As practice shows, failure of the speedometer and tachometer is a fairly common occurrence.

On the one hand, such breakdowns do not affect the basic functions of the car, but on the other hand, the driver does not receive important information, which can lead to more serious malfunctions or even an accident.

Therefore, if your speedometer stops working or the tachometer needle begins to “take on a life of its own,” you need to urgently take some action.

In this article we will look at what and how to do.

Tips for motorists

Quite often, in domestic cars equipped with ECUs, there are malfunctions in the operation of the dashboard instruments. These include the tachometer.

Many drivers, especially beginners, ask the question why the tachometer on the VAZ 2114 does not work ? There may be several reasons for this.

First, let's check the serviceability of the indicator itself; to do this, we carry out diagnostics on the instrument panel by clicking on the odometer reset, with the ignition off, turn on the ignition, as a result of which all the instrument panel arrows should rise to the maximum level and return back. If the tachometer needle does not respond during diagnostics, the pointer is most likely faulty; the remedy is to replace the instrument panel. It’s even easier to check the indicator, if the car has an on-board computer and it shows the revolutions, it means the problem is in the indicator.

Sometimes a malfunction occurs, expressed in jumps in the tachometer needle, or periodic shutdowns (works, does not work), most likely the fault here is poor contact in the wire blocks that supply and control the tachometer, or weak ground contact, on the tachometer or on ECU. It is also possible that the control circuit from the computer to the tachometer may be broken. The solution is to check the quality of the contacts on all tachometer wires. Also, the tachometer may not work together with all the other devices; the reason here is most likely in the supply of power to the panel, or rather its absence or not constant contact. The elimination method is to eliminate the cause of the lack of power - a blown fuse or an open circuit.

So, why does the tachometer on the VAZ 2114 not work? It does not work because either the device itself is faulty, or the circuits that supply and control it have a break or unauthorized contact, i.e. short circuit.

The tachometer in a car is used to indicate the number of revolutions of the engine crankshaft. Let's look at why the tachometer doesn't work and how to find and eliminate the cause of the breakdown. We will definitely dwell on the device and principle of operation, which will help to find out why the tachometer stopped working, the needle twitches or behaves inappropriately.

Poor contact on the connector

Driving on bad, bumpy roads leads to a violation of the reliability of fastening the contacts and plugs of the devices inside the panel. Low reliability of fastenings leads to loss of contact on the tachometer connector.

In the photo above you can see the white plug for connecting the wire block. The presence of oxides on the surface of the plug can interfere with the normal operation of the tachometer. Also, due to a poor fit of the plug, the sensor may act up and periodically display incorrect speed readings. On the surface of the board there are transistors, resistors, microcircuits, and board tracks. Failure of any of the listed elements can lead to failure of the device.

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Types of tachometers

There are two types of tachometers: analog and digital.

Analog instruments use an induction magnetic coil, thanks to which the number of crankshaft revolutions is shown by an arrow moving along the scale. This device is installed as standard on most machines. It is almost the same size as the speedometer and is located next to it on the dashboard. This arrangement of the device is convenient for the driver, since it is always in front of the eyes and makes it possible not to be distracted from the situation on the road.

In digital devices, information is reflected on a liquid crystal or diode display. The number of revolutions is transmitted either by a magnetic sensor that records the passage of a specific point on the crankshaft near the measuring device. An electronic sensor – optocoupler – can be installed. It generates a beam of light and determines the rotation frequency by its reflection from nearby objects. The digital device is useful when tuning engines and operations with electronic ignition units.

Photo gallery

1. Analog meter

2. Digital measuring device

Devices differ in their installation location. They can be regular or remote. The default mode is usually set to analog. If there is no standard device, you can install an external one yourself. It is often installed on racing cars to provide more accurate RPM readings, as speeds must be changed at a certain number of shaft revolutions. To achieve this goal, they are equipped with indicators that indicate when a certain speed is reached.

Information on pointer devices is better perceived by humans than on digital ones.

True, if the tachometer needle twitches, then the information may be unreliable. The advantage of digital analogues is accuracy, although under normal conditions this is not of great importance.

General information about VAZ-2114 sensors

Sensors look like small mechanisms. However, their role in the operation of the entire vehicle system is simply colossal. They signal the remaining fuel in the gas tank, inform the driver of the coolant temperature, and determine the position of various engine elements in a certain operating mode. In order to know your car well and understand what could fail in a given situation, you need to know the entire list of mechanisms involved in the system.

We list all the sensors on the VAZ-2114 injector 8 valves, which are the most important:

- Crankshaft positions.

- TPDZ.

- Camshaft position sensor.

- DTOZH.

- Speed.

- Idle move.

- DMRV.

- Lambda probe.

These devices are in most cases located in the engine compartment. Almost all of them are installed at the factory during vehicle assembly. But the driver himself can install some sensors at any suitable time. It is also important to know how each of these devices works and what primary task it performs.

Device failure

After checking the connectors, ground and integrity of the wiring, you should examine the condition of the device. Because The design of the speed arrow includes a gear motor; its failure can also cause a malfunction.

Finding a separate part for installation in an old panel is difficult, because... This motor rarely fails. Purchasing a new panel assembly is expensive. The cost of a new spare part is about 300-500 rubles, but it is often difficult to find this element in stock. To restore its normal operation, you can clean the motor from dirt and try to fix the mechanical failure.

Crankshaft position sensor

You can often hear drivers with many years of experience calling this mechanism nothing other than a synchronization sensor. This name comes from the principle of operation of the device. The tasks of the DPKV are to synchronize the operation of the electronic unit and the gas distribution mechanism.

The VAZ-2114 is equipped with an inductive type DPKV. The cost of such a sensor is relatively small. If a vital controller for a car fails, most drivers prefer to immediately replace the device with a new one.

If the DPKV breaks down, further operation of the vehicle will become impossible. Without this mechanism, the fuel supply system will stop working, because the ECU will not receive information about when it is necessary to give a command to inject fuel into the cylinders. The location of the DPKV is in close proximity to the camshaft.

Electronics are responsible for fuel delivery in the VAZ-2114 car system. Without TPS, the control unit will not be able to determine the optimal time to supply gasoline. Deviations from the correct operation of the TPS lead to an increase in the amount of fuel consumed. The operation of many other car systems depends on the angle at which the remote control is located: cooling, fuel supply.

see also

The TPS is located near the idle speed sensor. In the “fourteenth” system, the work of these two devices is closely linked.

When the TPS breaks down, the car begins to twitch in a certain position of the damper, and instability of engine operation is also noted. All VAZ-2114 8 valve sensors are interconnected in their operation, so two different devices sometimes exhibit the same symptoms of malfunction. If symptoms of a breakdown occur, it is necessary to take a comprehensive approach to checking all controllers.

Troubleshooting Methods

Usually, the functionality of control devices can be restored by replacing the speed sensor. As an example, consider the Hyundai Accent car. The speedometer needle twitches - we go to the store to buy a new speed sensor. With a high mileage of this brand of car, this is a completely typical problem that many motorists encounter. If the gearbox is mechanical, then the problem is most often solved by replacing the cable. Lubrication with WD-40 also helps, but this is more of a temporary solution, so the problem may return in the future.

Camshaft position sensor

This mechanism is located near the cylinder block. The main task is to transmit data to the ECU regarding the current operating cycle. Among specialists, the mechanism is called a Hall sensor. The operation of the device is based on the following principle: in accordance with the location of the crankshaft, the position of the gas distribution mechanism is determined. The data received by the sensor is reported to the electronic unit. Fuel is injected and the mixture is subsequently ignited.

diagram, icons, shield and repair

The instrument panel of the VAZ 2114 is designed to inform the driver about the condition of the vehicle components. Beginning motorists should find out more about the functions and capabilities of the panel, as it allows timely detection of some serious breakdowns. In addition, some users may be interested in tuning the panel, so below are tips on what should be changed in the interior and how.

Main information devices

The instrument panels of the VAZ 2114 show information about the status of important operating components of the car. The main part is an information block with two round scales and several smaller indicators.

Indicators

The VAZ 2114 injector dashboard indicators play an important role in informing the user about malfunctions. They help prevent errors in the system, so it is important to know which indicator means what. How does the panel work? If any problem occurs, the sensor immediately sends information to the panel, and the driver will see an orange signal light up.

The earlier version of the 2114 instrument panel had some other symbols, such as emergency oil pressure, handbrake engaged, Chek Engine light, and several others that indicate minor operating errors, but which are no longer used.

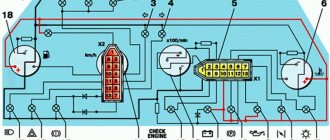

Pinout

The VAZ 2114 instrument panel pinout shows the correct order of connecting the wires of measuring and information devices, in other words, this is the electronic circuit of the instrument panel. You will need it if you want to make any changes to the standard panel configuration or carry out repairs and replacement of parts. For each car model and specific dashboard, the diagram will be slightly different; for example, the diagram on the VAZ 2115 has significant differences from the 2114 model.

The circuit consists of 26 connections, which are made according to an electronic circuit. Usually the diagram should come with the car manual. It’s not a problem to get a description of her work now.

There are two pads inside the panel - one red and one white. The devices will be connected to them in a certain sequence.

There is nothing complicated in the pinout if the user has basic knowledge of the rules for connecting wires - plus to plus, minus to minus. If you have a diagram of the instrument panel on hand, you can start tuning individual devices or the entire set so that the instrument panel of the 2114 model becomes more visually pleasing.

Tuning options

The instrument panel of the 2114 looks rather dim, so the first option for tuning it may be to install a backlight. This is done quite simply:

In order for the instrument panel on the VAZ to have a clearer visual perception, the buttons should also be backlit.

Conclusion on the topic

The 2114 dashboard is quite simple in terms of both operation and repair.

Of course, her appearance leaves much to be desired, but this can be changed by adding a little visual effects. The last tuning option is to completely replace the panel with a European version. Everything you need is already installed, all you have to do is connect a few wires and turn on the new display system.

Replacement

Practice has shown that the weakest unit in the speedometer system is the EMF. The plastic parts of this unit are very fragile and quickly wear out from friction. A faulty sensor will have to be completely replaced. To do this you need:

- Disconnect the “+” terminal from the battery.

- Remove the air purification filter and its pipe.

- Disconnect the current-carrying EMF connection.

- Using the “22” key, unscrew the part.

- Wash the sensor installation area thoroughly with solvent.

- Replace the rubber seal ring.

- Install a new EMF analogue.

- Reinstall previously dismantled parts.

Attention! Devices with gears have different numbers of teeth. If you install a part that differs from the original, a problem may arise in the accuracy of the speed readings.

Private situations

General signs do not always indicate specific breakdowns. There may be exceptions.

If individual devices refuse to work, it is quite possible that this is their personal problem. You'll have to parse the specific pointer. It may have a cracked gear that needs to be replaced.

Also, why doesn’t the instrument panel of the VAZ 2114 work? If the fuel gauge and tachometer are capricious (either they function, or they don’t react at all), the contacts and the mounting block are normal - you need to do a small check.

Reset is pressed and held, and the ignition is turned on at the same time. Raised arrows indicate the need for further searches. Lifeless - that microcracks have appeared in the shield itself. You will have to remove it and examine all soldering and traces under a magnifying glass. In principle, these are all the main options. If calling all the listed components and parts did not lead to the revival of the instrument panel, your case is individual, and you will have to determine the situation in the company of an experienced auto mechanic.

The sensors are checked after its dismantling. To carry out diagnostics, you must have a thermometer and a multimeter.

Let's start checking

- It is necessary to boil water and immerse the thermometer in it.

- Next, set the switch on the device to measure resistance.

- We connect the probes to the sensor and lower the DTOZH into water so that its contacts do not get wet.

- We compare the obtained readings with the table below.

If the parameters do not match, then the sensor is faulty and requires replacement.

Analogs

Original speed sensors for injection VAZ-2114 are marked with article number 2111-3843010. This is a part in a plastic case, with a drive gear made of the same metal. The German analogue in a metal case is also suitable for this car model, but to install it you will have to redo the electrical contact socket.

Domestic EMFs are quite reliable. Their declared service life is up to 100–150 thousand kilometers. Rapid wear occurs due to dirt or damage to the housing itself during the repair of other components. You just need to monitor the condition of the part during operation.

Connection

Connecting a tachometer to the electrical circuit of a VAZ-2114 car is not difficult. It is necessary to be guided by a clear connection diagram.

Below are step-by-step instructions explaining the diagram:

- Terminals “2” and “8” go from the white power connector on the dashboard to the tachometer.

- Terminal “2” is connected to the pulse, central contact of the tachometer. Connects directly to the ignition unit, and in parallel to the router and ECU via terminal “7”.

- Terminal “8” is connected to terminal “3” of the ECU.

- Terminal “1” is “ground” and is connected to terminal “6” of the ECU.

When connecting, you should especially carefully inspect all plug connections for contact rigidity. All contact connections from the instrument panel go through the safety block; without it, connection is prohibited.

More complex breakdowns

When, along with the tachometer, absolutely all the electrical equipment of the panel fails, you will have to look beyond the fuses. There is a risk that the problem lies in the ignition system. In particular, here the contacts on the lock are often charred or the track on the board of the VAZ-2114 mounting block is damaged. In the first case, the mechanism must be removed and cleaned, and in the second, the element is replaced with a new one.

The tachometer needle began to twitch - such a malfunction is far from uncommon. To find the cause, it is recommended to use the self-diagnosis mode of the standard on-board computer. It will show a list of errors, and all you have to do is start fixing them.

If there is no ECU, then first check the wiring, since a jerking arrow often indicates poor contact.

Also carefully inspect the mass of the VAZ-2114. This is all the more necessary to do when other panel devices are functioning with obvious disturbances.

Be sure to find out whether the contacts of the distributor are clean and whether the capacitor installed in its cover is still working. The latter loses capacity over time, which disrupts the operation of the entire vehicle ignition system.

Sometimes problems arise immediately after replacing the old tachometer of the 2114 model with a new one. Usually this is not a malfunction, but a bad setup. Do this:

Symptoms

Poor tachometer performance is due to several reasons. Symptoms of the malfunction are:

- Complete tachometer failure. The arrow completely or partially stops functioning. Often freezes in a certain position or trembles. The cause of the phenomenon may be an unstable contact connection in the power connectors.

- Poor start of a cold engine. The problem may be related to the connection of the autostart system to the tachometer. A connection problem or error disables the tachometer.

- Loss of power. Power is lost due to incorrect calculation of the fuel supply by the on-board system.

- Engine speed instability at low speeds.

- Increased fuel consumption.

- Complete loss of performance of the power unit. The cause may be a failure of the crankshaft sensor.

These symptoms become the reason for checking and troubleshooting.