Grant's automatic transmission is a classic four-speed six-position automatic transmission (P,R,N,D,1,2) with a torque converter. In addition to the traditional “drive”, the Jatco box is equipped with several more modes - with a fixed first gear and with fixed first and second gears. In addition, there is an overdrive disable button that prevents the box from moving to the highest gear—in this case, fourth—gear. This helps a lot during long highway overtakings. But the developers themselves recommend using modes with fixed gears in conditions of long climbs or off-road conditions.

Automatic transmissions are produced at Jatco facilities in Japan, and on the assembly line of the Tolyatti plant they are only combined with the engine and installed on the car. VAZ dealers will not repair automatic transmissions; they are prohibited from doing so. The service life of the automatic transmission is 10 years. According to the assumptions of VAZ specialists, the “automatic” should easily run up to 150 thousand kilometers, subject to all operating conditions. Within the warranty period of the transmission (and it coincides with the warranty period of the car itself), all problems with the transmission will be solved in only one way - replacement.

All this is good, but sooner or later the chassis will have to be repaired and this is what we will have to face.

Nova Granta with automatic transmission received more than 30 design changes and new components. Let's look at some of them.

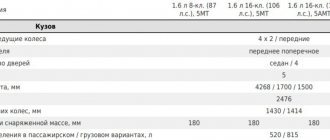

A more powerful engine with a displacement of 1.6, 16-valve with a lightweight ShPG, was equipped with a cast crankcase instead of a stamped one, and new mounting points were invented for the sump - directly to the torque converter. This increases the rigidity of the entire structure. The torque converter housing itself was also replaced to fit it into the engine compartment. All this lowered the ground clearance: Granta with automatic transmission has 140 mm ground clearance versus 160 mm for a “manual” sedan. Unfortunately, there is no crankcase protection.

Since the engine-gearbox connection became heavier by 33 kg, the sedan received new, stiffer springs in the front suspension. Externally, they are no different from ordinary 1119, but the markings have a different appearance.

The rear support of the automatic transmission has also undergone changes. It became stiffer and received a more reinforced bracket.

The levers and “crabs” are connected not by the “eighth”, but by their own, more curved stretch.

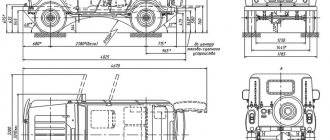

The outer CV joints are unified with the usual “Granta”, and for the internal joints “tripods” are used, specially selected for the Jatco differential. “Tripods” allow you to achieve a larger operating angle for transmitting torque, and they also have a longer service life than a conventional CV joint. Drive shafts vary in length, so their diameters vary. A rod is used on one side and a pipe on the other. In this way, balance is achieved so that the car does not pull to the side at the moment of sudden addition of traction.

A new, more efficient cooling radiator, which also includes an oil cooler. Now such radiators will be used on all Grants that come with air conditioning.

A vehicle with an automatic transmission is the desire of every lover of the domestic automobile industry. The first cars equipped with automatic transmission were produced in the middle of the 21st century, but until now this technology has not been widely used on VAZ models. But experiments were still carried out.

As far as we know, the “nine” car was not equipped with an automatic transmission, but with a V-belt variator. Thus, the usual stepped hydromechanical automatic transmission is not the best option for domestic vehicles with an engine displacement of less than 2 liters. Causes:

- the transversely located engine makes installing an automatic transmission on the ninth VAZ model quite a difficult task;

- hydromechanics service may not be affordable for everyone;

- insufficient power and torque can cause shifts that are not always intended.

Installing an automatic transmission on a VAZ 2114

— As practice shows, the best option for a VAZ 2114 car is an automatic transmission from a Toyota Camry car. Previously, the automatic transmission from Toyota Camry undergoes a major overhaul with the replacement of worn parts.

— Installing an automatic transmission on a VAZ 2114 begins with preparing the car for such a replacement. The air intake system is removed from the engine compartment, the front wheels are removed, the suspension and steering gear are disassembled, and the axle shafts are removed.

“Then it’s the engine’s turn. The engine is completely removed downwards from the engine compartment using a dolly.

— Preparing the engine for installation of a new box begins with removing the brackets that have become unnecessary for attaching the transmission to the body.

New brackets will be installed instead.

— We are starting to prepare other components of the car for the installation of an automatic transmission. It is necessary to install an additional radiator for the box cooling system.

— At this time, another mechanic is dismantling the manual transmission of the VAZ 2114 and preparing a place for docking the engine with the automatic transmission.

— Now it’s the turn of the clutch and flywheel. These details are no longer needed.

— Next, it is necessary to carry out an important operation to refine the angular velocity joints. The diameter of the axle shafts is reduced on a special machine. Without this work, joining the VAZ axle shafts to the new gearbox will be impossible.

— Now it’s the turn of the new flywheel, with this operation the process of installing a new gearbox on the old engine begins. Install a new box on the engine.

— The key operation is to attach the new box to the flange of the VAZ 2114 engine. It must fit exactly where the old box is attached.

— It is necessary to adjust the seats to the engine housing and gearbox for a tighter fixation of the brackets.

— Now install the box together with the engine in the engine compartment of the car.

— All that remains is to connect the electrical wiring harnesses of the transmission control unit to the vehicle’s on-board network. And also carry out a complex of installation work in the cabin.

The following video talks about installing automatic transmissions on VAZ cars.

If you need to move quickly and comfortably, it is recommended to use the services of a taxi in St. Petersburg. Qualified driver, reasonable prices and quality service. A nice fact is that you can order a taxi to the airport online.

Tuning the VAZ 2109 transmission

The classic transmission of all VAZs is manual. It is quite reliable, cheap to maintain and well suited for use on domestic roads.

Upgraded car

There are several popular types of tuning for manual transmissions. They appeared as a banal need to improve the performance of the car. The main work packages include:

Let's take a closer look at one of the tuning options. Replacing the rocker with a short-throw one is a useful tuning that will significantly simplify gear shifting. We all know that the lever of the “nine” and most other VAZ cars is absolutely inconvenient. It has a huge backlash, which simply has a terrible effect on the accuracy of gear shifting. If men with long hands can still cope with it without any critical effort, then women will have a very difficult time with it.

The easiest way out of the situation is to install a short-stroke cardan from the Lada Kalina on the 2109. Such tuning will cost you approximately 1,500 rubles. Along with the cardan, you will have to get a boot from the same model, because it won’t be original with it.

The necessary tools for work are a set of keys, a slotted screwdriver and a hammer. It will also be very good to have an assistant.

DIY automatic transmission for VAZ 2114

Our service offers an exclusive service for owners of front-wheel drive fuel-injected VAZ cars - installation of an automatic transmission from Toyota cars.

A four-speed Toyota automatic transmission is installed on the Lada model of the tenth family, Lada Kalina, Priora, and the Samara model family. A car with an automatic transmission is distinguished by its smooth ride, ease of control, and good dynamic characteristics. The installation kit includes a Toyota automatic transmission, a starter, and a flywheel from a Toyota vehicle. A gear selector is installed in the cabin. Automatic transmission installation time is 4-5 working days.

In total, we have installed more than 50 automatic transmissions for various models. The warranty on the installed automatic transmission is 1 year or 40,000 km.

The cost with installation in our service is 50,000 rubles. Installation is carried out by appointment.

It is possible to ship automatic transmission kits to VAZ for self-installation. Currently, it is possible to supply kits for models of the Kalina family and models from the VAZ 2110, 11, 12 series. The kit includes: a four-speed Toyota automatic transmission ready for installation, an adapter plate, a starter, a flywheel converted for VAZ engines, a gear selector, a control cable , electrical wiring harness, a set of converted internal CV joints, modified front suspension brace, automatic transmission mounting brackets, fasteners, detailed installation instructions. The cost of the set is 45,000 rubles.

AUTOMATIC TRANSMISSIONS based on automatic transmission ZF 4НР-22 for GAZ-3110 and GAZ 3111 with ZMZ 406 engine.

The cost of automatic transmission is 60,000 rubles. The cost of automatic transmission with installation is 75,000 rubles. Warranty 2 year or 40,000 km.

At the moment, 85 machines are in trial operation.

AUTOMATIC TRANSMISSIONS based on the ZF 4НР-22 automatic transmission together with a transfer case and limited slip differential (Torsen Audi A-6) for VAZ 2120 NADEZHDA, VAZ 2113, VAZ 2123 NIVA with 1.8 liter and 2.0 liter engines

The cost of automatic transmission is 75,000 rubles. The cost of automatic transmission with installation is 90,000 rubles. Warranty 2 years or 40,000 km.

At the moment, 15 machines are in trial operation.

AUTOMATIC TRANSMISSIONS based on automatic transmission ZF 4НР-14 for VAZ 2110, VAZ 2111, VAZ 2112, VAZ 2113, VAZ 2114, VAZ 2115.

The cost of automatic transmission is 50,000 rubles. The cost of an automatic transmission with installation is 75,000-80,000 rubles. Warranty 2 years or 40,000 km.

At the moment, 80 machines are in trial operation.

AUTOMATIC TRANSMISSIONS based on automatic transmission ZF 4НР-14 for LADA 1118, LADA 1119

Lada Sagona 21099 1987 - 2016

Lada 21099 automatic transmission guarantees reliability, controllability, mobility and safety of your car on the roads. Original and branded spare parts are always available in warehouses at reasonable prices.

However, speaking of repairs, even more important for driving safety is regular maintenance and timely repairs, subject to vehicle maintenance regulations:

- works well,

- does not lose its performance over long runs,

- more reliable and safer to operate

We make it easy to keep your car in good condition and provide great deals on our entire range of parts. Everything you need for service and repair can be found right here in our digital warehouses. Instead of endlessly searching for a retail auto parts store near you that doesn't necessarily have the parts you need, just pick up the phone and we'll deliver the auto parts you need to your door.

The main emphasis when selecting spare parts is based on the company’s experience.

It is profitable and safe to buy from us for a number of main reasons:

- Autocompas.ru is one of the leading online stores of auto parts, with daily traffic on the site of more than 30,000 people,

- Certified and reliable suppliers provide a full range of auto parts within access to their warehouses,

- The system has more than 500 suppliers and manufacturers who regulate prices with an eye on competitors and strive to make their goods more profitable to purchase.

Why look for Automatic transmission Lada 21099 somewhere else, wasting time? We have competent staff, payment, delivery and support services.

VAZ 2109 gearbox VAZ 2108 | VAZ 21099 | VAZ 2113 | VAZ 2114 | VAZ 2115 installation | buy | Replacement of manual transmission of VAZ of all modifications, replacement of clutch, Moscow

Artem Vadim 8 925 675 78 75

Your transmission will be overhauled within 2 hours in your presence. The cost of the bulkhead is 4000 rubles. + spare parts due to wear. Removing and installing the box on a car – 2000 rubles.

ATTENTION: for your convenience, there is a service - express replacement of a VAZ 2109 - 2115 class gearbox. When there is no time to wait for yours to be overhauled, or repair is impractical - the cost of spare parts exceeds the cost of the unit itself, we will offer to replace it with a similar one restored by our mechanics and fully prepared for operation.

Prices for replacing manual transmissions of the VAZ 2109 family are fixed and are indicated on the condition of the entire housing and gear unit. In the event of a defect in one of the parts of the housing, the gear block of 1-2, 3-4, 5 gears or the main pair, the cost of this part is added to the cost of exchange - 2000 rubles. The work takes from 1.5 to 2.5 hours.

Installing an automatic transmission on a VAZ 2114

— As practice shows, the best option for a VAZ 2114 car is an automatic transmission from a Toyota Camry car. Previously, the automatic transmission from Toyota Camry undergoes a major overhaul with the replacement of worn parts.

— Installing an automatic transmission on a VAZ 2114 begins with preparing the car for such a replacement. The air intake system is removed from the engine compartment, the front wheels are removed, the suspension and steering gear are disassembled, and the axle shafts are removed.

“Then it’s the engine’s turn. The engine is completely removed downwards from the engine compartment using a dolly.

— Preparing the engine for installation of a new box begins with removing the brackets that have become unnecessary for attaching the transmission to the body.

New brackets will be installed instead.

— We are starting to prepare other components of the car for the installation of an automatic transmission. It is necessary to install an additional radiator for the box cooling system.

— At this time, another mechanic is dismantling the manual transmission of the VAZ 2114 and preparing a place for docking the engine with the automatic transmission.

— Now it’s the turn of the clutch and flywheel. These details are no longer needed.

— Next, it is necessary to carry out an important operation to refine the angular velocity joints. The diameter of the axle shafts is reduced on a special machine. Without this work, joining the VAZ axle shafts to the new gearbox will be impossible.

— Now it’s the turn of the new flywheel, with this operation the process of installing a new gearbox on the old engine begins. Install a new box on the engine.

— The key operation is to attach the new box to the flange of the VAZ 2114 engine. It must fit exactly where the old box is attached.

— It is necessary to adjust the seats to the engine housing and gearbox for a tighter fixation of the brackets.

— Now install the box together with the engine in the engine compartment of the car.

— All that remains is to connect the electrical wiring harnesses of the transmission control unit to the vehicle’s on-board network. And also carry out a complex of installation work in the cabin.

The following video talks about installing automatic transmissions on VAZ cars.

If you need to move quickly and comfortably, it is recommended to use the services of a taxi in St. Petersburg. Qualified driver, reasonable prices and quality service. A nice fact is that you can order a taxi to the airport online.

gearbox /refurbished/ for sale:

Warranty 1 year or 60,000 km. mileage for work and VAZ gearboxes

| Phone number of the repairman: | Artem 8 /965/ 126 13 83 Vadim 8 /925/ 675 78 75 |

| Tow truck assistance /24/7/, dispatcher: | 8 /926/ 167 15 40 8 /985/ 888 68 14 |

New gearbox VAZ 2109

Prices for additional work when repairing a VAZ manual gearbox:

Comprehensive troubleshooting / disassembly /

Replacing the clutch /as a separate job/

Removing and installing a manual gearbox as a separate job - without repair

Replacing the clutch with the gearbox removed

DIY automatic transmission for VAZ 2110

The first cars with automatic transmission were produced in the middle of the 20th century, but this technology is still not widely used at VAZ. But experiments were still carried out: The initiator of the installation of an “automatic” on the VAZ 2112 was the AvtoVAZ development department.

The order was accepted by the Moscow Center for Automatic Transmissions MAI together with the German company ZF. In fact, the car of the tenth family was not equipped with an automatic transmission, but with a V-belt variator. The fact is that a traditional stepped hydromechanical “automatic” is not the best option for cars with engines up to 2 liters.

Firstly, the transversely mounted engine makes installing an automatic transmission on the ten very difficult. Secondly, “hydromechanics” are expensive to maintain. Thirdly, a lack of power and torque will cause shifts that are not always predictable. Therefore, a V-belt variator is better suited for such engines.

Stacked steel “push” belt, which allows you to transmit impressive torque between the pulleys. The main unit of the V-belt variator is two sliding pulleys with a steel belt stretched between them. By moving the “halves” of the drive pulley apart and reducing its working diameter while simultaneously compressing the driven pulley, we get a “low” gear. When both pulleys are in the middle position, it is a "direct drive". And an increase in the diameter of the drive pulley with a decrease in the driven pulley gives an “overdrive”.

Let's sum it up

Russian developments in the field of automatic transmissions have become one of the best options for technical progress that we could expect from AvtoVAZ. The company received a big push forward when other cars on the market began to rise in price. Today VAZs have truly become the most attractive offerings in terms of price and technology. But we can safely say that in technical terms, the cars are not inferior to their budget rivals from other countries.

Granta, Kalina and Vesta with automatic transmission, as well as Priora and the planned AvtoVAZ models, received excellent reviews from buyers and became targets for purchase from many potential motorists. The flow of investments into the company is increasing today, sales of new cars also continue to grow, so we can safely say that the concern will be able to continue to develop and grow well in the future. Do you think the automatic transmission options installed on the VAZ are reliable?

Source

Peculiarities

The design of the unit allows, during acceleration (pedal to the floor), to constantly maintain engine speed corresponding to maximum power, and the speed is gained by smoothly, steplessly changing the gear ratio. And with any manual transmission, the engine is forced to operate more often in less favorable transient conditions. Therefore, theoretically, a car with a CVT can accelerate faster than with a manual transmission.

To prevent sudden braking on the drive wheels from causing a skid on a slippery road, use speed braking. On a manual transmission this process is known to everyone, but on a CVT it has some peculiarities.

In Drive mode, the variator perceives the released gas pedal as a signal to shift to the highest gear, so the car practically does not brake with the engine. But if you switch to Low mode, everything changes. The CVT shifts to slightly higher gear ratios (“low gears”) and continues to hold them when the throttle is released, helping to increase engine braking efficiency. Thus, if you move the lever from “D” to “L” right on the move, engine braking will begin very smoothly and with a noticeable delay. The well-known transmission company ZF bought one of the Van Doorne Transmissie enterprises in Belgium and began producing CVTs by order of BMW for Rover and MG cars, and then for the new Mini.

There is always a way out

For these reasons, the most suitable option for these engines is a V-belt tensioner. A stacked “pushing” element made of steel allows significant torque to be transmitted between the rollers. The main unit of the V-belt tensioner is two sliding rollers, between which a special belt is tensioned. By moving the halves of the main pulley apart and reducing its working profile, the landing roller while simultaneously compressing it, you can get an enhanced transmission. When the two rollers are in the central position, this is the main gear, and accordingly increasing the profile of the main pulley with lowering the driven one gives an overdrive.

The structure of the design makes it possible, while accelerating, to constantly maintain the motor in operating mode corresponding to the highest power indicator, and the increase in speed occurs through slow, smooth switching of the transmission indicator.

With various manual transmissions, the engine must operate more often in the minimum favorable speed modes; for this reason, a vehicle with a CVT can pick up speed in a shorter time than with a manual transmission.

To prevent wheel engagement on a slippery roadway from causing the car to skid, it is necessary to use a low gear in the manual transmission. In mechanics, everyone knows this process, but in automation it has completely different principles. In the “Drive” mode, the variator perceives a decrease in engine speed, and thus the box automatically switches to a lower gear, so the car is almost unable to brake with the engine, but when switching to another mode, changes appear. Lower rpm equals better braking. In order to switch the joystick from one mode to another when moving, engine braking will start quite slowly and a significant delay will be felt.

Car acceleration

Acceleration of the car is accompanied by the monotonous sound of the engine running at the same speed, which causes the feeling of a burnt out clutch. That is why, for some, this causes hostility towards CVTs. But the CVT VAZ is free of this drawback. Up to 3000 rpm, even with the gas pedal fully pressed, the engine spins up almost synchronously with the acceleration. It feels like acceleration occurs in one, smoothly increasing gear. And after overcoming this milestone, a sudden increase in revolutions occurs, which is accompanied by a noticeable increase in acceleration - as if a classic stepped automatic transmission was under the hood and the Kick-down mode was activated. To install the CVT on the VAZ, one of the mounting points of the internal combustion engine had to be moved to the body.

Despite this, vibrations have become noticeably less. If with a “mechanics” the engine skips at the moment of starting, which causes shaking, then with a variator this effect is noticeable to a much lesser extent. The speed is maintained automatically and drops less frequently into the “critical” zone.

Vehicle characteristics with manual transmission and automatic transmission (CVT) comparison

If we talk about the characteristics and performance of two cars of the tenth family, with a CVT and a manual transmission, then: Acceleration to 100 km/h - there is no difference in time. Acceleration at 400 m - the CVT wins by 0.2 seconds. Acceleration at 1000 m - the CVT wins by 1.1 seconds. Acceleration from 60 to 100 km/h (manual transmission - 3rd gear, CVT - "D") - again the CVT wins by 1, 25 seconds. Maximum speed - here the “mechanics” turned out to be faster by 4.2 seconds. Fuel consumption - tests have not been carried out, but theoretically the CVT should reduce gasoline consumption.

An interesting article about biofuels produced from ordinary sawdust, read more here.

DIY automatic transmission for VAZ 2114

The price is, of course, serious, but when I think that I’ve pressed the pedal and you’re driving, it’s absolutely breathtaking

I’ve never driven a car with an automatic transmission, but I think it’s incredibly convenient.

Question about installation on a VAZ. The advantages seem obvious, but what about the disadvantages? I personally won’t have any problems with maintenance. What about the rest? What pitfalls may await?

To be honest, it would have been easier for me if they had talked me out of it. But I want arguments, not just “You fool, don’t bet!”

THANKS FOR ANSWERS!

I doubt it's cheaper

Besides, you don’t want to get used to a new car. It is clear that there are other ways to ride comfortably. You can even buy a new one. But personally, I’m interested in whether something bad threatens the installation of an automatic transmission on a VAZ, or whether everything is as cool as it seems in theory.

There are no advantages visible. if only your friend will ride it. One of the advantages is that there will be two pedals left.

1. Box curvature. What is she like? How many electronics does it have? What controls it? 2. What is it for? You don’t know how to drive a car with an automatic transmission, but you already want one. Maybe it’s better to try on another machine and then decide whether you need it or not? 3. Who will service the box? Are there any commonplace diagnostic scanners for this (like checking the temperature) 4. What happens if the box breaks completely and irrevocably? 5. How are the gear ratios selected? 6. How is cooling implemented? . and a bunch of other technical issues

No offense, but if you pour cologne on shit, it will still remain shit. In your case, you want to try to pour, frankly, a shitty liquid that smells strangely: either it will add to the smell, or it will knock it off a little.

For example. Just before my eyes, a ’99 Corolla 5-door with a 1.6 100+ hp engine, air conditioning and automatic transmission was sold for 230 thousand rubles. Believe me, your basin was not even close to this car. So sell your car and buy yourself a foreign car. Left hand drive.

VAZ 2114 gearbox: device, malfunctions, removing the gearbox yourself

The fourteenth VAZ (like the VAZ 2113 and VAZ 2115) is equipped with a five-speed manual gearbox. This gearbox is similar to the units that were installed on the eight, but the main pair has been changed.

From this article you will learn the technical characteristics and design features of the gearbox on the VAZ 2114, how the repair and maintenance of the fourteenth gearbox is carried out, and what is the current cost of used and new units.

Disassembled gearbox

CONSTRUCTION FEATURES

Structurally, the gearbox device is divided into 3 main parts: gearbox housing, rear cover and clutch housing. The internals of the device can be divided into two groups - the main pair and the differential with gear ratios.

The main pair, also known as the drive shaft of the gearbox, performs the function of reducing the speed transmitted from the engine to the crankshaft. The VAZ 2114 GP gearbox reduces engine speed by almost four times (gear ratio – 3.7).

Manipulations with the main pair, aimed at changing the gear ratio, allow you to change the length of the gears, which makes it possible to influence the acceleration and maximum speed of the fourteenth. However, it is not recommended to interfere with the operation of the box without proper qualifications - you can do irreparable things.

POSSIBLE FAULTS

Despite the imperfect operation, the VAZ 2114 gearbox, when used correctly, is distinguished by good endurance and durability. If you do not hesitate to prevent and promptly eliminate breakdowns, repairing it is not expensive.

Let's consider the main gearbox malfunctions that the owner of the fourteenth may encounter:

- Lack of speed fixation when switching. If the speeds are out of whack, the cause is most likely worn teeth on the gears and clutch. Accelerated wear of these parts is caused by incorrect gear shifting and non-compliance with the speed limit. The problem is resolved by replacing the gears.

- The gear shift lever is tight. The reasons are mechanical damage to the teeth of the lever fixing on the hinge or wear of the reaction rod; it’s also a good idea to check the integrity of the plastic parts of the gearbox drive;

- The VAZ 2114 gearbox is humming. Most often, the gearbox is humming in neutral gear. First of all, you need to check and, if necessary, add oil (in general, the box may hum due to the use of low-quality lubricants). If the oil is normal, the problem is wear of the bearing on the input shaft, which can only be determined through diagnostics or by disassembling the gearbox;

- Crunching sound when changing speed. Here it is necessary to change the worn out synchronizer, and it must be changed immediately after the problem has been discovered, because if you tighten it, the gear unit will completely fly off;

- Knock. The gearbox on a VAZ 2114 can knock both under load and without it, and in any gear. The cause of the knocking noise is a damaged drive gear of the problematic transmission.

One of the key factors for the trouble-free operation of gearbox number fourteen is the use of high-quality lubricants. The most suitable option is GL-4 mineral oil. It is not cheap, but it does its job at 5+; when using mineral oil, VAZ gearbox repairs are usually required extremely rarely.

Most VAZ 2114 owners agree that the best gearbox oil is 75W90. It is distinguished by greater fluidity than typical gearbox oils, due to which the lubricant better gets into those places of the gearbox, the lubrication of which is provided exclusively by splashing. Good options for 75W90 are Hypoid-Getriebeoil TDL and Liqui Moly Vollsynthetisches Getriebeoil (GL-5).

Checking the oil level should be carried out every three weeks. In the gearbox, the fourteenth gear is placed vertically, the topmost is the fifth, it is the one that is most susceptible to failure due to lack of lubrication, so it is always necessary to fill in oil to the maximum mark, and best of all - 200-250 ml. more than the required norm.

Replacing the engine mount

To perform this activity, you should purchase a set of power unit supports, since it is not practical to change them one by one. To replace these elements yourself, you will need the following tools:

- Set of wrenches.

- Scrap.

- A pair of powerful jacks.

- Glue.

- Durable cable.

Advice! It is worth inviting an assistant in advance, since during certain stages of the repair it will be necessary to lift quite a lot of weight.

The process for replacing pillows varies. Sequence of actions when replacing the front engine mount:

- it is necessary to immobilize the car in advance by tightening the parking brake and placing shoes under the wheels;

- you can only get to the support after dismantling the upper protection of the power unit;

- Let's start jacking up the engine. To avoid damaging it when doing this, it is worth preparing a strong board in advance, which is placed between the jack pusher and the bottom of the motor;

- you can unscrew the bolt securing the pillow to the bracket, since it is no longer under load;

- We carry out a similar procedure with the bolt securing the support to the engine;

- remove the worn element and install a new one.

Sequence of actions when replacing the rear and side supports:

- The car's transmission must be hooked up with a cable, and then a jack must be placed under it;

- loosen the bolt securing the gearbox to the support;

- We perform a similar procedure with the nuts securing the power unit cushion;

- Having jacked up and raised the gearbox, remove the nuts and bolts securing the cushion;

- remove the worn out part and install a new one, assembling everything in the reverse order.

The side cushions of the VAZ-2114 engine change in the same way. The only thing is that if the starter is large, it will need to be dismantled, since it will not be possible to get to the support mounts properly because of it.

This is the entire process of replacing worn out engine mounts. As you can see, it will not cause any particular difficulties, and its timely and competent implementation will help to avoid serious problems in the future and save on expensive repairs.

Attention! I advise you to save not only on repairs, but also on fuel. How to do this - here is a separate article on this topic.. As you know, during operation, a car engine creates a noticeable vibration, which is dampened by special parts

In old VAZ models, this function was performed by several rubber cushions, and the weight of the power unit rested on a metal frame. In front-wheel drive models, in particular the VAZ 2114, manufacturers have made significant changes to the design of the front part of the car and now the pillows additionally serve as support.

As you know, during operation, a car engine creates noticeable vibration, which is dampened by special parts. In old VAZ models, this function was performed by several rubber cushions, and the weight of the power unit rested on a metal frame. In front-wheel drive models, in particular the VAZ 2114, manufacturers have made significant changes to the design of the front part of the car and now the pillows additionally serve as support.