Published: 11/02/2020

- Check the cost of repairs

- How to cook ceviche

- How to tighten the steering rack on a VAZ-2115

- The main faults of the steering rack on the VAZ 2115

- Steering rack repair

- Tightening and adjustment

- Also check out

- How to assemble a VAZ steering rack

- DIY repair

- Let's summarize

- Why should you order from us?

- see also

- Replacing the steering rack on a VAZ 2114

- Signs of insolvency

- Latest articles

- We will answer your questions

- Replacing the steering rack of a VAZ 2114 with your own hands

- Step-by-step instruction

How to tighten the steering rack on a VAZ-2115

Many car enthusiasts are mistaken in believing that the steering rack on a VAZ is not adjustable and it is impossible to do it yourself. This is a misconception and adjustment of the steering rack on a VAZ car can be carried out by any car enthusiast independently. We will now explain how to tighten the steering rack on a VAZ-2115.

On the website of the official Moscow VAZ dealer, read the description of the entire model range, pay attention to the Lada Largus - what configuration the car is currently offered, with what engines and in what version. For each Lada Largus model, exact prices are indicated

Choose a new car!

Now let's tighten the steering rack:

How to tighten the steering rack on a VAZ-2115

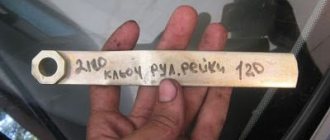

So, if you have a question about how to tighten the steering rack on a VAZ 2115, you will have to purchase a special octagonal wrench, the size of which is 17 mm.

A VAZ 2115 car requires adjustment of the steering rack when a knocking noise occurs when the steering mechanism operates. When you feel a knocking sound from the steering mechanism while driving your car, this is a signal that it needs to be adjusted.

Typically, a slight kickback in the steering wheel of a car occurs when it hits an obstacle or the car wheel gets into a hole.

The steering rack is adjustable only on an overpass or lift, and you can also drive into the inspection hole to do this.

First of all, it is necessary to remove the engine protection and it is almost impossible to do this without an inspection hole or a lift. After removing the protection, you need to take a carrying lamp and a flat-head screwdriver. From the back of the subframe you get to the back of the rack and at the place where the steering shaft and rack intersect, you need to find the adjusting nut on the body.

Many novice car enthusiasts may confuse the adjusting nut with a plug; it is also difficult to find, since it is covered with a layer of dirt. This nut can only be adjusted with a special wrench that you have already purchased.

If no one has touched the steering mechanism before, then there will definitely be a green plastic plug on the nut, which plays the role of a stopper and is installed at the factory. The specified plug must be removed using a screwdriver; although it is quite fragile, you will not be able to turn the adjusting nut until it is removed.

After removing the stopper, using a special wrench, tighten the adjusting nut clockwise. It is not recommended to press it all the way; the level of clamping depends on how hard the steering mechanism was knocking before.

To check the level of tightening of the nut, you need to sharply turn the rack in one direction and the other; if there are no extraneous sounds or noises, then the nut is tightened enough. If you decide to put the stopper back, you can do it, but it won't do any good.

How to tighten the steering rack on a VAZ-2115 - the entire adjustment of the steering mechanism will take you no more than 20-30 minutes if you are doing it for the first time and the main thing is that you will do it all yourself. Many service stations do not want to adjust the steering rack, since this is a cheap operation; it is much easier for them to replace the specified mechanism, but this already costs the car owner.

Thus, having carried out a fairly simple adjustment of the steering rack, spending no more than half an hour on this, the car enthusiast is convinced that the VAZ 2115 car has an adjustable steering mechanism and can do this independently.

We told you how to tighten the steering rack on a VAZ-2115 - try it!

This blog is already read by 4756 people. Read it too!

coupling

Now is the most difficult and labor-intensive moment. On the interior side, the ends of the control shaft are aligned with the gear shaft. It is best to do this together, because you will spend a lot of time on a similar event alone. Don’t forget about the special flat on the shaft - the coupling bolt must “climb” onto it.

The latter is planted using a hammer (the blows are applied smoothly and very carefully). Finding the correct order of work is painfully simple - to do this, connect the removed battery terminal and press the horn. If the element does not make a sound, it means that the part that suits us is not put on one hundred percent. In this case, we continue to tap it with a hammer.

How to install the control rack (VAZ-2114) next? A bolt is inserted into the “ears” of the coupling and clamped tightly with an open-end wrench. Self-locking nuts are tightened on the clamps of the spare part, and the studs are treated with Movil. Now all that's left to do is to connect the rack arms to the ends and tighten all the fasteners. That's it, the replacement of the VAZ-2114 control rack is successfully completed. All that remains is to put on the negative terminal, fasten the wheels, check the brakes and do the wheel alignment. Typically, dismantling and installing this part takes up to 3-4 hours of free time. Yes, you have to tinker. But after that, the knock of the VAZ-2114 control rack will definitely not bother you. In terms of mileage, this is approximately 100-150 thousand km.

So, we found out how you can tighten the steering rack of a VAZ-2114 with your own hands. Success!

The main faults of the steering rack on the VAZ 2115

Let's highlight the main symptoms of a malfunction and their possible causes:

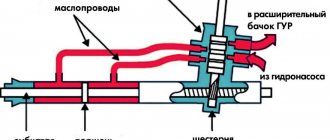

- The rotation of the steering wheel is too tight, and unnecessary sounds appear in the form of a whistle. A possible reason is leakage of power steering fluid and its reduction to the minimum level, abrasion of the rotor pair.

- The rotation of the steering wheel is difficult, but after gaining speed the situation returns to normal. At the same time, an unpleasant “itching” noise appears. The main reason is the appearance of scoring on the rotor part and the mating surface.

- It is difficult to turn the steering wheel only to the left or right and when the power steering temperature is low (below 25-30 degrees Celsius). As soon as the liquid warms up to 55-60 degrees, the noise disappears.

- The driver's turn of the steering wheel does not coincide with the actual turning angle of the car's front wheels. When such a problem occurs, the car ceases to be controllable and starts tossing around corners.

- There is strong vibration in the steering wheel when driving on a bad road. If you turn the steering wheel in one direction or the other, the sound may disappear.

- The steering rack is leaking. In this case, power steering fluid appears on the boots. In this case, the leak will be noticeable by a decrease in the level in the power steering reservoir. If you do nothing, the shaft seals may fail, increase wear, or cause rust.

- The steering wheel refuses to return to its original position, or it does, but very tightly. The reason for this problem is the deformation of the rack shaft or housing.

But that is not all

You should pay attention to malfunctions of the power steering itself

Here, signs of steering rack problems may be as follows:

- Increased foaminess of power steering fluid. It's easy to diagnose - just look into the tank;

- excess noise appears when turning the steering wheel and power steering operation;

- At idle speed the power steering does not work at all. As the speed increases, it is easier to turn the steering wheel;

- The effort disappears when turning the steering wheel in both directions. As a rule, the cause of this problem is the destruction of the rubber ring.

Symptoms of a problem

To understand that the racks require repair, you need to monitor the behavior of the car and know the characteristic signs of a malfunction of this element.

Is it possible to determine whether the unit requires a complete replacement, or can you get by with simple repairs? We will tell you about this in the table below.

| Sign | Necessary actions |

| When turning the steering wheel, a knock is heard and play occurs | If the situation occurs while the car is moving, it is enough to carry out repair measures, use a repair kit |

| Knocking and play occurs when the steering wheel is turned when the car is stationary | This is clear evidence of the critical state of reiki. The problem can only be solved by completely replacing it. |

Steering rack repair

The car is secured against unexpected movement by installing stops under the rear wheels. Pull the handbrake and lock the steering wheel.

So:

The front wheels are removed. Using a puller, remove the fingers from the lever struts, having first unscrewed the tip nuts. After installing the puller, tighten the screw until it stops. When the key is in tension, the finger is knocked out of the lever with a hammer. The nuts securing the rack brackets are unscrewed. The bolt on the steering shaft is loosened from inside the passenger compartment. Having completed all preliminary operations carefully so as not to damage the splines, using oscillatory movements, the gear shank is disconnected from the steering shaft. The entire assembly is pulled out through the right hole in the car body.

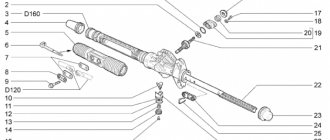

Steering mechanism with tie rods

Next, the VAZ 2115 steering rack is directly repaired:

- The structure is clamped in a vice. Use a special brush or a cloth soaked in white spirit to clean all surfaces of the product.

- The steering rods are removed. To do this, unscrew the bolts on the bracket securing them, after bending the “antennae” of the locking plate, using a “22” key.

- The locking and connecting rod plates are removed.

- The tie rods are removed.

- On the right side, the support and retaining ring are removed from the steering gear housing.

- The clamps with which the protective cover is attached are cut off. Disposable parts are made of plastic.

- The protective cover is removed.

- On the left side of the device, the support and protective cap are removed.

- Using a “17” wrench with an octagonal head, the rack stop nut is unscrewed, the part is removed, the spring and the retaining ring are removed.

Removing the nut, spring and retaining ring

The rack stop is knocked out of its socket. To do this, the crankcase hits a wooden stand. For sealing, a rubber ring is mounted in the groove of the stop.

- The seal is removed.

- The gear boot is removed by simply prying it off with a screwdriver.

- The lock washer is removed.

- Use a special 24mm wrench with an octagonal head to unscrew the nut that secures the gear bearing.

- The nut is removed from the shaft.

- Using a “14” wrench, the gear is removed from the crankcase along with the bearing.

Removing the gear with bearing from the housing

- The rack is removed.

- The bushing is removed. To do this, use a screwdriver to pry up the support sleeve, its protrusions should fit into the crankcase holes and the part can be freely removed.

Removing the support sleeve

- A new bushing is installed. To do this, new damping rubber rings are put on it so that the thin parts of the ring are located opposite the cuts in the bushing. The protrusions of the bushing must fit freely into the holes in the crankcase.

- Along the edges of the bushing, the rubber rings are cut and the cut off parts are removed.

- The retaining ring is removed from the gear shaft.

- Using a two-jaw puller, the ball bearing is pressed.

Removing the ball bearing

Pressing out the needle bearing is done using a special puller. If it is not there: two holes with a diameter of two millimeters are drilled in the end of the crankcase to allow the needle bearing to exit onto the ring. Through it, the bearing is knocked out of the crankcase.

Pressing out the needle bearing

The crankcase cavity of the structure is washed. The needle bearing is pressed into place using a piece of pipe. After this, the hole is sealed with preparations similar to “cold welding”. Bearings, drive gear and teeth on the rack are generously lubricated with FIOL-1 lubricant.

UNIOL-1 lubricant is placed in the cavity, which is located above the nut holding the bearing of the drive gear. The steering rack assembly is assembled in the reverse order. The protective cover is attached and secured with clamps. The rack stop and nut are adjusted so that there is a gap of 0.12 millimeters between them. After adjusting the rack clearance, the stop nut is capped to prevent unwinding.

When replacement is required

If you encounter one of the above signs of malfunction, the rack must be repaired or replaced. By ignoring this need, you risk losing control at any moment. While on the road and driving at high speed, losing control of the car can lead to the most dire consequences.

There are three ways to solve the problem of faulty steering racks.

| Way | When is it relevant? |

| Adjust the rack | If diagnostics show that the unit does not require repair or replacement |

| Repair | If diagnostics allows for partial replacement of elements. Replacement is provided using a repair kit |

| Replacing the unit | If the test shows a complete failure of the node. Installation can be carried out with new rods or old ones, depending on their condition. |

Let us add that if the old steering racks on your VAZ 2114 have covered more than 100 thousand kilometers, their malfunction is unlikely to be corrected with the help of a repair kit. The best option in this case is a complete replacement of the unit.

Removing the boot

Tightening and adjustment

As the practice and experience of VAZ 2114 owners shows, if problems arise with the racks, they can most often be repaired. The only condition is that you have an inspection hole at your disposal.

Full analysis

The first step is to tighten the rack. But how is this done? To do this, simply tighten the adjusting bolt. Adjustment is made with a 17 mm key.

After tightening the bolt, take your car out for a few kilometers to check whether the knocking or play remains. If these symptoms of the problem disappear after you have tightened and adjusted the steering rack, the repair can be considered complete.

But this doesn't always happen. The knock may remain, but the play may go away, or vice versa. In any case, if at least one sign still remains, you will have to begin a full-fledged repair with your own hands. Now you can find a number of useful videos that describe in detail the procedure for repairing this unit. Take a look, it will be useful for you.

Article on the topic: Selecting and replacing brake fluid on a VAZ 2114

Price issue

A new rail will cost you about 3 thousand rubles. The cost of service stations for replacing slats costs about 2 thousand rubles. That is, in total you will have to spend 5 thousand rubles if you entrust the work to the masters.

Repair kit

However, the rack is not difficult to repair. Most VAZ 2114 owners perform this event with their own hands. Plus a decent saving of money.

Also check out

- If you don’t have a tie rod puller with you, you can use a hammer and a powerful pry bar.

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

- Unscrew the nuts that secure the steering rack.

- Remove the rack on the right.

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

- Remove the rack from the splines. Usually this does not cause difficulties.

- After removing the rail with lugs, unscrew the lugs and count the number of screws. Thanks to this, after replacement it will be more comfortable to get to the service station.

- Open the side plugs on the new rail. Fill the holes with lithol.

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

Self-replacement of the VAZ 2115 steering rack - step-by-step instructions

When screwing the tips, it is important not to confuse the sides, because the left one is different from the right one. To install a new rail you will need someone's help. Return the rack back, attach the fasteners on the right

A partner must provide assistance if the steering cardan gets into the splines. To loosen the clamp, drive a chisel into it. After this, the slots will fit in easier.

Worth checking out:

Installation of new front struts on Lada Priora cars

- There is a special groove on the rack in which a locking bolt must be installed.

Reassemble in reverse order. After the VAZ 2115 steering rack has been replaced, make the wheel alignment adjustment.

Final stages

Next, the gear and bearing are pressed in until they stop (the shaft and housing are clamped in a vice). Then the stop, spring and nut are inserted. The hole in the latter is closed with plasticine. The rubber ring from the repair kit is installed on the shaft side and tightened with another nut. Then the cover and lock washer are put on.

Afterwards the “whiskers” of the slats are installed. With quite a bit of effort, the locking plate is tightened and bent. Next, rubber plugs are installed. The left side of the cover should rest here.

That's it, our set is assembled. Now the control rack (VAZ-2114 will soon be ready for use) is being installed back into the car. The part is installed in its original place, and the shaft must fit into the body hole. Then clamps are put on and nuts and washers are attached.

DIY repair

First you need to stock up on the necessary set of tools:

- repair kit for the steering rack (as mentioned above, they are sold in three variations);

- bearings;

- lubricant;

- necessary keys and screwdrivers;

- We should talk separately about repair kits.

Minimum basic sets. Such sets usually have only 4 elements:

This set can only fix the simplest faults. Medium priced sets. Here, in addition to the things described above, there are shafts and other bearings. Expensive sets. There may already be entire slats here.

When purchasing, please note that you are purchasing a set specifically for your car (the brand is indicated on the package). Sometimes it happens that a car has a non-original rack, then it is necessary to purchase a repair kit for the car from which this rack was removed

Actually, any repair must begin with disassembling the steering rack. Often the problem is just a small bearing, and the entire rack does not require replacement.

Work order

- Removing the steering rack

- Unscrew the thrust nut using a 17mm hexagon.

- Remove the thrust nut, retaining ring, rack stop and spring.

- Remove the drive gear shaft boot, and then the retaining ring.

- Unscrew the nut holding the steering gear bearing. It goes quite tight - this is normal.

- Press out the drive gear shaft.

- Remove the rail itself from the housing.

- Remove the support sleeve, then lubricate it and insert it into place (this will need to be done with force)

- Replace all bearings. Some will be difficult to get (very difficult), so you can simply chop them with a chisel and pull them out with tongs.

- Inspect all parts for defects, replace broken ones with new ones (from the repair kit), lubricate all moving parts.

- Reassemble the rail in reverse order.

- That's all, if you did everything correctly, then the rack works with a bang. All that remains is to put it in place.

Putting the rack in place

- First, you need to enlist the help of a partner; without him, you won’t be able to do everything quickly and accurately.

- We install the rail in the same place and attach the fasteners.

- With the help of a partner, we insert the rail into the spitz.

- To loosen the clamp, use a chisel.

- We tighten the mounting bolt.

That's all, now the rack is in place, then we put the wheels on, tighten the nuts and remove the car from the jack. Now you know everything you need to repair your steering rack in a timely manner. The main thing to remember is that you shouldn’t delay repairs.

We repair it ourselves

To get started, you will need a set of tools and repair kits.

Replacement kit

Be sure to include the following in your list of tools and materials:

- Repair kit for one of three configurations (more about them below);

- Bearings;

- Lubrication;

- Set of keys and screwdrivers.

Selecting a repair kit

Spare parts

As for repair kits, the standard minimum set includes four elements:

- Washers;

- Nuts;

- Bearings;

- Bushings made of fluoroplastic.

But is it enough for your specific steering rack situation? Let's try to understand the purpose and configuration of each of the three types of repair kits.

- The cheapest repair kit, the contents of which you are already familiar with, allows you to solve the most minor problems that have arisen with your slats.

- The middle kit additionally includes other bearings and shafts. Designed for more serious repair work.

- The most expensive repair kit may consist of whole new slats, that is, it involves not a repair, but a simple replacement of units.

When choosing a repair kit, it is important to make sure that it is suitable not just for repairing steering racks, but also for your specific VAZ 2114 car. Plus, it is important to know which rack is currently on the car. If this is not an original part, which happens quite often, then the repair kit for the “fourteenth” model will no longer be suitable. You need a kit that matches the vehicle the steering system part was taken from.

Let's summarize

As you can see, the work will require some skill. But, if desired, they can be performed by a beginner who knows how to handle the tool and has common sense. Repeating the operation no longer causes problems.

After repairs, you should perform a wheel alignment procedure or do a simple check. To do this, you need to start the car and drive at a slow speed. If, with the steering wheel in a straight position, the vehicle does not pull to the side, everything is in order.

To protect fasteners with threaded connections from dirt and water, experts recommend using lithol or graphite-based lubricants. Parts must be lubricated carefully. You can further enhance the protection with tubes. They are put on the joints of the steering tips and traction devices (heat shrink can also be used).

Repair work on the rack itself

While the car remains disassembled, we work on the part itself. First, the rail is clamped in a vice and thoroughly cleaned with a wire brush. Next, its surface is treated with a strong White Spirit solvent and wiped with a piece of rag. After this, the so-called mustache bolts are unscrewed. At this time, it is recommended to check the silent blocks - if there is play or their condition is very unsatisfactory (microcracks are present), we replace the parts with new ones.

Using a chisel, the plate is bent, the bolts are unscrewed and the “whiskers” are removed. The plugs and cover are pulled off from the end of the part and the rubber bands are removed from the shaft. Everything except the cover is thoroughly washed and then dried (just not in the sun). Using a minus screwdriver, remove the bearing lock washer. The nut is unscrewed with the same wrench.

Why should you order from us?

Experienced craftsmen

Diagnostics in just 1 hour

Repair in just 1 day

Hunter 3d stand

Guarantee on all work

Your own turning park

Typical breakdowns

Torn steering rack boot

There are several most common reasons why the unit may need to be replaced:

- The rail has exhausted its service life;

- The vehicle is regularly driven on uneven roads;

- Having turned the steering wheel to its extreme position, sharp accelerations are often made;

- The presence of mechanical damage due to collisions with potholes, accidents, etc.

Drivers should pay attention to the behavior of their car, which itself may indicate that the steering is out of order. This may manifest itself as follows:

- The rack knocks when turning the steering wheel;

- The steering wheel jams and turns to the sides with some difficulty;

- There is knocking and vibration during travel;

- The play at the steering wheel has increased;

- The wheel alignment is disrupted. This can be determined by uneven wear of the rubber.

https://youtube.com/watch?v=vOAgjW9-EX4

Replacing the steering rack on a VAZ 2114

Now let's proceed directly to the procedure. If the operation is not carried out on a lift, then you need to hang out the entire front part and use some kind of stands or pedestals. It is imperative that the car is stable.

Next, use a 22mm wrench to unscrew the steering ends, then knock down the bipod with a hammer. If you plan to install the tips in the old places, then under no circumstances should you use all kinds of pullers, because the fork will pull out the finger, and the thread puller will ruin the thread, you will have to either go through it with a hole saw or change the tip.

Now you need to unscrew the four nuts securing the rack to the body. This must be done from under the wheel arch, otherwise you won’t be able to reach it. It is advisable to use a ratchet with a long head of 13. After this, we crawl under the driver’s feet and unscrew the bolt of 13 from the steering shaft. To loosen the clamp, you can insert a sharp chisel and hit it with a hammer several times. At this time, it is advisable to pull the rack from the shaft; this can be done well using a crowbar.

The rack is installed in the reverse order. After replacement, it is imperative to adjust the wheel geometry, otherwise goodbye, tires.

Video: replacing the rack on a VAZ 2114

As you know, the performance of any vehicle depends on the serviceability of each component. If one element is faulty, soon the next one will not function in a chain reaction, and so on until the fault is repaired. If the problem is not resolved in time, it will not only entail additional costs for spare parts, but will also significantly affect traffic safety, on which your life and health depend. Therefore, you should not neglect replacing parts, especially if this VAZ-2114 is no exception: spare parts here fail in the same way as on any other car.

How is this element dismantled and how to adjust it? We will consider the answers to all these questions in our article today.

Parsing the elements

The gear rack is also pulled out from the housing. It also needs to be treated with white spirit. After the surface has dried, re-coat the part with lubricant. The plastic insert is pulled out through the slot in the housing and the clamping nut is unscrewed. Usually it gives in very hard, but this is not terrible - the repair kit contains a brand new spare part. We take out the stop, change the O-ring and look at the “whiskers” of the rack. As a standard, the tips should be in good condition, without any play. The “fingers” should move with normal effort. The same goes for covers - they should not have any flaws. If one of the listed parts (or several) does not meet these characteristics, only replacement will help the situation. When performing similar work, experts advise treating the threads with Movil to protect them from rust.

We will answer your questions

Good afternoon. Yes, we can repair it within one day.

No, this shouldn't happen. Regarding self-repair of such important mechanisms, we are always against it. Not only because they are interested in providing services, but also because then we will have to correct your mistakes during independent repairs, and this is much more difficult. When there is a knock in the rack, in order to determine the cause, you must initially completely disassemble it. Only knowing how the mechanism should be designed can you notice its malfunction. Not everyone, even the most experienced driver, is sufficiently knowledgeable about the internal structure of the rack.

We have not yet learned how to conduct remote diagnostics. This can indicate either the situation you first voiced or signal a serious breakdown. In a car service center, in case of temporary wear, you may be offered a rack restoration procedure. In this case, the mechanism is disassembled, and all obsolete parts are replaced with completely new ones. If repairs are necessary, the technician will disassemble the rack and decide what and how to change or repair.

Since you come into contact with its work directly while driving a car, it will not be too difficult to detect a breakdown. If not during the next diagnostic, then while driving the car, you will notice noises or knocking, play in the rack. This serves as a direct signal to visit a car service center.

No, depending on the design of the mechanism, the racks can be electrical, hydraulic or mechanical. In each individual case, the master must understand the mechanism and carry out the repair procedure in accordance with its structure.

Yes, this is a very important component of the car. Scientifically, it is called hydraulic power steering, and its purpose is already clear from the term itself. The rack helps you turn the steering wheel

It is also an important part of the hydraulic system. Now the second part of the answer: do you think that you will be able to drive your car normally if you cannot turn and brake normally? The question of the importance of a working steering rack should not even arise

Adjusting the steering wheel position

If you don’t like the height and position of the steering wheel, then you will need to grind the edges of the shaft to the size you need or install gaskets between the plate and the body. It is worth remembering that the electric power steering is automatically switched off at speeds above 50 km/h, unlike the same power steering.

Installing electric power steering on your own is quite possible. You just have to remember that even for an experienced driver it will take a lot of time and effort. But for a lover of comfortable driving, the result will justify all costs and hopes.