October 28, 2015 Lada.Online 237 616 112

In 2013, AVTOVAZ decided to modify the manual transmission (manual transmission 2180). A cable replaced the gear shift drive with rods. The design of the box was modernized, and the following serial number was added to the name (manual transmission 2181). Let's look at the features of a cable gearbox.

REQUIREMENTS AND SUGGESTIONS

The new product, which is installed on the “Norma” and “Lux” versions, is based on the same gearbox that appeared on the VAZ-2108 and, with minor upgrades, has survived to this day. Its weaknesses are well known: difficult activation, large lever strokes, smeared switching pattern, low vibration comfort.

Figuring out what and how we could improve, we agreed on one thing: not to touch the gear part, namely the shafts, gears, and synchronizers. Otherwise, huge financial costs will be required to launch a new gearbox into production - without high-precision equipment, it will not be possible to ensure the proper quality of engagement, operation and synchronization.

So what's new in the box with the VAZ-2181 index?

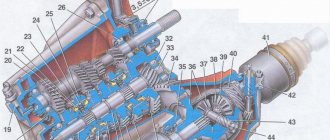

Main elements of the VAZ-2181 gearbox:

Work principles

Old box with modernization

The new design is the old gearbox with significant upgrades. The previous design is known to us for its shortcomings: large lever strokes, difficult activation and low vibration comfort.

The cable driven gearbox is not a new type. The device can be safely called an updated version of the previous design, which has been made more convenient by improving it. It follows from this that the driver, accustomed to the previous version of the box, will not need to relearn. For cable gearboxes, the diameter of the clutch has been changed, increased from 200 to 215 mm. The starter was moved, installing it along the engine.

Two cables, when interacting with the box, will dampen the transmitted vibrations. This will make the shifting smoother and also reduce the travel of the gearshift knob. The cable design allows shifts to be crisp rather than harsh. In addition, the travel of the shift lever has been significantly reduced. Cable drive is superior to other design solutions in terms of seasonal changes in weather. As a result of replacing the traction drive with a cable drive, the amount of oil poured decreased by 30% due to the transfer of the gear selection mechanism to the top from the bottom.

Severe frost helps the butter thicken. A conventional gearbox requires a lot of effort to start the engine. But the cable mechanism eliminates this problem because the shift mechanism is not submerged in oil, as it is located on top.

The use of a cable drive helps to significantly reduce longitudinal movement - up to 13 cm, and transverse movement - up to 9 cm. The design is made reliable and maximally optimized. This type of gearbox is good for cars with high power engines. Since the clutch has been increased, its torque is quite high.

Box with upgrade

Shift quality and machine vibration comfort

The gearbox is a complex unit. According to many car enthusiasts, changing gears is not an easy operation. Over time, each driver gains experience in driving a car. But during the adaptation period, a huge load falls on the transmission. Drivers who lack confidence often forget to press the pedal when changing gear.

The design of the box makes it possible to have less impact on the box itself due to the reduced number of strokes. In addition, the possibility of oil leakage is eliminated. Car manufacturers believe that this box option will not affect the cost of the car.

Reviews of the updated gearbox confirm the fact that it is silent when starting the engine and when releasing the clutch. Car enthusiasts talk about easy start-up and lack of vibration. Many users agree that it is now pleasant to change gears. In reviews, some motorists point out that almost nothing has changed in the movements of the lever, but it does not dangle and clicks quietly due to the absence of play in the drive.

1_no_copyright

1 - main gear drive gear;

2 - secondary shaft;

3 - input shaft;

4 — fifth gear fork;

5 — fork for selecting third and fourth gears;

6 — reversing light switch;

7 — clutch housing;

8 — gear shift mechanism;

9 - central lock.

SYNCHRONIZER

So, the gear part remains the same. Almost the same: in first and second gears, we still had to install multi-cone synchronizers. Firstly, for the sake of reliability: the second stage is the most loaded, and the multi-cone will undoubtedly extend its life. Secondly, to reduce the effort when shifting gears. In addition, they plan to install the VAZ-2181 gearbox on models with more powerful engines. Therefore, a clutch with a larger diameter (215 mm) is required, which naturally has a larger moment of inertia. This is an additional argument in favor of a multi-cone synchronizer. A more powerful clutch required a different housing, because the previous one accommodated a maximum of 200 mm disc. The starter also had to be moved; now it is located not along the box, but along the engine.

The first samples were equipped with a three-cone synchronizer. But calculations have shown that double-cone, cheaper ones, can withstand the required torque with a margin (see pictures). Among other advantages, they made it possible to get rid of the problematic cone on the gears of the first and second gears, which is in contact with the synchronizer ring and requires high precision in manufacturing. The ring set now creates two friction surfaces for smooth and efficient synchronization. In addition, the German manufacturer (Ho¨rbiger) applies an additional coating to the intermediate ring, which reduces wear and ensures stable operating parameters, including the required coefficient of friction.

To make shifting easier, the bevel angle of the synchronizer teeth was reduced (from 125 to 100º) and the preload force (from 150 to 70 N). If the developers had kept the same single-cone assembly with these changes, it is possible that a crunch would have appeared when the second stage was quickly implanted (especially at low temperatures) - the so-called synchronizer breakdown. This will not happen with a multi-cone due to the larger working surface.

Structure of VAZ-2110 (A) and -2181 (B) gearbox synchronizers:

Characteristics of all types of Lada Granta gearboxes

The first manual transmission of this sedan and liftback class model received the index 2180. It was soon replaced by a modernized cable-driven gearbox, which is indexed as 2181. It is installed starting with the “standard” configuration.

Traction and cable gearbox Lada Granta

The difference between these two checkpoints is obvious. The first and most important thing is to use, instead of rigid rods that increase vibration on the body and rocker, more flexible cables from the Japanese manufacturer Atsumitec. In addition, gearbox 2180 differed from 2181 in other parameters.

- The 2181 has cone-shaped synchronizers, which reduces the impact on the gear lever when setting 1st or 2nd speed.

- The clutch disc has become larger in diameter (215 mm). Because of this, the clutch housing increased in size, and the starter began to be located along the internal combustion engine.

- The synchronizers received teeth with a reduced angle bevel (100 degrees), and the initial preload force was reduced to 70 Nm.

- A different mechanism for selecting speeds was developed by Schaeffler. In addition, it was moved upward, which made it possible to reduce the effort when switching in cold weather and eliminate oil smudges.

- The clarity of gear shifting is made possible, among other things, thanks to the selector plate.

- Instead of mineral gear oil, semi-synthetic oil was used from the factory, and the oil volume was reduced to 2.2 liters.

Structurally, the gearbox has become not only more reliable, but also more comfortable for the driver. Vibrations to the gearshift lever and the body as a whole have decreased significantly. The speeds began to turn on clearly and without delay. At the same time, the modernization of the gearbox on the Lada Granta and Kalina 2 entailed an average increase in price by 5,000 rubles. According to experts, the main difference between the updated transmission is not so much in reliability, but in the quality of gear selection.

What is characteristic is that the new editions of the Lada Priora did not receive a cable gearbox; this car is still equipped with an outdated VAZ 2180 with rigid rods.

Features of a robotic gearbox

In addition to the updated mechanics, the Lada Granta since 2015, starting with the “luxury” configuration, can be equipped with a robotic gearbox. The new transmission will be available in “standard” and “luxury” variations. According to the engineers, this device should completely eliminate the negative impact of the human factor, in which various errors are made.

Granta became the first car of the VAZ family to receive a robotic transmission option. The main manufacturer was the Japanese company Jatco, known in its field for the development and production of robotic, automatic transmissions and CVTs. They began installing a 4-speed gearbox, proven over the years, on the Grant. Not the most modern, but reliable.

Features of automatic transmission

The period of adaptation of the robot and the release of the first pilot versions of Granta on the machine lasted quite a long time. During this time, the symbiosis of domestic and Japanese developments was subjected to numerous calibrations. The modernization included about 30 modifications, and engineers from Austria were involved in the process. Only after this did the automatic transmission go into production.

Experts even took into account ergonomic issues: the hand fits comfortably on the gear shift lever. The selection of the appropriate modes is indicated on the selector; the specified mode is also duplicated on the BC screen. The only drawback revealed during operation is the unreliable fixation of the lever in the selected mode.

The gearbox operates in several modes. First and second gears are fixed. There is an overdrive button, thanks to which the automatic transmission will not switch to fourth speed. This mode is relevant when overtaking on the highway. Fixed first two gears are used for off-road driving or long uphill climbs. In winter, the transmission will not engage in higher 3rd and 4th gears until the oil warms up to 15 and 60 degrees, respectively.

Unlike the manual transmission of the Lada Grant, the automatic transmission does not have a flywheel. A drive disk is used instead.

Features of the automatic transmission scheme led to a decrease in the vehicle's ground clearance. The electronics that control the device are located behind, on the left side below the headlight. Many believe that such a location will lead to uncontrollability of the car in an accident. But engineers think differently. Automation will reliably control the work. Judging by the reviews, the system really functions flawlessly, and this is good news.

SWITCH MECHANISM

In the old box it is located at the bottom and bathes in an oil bath. After spending the night in the cold, the oil thickened, making it difficult to change gears for the first few kilometers. In addition, at the bottom of the box there were clamps for the rods and reverse forks, a reverse light switch, and a gear selection seal - all of these are potential sources of leakage. Sealants and other materials, of course, helped, but the problem was radically solved only by moving the mechanism upstairs.

The new mechanism is a separate module. It can be installed last and removed if necessary without disassembling the box. This is technologically advanced not only in production, but also in repair. Already at the concept stage developed by the VAZ team, a selector grill appeared in it, clearly repeating the gear shift pattern and setting the lever stroke when selecting gears. The mechanism includes a lock against accidental reverse gear, which is only accessible from neutral.

Having embodied the concept in metal and made it work correctly, the unit was sent for fine-tuning to the German company (Scha¨ffler), which has long been engaged in the engineering and production of engine, transmission and chassis parts. One of the most interesting changes proposed by foreign experts is the so-called three-dimensional central plate instead of several return springs and locks. Its spatial shape is calculated by a complex computer program, and the manufacturing equipment requires high precision. After all, the central locking ball walks along this plate, and it is this plate that sets the necessary forces when turning on and selecting speeds.

The characteristics of the mechanism were selected on the original simulation stand. The tester sits down on the seat and begins to go through the gears, while the automatic system imitates the shift pattern, forces and lever strokes implemented on a specific production car. You can also upload your own settings. Don't like an overly tight lever? A couple of taps on the keyboard and the effort is reduced. So, step by step, we selected the optimal settings for the “eighty-one”. The computer processed the data and produced parameters for constructing an accurate mathematical model, according to which those very tricky central plates were made.

Transmission malfunctions on the Lada Granta and methods for eliminating them

First, we need to note the disadvantages of a manual transmission as a cheaper and more popular transmission option on these cars. The problems and their solutions are clearly presented in the table.

| Fault type | Solution |

| Noises during transmission operation | |

| Gear teeth are worn. | Replacing gears. |

| Severe bearing wear. | Replacing bearings. |

| The oil level is below the permissible level. | Add oil and repair leaks, if any. |

| Difficult to change gears | |

| The clutch does not disengage completely | Fix clutch problem. |

| The gear shift drive rod is damaged. | Eliminate deformation of rods. |

| The fastenings of the mechanisms have been loosened. | Tighten the fasteners. |

| Drive not adjusted. | Adjust the drive. |

| The plastic drive elements are broken. | Replacement of worn parts. |

| Transmissions turn off on their own | |

| Wear of synchronizer teeth on the gear. | Replace worn elements. |

| Damage and wear of engine mounts. | Install new supports. |

| The gear shift mechanism drive is not adjusted. | Adjust the drive. |

| Extraneous noise when shifting gears | |

| The clutch does not disengage. | Adjust the clutch and eliminate faults. |

| The ring blocking the synchronizer is worn. | Replace the ring. |

| Oil leak | |

| Wear of seals. | Check all oil seals in the gearbox and replace worn ones. |

| The crankcase, gearbox cover, and drain plug are loose. | Tighten loose elements and replace sealant if necessary. |

Transmission malfunctions are often closely related to a faulty clutch. Characteristic signs may indicate many breakdowns. Detailed and more objective diagnostics are carried out only after dismantling the gearbox and completely disassembling it to identify problems.

It is not recommended for beginners and those who have no idea about the technical structure of this unit to carry out repairs. The fact is that the gearbox is a complex mechanism with many parts. With inept repairs, there is a high probability of getting even bigger problems, up to and including complete failure of the unit.

When contacting a car service center, you should take into account that not every mechanic has the appropriate qualifications, and repairing a Lada Granta gearbox with a cable drive can cost a lot of money.

For example, replacing oil seals involves a complete disassembly of the gearbox and is estimated on average at least 6,000 rubles. You can carry out repair work yourself. Yes, this will save money, but it will take up a lot of free time, and you will also need an assistant. Alternatively, in case of serious problems, motorists simply change the gearbox assembly. In some cases this is the only rational solution.

Automatic transmission malfunctions

To independently identify automatic transmission problems, you should drive the car. Characteristic signs of gearbox malfunction:

- gears are not included;

- strong jerks when moving;

- flashing of the corresponding indicators;

- transmission oil leak.

The presence of these problems indicates the need for urgent repair of the gearbox. And automatic transmission malfunctions also affect the robotic transmission. The robot is a kind of middle option between an automatic transmission and a manual transmission, and therefore it can be affected by breakdowns of both transmissions.

It is not possible to repair an automatic transmission at home. The design of the machine and the robot in particular is too complex and cannot be done independently. Moreover, not even all service centers do this. An experienced car owner will be able to eliminate the simplest faults, such as oil leaks and problems with spontaneous gear shifting. Moreover, in the latter case we are talking about cleaning contacts.

Most often, owners of a Lada Granta with an automatic transmission may encounter problems typical for this transmission.

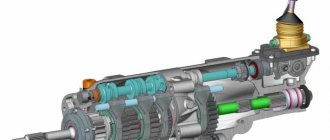

ROPE DRIVE

Despite the simplicity and low price, almost all manufacturers abandoned the rod drive, like on the old box. Today, designs of several rods with complex scenes are used to dampen vibrations on the lever, or a more expensive and convenient cable drive. AVTOVAZ experimented with the latter back at Samara, purchasing parts from. But with the switching mechanism located at the bottom, the performance of such a circuit is problematic, and the price of components was scary at that time. Work on the cable-driven gearbox continued as part of other projects, but the production model could only be realized now.

4_no_copyright

The single-rod gear shift drive was replaced by a cable. The unpleasant vibrations on the lever are gone, there is less play, and shifting is clearer.

It is curious that in the clutch drive, on the contrary, they planned to abandon the cable in favor of hydraulics. Unfortunately, for economic reasons, they left the previous design, although the hydraulic drive has better characteristics. In particular, the clutch pedal works more logically and clearly with it. The advantages in the layout are also obvious: it is easier to lay tubes and hoses. But the cable for the new box had to be lengthened. These are unnecessary mechanical losses, which means additional effort on the pedals and worse information content.

What did you get?

The design of the gearbox was not only optimized and made more reliable, but also almost completely eliminated unpleasant vibrations on the lever and the car body. The backlash has become smaller and the shifts are clearer. It is worth noting that the use of a modernized gearbox on the Lada Granta and Lada Kalina 2 entailed an increase in the cost of these cars by an average of 5,000 rubles. By the way, the cable box is not installed on the Lada Priora; this car uses a 2180 manual transmission with rigid rods.

7_no_copyright

1 — gear selector levers;

2 — selector grid pin;

3 — selector grid;

4 — reverse locking mechanism;

5 - central three-dimensional plate.

However, the developers are not delaying documentation on the hydraulic drive and plan to launch it into series. As well as other improvements, by the way, which for various reasons were not implemented this time. For example, a multi-cone synchronizer in third gear and an equally interesting solution that makes the transition to the fourth and fifth stages clearer and more enjoyable. Not otherwise, appetite comes with eating. By the way, the food turns out delicious - I tried it myself. The main thing I would like to wish to the developers is not to be late with changing dishes. And to consumers - bon appetit!

Thank you for your help in preparing the material.

developers of the VAZ-2181 box

Mikhail Votinov, Vladimir Petunin, Sergei Ishchenko, Dmitry Gorev.

New gearbox "Grants" and "Kalina": traction to the cable