The wiper trapezoid is a mechanism for transmitting force from the windshield wiper motor to the wiper arms. In this case, the mechanism during operation:

- gradually wears out;

- trapezoid hinges become clogged with dirt;

- The grease is gradually washed out of the joints.

As a result, high loads on the wiper motor disable the motor, the driver is faced with poor quality of windshield cleaning, extraneous noise appears during wiper operation, etc. The solution in such a situation is to repair the trapezoid or replace the wiper trapezoid. Read more in our article.

Wiper design

The main parts of the windshield wiper are the supporting frame and the cleaning element.

Wipers with metal frame

The supporting frame is made of metal or plastic. Wipers with a metal frame are more durable and strong. This frame is used to make winter windshield wiper blades.

Wipers with plastic frame

There is another type of brush design - frameless brushes. The frame in such brushes is a cleaning rubber band and the wiper itself is made entirely of rubber.

Frameless wipers

The cleaning element is made of soft rubber or silicone, which ensures a tight fit to the windshield and excellent cleansing of moisture.

Types of wipers

- Classic.

The design consists of seven metal “rocker arms” arranged pyramidally. The largest arc holds two smaller ones, which, in turn, hold even smaller ones and are attached to a rubber blade. This design allows the downforce of the wiper to be evenly distributed. Slowly going out of fashion, these wipers are falling in price every day, while performing their functionality very well in the warm season. The main enemy of such a wiper is snow. But it is impossible to say that these brushes are worse in functionality than frameless ones. The pressing effect of such a design loses its properties over time. Therefore, it is better to change the brush frame itself after a few years.

- Frameless.

The “rocker arm” system for this type of wiper is replaced by a thin metal plate that passes through the entire length of the brush. It is a frame, despite the so-called frameless classification. They tolerate snow better, but this design has a disadvantage - the distribution of downforce here is worse than that of “rocker arms”. In the cold there is a shrinking effect. The advantages of these brushes over the previous ones can be called design. Although the taste and color as they say... .

- Winter brushes.

They repeat the classic summer design, but all its moving parts are hidden under a rubber cover. But these brushes are not very suitable for summer, since the casing causes too much windage. If the speed is above 90 km. at an hour, the brushes begin to move away from the glass. As good as such brushes are in winter precipitation, they are just as bad in summer precipitation.

- Hybrid.

These brushes are the latest development for today. Metal “rocker arms” here replace three plastic arcs, they also act as a winter cover, thereby allowing these wipers to be called hybrid. Another distinctive feature of these wipers is improved aerodynamics. Headwind increases downforce. Although in such a design there is something to freeze on.

In conclusion, we can say that in winter it is better to use winter wipers, and for summer any wipers except winter ones are suitable. It's up to you to choose. In any case, new wipers, no matter what design, are better than those that do not perform their functions at all.

Device design

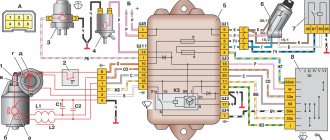

ten The three-speed windshield wiper system is one of the most vulnerable in the domestic “ten”. Almost any component can play the role of a weak point: steering column switch, relays, fuses, gear motor.

The design of the windshield washer on the VAZ 2101 consists of a gearmotor powered by an incoming current that drives the washers, a switch, a switch, a relay for switching on the intermittent mode, an additional relay, etc.

Glass cleaner device

The node consists of:

- Windshield wiper trapezoids: with its help, the motor transmits movement. It wears out quickly, so sometimes repairs to the trapezoid are necessary.

- An electric motor drives the wipers of the VAZ 2110. If the motor burns out, the entire unit will fail.

- The windshield wiper pump pumps cleaning fluid. If the electric pump breaks down, then, despite the operation of the wipers, the windshield will not be cleaned.

- The purpose of the tank is obvious - window cleaning liquid is poured into it.

Thanks to the electric motor, the wipers on the VAZ 2110 can operate in three modes:

- Intermittent. The switch lever is in positions II and III.

- Constant - with a low speed of movement of the brushes. The switch lever is in position IV.

- Constant - with fast movement of the wipers. In this case, the shift lever is in position V.

First, let's try to understand how the windshield wiper circuit on the VAZ 2110 works and what components form a solid unit called a windshield wiper.

Device Characteristics Electric motor It is responsible for rotating the wipers at different intensities. The electric motor contains a gearbox, and the motor itself operates due to the DC current supply. There are three built-in blades in the armature of the engine, providing three operating modes of the windshield wiper - fast, slow and with pauses. Although it is believed that the VAZ 2110 has only two brush rotation speeds. Electrical components This is a steering column switch, a wiper relay, which allows you to activate the intermittent brush movement mode. Plus, don't forget about the switch. The entire electrical system is integrated into wires running through a bimetallic heat-resistant fuse

It is important to note that both relays and fuse F5 are located in the mounting block, and the bimetallic fuse and switch are in the gearbox of the electric motor. Windshield wipers. At the same time, the size of the wipers on the VAZ 2110 may be different, which we will talk about later. They differ in shape, material of manufacture, design Mechanical drive An important component, which, alas, often breaks on the “ten”

What is a windshield wiper trapezoid and what is it for?

The trapezoids are around here somewhere!

The wiper trapezium is a special unit that converts the engine impulse into forward movements of the windshield wipers.

Simply put, it is she who is responsible for their movement along the windshield or rear window of the car. Since weather conditions are often unpredictable, and the windshield must provide complete visibility, failure of this part must be quickly identified and repaired.

Principle of operation

Most often, plastic bushings wear out in trapezoids.

This is interesting: Methods for replacing the coolant in a car yourself and choosing Antifreeze

Although, at first glance, it seems that the movement of the brushes occurs directly, in fact, a trapezoid, which is an electromechanical unit, is responsible for it. It works on the following principle:

- The windshield wiper motor uses the finger, which drives the trapezoid itself.

- Due to the connection of the gearbox and shafts, oscillatory movements occur, causing the brushes to move along the glass, cleaning it.

It often happens that the trapezoid fails. This happens especially often after or during the winter season. Some inexperienced VAZ-2110 owners turn on the “brushes” without bothering to clear the snow from the glass. Often the wipers freeze to the glass, and an attempt to move them ends in breakage. To prevent this from happening, you should always check the brushes before turning them on in winter for freezing.

How to care for your wipers to extend their lifespan

To ensure that your wipers last as long as possible, follow these tips:

- Wipe dirt-stained brushes with a clean, damp cloth or sponge. This way you will not only get rid of dirt, but also protect the glass from scratches.

- If the front glass is covered with a layer of dust and the car washer fluid has run out, do not turn on the cleaner. This will also cause scratches on the glass.

- In winter, especially during snowfalls, do not leave the wipers leaning against the windshield - they will freeze. It is better to raise the leashes so that the brushes are suspended.

- If the windshield wipers are still frozen, do not under any circumstances try to tear them off by force. This will only damage the rubber band. Start the engine, turn the heater on to blow the windshield and wait until it defrosts.

- You should also not knock ice off the frame or brush. Gently bend the elastic until it peels off in small pieces.

- When replacing wipers, place some thick cloth on the windshield. This will protect it in case the spring-loaded leash slips out of your hands.

The trapezium of the wipers transmits the force from the engine to the windshield wiper arms. The best quality of windshield cleaning will be only if all elements of the wipers are in working order. If the trapezoid hinges are clogged with dirt or the lubricant has dried out, the motor energy will not be enough for proper cleaning. Therefore, owners of cars of the tenth family are forced to repair the trapezoid once every 5–10 years in order to avoid deterioration in the performance of the wipers.

What affects the condition of the trapezius

The main cause of all problems associated with the trapezoid is the location of the mechanism. The wiper motor and trapezoid are located directly under the glass.

Dirt, small abrasive particles, water and washer fluid constantly accumulate in this area.

This leads to wear at the moving joints and loss of lubricant. Active wear of the plastic bushings of the hinges is observed, backlashes appear, resistance noticeably increases during operation and the load on the motor increases. In such conditions, the trapezoid for the wipers and the motor quickly fail.

As a rule, the VAZ 2110 trapezoid requires revision every 2 years. Such an inspection should mean cleaning the trapezoid from dirt and additional lubrication. If this is not done, after 5-6 years the trapezoid will need to be replaced or repaired (a trapezoid repair kit is used).

The wiper motor and trapezoid are located directly under the glass, so some of the water or washer fluid falls on them. In addition to water, dust, dirt and various small debris get there. All this leads to a change in the properties of the lubricant and deterioration in the performance of the trapezoid. When the lubricant loses its properties, the plastic bushings of the hinges begin to wear out, resulting in backlash and increasing resistance during operation.

Alternative solutions

Often this happens because they do not see alternatives and are not familiar with them.

For all VAZ 2110 models, regardless of the year of manufacture, it is possible to install windshield wipers for the driver and passenger sides of the same size - 20 inches. The length of the brush is 508 millimeters.

But this size can be increased to 530 millimeters. It is not recommended to install more, since this way the windshield wiper will not be able to work effectively, and the drive simply will not cope with the load. As a result, too long brushes cause squeaking and jerky work. Plus, don’t count on a long service life of the wiper mechanisms.

The original windshield wipers for the 10 are quite good. But there are more expensive, but also more highly efficient, high-quality devices.

But as practice shows, on the windshield of the VAZ 2110, as well as other VAZ models, they do not look very nice, because the fasteners on the leash turn out to be massive. Although if you modify them a little, you will get a very good result.

Spare part selection

The catalog number of the original wiper trapezoid is 2110-5205010. Give preference to trapezoids from manufacturers:

- Balaton;

- At program;

- Startvolt.

Part of the old and new sample

Selecting a new part for a VAZ-2110 is not such a simple matter. Not everyone knows that there are old and new trapezoids.

The old-style trapezoid rods are secured with two studs.

The new type of rods are installed without problems if you remove one pin.

Therefore, it is better to remove the old part and take it to an auto parts store. They are not only attached differently, but also differ in the connectors through which they are connected to the motor. If you can’t find an old-style trapezoid, and this is exactly what you have, you’ll have to redo the system or look for a used part.

- As a rule, trapezoids of a new type are available for sale from various manufacturers. One of the popular models has the article number VLT2110–5205010-Р.

If the windshield wiper motor is working properly, you can only change the trapezoid itself.

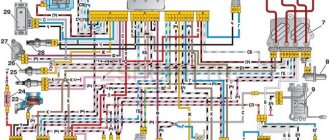

Incorrect operation of the intermittent wiper mode on a VAZ 21213 car

For the “ten” there are old and new type windshield wiper trapezoids, catalog numbers:

- 2110-5205015

- 2110-5205015-01

- 2110-5205015-11

- 2110-5205015-20

- 2110-5205015-21

In addition, on the “ten” you can install a Priora windshield wiper trapezoid; by the way, it is cheaper than the original one. The differences will be: 1. In the studs for the windshield wiper arms, on the VAZ 2170 trapezoid they are “13”, and on the VAZ 2110 they are “10”; accordingly, the wiper arms will have to be replaced. 2. In the wiper motor connectors. Connect according to the color of the wires (the photo shows a temporary connection method; ideally, all wire connections should be well insulated).

Quite often situations occur when the wipers do not work correctly on VAZ 21213 and VAZ 21214 cars. The most common problem is the negative functioning of the intermittent wiper mode. The source of its occurrence is burnt contacts of the gearmotor.

If you find yourself in a similar situation, here is the solution:

- Remove the gear motor together with the rack (look at the motor shield, there you will find two nuts in the area where the heater casing is located). There will also be two windshield wiper arm nuts.

- Remove the cover from it, tighten the contact, and then drop a little superglue (one crank nut and four screws).

- Once the assembly is complete, the system will function properly.

Do-it-yourself modification and replacement of wipers

Which wipers are better is up to the car owner to decide. Those installed on the VAZ 2110, as well as on the UAZ, do their job well from the factory, but it can be modified with washers from other companies that are of higher quality. Many people are attracted to frameless brushes - this is a good option. They are compact in size and equipped with a special leash mechanism. True, they do not look very attractive on the VAZ 2110, since the fastener to the standard washer arm turns out to be massive. Therefore they need improvement.

Frameless car washers

To perform a replacement or modification, you must perform the following steps:

- First you need to disconnect the negative terminal on the battery.

- Then you need to tilt the mount towards you and remove the brush.

- If there is a decorative trim, it must be removed.

- By unscrewing the bolt, you can remove the old brush.

- Before replacing parts, be sure to check the dimensions of the new washer with the old one. It is advisable that the new one does not exceed the size of the old one by more than 2 cm.

- Installation of the new kit is carried out in the reverse order.

This is interesting: Where are the fuses of the Toyota Corolla 150: block diagram in the cabin

After upgrading, you should check the functionality of the unit: whether the brushes creak, how they work when switching modes. At high speeds of the windshield wiper motor, the wipers should work quickly, at low speeds - slowly. In addition, they must support intermittent operation.

Sorry, there are no surveys available at this time.

Incorrect operation of the intermittent wiper mode on a VAZ 21213 car

For the “ten” there are old and new type windshield wiper trapezoids, catalog numbers:

- 2110-5205015

- 2110-5205015-01

- 2110-5205015-11

- 2110-5205015-20

- 2110-5205015-21

In addition, on the “ten” you can install a Priora windshield wiper trapezoid; by the way, it is cheaper than the original one. The differences will be: 1. In the studs for the windshield wiper arms, on the VAZ 2170 trapezoid they are “13”, and on the VAZ 2110 they are “10”; accordingly, the wiper arms will have to be replaced. 2. In the wiper motor connectors. Connect according to the color of the wires (the photo shows a temporary connection method; ideally, all wire connections should be well insulated).

Quite often situations occur when the wipers do not work correctly on VAZ 21213 and VAZ 21214 cars. The most common problem is the negative functioning of the intermittent wiper mode. The source of its occurrence is burnt contacts of the gearmotor.

If you find yourself in a similar situation, here is the solution:

- Remove the gear motor together with the rack (look at the motor shield, there you will find two nuts in the area where the heater casing is located). There will also be two windshield wiper arm nuts.

- Remove the cover from it, tighten the contact, and then drop a little superglue (one crank nut and four screws).

- Once the assembly is complete, the system will function properly.

Replacing the trapezoid

The replacement process is simple, but it involves manipulations that require increased attention and accuracy - there is a danger of damage to neighboring components and mechanisms.

We de-energize the car by removing the “negative” terminal. We remove the special wind cover (the so-called “jabot”) and the expansion tank. The latter must be removed at an angle - there is a possibility that some of the coolant will spill out, so it is useful to first drain some of it into a previously prepared container.

Then you need to turn off the gearmotor

. To do this, remove the corresponding connector. Carefully pull out the trapezoid (depending on the year of manufacture, it can be attached to two or four studs) and carefully remove it from the air supply box. That's it, the work is completed.

Installation of a new trapezoid is carried out in the reverse order.

How to remove the windshield wiper trapezoid

To remove the trapezoid you will need:

- key to 10;

- thin flat screwdriver;

- crosshead screwdriver.

First of all, you need to remove the wipers. To do this, you need to remove the plastic pads and unscrew the nuts with which they are attached to the trapezoid studs. Then unscrew the screws and side fastenings of the protective casing (jabot) and remove it. If the fasteners do not come out, treat with WD-40. Before removing the casing, make sure to remove all screws, bolts and nuts. If the cover does not come off, look for a fastener that you did not remove. Lifting the frill, disconnect the washer fluid supply tube from the tee, and then move the casing to the side.

Remove the belt that supports the radiator tank and move the tank to the side. Then pull out the partition (sound insulation), which is located behind the tank. Don't forget to remove the washer fluid supply tube from it. Disconnect the electric motor power connectors. After this, unscrew the bolts securing the trapezoid and electric motor. To remove the trapezoid, you must either struggle for a long time, coming up with various options, or place a thin flat-head screwdriver under the far end (relative to the motor) of the lower rod of the trapezoid and pull out the entire structure as if on a slide. You can also turn the left edge of the trapezoid clockwise and pull it out, then remove the engine.

Putting the trapeze in place

Usually, installing the trapezoid into place does not cause difficulties. Insert it and secure with bolts. Do not overtighten the motor mounting bolt; the motor may need to be turned slightly to get the trapezoid to operate smoothly. After making sure that the trapezoid is working properly, tighten the electric motor mounting bolt, install and secure the sound insulation, frill (do not forget to connect the washer tube), and the expansion tank. Insert the plastic plugs and install them in place, install the arms with brushes and check the operation of the wipers in all modes.

Helpful information

Before purchasing a part, you need to find out which trapezoid is needed: there are “old” and “new” samples, indistinguishable in appearance. However, there are quite serious internal differences, which makes it impossible to install the “wrong” trapezoid.

However, our mechanics found an interesting way: a small modification (removing “extra” fastening studs on both sides of the body) solves the problem.

Moreover, experts advise installing a trapeze from Priora on a VAZ 2110 - in this case, a rework is also needed, but some cost savings are achieved (spare parts from Priora are cheaper). The modification consists of replacing the wiper arms ( on the VAZ 2110 they are slightly smaller

In addition, the connectors for connecting the electric motor are different. Here you need at least minimal knowledge in electronics, because you will have to install new wiring, reliably insulating it.

Trapezoid repair

During repairs, it is necessary to clean all elements of the trapezoid from dirt and inspect the studs. If wear is detected on their ribs, the trapezoid will have to be replaced. Repairing a trapezoid involves replacing the plastic caps. To do this you will need a repair kit and boiling water. First, disassemble the trapezoid using a pry bar or a heavy-duty flathead screwdriver as leverage. After this, cut off the old plastic caps. If you can’t cut it, use side cutters and bite off the caps piece by piece until you can pull them out of the trapezoid rods. You can also hold the ends of the trapezoid in boiling water, 2 to 3 minutes is enough, then push the caps out of their seats.

This is interesting: Replacing brake fluid: how much to pour, how often to change

Three types of trapezoids were installed on cars of the “tenth” family - VAZ 2110, 2111 and 2112, which differed in minor details. Therefore, there is a possibility that either the trapezoid rods or the caps will have to be adjusted. Remove the cap and inspect it. If there is a fixing protrusion on top of it, check the recess for it on the rod seat. If there is no notch, you will have to either cut off the protrusion on the cap (does not affect the performance and reliability of the trapezoid) or saw through it in the draft. If there is no protrusion on the cap, no adjustment will be necessary.

Clean the rod and seat, then lower the cap into boiling water for 10 - 15 seconds. After this, it will soften and easily fall into place. Do not install a cold cap as this will destroy it. After the cap has cooled completely (20 minutes), the rod is ready for assembly. Before assembly, lubricate the bushings with graphite grease.

Check the serviceability of the electric motor. To do this, disconnect it from the trapezoid (you need to unscrew the fastening nut) and connect it to the car battery. When working, it should make a low buzzing sound. If you don't know how to connect the motor to the battery, then connect it to the power connector. Turn on various operating modes of the electric motor for 10 - 15 minutes. After that, feel it. If the motor gets hot, it needs to be replaced. An electrical technician can try to repair this device, but regular drivers and car enthusiasts need to replace it.

Repairing a trapezoid using a repair kit

If the bushing in an old part is simply worn out, it is not necessary to change the entire trapezoid. It is enough to simply repair it using a repair kit. As a rule, it has everything you need. To repair the trapezoid, you will also have to remove it. When removing the wiper arms, you must try to act extremely carefully, otherwise you may damage the glass or paint on the edge of the hood.

Worn bushings.

Instructions for installing parts.

New details.

Litol for abundant lubrication of friction units of parts.

What are the causes of breakdowns?

The most likely factor causing the wipers to stop is the blown working element in the fuse. Eliminating this malfunction involves performing the simplest action - replacing the fuse link. It is located in the corresponding mounting block, located on the left side of the steering column. It will be useful to stock up on a fuse diagram, which will help you easily find the insert we need.

When the purifiers stopped functioning intermittently, the control relay most likely became unusable. This component is also located in the previously designated block. When a relay fails, it is replaced with a new analogue. However, we note that according to numerous reviews from owners of domestic small cars, certain statistics have been formed indicating the small number of cases of breakdowns of this kind.

The most common cause is the destruction of bushings. They are made of plastic, so they do not boast a long service life, which reaches a maximum of three years. The process of destruction of elements is primarily influenced by the quality indicator of the material. Here, the only effective measure is replacement, and to carry it out you should acquire a repair kit, which is available at a specialized retailer. In this case, the trapezoid is replaced.

If the owner of a Lada Kalina discovers that the wiper drive is not working, this indicates that the unit’s motor has failed. In order to verify this fact, you will need to make sure that voltage is supplied to the motor contacts from the on-board network. This procedure is easily performed using a regular tester. If there is power, then we definitely change the motor.

Recommendations

Often the wipers on the VAZ 2110 begin to work poorly as a result of problems with the electric motor, and not the trapezoid. For this reason, when servicing or replacing the trapezoid, it is important to check the serviceability of the electric wiper motor.

- To check the wiper motor, you need to disconnect it from the trapezoid by unscrewing the mounting nut. The motor is then connected directly to the battery or via a standard power connector. A low buzzing sound during operation is considered normal. At the same time, noise, grinding and crackling when power is supplied are unacceptable. We also recommend reading the article on how to replace windshield wiper blades. From this article you will learn about the features of replacing wiper rubber bands, as well as what you need to consider when performing this procedure.

- Experts also recommend turning on different operating modes so that the engine as a whole runs for about 10 minutes. Next, you should feel the motor. Strong heating will indicate that the wiper motor will soon fail and needs to be replaced. It is also possible to repair the motor, but it is easier and faster to purchase a new device, since its cost is not high.

Finally, we note that the VAZ 2110 windshield wiper requires regular trapezoidal maintenance. At a minimum, cleaning from dirt and lubrication is necessary. This allows you to significantly increase the service life of the mechanism and reduce the load on the electric motor, increasing its service life and productivity.

Causes of malfunction

Therefore, if the brushes are completely frozen, or only squeak, the root cause should be sought in the electric motor. Not forgetting that in addition to electrical problems, there may be mechanical problems.

The most common ones are:

- When you turn on the windshield wiper, you can hear the motor running, but it only jerks or remains motionless. First of all, you need to suspect that the nut securing the crank to the gearbox axle has become unscrewed or loosened;

- If the windshield wipers operate but are not synchronized, the leash may be the culprit. Most likely, the nut securing it has become loose. Before tightening it, you need to put the wipers in the correct position.

If the electrical part is faulty, the symptoms will be:

- The wipers work slowly, stop wherever they want, and do not want to take the lower position. The limit switch may be to blame for this. Its adjustment consists of bending the contacts. If such repairs do not help, then the entire electric motor assembly needs to be replaced, since it is sold only together with the gearbox;

- Intermittent mode is turned on, but the brushes work without stopping. Most likely the relay has failed and needs to be replaced. This is definitely a relay if on a VAZ, when the intermittent mode is on, the noise of the rotating armature of the wiper motor is inaudible. But if the replacement did not help, the contacts of the limit switch may have oxidized or burnt;

- You turn on any of the modes, and you only hear the thermometallic fuse click. The brushes “stand still” and the anchor is also inaudible. First of all, check to see if the brushes are frozen and therefore do not move. By the way, fuse F5 often blows in this case. Another possible reason is that the anchor burned out;

- The electric motor does not work, although both fuses are intact. It is necessary to check all the contacts that the drive has, as well as the motor. Perhaps the brushes are stuck or the armature is burnt out.