Brake discs are an element fixed to the car hub and serve to reduce speed when in contact with the pads due to increasing friction force. The part can be made of cast iron or ceramics: the first type is cheaper, the second is more expensive, but has less weight.

For the Russian car VAZ 2112, mainly ventilated models are produced, which have an effective cooling system and are considered more reliable and durable. The cost of spare parts depends on their type, country of production, type of sale (pieces or sets).

Original

Factory wheels are produced by the Autoreal plant, they have article number 2112350107002 and are sold both individually and in sets. The cost of one part is 850-1000 rubles, depending on the store and city. In addition, in the assortment you can find disks with code 21123501070, they are produced by the same company, the price of such a set varies between 2.2-2.5 thousand.

The products are of good quality and can be found both in regular spare parts stores and online catalogues. Many car owners argue that it is better to purchase parts in a simple store, where you can personally check them for quality.

Rear disc brakes VAZ 2110 and their replacement

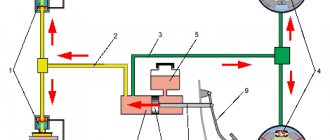

If previously the rear disc brakes of the VAZ 2110 were considered not a cheap pleasure, today they are installed on the car easily and simply. For just 3,000 rubles you can purchase them and easily replace drum brakes. On the VAZ 2110, rear disc brakes have many advantages over drum-type brakes.

Advantages

As mentioned above, on the VAZ 2110 rear brake discs have advantages over drum brakes. In particular, these are such advantages as:

- more reliable braking of a front-wheel drive vehicle and reduced braking distance;

- uniformity of braking forces;

- significant minimization of the time when the brakes are activated;

- significant reduction in unsprung masses;

- Heat dissipation occurs better with this type of brake.

Note. Improved heat dissipation is a very important factor, especially during active driving. In addition, this is relevant when driving at high speeds and on mountain roads.

- significant improvement in brake cooling;

- ease of installation and dismantling in case of replacement; eliminates the need to tighten the parking brake each time;

- reliability of these brakes;

- disc brakes, unlike drum brakes, do not freeze in winter after washing;

- ease of monitoring brake wear;

- an appearance that makes the car look like a sports car (you definitely can’t say the same about the VAZ 2110 with rear drum brakes).

Analogs

When choosing front discs, you can also pay attention to more expensive similar parts from foreign manufacturers. Information on them is collected in the table below.

| Brand | A country | vendor code | Peculiarities | Price in rubles |

| Brembo | Italy | 09.8903.75 | Corrosion-resistant products, the surface has a wear marker, the parts provide effective braking even over a short distance, do not deform upon impact, and are therefore suitable for car owners who value aggressive driving | 3000-3200 per piece |

| ATE | Germany | 24.0320-0142.1 | Improved design with a multi-functional groove, the part provides comfort when decelerating, wears out slowly | 2700 per unit |

| Allied Nippon | Japan | ADC 1712V | Lightweight, wear-resistant and corrosion-resistant products, designed for harsh operating conditions, slightly susceptible to the negative effects of high temperatures | 1800 per piece |

| Hofer | Germany | HF130218 | Inexpensive, but high-quality perforated discs with notches and grooves, have good resistance to friction and mechanical shocks | 2000-2100 per part |

see also

Comments 40

Is it possible to use 5mm steel 45?

I can’t say for sure, but I read here that someone made it from it, because there was no 6mm blank

Material not specified. Can you tell me which one is needed?

Honestly, I don’t know who writes what. I made it from sheet metal. All is good. A friend already travels with these.

I also made kentu from sheet metal - I have metal, cutting + communication with a turner =), no complaints in 4 years.

That's it, this is great, but there is one BUT. Handbrake hydraulics make it, as they say, a turd question. But when you tighten the handbrake, the brakes will logically apply on all 4 wheels. Well, one more thing, where will the brake fluid from the handbrake go, back to the reservoir? That is, the handbrake is for 1 time, and it’s not a fact that it will work. Maybe someone already has a hydraulic handbrake, maybe I’m wrong about all this, so describe it, because personally, on my filly, the rear drum brakes have already worn out, to put it mildly.

The classic clutch master cylinder is well suited for the handbrake. It needs to be modified for fittings, study it properly and you will understand that everything as you write is far from correct

Is it possible to redo the drawing? If you have the skills?

It depends on what size you need. It's not a problem to do it.

Is there a faceplate for Okovskie brakes? maybe overbraking is true, I made a huge mistake; I had 4 pistons in the front and 14 pistons in the rear, but 2108, and I was very surprised why they were overbraking)))) but the Okovskys want there to be more balance of adjustment; it’s not interesting that the regulator is permanently screwed in!

Analogs

Below is a table that contains data on the most popular manufacturers of foreign similar spare parts. They are distinguished not only by diameter and price, but also by quality; Almost all of them are sold in sets.

| Brand | Country of Origin | vendor code | About the product | Price |

| Design Service | Russia | 2172-3502000 | An inexpensive set of wheels for the VAZ 2112 modification with ABS, the parts are fully certified, the set includes, in addition to the main products, all consumable components | 21-22 thousand |

| Tornado | Russia | 2108-3502200-12, 2108-3502200-08 | Products with the first article are installed on VAZ 2112 equipped with ABS, and parts with the second number are installed on cars without this system | 15-15 thousand depending on the type of part |

| Lucas | Germany | FR-00000627 | Wheels of size R14, designed for cars with a simple parking brake, are highly reliable, have a long service life, and are fully compatible with a number of AvtoVAZ models | 18-18.5 thousand per set |

Design features and markings of Grants disks

The rim is the main part of the wheel that serves to secure the car tire and transmit torque by securing the disc to the hubs. Don’t be confused - the Lada Granta wheel bearing has nothing to do with discs. Structurally, the product consists of two parts:

- rim - comes in different sizes and shapes, serves to fix the rubber;

- flange - with its help it is attached to the hub with bolted connections.

The appropriate tire is selected according to the diameter and width of the wheel. The departure is marked as ET. Conventionally, this is the distance between the center and the mounting surface. The larger it is, the more the wheel extends outward from the wheel arch. The center hole size is marked as DIA, and the diameter of the middle of each mounting hole is marked as PCD. Based on this data, nuts, bolts, and washers are selected.

As standard, the rim width on the Lada Grant is from 5.5 to 6 inches. The mounting flange has 4 holes for fixing bolts. The distance from one to the other is 98 mm. The disc can be of size R13, R14, R15 - diameter from 13 to 15 inches. The diameter of the central hole is 58.6 mm, and the overhang size is no more than 38 mm. Based on this data, you can indicate the marking of the standard wheel for the Lada Granta: 5.5x14 4/98 ET35 D58.6.

How to replace brake discs on a VAZ 2112

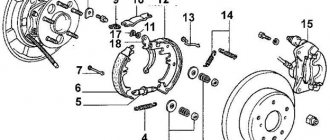

Replacement of such spare parts takes place according to the following algorithm:

- First you need to unscrew the wheel mounts and dismantle it, then remove the pads.

- Loosen and remove a couple of bolts securing the block to the cam, and remove the entire brake mechanism. Only the attachment of the hose to the cylinder should be left.

- Attach the caliper to the suspension using a rope or wire connection, making sure that the hose is not pinched.

- Clean the disc and hub from dust, dirt and corrosion. The anthers should be lubricated; if they are torn, replace them. To remove rust stains faster, you can treat them with WD-40 and then wipe them with any cloth.

- Unscrew the disc from the hub, pulling out the guide pins (if they are soured, you need to use a hammer with a rubber tip and knock them off), remove the ring and the part itself.

- Remove the beads on both sides if you plan to replace the restored disk: this can be done using a file.

- Install a new or restored element and perform assembly in the opposite order.

After completing the repair work, you should perform a test drive to make sure that the spare part is installed correctly and that braking is carried out without interference. New discs should respond immediately to pressing the brakes, while acting smoothly, and there should be no extraneous sounds. If necessary, even a person who has little experience in car repairs can replace the disc with his own hands. If the procedure fails, the owner does not have the appropriate experience or does not have time for work, it is better to contact a service center where specialists will take care of the car.

Disc Specifications

The standard parameters for installing VAZ wheels (meaning the placement of studs) are 4 by 100. But in the Hyundai Accent, the distance is slightly smaller, 4 by 98. That is, it will not be possible to install the wheels using the “standard” method.

However, some manufacturers of aftermarket components and spare parts have provided for this case and have produced special cone bolts with an offset center of fastening. With their help, the discs are actually installed well, but there is a possibility of making a mistake during the installation process and shifting the center of gravity. How can I check this? By jacking up the drive axle and accelerating to approximately 80 km/h. It is advisable to do this on a specially equipped overpass.

So, the adjustment was made incorrectly if at maximum speed:

- a metallic knock is heard;

- the wheels of the drive axle vibrate noticeably;

- the bridge itself is knocking;

- There are extra sounds in the wheel area.

In this case, the discs will need to be removed and re-centered. The angle of entry of the bolts must be the same everywhere.

If there is a displacement of even a few degrees on several of them (those located opposite each other), this will lead to accelerated wear of the wheel rim, the tire itself, the hub and even the brakes.

Unfortunately, it is unsafe to operate the vehicle in this case, especially at high speed. Anything can happen, from a broken hub to a split wheel rim (if they are not original, but, for example, Chinese handicraft).

The bolts themselves for attaching wheels from an Accent to a VAZ are, as a rule, sold in every second automobile parts store or at tire stations. They cost pennies, and you can install them yourself. The only caveat: the mounting angle must be maintained. This is extremely important. It is advisable to re-check after traveling 10-50 km to see if any displacement has occurred.

Installation Quality Check

Ventilated

When you complete the assembly process, be sure to check how sealed the installation was on each of the wheels.

- Press the brake pedal. If you did everything correctly, pressing will be accompanied by tightness and effort;

- You or your assistant press the pedal again, while the second person begins to turn the new disc brakes;

- If you couldn’t move anything, it means the assembly was done efficiently and reliably.

Why is it important to choose the right size?

The most popular wheel sizes for installation are R14 and R15. This is due to the fact that they can be easily selected in a store and installed on a car. The main thing is to comply with the required dimensions and bolt pattern parameters specified by the manufacturer. If products with dimensions different from the factory ones are selected, then special adapter rings should be used. They often come with the product.

You may be interested in this About the wheel bolt pattern on Opel cars

Adapter rings for wheels for VAZ 2112

Note!

The main problem that prevents the installation of large products is the size of the wheel arches.

If you exceed the dimensions and do not modify the wheel arches, then the rubber will touch the body structure itself during maneuvers, which leads to increased wear of all suspension components and parts and a decrease in safety.

To avoid these difficulties, it is necessary to install products only with guaranteed suitable parameters and dimensions. For the VAZ 2112, these are the diameters R14 and R15, which have factory parameters and meet all safety requirements and other characteristics.

Wheels of this size will give the car the best level of driving comfort.

As for increasing the size of the rim, their operation has its positive and negative sides, which every car enthusiast needs to know. However, the decision to purchase and replace disks should be made only by the owner of the machine.

Pros:

- Good car behavior in the lane;

- Improving the exterior of the car;

- The best road qualities, including dynamics and handling;

- Maximum absorption of potholes and road defects;

- When using rubber with a high profile, the wear resistance of chassis parts increases;

- Reducing the braking distance.

Minuses:

- Reduced level of comfort in motion. This is due to the high sensitivity of the chassis to road defects;

- Difficulty in parking and driving on poorly paved roads;

- Increased requirements for pressure control in low-profile tires;

- Increased gasoline consumption, which is associated with the increased difficulty of driving the wheels;

- High price.