Do-it-yourself repair and replacement of the windshield wiper trapezoid

The safety of the driver and the people in the car with him when driving in bad weather depends on the cleanliness of the windshield. The glass surface is cleaned by a cleaner, so its serviceability will determine how clean the glass will be. The article discusses the windshield wiper trapezoid (WW): the device, signs and methods of malfunctions, and instructions for replacement are given.

How to change a wiper motor: simple tips from experienced car owners

Issues discussed in the material:

- Windshield wiper system design

- Causes of wiper motor malfunction

- Replacing the wiper motor yourself

- Advice from car enthusiasts and professionals

Any vehicle must be equipped with wipers. Their main function is to clean the windshield from traces of dirt, dust, rain or snow. In this way, the driver can significantly improve visibility without leaving the cabin.

Car windshield wipers are an integral part of the vehicle's structure, so if they are faulty, it should not be used. How to understand that a malfunction has occurred and how to change wiper motors is a hot topic, and the answer to these questions and advice from professionals will help you deal with this problem on your own.

Characteristics of the windshield wiper trapezoid

The trapezoid is one of the most important elements of the windshield wiper mechanism. The operation of the entire unit depends on its serviceability. To maintain the functionality of the vehicle, you need to know what its device is and how it works.

Purpose and device

The trapezoid is the element of the glass cleaner that translates the rotational movements of the electric motor shaft into the movements of the wipers. Therefore, it is one of the components of safety in bad weather conditions.

Disassembled device

The design of the vehicle is almost the same for all car models. The differences lie in the shape, size of its components and methods of fastening.

The device consists of the following parts:

To reduce friction losses and energy consumption, the device connections are made of polyformaldehyde. It has a low coefficient of friction and high wear resistance. Metal parts are protected from corrosion processes and friction by a galvanic layer.

The principle of operation is as follows: the motor drives the finger, which causes the trapezoid to move. The shafts are connected to the gearbox using rods, performing oscillatory movements. The result of this work is the movement of the wiper brushes from side to side, due to which the glass surface is cleaned.

Symptoms of malfunctions and ways to eliminate them

In order for the windshield wiper trapezoid to be operational, you need to know the signs of its malfunction and try to eliminate them as soon as they are detected.

Another sign of a mechanism malfunction is intermittent, irregular movement of the brushes. The reason for this is oxidation on the drives of the drivers located in the vehicle bushings. If you do not pay attention to the oxide, the electric motor may fail, since a large load is placed on it.

Windshield wiper motor

If the windshield wiper trapezoid bushings are worn out, play in the windshield wiper arms appears. The weakening of the pressure in the assembly leads to the fact that the wiper does not fit tightly to the glass and cannot cope with the flow of rain. If the linkage of the windshield wiper is faulty, the movement of the blades becomes difficult.

The cause of the malfunction may be wear of individual parts. In this case, you need to remove, disassemble the mechanism and replace worn elements.

Lubrication

Heated windshield: DIY heated windshield

8. The shafts of the brush levers are secured in the bracket using an E-shaped lock washer installed in the groove of the axle. We insert a thin slotted screwdriver into the hole in the lock washer and, turning the screwdriver around the axis, remove the lock washer.

9. Remove the upper adjusting washers from the axle.

10. Remove the shaft from the bracket and remove the lower adjusting washers. We fold the upper and lower adjusting washers separately so that when assembling, all the washers are installed in their places.

Note. Be careful not to lose the rubber O-ring located in the bracket hole. A damaged ring should be replaced.

11. Using a rag moistened with white spirit, clean the shaft from old grease, dirt and traces of corrosion. Apply grease to the shaft (Litol-24 or equivalent).

12. Similarly, lubricate the shaft of the other wiper arm.

13. Using a rag moistened with white spirit, clean the hinge joints of the windshield wiper rods from old grease and dirt. Apply grease to the hinge joints.

To repair this unit, you need a minimum of tools:

- Set of keys and sockets.

- Screwdriver Set.

- WD-40.

- Rags.

- Replacement parts.

It is quite easy to determine which parts are not working. For example, if the wipers do not move, then the motor has failed. If the trapezoid moves, but the glass remains dirty, then the pump or tank is damaged. The size will help you understand what condition the part is in - if the size has decreased too much, then the element needs to be changed. In any case, you need to make sure of the speculations; for this you should analyze:

- The first step is to dismantle the car's dashboard;

- Next you need to find the relay related to this mechanism. It is screwed to the body of the VAZ 2110. If the electrical elements do not work, then the relay needs to be changed; repairs will not help;

In what cases does a part need to be replaced?

If there are signs of a vehicle malfunction, in order to figure it out, repair or replacement is necessary, diagnostics should be carried out. If it is possible to repair the windshield wiper trapezoid, then you should replace broken or worn parts (video author - GARAj Alex Fierro).

If it is customary to completely change the device, then when purchasing a new product you should pay attention to the mounting method and size. Trapezoids may differ in the plug for connecting to the electric motor and the size of the leads.

One conclusion can be drawn: you should buy original products designed specifically for your car model.

Part of the old and new sample

Selecting a new part for a VAZ-2110 is not such a simple matter. Not everyone knows that there are old and new trapezoids.

The old-style trapezoid rods are secured with two studs.

The new type of rods are installed without problems if you remove one pin.

Therefore, it is better to remove the old part and take it to an auto parts store. They are not only attached differently, but also differ in the connectors through which they are connected to the motor. If you can’t find an old-style trapezoid, and this is exactly what you have, you’ll have to redo the system or look for a used part.

- As a rule, trapezoids of a new type are available for sale from various manufacturers. One of the popular models has the article number VLT2110–5205010-Р.

If the windshield wiper motor is working properly, you can only change the trapezoid itself.

Instructions for replacing the trapezoid

Replacing the windshield wiper arm can be done by yourself as it is a simple process. The entire mechanism needs to be replaced.

Before work, you should prepare the following tools and materials:

Photo gallery “Step-by-step replacement of the windshield wiper trapezoid”

To do this, follow these steps:

- First of all, you need to turn off the power to the car by removing the “-” terminal from the battery.

- The next step is to dismantle the old trapezoid. To do this, you need to remove the windshield trim and the expansion tank.

- Then you need to disconnect the wiper motor connector.

- Next, you need to unscrew the left and right nuts securing the glass wiper, remove the wipers, all plugs and fasteners using a Phillips screwdriver. The plastic parts on the casings also need to be removed.

- Then you need to unscrew the fastening nuts of the electric motor bracket to the car body, as well as the fasteners connecting the trapezoid to the motor. After this, you can dismantle the motor.

- After dismantling the electric motor, the vehicle can be removed.

- Before installation, the new vehicle must be assembled, since it is sold disassembled.

- After installing a new product, the mechanism should be assembled in the reverse order.

When the assembly is completed, you need to adjust the brushes and lubricate all components and parts of the graphite lubrication mechanism.

Putting the trapeze in place

Usually, installing the trapezoid into place does not cause difficulties. Insert it and secure with bolts. Do not overtighten the motor mounting bolt; the motor may need to be turned slightly to get the trapezoid to operate smoothly. After making sure that the trapezoid is working properly, tighten the electric motor mounting bolt, install and secure the sound insulation, frill (do not forget to connect the washer tube), and the expansion tank. Insert the plastic plugs and install them in place, install the arms with brushes and check the operation of the wipers in all modes.

The design of the windshield wiper on the VAZ 2110 is quite reliable and during normal operation the motor and the trapezoid itself can easily move all 300,000 km, which has been proven by the personal experience of many owners. But there are also exceptions to the rules.

It often happens that the splines are bypassed or the trapezoid structure simply breaks down. If you have such problems, the repair procedure will be discussed below.

To replace all the wiper parts, we will need the following tool:

- screwdriver flat and Phillips

- 10 mm socket head

- ratchet handle

To do this job, you first need to do some preparatory steps, namely:

- Remove the windshield trim (jabot)

- Remove the insulation and seal under the hood

- Disconnect one end of the expansion tank rubber and move it to the side

Replacing the windshield wiper trapezoid

Windshield wipers prevent snow, rain, or dirt from sticking to your glass. They include a trapezoid, which can fail, so it is necessary to detect the breakdown in time and repair it.

It is almost impossible to imagine a production car without a windshield wiper, and its breakdown in bad weather conditions can lead to an accident. As a rule, moving mechanisms fail. Let's consider what frequent breakdowns are observed, the principle of their elimination and replacement of the trapezoid.

How to repair rear wipers?

In addition to the front windows, the car also has rear windows, which in station wagons and hatchbacks usually also have wipers. They, like the front ones, can fail. Diagnosing them will be a little more difficult: the design of rear wipers on modern cars is more sophisticated than what we described above. Moreover, it is less common to find universal parts in them. But it’s still worth trying to figure out what’s wrong.

- Check the wiring in the trunk lid area: it is especially vulnerable.

- Check to see if the fuse is broken or carbonated. This needs to be done first if, in addition to the wiper, for example, the stove also stops working.

- Inspect the bushing for rust.

- Make sure the problem is not loose bolts.

- Check the steering column switch.

- Make sure that the problem is not a breakdown of the gear motor installed at the location where the windshield wiper is installed.

Signs of trouble

In order to fix the breakdown in time, you need to know the first signs of problems associated with the windshield wiper mechanism, namely the trapezoid. It's not that difficult to spot them. First of all, problems with the trapezoid may be indicated by poor performance of the wipers. For example, they may move out of sync or too slowly. Also, intermittent movements on the glass or a characteristic creaking sound can be a signal of problems with the trapezoid.

However, these signs may indicate problems with the wipers or other mechanisms. In order to find out the true cause of the breakdown, you must fully diagnose the system.

Often, problems with wipers lead to wear on the trapezoid bushings. A clear sign of this problem may be the formation of backlash. The main reason for this is the formation of oxide, which subsequently causes the electric motor to malfunction.

In any case, these signs indicate the need to repair the trapezoid mechanism. Depending on the stage of the device failure, you can either repair the problematic elements or completely replace the device.

Prevention

To avoid wasting your nerves, money and time, you should follow a number of recommendations that will help minimize the risk of wiper failure.

- Inspect your windshield wipers and related mechanisms from time to time. Is there any visually noticeable damage, corrosion, and are all fasteners reliably performing their functions?

- Unfasten frozen wipers from the glass in winter (before turning them on). Try not to leave ice underneath them.

- Remove snow from the glass before turning on the wipers.

- When picking up your car from the service center, do not forget to check whether the windshield wipers are working and whether the wiring has broken.

We went through the main causes of windshield wiper failure and how to fix them. Many of the breakdowns can be eliminated independently, without special costs. But it’s impossible to fix some things in a car without special education and equipment, so, unfortunately, problems with the wipers can be a reason to contact a service center. The life and health of you and your passengers depend on the cleanliness of the glass and freedom of view. Delaying repairs is unacceptable.

To learn why the wipers don't work, watch the following video.

Repair and replacement of trapezoid

Before you start work, you should prepare all the necessary tools, namely a Phillips and flathead screwdriver, keys, and lubricant.

In case of complete replacement of the trapezoid, it is necessary to carefully select a new device. It is better to choose a branded device, since the trapezoid itself of different models has a similar appearance, however, the mounting methods or dimensions may differ significantly. It is best to use trapezoids from well-known companies Original Equipment Manufacturer (OEM), Fabryka Samochod?w Osobowych (FSO) and GENERAL MOTORS (GM), which are famous for producing quality parts.

The next step is to disconnect the trapezoid from the motor. This stage can be difficult, since the nuts are often very tightly fastened, and it is not always possible to unscrew them with a simple wrench. In this case, a drill, crowbar or any other tool capable of removing the nuts will do. Once you have managed to disconnect them, remove the motor and take out the trapeze.

Before installing a new part, you should check its integrity. After this, you should assemble the entire structure in reverse order. After securing and screwing in all the necessary parts, it is necessary to check the presence of lubricant. If it is missing, you need to lubricate the parts that rub against each other. Basically, a graphite-based lubricant is suitable for this, which is durable and protects parts from rust and overheating. Another popular type of lubricant is lithol. However, it is better not to use it, since the lubricant is quite unstable and under low temperature conditions it partially loses its original properties.

In the case of repairing a single part, there is no need to completely disassemble the entire trapezoid mechanism. In this case, you only need to replace the worn bushings. To do this, unscrew the nuts and other fasteners. After you have removed the worn bushings, you should clean the axle from adhering dust and dirt. There may also be rust on it that needs to be removed. Then you need to secure the new aluminum bushings so that they slide in easily and smoothly. After everything, lubricate the necessary parts with graphite lubricant and reassemble the structure in the reverse order.

Lada Priora Hatchback Cons >› Logbook › Wipers! Repair of trapezoid!

A lot of letters... Blah... it’s just something unimaginable... Unfortunately, on my car, I’m gradually coming to the conclusion that this is the weakest point.

Around the middle of last summer, I noticed clicks and so-called braking when the windshield wipers were operating, which I think is familiar to many Priorovods. As a result, one rainy day while at the dacha, I decided to deal with this problem and began disassembling the wiper mechanism, the first time it took a crazy amount of time! I filmed the trapeze for about 3 hours! Who came up with this system? How is this possible?

There was no Internet at the dacha, and it was not possible to see how to do this easier at that moment!

I took it off, disconnected the wiper motor from the trapezoid, disassembled it and was shocked! The gears in the motor are plastic! They stupidly rubbed against a steel pulley... and were completely erased! After thinking a little, I decided to go to the nearest stores in search of a repair kit or a new wiper motor!

Stressing a little and remembering that according to the rules it is prohibited to operate a car with faulty windshield wipers on the driver's side, and also keeping an eye on changes in the weather, I drove through about 6 stores with spare parts, of which only 1?! there was a trapezoid and a motor for the windshield wiper mechanism on the Priora! And they haven’t even heard of repair kits...

As a result, I put everything back, which required about 2 more hours of torment, three floors of swearing and curses in a faulty state, returned to Nizhny and arrived at the service center and changed the assembled mechanism for 3000 rubles along with the work of a master (from whom I heard many friends words ala *ala who came up with this?! Where do their hands come from?! What kind of car is this anyway. in the course of work on replacing the mechanism) And then, around mid-April, in a good mood, heading to work in the morning, a light drizzle began... As if nothing had happened, I’m trying to turn on the rain sensor while sitting in a traffic jam, but what the hell?! They just don’t move... the washer motor is working, but the wipers haven’t moved one step! Luckily the rain stopped, and the next day was a day off, so I got ready to disassemble it again! This time, having already gotten the hang of it, removing the mechanism took no more than 15 minutes. In fact, removing the trapezoid on a car with climate control is simple - first, remove the frill, remove the expansion barrel for antifreeze, simply fold it out of the mounts, then disconnect the motor from the trapezoid mechanism directly on the car, then the trapezoid is easily removed.

This time the reason for the windshield wiper failure was a jammed trapezoid; I had to knock it out with a hammer,

and then re-cut the thread on the driver's wiper pulley, liberally lubricating the trapezoid with Litol, it worked just fine!

But during installation, as I understood after the final assembly, I incorrectly attached the wiper guide to the motor. Now the driver’s wiper does not reach the area that was previously cleaned by about 1 cm, but stops in the lower position 2 cm higher than it should be, one of these days I’m thinking of disassembling the trim again because when disassembling the wipers, I discovered that it was necessary to change or glue the frill with normal double-sided tape - in some places the standard tape began to peel off. I’ll write here about adjusting the wipers and, at the same time, about replacing/sizing the frill.

Now they say that BOSCH windshield wiper mechanisms have appeared, maybe someone has installed them? Can you share your impressions of the operation of this mechanism?

PS the next day after the repair, two days of intermittent rains began... Well, at least the mechanism did not fail in a situation when it was necessary to go somewhere urgently or on the highway when traveling long distances...

Repair cost

You can repair or replace the trapezoid at any car service center. However, the price for this service is quite high. In case of self-repair, all parts can be found in any automobile store. Trapezoid parts are sold disassembled, and their price ranges from $40-70. The cost of graphite lubricant is approximately $10-20.

Video about replacing the VAZ 2110 windshield wiper trapezoid:

Let's summarize

Replacing a trapezoid without experience in car maintenance will take approximately thirty minutes. The price for replacing a VAZ 2110, 2111, 2112 trapezoid at service stations is from 500 to 1000 rubles.

Sources

- https://enginehack.ru/dvorniki-shhetki-lady-priory-zamena-i-raznovidnosti/

- https://AutoManya.ru/uncategorized/mehanizm-stekloochistitelya-vaz-2110.html

- https://carfrance.ru/trapecia-dvornikov-na-vaz-2110/

- https://VipWash.ru/lobovoe-steklo/trapeciya-dvornikov-zamena-na-vaz-2110

- https://autorn.ru/vaz/2110/438-zamena-i-remont-trapecii-dvornikov-vaz-2110-2111-2112.html

- https://lada-avia.ru/drugoe/kak-snyat-trapeciyu.html

- https://prometey96.ru/ekspluataciya/privod-dvornikov-vaz-2110.html

- https://KrutiMotor.ru/zamena-trapetsii-dvornikov-vaz-2110-svoimi-rukami/

What is a windshield wiper trapezoid?

Windshield wiper trapezoid - a windshield wiper drive, a system of rods and levers that provides reciprocating movements of the wiper blades on the windshield or tailgate glass of vehicles.

Cars, buses, tractors and other equipment must have a windshield wiper - an auxiliary system that cleans the windshield of water and dirt. Modern systems are electrically driven, and the transmission of force from the electric motor to the brushes is carried out using a system of rods and levers laid under the glass - a windshield wiper trapezoid.

Advice from car enthusiasts and professionals

1. How to change the rear wiper motor

The mounting of the rear window of a car is usually different from the front. Therefore, the windshield wiper drive system is also designed differently there. Accordingly, the answer to the question of how to change the rear wiper motor also has a number of nuances:

- First of all, the windshield wiper is fixed in a vertical position to provide access to the fastening screws.

- The next stage is to disconnect all external communications from the mechanism and disassemble the structure itself. First of all, dismantle the lever, then the protective cap of the rotary shaft and unscrew the bracket fasteners.

- It is impossible to remove the rear wiper motor without freeing the trunk from the upholstery. It is held on by pistons that need to be removed in those places where the wiring connection block to the gearmotor is located.

Be sure to disconnect two pads. One is used for connecting cables, the second for cables.

- After disconnecting the electrical part, unscrew the screws holding the motor.

- Then you can remove the engine by turning it left and right.

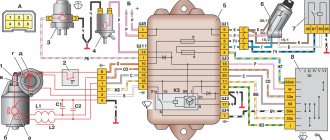

Types, design and operating principle of windshield wiper trapezoid

First of all, all trapezoids can be divided into three types according to the number of brushes:

- For single blade wipers;

- For double blade wipers;

- For three-blade windshield wipers.

In this case, the drive of one brush cannot be called a trapezoid, since in most cases it is built only on an electric motor with a gearbox without additional rods or with one rod. And two- and three-brush trapezoids have a fundamentally identical design and differ only in the number of rods.

In turn, two- and three-brush trapezoids can be divided into two types according to the location of the electric motor connection:

- Symmetrical - the electric motor is located in the center of the trapezoid (between the brushes), ensuring the movement of both brush rods at once;

- Asymmetrical (asymmetrical) - the electric motor is located behind the trapezoid, providing its drive with additional lateral traction.

Today, asymmetrical trapezoids are the most common; they have a fairly simple structure. In the general case, the basis of the design is made up of two hinged rods; in the hinge between the rods and at the end of one of them, leashes are installed - small length levers, rigidly connected to the rollers of the brush levers. Moreover, the middle leash can be installed directly into the hinged connection of two rods (in this case, two rods and a leash come out from one point), or it can connect the rods with two hinges, and carry a roller in the middle part. In both cases, the leads are located perpendicular to the rods, which ensures their deflection during the reciprocating movement of the rods.

The rollers are made in the form of short steel rods, on the top of which a thread is cut or slots are provided for a rigid fit of the windshield wiper blade arms. Typically, the rollers are located in plain bearings, which, in turn, are held by brackets with holes for fasteners. With the free end of the second rod, the trapezoid is connected to the electric motor gearbox, which has the simplest design - in the form of a crank directly located on the motor shaft, or mounted on the gear of a reduction worm gear. The electric motor and gearbox are assembled into a single unit, which can also contain a limit switch that ensures that the blades stop in a certain position when the windshield wiper is turned off.

Rods, drivers, rollers and brackets of the mechanism are made by stamping from sheet steel or by bending tubular blanks that have high bending rigidity. The hinges are made on the basis of rivets or pistons; plastic bushings and protective caps are installed at the hinge joints; additional lubrication may also be provided. The holes for the hinges in the leads are often made oval to ensure the necessary trajectory of movement of the brushes.

The windshield wiper drive works as follows. When the windshield wiper is turned on, the crank converts the rotational movement of the electric motor shaft into the reciprocating movement of the trapezoid rods, they deviate from their average position to the right and left, and through the leads they force the rollers to rotate at a certain angle - all this leads to characteristic vibrations of the levers and the brushes located on them.

The trapezoids of three-blade windshield wipers are designed in a similar way, only a third rod with a leash is added to them; the operation of such a system is no different from that just described.

Symmetrical trapezoids also represent a system of two hinged rods and leads, however, the leads are located at opposite ends of the rods, and an additional leash or lever is installed in the hinge between the rods for connection to the electric motor gearbox. To increase rigidity and simplify installation, a bracket can be inserted into such a trapezoid - a pipe connecting the brush leads, in the central part of which there can be a platform for mounting an electric motor with a gearbox. This system does not require separate fastening of leads or rollers, which increases its convenience and reliability compared to other types of trapezoids.

Windshield wiper trapezoids can be located under or above the windshield in a special niche (compartment) formed by body parts. The brackets with the rollers of the brush levers are mounted on the body (flush) using two or three screws (or bolts), and the leads of the rollers are usually sealed with rubber rings or protective caps/covers. The electric motor with gearbox is mounted directly on the body part or on the bracket included with the trapezoid. Single-blade tailgate glass wipers are installed in the same way.

Wiper design

The main parts of the windshield wiper are the supporting frame and the cleaning element.

Wipers with metal frame

The supporting frame is made of metal or plastic. Wipers with a metal frame are more durable and strong. This frame is used to make winter windshield wiper blades.

Wipers with plastic frame

There is another type of brush design - frameless brushes. The frame in such brushes is a cleaning rubber band and the wiper itself is made entirely of rubber.

Frameless wipers

The cleaning element is made of soft rubber or silicone, which ensures a tight fit to the windshield and excellent cleansing of moisture.

Types of wipers

- Classic.

The design consists of seven metal “rocker arms” arranged pyramidally. The largest arc holds two smaller ones, which, in turn, hold even smaller ones and are attached to a rubber blade. This design allows the downforce of the wiper to be evenly distributed. Slowly going out of fashion, these wipers are falling in price every day, while performing their functionality very well in the warm season. The main enemy of such a wiper is snow. But it is impossible to say that these brushes are worse in functionality than frameless ones. The pressing effect of such a design loses its properties over time. Therefore, it is better to change the brush frame itself after a few years.

- Frameless.

The “rocker arm” system for this type of wiper is replaced by a thin metal plate that passes through the entire length of the brush. It is a frame, despite the so-called frameless classification. They tolerate snow better, but this design has a disadvantage - the distribution of downforce here is worse than that of “rocker arms”. In the cold there is a shrinking effect. The advantages of these brushes over the previous ones can be called design. Although the taste and color as they say... .

- Winter brushes.

They repeat the classic summer design, but all its moving parts are hidden under a rubber cover. But these brushes are not very suitable for summer, since the casing causes too much windage. If the speed is above 90 km. at an hour, the brushes begin to move away from the glass. As good as such brushes are in winter precipitation, they are just as bad in summer precipitation.

- Hybrid.

These brushes are the latest development for today. Metal “rocker arms” here replace three plastic arcs, they also act as a winter cover, thereby allowing these wipers to be called hybrid. Another distinctive feature of these wipers is improved aerodynamics. Headwind increases downforce. Although in such a design there is something to freeze on.

In conclusion, we can say that in winter it is better to use winter wipers, and for summer any wipers except winter ones are suitable. It's up to you to choose. In any case, new wipers, no matter what design, are better than those that do not perform their functions at all.

Symptoms of a malfunction and how to fix them

A trapezoid is an electromechanical device whose purpose is to convert the rotational impulse of the engine into forward-return movements of the wipers.

The principle of operation is simple: a motor uses a finger to activate the trapezoid mechanism. The rods connecting the shafts and the gearbox convert rotary motion into translational motion and activate the wipers.

Signs of a faulty windshield wiper trapezoid:

- the appearance of extraneous noise during operation;

- loose fit of the brush to the glass. Over time, the gap will increase, snow/water will no longer be cleared off at all;

- windshield wiper blades do not cope with heavy rainfall; the trajectory of the wipers changes (they go too low or too high, leaving uncleaned areas);

- the mechanism interferes with opening/closing the hood and scratches the paintwork.

There are two ways to fix the problem - replacing the wiper trapezium or repairing it.

cut off the slots on the wipers

the car stood in the yard for a week, snow fell on it, it thawed, etc. I returned from vacation and did not notice a decent amount of ice at the bottom of the windshield. as a result of turning frozen wipers, the splines were cut off (this is in the place where they are seated on the shafts). Is this treated with “improvised means” or only by replacing parts?

Are you sure that the electric motors turn on and the wiper axes rotate? Maybe the electronics cut off the electric motors due to current when they jammed?

It also seems to me that they should have passed out.

The electronics turn off the wipers if there is an overload. The error must be erased in the block, or it should go away on its own.

I had this happen, you turn on the wipers and they don’t scrape.

The axles are spinning - I checked. The fact of the matter is that it didn’t jam or cut off, the wipers nevertheless moved a little and dragged a piece of ice that had frozen to them; the cut slots after removing the wipers were visible to the “naked eye”; by the way, bus wipers (or parallel ones). which the plant stopped supplying from the 22nd week.

replacement of parts 1T0955601A and 1T0955602A for 4450 rubles or to Kulibin

Are the slots on the leashes intact?

Well, try the traditional method - put metal foil where the slots should have been and screw it a little tighter. It helped me on the BMW, but then the whole trapeze fell apart.

The slots on the axle on which the windshield wiper arm sits and is tightened with a nut are licked. Thus, the brush on the passenger side does not work (turns), if you put some foil and tighten the nut, will it work? VAZ 2112

How to change a windshield wiper trapezoid

It is necessary to select a new spare part suitable for a specific vehicle and prepare the tool. You will need several different wrenches, a flathead and a shaped screwdriver. Depending on the make/model of the machine, the process of disassembling and reassembling the mechanism may differ.

Replacement is carried out according to the following algorithm:

- The wiper arms are unscrewed.

- The wipers themselves are removable.

- The retaining ring and casing are dismantled.

- The rod is disconnected from the drive joint of the mini-motor.

- The fastening elements of the brackets are unscrewed.

- The trapezoid is removed.

- The windshield wiper trapezoid is being replaced with a new one.

- Reassembly is carried out in reverse order.

Replacing the wiper mechanism

Change the mechanism or repair it - this will be shown by system diagnostics. When replacing, the windshield wiper trapezoid is purchased entirely and only for your car model from the original manufacturer. Because outwardly similar trapezoids from different manufacturers may have different connection connectors and be connected in different ways. For VAZ cars, two types of trapezoids are produced. One is fixed with two studs, and the second with four. They have different sizes of wiper arms and connectors for connecting to the electric motor.

For Lanos and Sens cars, the catalog number of the trapezoid mechanism is 96303360 (Korean model) and 245215200 (Ukrainian standard). How is a part replaced and where can it be done? The replacement work can be done at a service center or independently:

- The old part is dismantled using a 10, 12, 13 wrench. The nuts that secure the wipers are tightened, then the brushes are removed. You need to bend the leashes in advance, since the elastic spring may make dismantling difficult.

- Then use a Phillips screwdriver to unscrew the screws and remove the plastic part.

- The plugs are pryed off with a knife, after which the remaining fasteners are removed.

- If you remove the plastic elements of the casing, you will have access to the trapezoid. The connecting part between the trapezoid, the electric motor and the body bracket is unscrewed. For safety reasons, turn off the power supply and remove the motor. The trapezoid is removed after removing the remaining fasteners.

- Before installation, the new part must be assembled, secured with three bolted connections. The first part, without twisting the bolt, is inserted into the eye, which is located near the casing. Then put on the remaining part of the knot, simultaneously adjusting its position. When everything is ready, tighten the nuts and install.

- Reassembling the entire assembly is done in the reverse order.

- After assembling the unit, the brushes are adjusted. This may take a long time.

- Be sure to lubricate all joints and rubbing surfaces with graphite lubricant. You should not use lithol. It loses its properties in cold weather.

How to repair a trapezoid

Repairs are rarely carried out when bushings break.

It is difficult to select them; it is easier to change the entire mechanism assembly. However, repair kits are available for some cars.

Spare parts can be plastic and aluminum.

The latter are more reliable, but they cannot always be found. And they are not suitable for every mechanism.

Repairs are carried out as follows:

- The mechanism is disassembled (as when replacing), the trapezoid is removed.

- Old parts are removed.

- The worn bushings are replaced with new ones from the repair kit.

- The mechanism is assembled in reverse order.

Bushing repair kit

For many foreign cars, it is very difficult to find a repair kit for new bushings in stores. But you can purchase a new rod, into which the bushings are already pressed. Such a part costs a maximum of $50. For rarer cars, even traction is almost impossible to find. In order not to run around the store looking for parts, it is better to restore this unit with your own hands. This is done in two ways:

- The bushing repair kit for VAZ cars is inexpensive and, due to their diameter, the bushings are well suited for trapezoid traction not only in gazelles, but also in foreign cars. But before buying a repair kit, you need to get the worn bushings and measure the place where they will fit. The outer diameter of the balls, which are located on the trapezoid rollers, is also measured. If you cannot find bushings of the required diameter in the store, they can be made to order.

- The production of bushings can be ordered at any car service center. The material used is any plastic containing Teflon. Thanks to Teflon, the parts have a low coefficient of friction and do not require frequent lubrication. Bushings made of caprolon material are additionally machined with collars. These collars prevent them from jumping out of their seats. You can make four bushings, two of which will remain spare. It is difficult to press bushings with collars made of inelastic plastic into the holes of the rod. Before pressing, they are softened in boiling water. There is no point in making the beads on the bushings from a very hard material, since they will deteriorate during pressing. The beads are made after the bushings are pressed into the holes of the rod. The ends of the bushings are flared using a soldering iron.

For what reasons might difficulties arise?

Carrying out the process itself is not difficult, but sometimes you still have to face problems and solve them:

- If a repair kit is not provided, the bushings are selected separately, but may not fit. In this case, they can be drilled out, making sure that the drill does not heat up too much and does not deform the plastic part.

- It is advisable to clean the surface of aluminum products, as there are often unevenness and roughness on it - this interferes with the installation of the part.

- The most common question that arises is how to remove the windshield wiper trapezium. The fact is that fasteners tend to “sour” without giving in to the key. In this case, you will have to resort to using a grinder or drill. At home, craftsmen often resort to using a hammer and chisel to cut off a tightly fixed bolt.

- Before installing a new trapezoid, its elements are inspected for lubrication. If it is missing, it is recommended to apply lithol or other lubricant to the mechanism components.

- When replacing the bushing with an aluminum one, it must also be lubricated.

- When purchasing an aluminum spare part, you should purchase four fastening elements (bolts, nuts) for it.

How to change the windshield wiper trapezoid quickly and efficiently? To do this, you will have to contact a car service. The technician will help determine the breakdown, advise which spare part to choose for a specific car and, most importantly, solve the problem with stuck bolts carefully, without the use of auxiliary tools, without causing serious damage. Any workshop has special solutions and devices to correctly solve the problem.

After installing a new trapezoid at a service center, you will not have skewed wipers, incorrectly adjusted position and other troubles that arise after amateur repairs.

Causes of wiper motor malfunction

The windshield wiper drive motor has a weak point in the form of a large number of contacts in the circuit. As a result, voltage losses are large, and even one poor-quality contact leads to deterioration in operating stability. However, the problem is not always in the engine itself. This means that you should not rush into the question of how to change the wiper motor without completely checking all the contacts in the electrical circuit.

Fuse. First thing to do is check the fuse. This is easy to do, but they fail quite often. Performance

Pay attention to the switch, whether it closes and opens the electrical circuit correctly. Operating Parameters

Check the resistance at the breaker terminals using an ohmmeter. If there is no resistance, then this is a sufficient reason to replace the breaker. Correct connection. Without turning on the wipers, measure the resistance between ground and terminal No. 4. If the device readings are different from zero, it is necessary to ensure normal grounding. Measure the voltage at terminal No. 5 with the windshield wiper turned on at low speed. If the value matches that on the battery, then the lack of movement of the motor indicates the need to study the next section, which tells how to change the wiper motor.

Tips for extending the life of your wipers

There are more radical methods for restoring the operation of windshield wipers, including:

- sanding;

- mechanical sharpening.

However, it is better for inexperienced drivers not to resort to this technique, otherwise there is a risk of permanently damaging the brushes without the slightest possibility of restoring them.

You can also turn to the experts, but most likely, their services will cost the same price as the cost of new wipers. To increase the service life of windshield wipers, it is necessary to regularly care for them, removing any dirt in a timely manner, and also not leaving the car for a long time under the scorching rays of the sun.

In addition, it is not recommended to save on such products, as well as on glass cleaning solutions, the quality of which also determines the lifespan of the element.