A sensor is a device for measuring the pressure of gases or liquids. Pressure is an expression of the force required to stop the expansion of a fluid and is usually expressed as force per unit area. ZMZ 409, ZMZ 406, ZMZ 405 - 4-cylinder 16-valve gasoline automobile engines. These engines are used in Volga 3102, 3110, 31105, Sobol and GAZelle cars. The ZMZ 406 automobile engine oil pressure sensor usually acts as a converter; it generates a signal depending on the pressure.

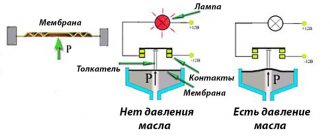

Standard sensors are activated, displaying a warning signal when the oil pressure is outside a preset range. The two important components are the spring switch and the diaphragm. The sensor is installed on the side of the engine block. When the pressure begins to build up, it exceeds the pressure of the sensor spring, which separates the electrical contacts to turn on the signal.

If the pressure drops below a set limit, the diaphragm releases the spring pressure to close the switch contacts, which usually provides a warning signal to the driver.

In short, the sensor is essentially a pressure gauge. If a lower than normal pressure is detected, the sensor will cause the vehicle's indicator to reflect this change.

There are two types of sensors:

- Emergency oil pressure sensor.

- Control (additional).

Functions performed by the sensor in a vehicle

Inside a car engine, motor oil has three important functions: lubrication, cooling, and cleaning. A problem with any of these three components can have serious consequences for the engine.

For this to work, the oil must be under pressure. It can't just move through the engine at its own leisurely pace; it must move quickly.

Keeping the oil under pressure provides the resistance needed to lubricate moving parts. The pressure prevents the lubricant from being moved by engine forces that try to force these components together.

Pressure indicators of GAZ car engines

Pressure in the lubrication system is necessary for the movement of oil and its supply to consumers. The practical performance of a serviceable motor is influenced by the following factors:

- oil viscosity,

- engine temperature,

- ambient temperature,

- crankshaft rotation speed,

- load,

- presence of an oil cooler.

Cars produced by the Gorky plant are equipped with different engines. The permissible pressure values in the engine lubrication system are given in the table.

The construction of the Nizhny Novgorod Automobile Plant (NAZ) was included in the number of priority construction projects of the first five-year plan and, although not without serious problems, was completed in just 18 months.

Alexander Klimnov

Truck Press

Table: pressure indicators of GAZ car engines

| Engine | Automobile | Pressure value (kgf/cm2) | Conditions |

| ZMZ-406 | "Volga" "Gazelle" | 2–4 | driving 50 km/h |

| 4,5 | cold engine | ||

| 1,5 | heat | ||

| 1 | fault criterion | ||

| ZMZ-402 | "Volga" "Gazelle" | 2–4 | driving 50 km/h |

| 4,5 | cold engine | ||

| 1,5 | heat | ||

| 1 | malfunction criterion at medium speeds in motion | ||

| 0,5 | idle speed fault criterion | ||

| ZMZ-405 | "Gazelle" | 4,6 | filter bypass valve activation |

| 6 | maximum permissible | ||

| 0,4–0,8 | activation of the alarm system | ||

| GAZ-560 | "Volga" "Gazelle" | >1 | idling 850 rpm, 80–85 °C |

| 5–7 | 3800 rpm, normal | ||

| 4 | 3800 rpm, short-term permissible | ||

| UMZ-421 | "Gazelle" | >1,3 | 80 °C, 700 rpm, oil cooler off |

| >3,5 | 80 °C, 2000 rpm, oil cooler off | ||

| >0,8 | 80 °C, 700 rpm, oil cooler on | ||

| >2,5 | 80 °C, 2000 rpm, oil cooler on |

Warning light

If the control light comes on, you need to pay attention to it. Every time this light comes on, even if you already know that the meter is damaged, you need to check everything. If the dipstick shows that the level is normal and the engine runs silently and without problems, then the indicator is faulty, probably the result of a faulty sensor:

- If the level is good but you hear a loud noise from the engine, this may indicate that the oil pump is not working and the engine should not be restarted until the pump is repaired.

- If a low level is detected, there may be a lack of pressure from a leaking hose or gasket. In this case, you must definitely stop driving until the problem is resolved.

- Periodic flashing of the indicator is probably the clearest signal that the meter itself is failing.

- Always check the oil level and make sure there are no unusual noises before continuing work.

Checking the oil pressure sensor yourself

If, while driving, a sharp warning sound is suddenly heard in the cabin and a light comes on on the instrument panel, this can be caused by a variety of reasons:

- the oil level has dropped;

- wear of liners in crankshaft bearings;

- incorrect operation of the pumping device;

- The DDM is out of order or there is a short circuit in its wiring.

As soon as the signal appears in the form of an oil can, you must immediately turn off the engine and stop. The first step, of course, is to check the engine oil level - it is quite possible that the sensor has tripped due to a lack of lubricant in the engine system. If this is indeed the case, then you will need to add the required amount of oil and you can start the engine and drive on.

However, if the signal is caused by DDM, it will be necessary to diagnose the faults. Owners of GAZ cars can cope with this procedure on their own.

Video: self-diagnosis of the device

Check procedure

- Open the hood and find the sensor location.

- Unscrew the device and connect it to the pressure gauge.

- Connect the pressure gauge adapter to the sensor socket.

- Connect the ground wire of the pressure gauge to vehicle ground.

- You will need to use an additional wire: connect a light bulb or LED to the “+” terminal on the battery and short the wire to the sensor contact. The light fixture should light up.

- After this you will need to start the engine.

- Smoothly pressing the gas pedal, you need to increase the engine speed. As soon as a pressure of 1.2–1.6 bar (gasoline power units) or 0.7–1.05 bar (diesel units) is created, the light should go out. If the light/LED continues to light even when the system pressure is high, the unit is faulty.

- You will need to increase the speed to 2 thousand rpm. The oil should already warm up to 80–90º C, so the pressure in the system should not be less than 2 bar. If the reading on the pressure gauge is lower, it means that the car has severe wear on the crankshaft bearings: the sensor itself is normal.

Related article: Polaroid glasses for drivers – necessity or luxury?

Pressure indicator

Consistently high readings may indicate a sensor failure. This could be an internal short in the sensor, or the signal path could be completely destroyed.

Again, it is important to relieve really low pressure by running the dipstick and listening to the engine. Too much grease can cause low pressure due to foaming, which is also not suitable for the car, so don't overfill it.

Damage to the sensor is not only a nuisance, but also a danger. You have to stop every time you feel like something is not right, and it gets boring quickly.

You can also blame a bad sensor for everything, when, in fact, a problem has arisen, and a faulty meter is not able to warn about it. A broken meter requires immediate replacement. This will save you hassle and possible damage to your car in the long run.

How to replace a pressure sensor yourself

Replacing the DDM on GAZ family cars is a fairly simple operation. Thanks to the convenient location of the device itself in the engine compartment, removing a failed sensor and replacing it with a new one is not difficult. The only thing is that you will need to wait until the machine cools down, since you can seriously burn your hands on hot metal parts.

Replacing a DDM with a GAZ involves dismantling and installing two devices at once: both the sensor itself and the alarm sensor, which is inextricably linked with it.

To carry out the replacement, you must prepare the tool in advance:

- flat screwdriver;

- open-end wrench 17;

- open-end wrench 22;

- sealant.

The first step in almost any operation to replace instruments and mechanisms is lifting the hood

The step-by-step algorithm for replacing DDM with GAZ is as follows:

- Open the car hood.

- Using a screwdriver, unscrew the screw securing the wire to the sensor contact.

- In the same way, unscrew the wires from the signaling device, which sends a command to the instrument panel in the cabin.

- The sensor itself is unscrewed with a 17 wrench.

- Use a 22 key to unscrew the alarm sensor.

- After which two new devices are inserted into the mounting sockets, it is recommended to first apply sealant to the threaded connections.

- The wires are connected to the sensors by screwing in the mounting screws.

- After replacement, you need to start the engine and check the functionality of the new devices.

- If an oil leak is detected, the connections must be tightened again.

Video: DIY device replacement

Drivers of GAZ cars can easily service their car without going to a service station. The design of GAZ mechanisms is quite simple, so the car enthusiast does not have to rack his brains about where this or that unit is located and how exactly to repair or replace it. DDM is one of the most prominent elements in the GAZ engine compartment. Therefore, its diagnosis and replacement, if necessary, will not require specific knowledge and skills from the driver.

Share with friends on social networks:

Telegram

Sensor malfunctions and ways to eliminate them

When the dashboard light comes on, it only means there is an oil problem. However, it is likely that this light will not come on if the oil level drops suddenly, which would result in a fault being detected in the sensor or any other device in the engine oil measuring system.

It is necessary to familiarize yourself with the malfunctions and solutions associated with the oil pressure sensor

Low oil pressure

This is the main reason why the dashboard light comes on. The sensor determined that not enough oil was pumped into all parts of the engine.

If this is the case, the friction of the parts pulling against each other will cause extreme heat and abrasion inside the engine, causing permanent damage. The only possible solution to this problem is to look at why the oil pressure is dropping at such an alarming rate.

Defects in the oil pump

Low engine oil pressure can also be the result of a failing oil pump. If this pump is damaged, the pressure will be drastically reduced, causing the meter to detect the drain and alert through the panel.

The only viable solution to this problem is to replace the entire oil pump.

Very low oil level

Typically, low oil level is not the direct cause of sensor failure. You need to check the oil circulation through the engine and measure its proper pressure. Reasons why the gauge detects low oil level:

- Due to leaks in the distribution system.

- If debris gets into the oil pan.

- If the oil filter is replaced incorrectly.

When faced with this problem, it is necessary to determine the real cause of the low oil level and solve it as quickly as possible.

Faulty sensor

From time to time, the sensor may become obstructed, especially if the vehicle's engine is not properly maintained. As a result, the meter gives false readings and turns on the warning lights unnecessarily, which can lead to misunderstandings and damage the very dynamics of the car.

Therefore, in order to solve this problem, you need to check the following possible causes:

- The sensor is indeed damaged.

- The cable connecting the meter and the warning lamp is damaged.

- The oil pump did not retain air in the suction port.

- The pressure control valve was stuck and would not open.

- Therefore, it is best to replace the meter with a new one that is in perfect condition.

Location of DDM in Gazelles and other cars of this family

In cars of the GAZ family, it is quite easy to find the DDM due to the specifics of its connection. If you open the hood and look at the mechanisms from above, then at the top right you can see the DDM directly above the engine cylinder head.

Article on the topic: Which is better front or rear wheel drive?

GAZ sometimes uses two types of devices: one shows the current pressure in the system, and the other performs the function of transmitting a signal to the cabin about a critical pressure condition. Two sensors for the display meter and for the lamp are screwed into a tee, which is connected to the cylinder head. The unit is installed immediately after the thermostat.

Thanks to its convenient placement, dismantling and installation work will be very simple