control unit does not supply power to the module. This means the reason lies in the ECU.

- We check the resistance of the primary windings of the coils - put the multimeter in resistance measurement mode and take readings from the rightmost and central terminals, then from the leftmost and central terminals. The nominal resistance of the primary windings is approximately 0.5 Ohm.

We measure the resistance of the secondary windings between terminals 1-4 and 2-3 high-voltage wires. Nominal value: 5.4 kOhm. If the readings do not correspond to the nominal value, the coil is not working correctly.

Check the module for a short circuit. To do this, install one tester probe on the central pin 15, the second on the metal body. The device should show the absence of a short circuit (one or infinity). Otherwise, one of the coils has shorted to the housing.

Starter problems

Many VAZ 2110 owners had a situation where the starter did not turn after inserting and turning the key. They heard characteristic clicks. This indicates that the solenoid relay is not working.

But the fact is that the “ten” does not have a starter relay, that is, an ignition relay as such. Instead, a solenoid relay works. It is supplied with a positive contact from the ignition switch. Mount this relay to the starter. It has a round shape and is approximately half the size of the starter itself.

Errors

A module malfunction can also be determined using an error scanner. Error codes associated with the module are:

- R-3000, R-3001, R-3002, R-3003 and R-3004 - gaps in sparking, the module itself, spark plugs, high-voltage wires or the ECU may be to blame;

- R-0351 - the coil of cylinders 1-4 does not work;

- R-0352 - the coil of 2-3 cylinders does not work.

The scanner readings do not yet indicate problems with the module itself.

It is possible that the spark plugs are not working or the high-voltage wires are broken, but if we initially diagnosed them, then the fault lies entirely with the ignition module. In this case, we can repair it ourselves, or buy a new one, which is faster, easier and guarantees uninterrupted operation of the ignition system. Good luck to everyone, strong spark and good roads!

Stage one

Typically, the symptoms of the problem are as follows: the starter rotates properly in its standard mode, but the engine does not want to start. One of the most likely causes is a fuel pump that does not start. By the way, on injection “tens” it is submersible and is placed directly in the tank.

View gallery

You can check the element by the presence of operating sound. Turn on the ignition - there should be a hum in the area of the rear seats. Sometimes he is missing. In this case, you should check the fuses. The VAZ-2110 is an injection car, and the fuse box is located on the side of the center console on the front passenger side. It is necessary to unscrew the fasteners, then remove the cover, check the fuses for functionality and, if necessary, replace them. If the elements are fully operational, then you need to check whether the relay will turn on, both the main one and the fuel pump. You can feel the moment of switching on with your finger. A characteristic click will also be heard.

If the fuel pump is operational, use a pressure gauge to check the presence of fuel in it. If there is no pressure gauge, then press the spool at the end of the fuel rail. This element may be contained in a protective cap. The pressure will be quite noticeable, although its power cannot be determined. A running pump and no pressure may indicate an obstruction in the fuel line. This may be caused by a clogged fuel filter.