In the life of motorists, a situation often arises when, when driving out onto the road and trying to accelerate, it is noted that the engine does not pull.

That is, the acceleration dynamics are very “sluggish”, the car is reluctant to pick up speed, and it feels like something is holding it back.

This problem can arise with almost any car - domestic or foreign, gasoline or diesel, with a carburetor power system and injector.

Often, a drop in traction is accompanied by additional symptoms - extraneous sounds appear when the engine is running, the engine may stall in one of the modes (usually at idle), the crankshaft speed is not stable and “floats”.

But this is not always the case; it happens that the unit behaves perfectly in all respects, but does not develop power.

Main reasons

There are many reasons for this phenomenon and in most cases they are associated with a malfunction of the systems and mechanisms of the power plant.

Some of them are trivial and very easy to fix, others require quite serious repairs.

The main problem with the fact that the engine does not pull is not related to eliminating the malfunction, but to finding it.

In some cases, it is very difficult to determine what caused the reduction in traction effort and you have to go through almost the entire engine.

Therefore, we will try to indicate the main reasons why the car accelerates very “sluggishly”.

Since engines on different cars have their own design features, we will consider specific models.

From clutch to filters

So, if the car does not pick up speed, the reasons for this may be the following. Firstly, if the car does not drive properly with a normal increase in speed, it could be a problem with the clutch, so it would be best to check the condition of the unit’s system. If this problem occurs in winter, when there is a stable sub-zero temperature outside, the cause may be frozen brake pads or a handbrake that was lowered before leaving, but in fact remained activated. Also, the answer to the question of why the car does not pick up speed may be hidden in the filters, when the air or fuel filter was simply clogged. The solution to the problem is their simple replacement.

Power drop on a VAZ carburetor engine

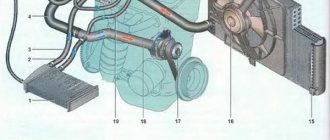

To begin with, let's take VAZ cars with a carburetor power system and an 8-valve timing system - VAZ-2109, VAZ-2110, VAZ-2114, VAZ-2115.

The same power plant is installed on these cars, so the reasons are identical.

Let's go through those components, due to malfunction of which a drop in dynamics may occur.

In general, the main reason that the engine does not pull is a change in the processes in the combustion chambers - a mismatch in the proportions of the air-fuel mixture, the combustion process is disrupted, the filling of the cylinders and the removal of exhaust gases does not occur as required.

Supply system

Very often, a drop in traction occurs due to the power system. Structurally, the carburetor fuel system used on cars from VAZ-2109 to VAZ-2115 is very simple and is almost completely mechanical, so identifying the cause is not particularly difficult.

A decrease in power can occur due to:

- Severely clogged fuel filter (its throughput drops and the pump is simply not able to pump the required amount of fuel);

- Contamination of the carburetor channels (the jets and fuel channels in this element have a small cross-section and debris often clogs them);

- There is air leakage in the area from the tank to the pump (because of this, the performance of the fuel pump drops sharply);

- Damage to the fuel pump membrane (a small crack in it leads to the fact that the vacuum required for pumping fuel is not created in the pump chambers);

- The fastening of the carburetor or intake manifold is loose (due to this, air leaks around the carburetor and the proportion of the air-fuel mixture is greatly disturbed);

- The hole in the fuel tank cap is clogged (because of this, a vacuum is created in the tank and it is much more difficult for the gas pump to pump gasoline out of it);

In addition to the elements responsible for supplying fuel, a drop in power also occurs due to severe contamination of the air filter element.

Ignition system

This system also takes part in the combustion of the mixture, which means a failure in its operation can affect power.

In carburetor engines VAZ-2110 and others, a decrease in traction can occur due to:

- Faulty spark plugs or changes in their thermal gap;

- Excessive wear of the contacts and the central electrode of the distributor;

- Voltage losses in high-voltage wires;

- Violations of the ignition timing.

Irregularities in the power supply and ignition systems most often cause a drop in power, so testing to identify the cause should begin with them.

If the operation of these systems does not raise suspicions, other components of the engine should be diagnosed.

Exhaust system, timing belt and crankshaft

Loss of traction can also occur due to the exhaust gas removal system, although problems with it rarely occur on carburetor engines.

The main reason here is the reduction in throughput due to large deposits in the muffler. Because of this, exhaust gases, without having time to escape from the cylinders, “choke” the engine.

The reasons for the drop in thrust are also often the gas distribution mechanism and the cylinder-piston group.

Here the reduction in power occurs due to:

- Violations of the thermal clearance of valves.

- Heavy carbon deposits on the valve plates and seats, or their burning.

- Occurrence of rings.

- Limit wear of the CPG.

- Cylinder head gasket failure.

In general, problems with the timing belt and CPG cause a drop in power in any engine - carburetor, injection, diesel. Therefore, we will not mention these mechanisms further.

Timing belt or chain

The crankshaft and timing shaft must rotate together and at the same time synchronously. This is what belts are used for. Here you just need to combine the marks that are on the chains, belts and gears.

It happens that the belt can jump to another tooth. Chains tend to stretch. However, if these mechanisms are maintained on time and correctly, this cause can be eliminated.

VAZ injection engines

In injection engines VAZ-2110, 2112, 2114, 2115, both 8-valve and with a timing belt with 16 valves, it is more difficult to identify the cause of the decrease in power due to the more complex design of the main systems.

Supply system

Any injector consists of a mechanical executive part and an electronic control part, and problems can arise in both of them, which will lead to a drop in power.

Let's look at the mechanical part first. Here, cravings can be influenced by:

- Severely clogged mesh filter on the fuel pump;

- Decrease in fuel pump performance due to wear;

- The fine filter is dirty;

- Malfunction of the fuel rail pressure regulator;

- Clogged injectors;

- Fuel filter dirty;

- Air leak in the manifold.

In general, almost every element of the injector executive part can be the culprit for a decrease in dynamics.

The situation is approximately the same in the electronic component.

The operation of the engine with the injector is controlled by an electronic unit, which constantly monitors the parameters through sensors installed on different systems.

The number of these tracking elements is considerable and the breakdown of any of them leads to the fact that the ECU incorrectly evaluates the indicators on the basis of which it controls the executive part.

Thus, the lambda probe, DPKV, mass air flow sensor, DPZ, phase sensors, detonation sensors and coolant temperature sensors in the event of a breakdown lead to a decrease in power, so you will have to check all of them in search of the cause.

Ignition and exhaust system

As for the ignition system of injection engines VAZ-2110, 2112 and others, the reasons may be:

- Candles;

- High voltage wires;

- Ignition module.

Another possible cause could be a misalignment of the generator drive pulley (with the ring gear).

IMPORTANT TO KNOW: What is an adsorber in a car.

Because of this, the DPKV readings are disrupted, as a result the operation of the ignition system is disrupted, which leads to a drop in traction.

In injection engines, the exhaust gas removal system more often creates this problem than in a carburetor car, and all due to the use of a catalyst.

The element's honeycombs have a small cross-section, so they become clogged quite quickly, which leads to exhaust gases “crushing” the engine.

Also, if the engine does not pull, check the lambda probe.

Stop driving with the handbrake, and traction will appear by itself

If you always set your car's handbrake but forget to release it while driving, prepare for compromised traction. When driving with the handbrake, you get the feeling that the car accelerates very slowly and it is too difficult to gain momentum. The driver immediately puts pressure on the engine, putting pressure on the suspension or gearbox. But he can’t even think that it’s enough to lower the handbrake lever for the problem to solve itself. Moreover, driving with the handbrake for quite a long time will cause the following troubles with the car:

- the rear brake discs (or drums, depending on the design of the car) become too hot;

- heating sometimes causes deformation or excessive wear of these parts with various consequences;

- wear in any case will be very high and will become the reason for the mandatory replacement of the pads and disc after 100 kilometers of such a trip;

- the drum brake may even fall apart during movement, reducing the safety of the trip;

- Heat and excessive friction can cause failure of some parts of the chassis;

- The brake system may also develop other problems that require immediate solutions.

These are the troubles that await you if you simply forget to remove the handbrake lever to its original position before moving off. If you have a manual transmission, keeping an eye on the handbrake becomes even more difficult. With an automatic, it is enough not to accelerate from the first second, but to let the car show its readiness for the trip, let it start idling. If you regularly leave the handbrake on, just stop using the handbrake. Leave it in gear, choose more or less level parking spots.

Main reasons with engines of other cars

Next, we will go through other cars, and we will indicate the most frequently occurring problems that lead to a drop in power.

So, on a Mitsubishi Lancer 9, the problem most often arises with the exhaust gas exhaust system. This car uses a double catalyst, which becomes clogged with carbon deposits relatively quickly.

Therefore, many owners of this car, when the power drops, recommend first of all paying attention to this system.

But in the ZMZ-406 and 405 engines, which are equipped with GAZelle and Volga cars, a drop in power often occurs due to:

- Ignition coil malfunctions;

- Losses in high-voltage wires;

- Non-working spark plugs;

- Failure of sensors (primarily DPKV).

But do not forget about the other above-mentioned elements of the power supply, ignition, as well as timing and CPG systems.

In Ford Focus cars, in general, problems with loss of traction arise due to malfunctions of sensors, as well as elements of the power system - especially the fuel module, which includes both a fuel pump and a filter, combined into a single structure.

Much the same applies to a car like the Renault Megane.

In this machine, power loss may occur due to:

- Wear of the distributor cover;

- Faulty spark plugs and high voltage wires;

- Weak exhaust system capacity;

- Worn fuel pump and dirty filter elements;

- Damaged injector sensors.

In general, first of all, you should look for the cause in the power and ignition systems, and only then move on to the timing belt and CPG.

Throttle valve

As one of the options, you can answer the question of why the car picks up speed poorly by diagnosing the throttle position. It happens due to long-term use of the car or due to erroneous actions of service station employees, the throttle valve begins to sink or opens only 2/3. The cause may be a bent fuel cable holder. If after checking all of the above options the problem is not solved, there is only one way out - detailed computer diagnostics at a service station.

Theme Options

If the diesel engine doesn't work

A decrease in traction can also occur in diesel engines. If we look at old cars that have completely mechanical power systems, then the most common cause is depressurization of the system.

As a result, air enters the fuel, which is why the fuel injection pump is unable to provide the required pressure.

Don't forget about:

- clogged filters;

- weakly pumping fuel priming pump;

- damaged plunger pair;

- Coking of injector nozzles.

And if we also add possible problems with the timing belt and CPG, then identifying the cause will not be so easy.

In modern diesel installations, where an additional electronic component is used, the search range will increase.

For example, the Common Rail system uses all the same sensors as the injection engine. And if at least one of them breaks, this will certainly affect the operation of the control part.

Checking the transmission

Sometimes the power unit can develop serious power, but it does not reach the wheels. If while driving you hear that the engine is working hard, but you don’t feel speed, then perhaps the automatic transmission system is slipping or there are blockages on the brakes.

To check, you need to drive onto a straight section, set the automatic transmission selector to position D, and then see how the car behaves. If the speed decreases, then the brake system should be diagnosed. If everything is fine with the brakes, you need to go to a good service station and check the automatic transmission.

You can also check the parking brake. To do this, you need to go to free space. Warm up the car and then pull the handbrake. Next, press the brake pedal and set the gearbox selector to position D. Next, press the accelerator. If the engine keeps the rpm around 2000, then everything is fine with it. If it is less or more, you should go to a service station to test the automatic transmission.

Why does an injection engine lose power?

Loss of power in an injection engine is often caused by improper operation of the electronics. There may be clogging of the injectors, breakdown or incorrect operation of various sensors.

- Air flow meter or mass flow sensor. The control unit instantly reacts to its failure, changing the OZ by several degrees in the direction of delay. The result is that the power first increases, but then begins to fall lower and lower. At the same time, fuel consumption increases and the exhaust becomes much dirtier.

- TPS or throttle position controller. When it deteriorates, the power of the unit instantly drops, unpleasant jerks and dips appear, and the idle speed is unstable.

- The pressure regulator makes itself felt by difficult starting, unstable speed at neutral speed and loss of traction.

- The antifreeze temperature sensor, if not working correctly, causes problems with engine response, especially in the hot season. The ECU receives an incorrect signal, detonation and power loss begin.

Thus, the loss of internal combustion engine power is primarily due to the following reasons:

- low-grade fuel, which can be seen immediately after refueling;

- clogged air filter;

- dirty candles;

- clogged fuel filter;

- errors in the operation of the injector;

- malfunction of the catalyst or the entire exhaust system.