Problems that arise with the brakes while traveling are considered critical and must be corrected immediately. The culprit of the malfunction is often the main cylinder, installed in the engine compartment and rigidly connected to the pedal. To find out the cause of the breakdown and repair the unit yourself, you need to know the structure of the brake master cylinder (MBC) and its principle of operation. During the diagnostic process, it is necessary to distinguish and filter out problems with other elements of the system.

Replacing the master cylinder of the Lada Kalina brakes

If the piston of the master cylinder jams (due to corrosion, breakage of the return springs), incomplete release of the brakes on all wheels may occur.

A defect such as “failure” of the brake pedal may also occur

Rebuilding the master cylinder often does not lead to the desired results, so it is recommended to replace the master cylinder assembly.

Replacing the brake master cylinder

Remove the battery and the air supply hose to the throttle body.

Having unscrewed the tank cap, remove the cap along with the liquid level sensor. Use a rubber bulb to remove liquid from the tank.

Use a rubber bulb to remove liquid from the reservoir.

Using a 13 mm wrench or a special wrench for brake pipes, unscrew the fittings of the two brake pipes.

We remove the tube tips from the holes of the master brake cylinder.

Using a 13mm socket, unscrew the two nuts securing the cylinder to the vacuum brake booster

Remove the brake master cylinder assembly with the reservoir.

The connection between the master cylinder and the vacuum brake booster is sealed with a rubber ring.

To remove the tank, press out the two tabs of the tank body and remove them from the bosses of the cylinder body.

Overcoming the resistance of the rubber sealing bushings, remove the tank fittings from the cylinder holes and remove the tank

If it is necessary to replace the sealing sleeve, remove it from the cylinder body

We assemble the brake master cylinder with the reservoir and install it in the reverse order.

We bleed the hydraulic brake system.

Source

How to replace the brake wheel cylinder on a VAZ 1117-VAZ 1119?

Note! There are two ways to replace this cylinder, both of them are very similar to each other and are done almost identically, but they differ only in that in one method you will need to completely drain the brake fluid from the car, and in the other you don’t even have to drain it at all, whichever you choose you decide for yourself, if you suddenly want to drain the fluid, we’ll say right away that the work will be very easy and there will be no dirt because the fluid will be drained, but if you choose the second method, then it’s not a fact that you won’t spill brake fluid from the hose, but it’s not very it has a good effect on human skin, but if you do everything correctly and competently, you won’t even spill anything, we’ll come back to this issue and tell you below how to replace the cylinder without draining the brake fluid from the car, and by the way, if you decide to drain it anyway , then in this case, study the article entitled: “Replacing brake fluid on a VAZ”, it says that you need to add fluid when replacing it, but since you are draining it, without adding anything, you simply loosen one of the fittings and, together with an assistant, drain all liquid through it!

Removal: 1) Now remove the wheel you need from the car (For information on how to remove wheels, read the article: “Correct replacement of wheels on modern cars”) and proceed with the replacement, first remove the brake hose from the bracket to which it is attached, this bracket is welded into the telescopic stand, and the hose with the part indicated below in the photo by the arrow goes into it, as soon as it is disconnected from the bracket, loosen (Do not unscrew completely) the nut of its fastening as shown in the small photo.

2) Next, use a screwdriver or something else to bend the tendrils of the lock washers and unscrew the two bolts holding the brake caliper; while unscrewing, hold the guide pins with a second wrench so that the bolts do not turn, you will find more details on how to do this in paragraph 2 of the article entitled: “Replacing the brake pads” and by the way, in addition to all this, also remove the brake pads, but just so you understand right away, that article describes unscrewing only the lower bolt that secures the brake caliper, and you need to unscrew these two bolts, that is, this the bottom and top and then remove the caliper itself from the brake disc.

3) And when the caliper is removed, completely unscrew the nut (Indicated by arrow) securing the brake hose with a wrench and disconnect the hose (If you don’t have brake fluid in the reservoir, then everything is fine and you can disconnect the hose without fear for anything, but if you don’t began to drain it, then read the article further and do not disconnect the hose yet), in order to unscrew the hose nut, hold it with one hand, and rotate the brake caliper with the other, and so on until the nut is unscrewed, let's return to the brake fluid, If you didn’t drain the liquid while doing the work, then do the same operation, but just when you disconnect the hose, carefully and at the same time pull it sharply up, thereby the liquid should stop flowing and to be sure, plug the hose with another bolt of a suitable diameter or whatever be a plug (To ensure that the hose is constantly looking up and the liquid does not drain from it, you can either ask an assistant to hold it for a while, or secure it somewhere carefully, well, it’s best to plug it with a plug to make it more reliable).

Note! By the way, there is a copper O-ring installed on the tip of the brake hose; if it is damaged in any way or is too compressed, then replace it with a new one!

4) Well, finally, using a hex wrench, unscrew the two bolts (They are the only ones, in the photo below they are shown with arrows for clarity, but unfortunately one is not visible) securing the working brake cylinder and as soon as the bolts are unscrewed, disconnect the cylinder from the brake caliper (It is best to do this operation provided that the brake caliper is clamped in a vice) and you can replace it with a new one.

Installation: Assembly and installation is carried out in the reverse order of removal; when installing, we recommend that you lubricate the guide pins with UNIOL-1 grease, and also check the condition of the anthers of these pins and if they are damaged, then replace them, and when the entire brake the mechanism will be assembled (don’t rush to put the wheel on yet), bleed the brake system, how to do this, read the article: “Bleeding brakes on cars.”

Additional video clip: Using the example of a VAZ 2110 car, you can see how to replace this brake wheel cylinder in the video clip located just below:

If the master cylinder piston jams (due to corrosion, broken return springs), incomplete release of the brakes on all wheels may occur. A defect such as “failure” of the brake pedal may also occur.

Rebuilding the master cylinder often does not lead to the desired results, so it is recommended to replace the master cylinder assembly.

Common GTZ malfunctions

Like any other mechanism, the GTZ has its own characteristic problems. One such problem is excessive pad wear and brake fluid leakage. As a result, the liquid level drops. If such a violation occurs, operation of the vehicle is prohibited until the problem is completely eliminated. In such a situation, you should definitely check the working and master cylinders, hoses and brake pipes, as well as the brake calipers for leaks. If a leaking part is found, it must be replaced. If the violation concerns the automatic drum brake adjustment system, this may be accompanied by a low brake pedal. In this case, you will need to restore the pedal travel manually. To completely eliminate the problem, you will need to completely clean the automatic adjustment system. Also, the problem can often be caused by depressurization of the brakes.

FakeHeader

Comments 110

Hello. What about technical inspection? They won't cower.

The car has been out of production for a long time... its receiver 2114... was not available. and there was this one. I installed it, the bolt fit... That’s the whole answer. But in fact, they know the weight of how they are doing maintenance right now

Did I understand correctly, the GTZ Kalina has a different thread than on the 99 tubes? (in my case 2108) And the diagram is as follows: Front - Inlet - adapter - tube - adapter - regulator - adapter - tee And the same thing back. Did I understand correctly?

something cleverly written hurts

So, it’s all the same... I’m starting my journey through the hemorrhoids... please tell me, have you ever thought about screwing the 3/40 into the GTZ right away? If I understood everything correctly, then in the state there are 10x1, and the regulator is 15x1. Maybe it’s easier to give the GTZ to a turner so that he can cut 15x1, of course I didn’t look at it, maybe they won’t let the shirts stretch so much in diameter... well, and the adapter right away. For some reason I already broke my head (after work, my brain doesn’t cook anymore) And with the front contour, leave the same tube just re-roll the end under 10x1.25. And if I understand correctly, the result is 4 adapters (elements)?

1 in the Nexia GTZ they look down, but in ours they look to the side, it will come out painfully grammatically 2 but the GTZ body won’t allow it to be sharpened like that 3 the front contour will go through the tee

Fault diagnosis: how to do it?

As a rule, if there is a problem with the brake system, a corresponding signal appears on the dashboard. After detecting the indicator, the motorist must visually check the master cylinder body for problems. In this case, you need to inspect it for leaks, and also pay special attention to the places where the pipeline and circuit outlets connect. After completing this activity, you should measure the pressure in the circuits using a pressure gauge. after which the measurement results must be compared with control parameters, which are usually contained in the vehicle operating instructions. If there is a difference in these readings, then this will be a sure sign of a violation. As for the tightness of the device, it can only be checked on a special stand. Therefore, in this case, you will have to seek help from specialists.

Symptoms of a GTZ malfunction

The GTZ, or master brake cylinder, is one of the most important elements of the braking system, since it is thanks to it that the car slows down after the driver presses the brake pedal.

Modern cars are usually equipped with two-section gas turbine engines, which form two circuits that operate independently. This system allows the brake system to remain operational even if one of the circuits fails or loses its seal.

The operation of the GTZ varies depending on the location of the drive. On front-wheel drive vehicles, the first circuit controls the operation of the front right and rear left brake pads, the second - the front left and rear right. On rear-wheel drive cars, the first circuit controls the operation of the front brake pads, and the second circuit controls the operation of the rear brake pads.

Where is the brake fluid located in the LADA Kalina?

This fluid completely fills the brake system: brake cylinders (main and working), brake hoses, pipes and reservoir. Its function is to transfer force from the brake pedal to the brake wheel cylinders. When the driver presses the brake pedal, the rod displaces the piston in the Kalina master brake cylinder, which presses on the fluid in the brake system. The fluid is incompressible, so it drives the pistons in the working cylinders, which press the mechanism pads against the brake discs and drums.

Working brake system: 1 — brake mechanism of the front left wheel; 2, 6, 12, 17 — brake hoses; 3, 7, 11, 18 — brake pipes; 4 — main brake cylinder; 5 — brake mechanism of the front right wheel; 8 — reservoir of the main brake cylinder; 9 — vacuum booster; 10 — brake pedal; 13 — brake mechanism of the rear right wheel; 14 — fluid pressure regulator in the brake mechanisms of the rear wheels; 15 — lever for regulating the fluid pressure in the brake mechanisms of the rear wheels; 16 — brake mechanism of the rear left wheel Note. Some cars are equipped with a braking system with ABS (anti-lock braking system).

Symptoms of problems

The general technical condition of the car (including the brake system) can be checked using a personal diagnostic adapter - a car scanner. These types of devices are widespread and have a wide price range. We would like to draw your attention to the budget model of Korean production Scan Tool Pro Black Edition.

At a cost of about 2 thousand rubles. This scanner is capable of fully diagnosing your car (engine, gearbox, transmission, abs, srs and much more), which will pay for itself in 1-2 trips to the service station. The adapter is quite easy to use, has Russian-language software and is compatible with most cars produced in 1993. The device will also be useful when buying a used car, as it can show its real mileage and VIN.

The fluid brake system consists of many parts that can become unusable: pipes, wheel cylinders, calipers, drums and pads. Typical signs of a faulty master cylinder:

- After pressing the pedal, the car stops slowly. The reason is that the cuffs of one or two pistons have lost their tightness - they have cracked or “floated”.

- To slow down, you need to press the brake pedal hard. The phenomenon occurs due to swelling of the rubber of the piston seals.

- The brake pedal travel is too short. The fluid inside the cylinder has nowhere to go because the compensation hole is clogged. Another option is that the passage is blocked by a swollen rubber seal.

- A common symptom is pedal failure, the brakes coming on at the end of the stroke. This indicates complete wear of the cuffs; as a result, liquid penetrates behind the piston and rushes into the expansion tank - the cylinder “bypasses.”

- The pads do not release the brake discs and drums and get very hot when driving. Options: one of the pistons is jammed or the bypass hole is clogged.

The listed symptoms of a GTZ malfunction are similar to malfunctions of other elements. Pedal failure also occurs when a large amount of air enters the tubes or loss of fluid in one of the working cylinders. Sluggish deceleration and increased force on the pedal are often caused by a breakdown of the vacuum booster - a cracked membrane or a lack of tightness at the joints of the hose that takes off engine vacuum.

There are signs that clearly indicate the performance of the main hydraulic cylinder and the malfunction of other elements:

- during braking, the car pulls to the side - the problem lies in a certain circuit or wheel;

- jamming of the brake mechanisms of one wheel;

- creaking and squeaking when braking;

- heating the discs and pads on one wheel.

If you eliminate these symptoms, it will become easier to check the brake master cylinder in a garage. This also includes obvious brake fluid leaks and the knocking sound of worn calipers.

Helpful information:

You can get professional advice when selecting a product and detailed information on all your questions by calling (calls within Russia are free).

Let's find out what could be causing your brake master cylinder to fail. First of all, its breakdown occurs due to the fact that the brake fluid is unevenly distributed inside the mechanism.

The cylinder itself consists of two working sections, each of which is responsible for braking one of the front wheels, as well as the rear one, located on the opposite side. You should know that in rear-wheel drive cars the picture is completely different: the sections are responsible for the operation of the brakes, which are located along the axes.

The work of the GTZ itself begins from the moment the pedal is pressed. If a vacuum booster is provided in the design of the car, then the brake cylinder contains 3 chambers, one of which converts pressing the brake into pressure, which makes it lighter. By pressing the pedal, a certain load is transferred to the piston section, which forces the brake fluid to press on the caliper. This, in turn, compresses the brake discs through the pads.

About checking the GTZ

Malfunctions of the master cylinder may require repair or complete replacement. It is recommended to start checking the brake cylinder with an external inspection. It is necessary to carefully check it for external defects and leakage of brake fluid. After a visual inspection, you need to check the operation of the brake pedal. To do this, you need to press on it and make sure that it does not jam or fall through.

As for the master cylinder, it can not only wear out, but also become rusty from the inside over time. This often happens due to the fact that the brake fluid contains oxygen and water in certain quantities.

Self-replacement of the GTZ on Lada Kalina

The need to replace the brake master cylinder (MBC) arises when characteristic signs of a malfunction occur. Braking becomes ineffective, the pads are not fully extended, the drums and discs heat up, the pedal sinks or braking occurs only at the end of the pedal stroke.

If you experience any of the above, most likely the GTZ has failed. There is nothing terrible about this, since replacing the master brake cylinder is far from the most difficult task, and almost anyone can do it.

To work you need to have:

- New GTZ;

- Key "13" + head "13" with ratchet, cardan and extension;

- WD-40 (preferably), container for TJ;

- Straight arms and some free time.

Failure of the gas turbine engine and its replacement

One of the common reasons why the brake master cylinder fails is its depressurization. In practice, this is noticeable to the naked eye: the brake cylinder will constantly leak, leaving a characteristic mark and a specific smell. The level of brake fluid in the reservoir will continuously decrease. All these signs indicate the need to repair the gas turbine engine and prevent irreparable consequences.

Depressurization of the brake cylinder

is a good reason to replace it with a new mechanism. Malfunctions of the master brake cylinder such as damage and severe wear of the piston seals, inlet collar, piston return spring, as well as scuffing and severe wear of the mechanism mirror indicate mandatory repair or complete replacement of the turbocharger.

Your life and safety depend on the proper operation of the braking system. Therefore, when the above symptoms appear, it is necessary to urgently eliminate the malfunction so that there is no sudden brake failure on the road.

How to replace the GTZ on a Lada Kalina - step-by-step instructions

- First of all, take a syringe and pump out the brake fluid from the reservoir.

- We remove the terminals from the battery, we will remove it.

- Next, we disconnect the connector from the hood end switch, it is marked with a red arrow, the adsorber power supply is marked with a blue arrow, the fuel injection system is marked with a yellow arrow, and the mass air flow sensor is marked with a green arrow.

- Now you can remove the battery; in principle, nothing else should interfere. We treat with penetrating liquid (VD-shkoy) the nuts securing the GTZ to the vacuum brake booster (VUT), as well as the nuts of the brake pipes.

- Loosen the brake pipe nuts, and then drain the remaining brake fluid from the reservoir into a container prepared in advance.

- Using a key set to “13”, unscrew the two nuts of the brake pipes, with your hand, holding the engravers that are under them, pull the GTZ towards you, rocking it slightly. Small difficulties may arise here, since due to the vacuum that forms at this moment, it is not possible to remove it immediately. To make this step easier, you can operate the brake pedal.

- We take the new master brake cylinder, put it in place, and fasten it with the same nuts on “13”, not forgetting about the engravers under the nuts.

- Next we screw the tubes. By the way, some recommend doing this before attaching the GTZ, but in my opinion this is not critical, everything is installed well anyway.

In general, we do the assembly, after which we pour new brake fluid into the reservoir and, of course, bleed the brakes.

Source

GTZ from Kalina and how to deal with it

The abrasion on the right near the rod is from the vacuum booster spring.

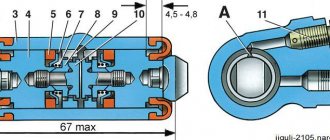

Marking on the end of the GTZ.

It can be disassembled very easily and simply; from the tools we will need duckbill pliers, a small flat-head screwdriver, a vice (optional) and some kind of long rod (during assembly).

So, all the insides of the main brake cylinder are held together by a spring ring. We hook the platypuses' ears and squeeze the ring. If you have a tool with a notch on the jaws, then you can easily pull out this ring. If not (like mine), then you’ll have to get creative and insert the tip of a flat-head screwdriver between the compressed ring and the cylinder.

Above in the photo is the tool and the ring extracted with its help.

The insides of the cylinder next to the body. The primary circuit valve is located inside the left end of the left (as shown in the photo) spring. If you pull it off, don’t lose the spring and the valve itself! It easily falls out of the nest. The black thing on the left is a plastic cylinder cap with a rubber ring seal around the cylinder body and rod. In order to extract everything shown above after removing the retaining ring and the pin (about which below), you need to click the rod. We press it in as far as we can and sharply release it. Gradually, the springs will push out the cork, the main thing is that the giblets do not fly apart. You can carefully clamp the rod in a vice and pull off the cylinder, but that’s how I did it.

In the top photo is the neck closest to the blind end, into which one of the fittings of the plastic reservoir with brake fluid is inserted. Note the middle hole. It contains a pin that limits the movement of the floating piston of the second circuit of the brake system. The pin is removed with the same platypuses. To make it easier to drag, press on the brake cylinder rod. The second photo shows the piston, pin and cylinder. If you look closely, in the piston window at the bottom you can see a valve rod rolled into the lower protrusion of the piston.

Floating piston The valve roll is visible on the right. The cuffs on the piston should open outwards from the middle. Like this: ]___[

Why didn't my brakes bleed with this GTZ? Very simple: dirt and rust under the valves prevented them from closing. I soaked all the tripe in a hot Fairy solution (with the smell of wild berries, if you are interested in such details) and rinsed it after a couple of hours. Then I blew air out of the valves and rinsed them in WD-40, then stuffed them with technical Vaseline.

After assembly (with the same Vaseline), the GTZ even pumped air quite well. Tomorrow I'll put it in its regular place under the hood.

Above in the photo is a special key that is essential for fiddling with the brake system. Without it, you risk ruining the union nuts on the tubes, and then you will have to change the entire tube.

So, the reason for the poor performance of the new gas turbine engine is improper storage conditions and/or the Koreans skimped on conservation lubricant. By the way, the Priora has exactly the same main brake brake. Not for everyone, but it happens.