Tuning is often a very expensive pleasure. As a rule, all trends come from the West, so in the arsenal of avid car enthusiasts there are many foreign words that are not known to the common man. So, for example, few people know what downpipes, dampers, and autobuffers are. The same situation repeats itself when we come across the concept of “coilovers”.

Coilovers are an adjustable shock absorber strut that allows you to change the stiffness of the shock absorbers and the ground clearance. Essentially, coilovers act as an adjustable suspension and consist of a support and a spring that wraps around its rod. Coilovers were first developed by Western professionals and used in sports and drifting competitions. The word consists of two parts - “coil” and “over”. If you translate each of them separately (the first is the spring, the second is around), then you can understand what coilovers are.

The main task of the device is to raise or lower the suspension. At the same time, it can be adjusted over a fairly wide range. Consequently, every day you can ride with completely new settings, because the product helps you easily change the ride height (clearance).

If you have a question about what adjustment range the screw suspension has, then the value is 8-10 cm when we are talking about A-arms. When we are dealing with a separate spring and shock absorber, the values vary and are 6-8 cm. However, there may be some variation within different models.

Coilovers (or struts) are an indispensable advantage on roads with poor surfaces or off-road.

What are Coilovers?

The spring and shock absorber serve as suspension elements, performing separate functions. The pairing of two components into a single unit gives a qualitatively new system, which is called a helical suspension.

The unit ensures comfortable movement of the car on uneven surfaces, elastic coupling between the body part and the wheels. A helical suspension with adjustable spring stiffness and height without removing the shock absorber strut is called a coilover .

Coilovers for VAZ and other methods of lowering (video)

With the help of comfortable coilovers, you can significantly change the characteristics of the suspension that is installed on a particular car. But you should definitely take into account typical driving conditions. They work differently on different surfaces

That is why it is important to be extremely careful when using such elements in your car. The consequences of such applications must be fully understood. As you know, any modernization is only good in moderation

As you know, any modernization is only good in moderation.

What elements does a screw suspension consist of?

There are two ways to equip a car with an adjustable coil suspension.

- The “standard” shock absorber is equipped with a thread and a spring with specified parameters.

- Installing a new node.

The first method results in deterioration of car controllability. Changing the ground clearance reduces the reliability of the shock absorber and the efficiency of the suspension system.

In the second method, the device parameters correspond to the specified loads. The reliability and service life of such an element are much higher.

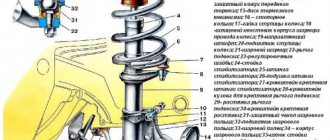

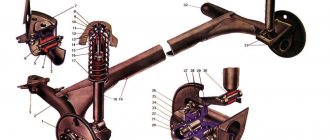

An adjustable coil suspension is a shock absorber with threads applied to the body or bushing. The bushing fits onto the shock absorber. Upper and lower stops are installed on the body. A spring is placed between the stops. The lower stop moves along the threaded surface.

A professionally manufactured helical suspension consists of structural units:

- Shock absorber.

- Upper stop (adjustable or non-adjustable for camber).

- Lower adjustable stop with internal thread. The shock absorber, screwing into the stop, reduces the vehicle's ground clearance.

- Lower stop locknut for fixing the height of the shock absorber strut and adjusting the ground clearance.

- The coil spring is the main functional element of the coilover. The rigidity of the element is selected depending on the type of suspension.

- Spring stop screwed onto the shock absorber strut. The key knurled stop is supported by a locknut, adjusting the spring preload.

- Key and hole for adjusting damping at the top of the shock absorber strut.

- The spring limiter locknut with key notches fixes the position of the limiter.

This is interesting: Online tire store

When moving the lower stop along the thread, the ground clearance decreases. The helical suspension allows adjustments in the horizontal plane, setting the required wheel camber.

Difference from conventional racks

The classic strut used in cars has a simple design of a body and a spring. This is a very reliable option that has been used all over the world for a long time. However, it has a huge drawback - adjustment of this design is not provided. The spring has two attachment points; it is not possible to change one of them. The only option is to change the spring length, which is often done by beginners in the tuning field.

As for the coilover, it is fully adjustable. The lower stop moves freely along the thread, changing the position of the spring. Thanks to this, it is possible to adjust the height of the car without irreversible methods.

Advantages

The adjustable suspension is easy to install and offers selectable spring pre-compression for increased ride height.

In addition to the ease of adjustment with traditional tools, coilovers have a number of advantages:

- Ease of installation.

- Affordable prices.

- Possibility of adjusting ground clearance without removing the suspension.

- Correction of shock absorber stiffness.

- Versatility of design. This type of suspension is suitable for cars of any brand.

- Reliability and long service life.

- Select settings for hardness and wheel camber.

The degree of lowering depends on the type of coilover and the make of the car.

Most adjustable devices allow you to reduce the ground clearance by 20-50 mm.

How to make coilovers with your own hands. Some secrets

If you wish, you can make coilovers yourself. If you don't want to spend money on new springs, you can simply purchase a kit that allows you to upgrade your old suspension. This is simply a casing equipped with threads. At the same time, your significant financial savings are obvious. You will also increase your own safety.

Flaws

Adjustable suspension requires proper maintenance and condition monitoring. The absence of seals on the rods leads to clogging of the shock absorber and its rapid failure. This is not the only weak point of coilovers.

Minuses:

- Tuning for specific road conditions eliminates a comfortable ride and good handling when switching to a different type of road surface.

- Unevenly adjusted suspension elements cause imbalance and reduced suspension performance.

- Adjusting the suspension requires professionalism and skill.

- After adjustment, it is necessary to adjust the wheel alignment.

- High cost of nodes.

- When installed on original racks, the reliability of the structure is reduced.

Shaking proves that the adjustments do not correspond to the operating conditions. Professional installation and debugging of the helical suspension ensure comfortable movement in any road conditions.

DIY coilover

Since the price for such an upgrade is high, there is always the opportunity to make the necessary components. Although this task is quite difficult, it can be done with the necessary skills. This will allow you to save a significant amount and choose the part for your car.

Before starting work, you should select a shock absorber. It is necessary for the further functioning of the system, being its basis. It is recommended to purchase sports options, whose rigidity is much higher than that of classic ones. This will allow them to work in any position of the puck.

Advice! Using old racks for such work is ineffective. It is recommended to purchase new ones to ensure their lifespan is complete.

Next you need to sharpen the parts. A coilover requires two – a casing and a coupling. The role of the coupling will be played by a nut, complemented by a support washer. After fitting the parts according to the thread, you need to move on to the next stage - assembly. It is carried out as follows.

- The protective casing is removed from the standard rack.

- A previously machined workpiece is placed in place of the casing.

- The nuts are screwed onto the workpiece itself and the support washer is put on.

- The silent block and boot are installed.

Important! The previous silent block on the shock absorber may not be suitable. Therefore, it is worth determining the required diameter in advance according to the diagram. The last stage of creating such a design is installing the spring

The process is very problematic if there is no appropriate equipment. It can be found at your nearest auto repair shop, the task itself takes just a few minutes

The last stage of creating such a structure is installing the spring. The process is very problematic if there is no appropriate equipment. It can be found at your nearest auto repair shop, and the task itself takes just a few minutes.

As a result, the homemade coilover is ready, you just need to place it in the car

It is important to test its performance and maximum load so that this does not lead to a dangerous situation in the future. It is recommended to test it in different positions to determine the approximate load range

The process of creating coilovers is quite complicated, and the effort may not be worth the result achieved. Therefore, it is often easier and more reliable to purchase a finished product than to manufacture its components yourself.

And this video clearly shows the process of making nuts for coilovers. Although the blanks already have internal threads, applying them is quite simple. The video will help you understand the nuances of manufacturing such nuts, which are the main components that fix the spring in the required position:

- How to bleed brakes on a Priora without ABS and with ABS

- Why is the parking sensor beeping all the time?

- How to make and install a heated steering wheel with your own hands

- How to use a torque wrench

Popular manufacturers

Coilovers from a reliable manufacturer pay for themselves due to their long service life.

Adjustable screw suspensions are produced by reliable companies:

- (Sweden).

- (Britannia).

- Concern "Kayaba" (Japan).

- Enterprise "H&R" (Germany).

- (Germany).

- (Netherlands).

- (Belgium).

- XYZ Racing (Taiwan).

- Guangzhou Fat Chassis Technology Company (China).

This is interesting: Customs clearance services

British is the world's most famous manufacturer of screw systems equipment. The company produces four types of coilovers for different purposes.

Types of coilovers

At the moment, there are all two main types:

- Allows you to mount a threaded enclosure onto your stock rack, making it essentially a must-have upgrade kit. The downside of such a system is that the standard rack may not be able to cope with the increased load on it and will quickly fail. Also, if the compression is too strong, it practically stops working altogether, which affects the handling of the car.

- This is a ready-made coilover assembly - we just remove the old struts and install new ones. The advantage here is that the rack is already designed for different load conditions, its service life is much longer.

Coil-type suspension with dynamic damping coordination system

(Germany) created an adjustable screw assembly to monitor motion parameters to coordinate damping. The KW DDC ECU equipment contains a set of components.

- The suspension is adjustable.

- Electronic control panel.

- Set of cables, switching device.

- Instructions.

The system allows for personal adjustment of the suspension height in accordance with standardized parameters. Coilovers, depending on the type, are used in various road conditions.

- Constant use on city roads. After professional setup, the device guarantees comfort, good controllability, and smooth running.

- Circuit racing requires a suspension with increased stiffness springs. Refined controllability is achieved by using a shortened rod and high viscosity oil.

- To participate in rallies, reinforced coilovers with remote-type oil tanks are used, which increases speed capabilities.

- Taking turns using the drift method requires the installation of special inverted “upside down” shock absorbers, which improve the car’s handling and stability during maneuvers.

The use of adjustable suspension on SUVs and cars allows you to increase the rigidity of the system, increase the speed and controllability of the vehicle. These elements are capable of changing the ride height without removing the suspension.

The functional purpose of the helical suspension is the ability to reduce the vehicle's ground clearance, which has a positive effect on stability. Well, in addition to everything, a change in appearance for the better.

tweet

back Lowrider or how to make a car jump and dance

Next What is a single wishbone car suspension

Springs for coilovers

- Batteries Battery mount

- Battery terminals

- Ammunition and Safety Linen

- Cases and capes

- Radiator pipes 4X4

- TopCool

- High temperature lubricants and pastes - Exhaust system repair products

- Cabin filters

- Blow Off Adapters

- 76-100mm

- valves

- Stainless steel pipe for routes

- BMW

- Metal sleeve

- AEM – INNOVATE – SHLZ

- Original

- Bypass rollers, tension rollers, supports

- Nuts - Bolts - Max Guard Locks

- Lexus GS300 (disassembled)

- TUOSEN

- LED bulbs

- Windshield washer pumps

- Hoses for installation

- Sheets - Rods

- Land Rover

- Suspension components (repair) Honda

- Springs

- Spacers

- Spacers

- Springs

- Spacers

- Pads on the pedals

- Straight Violet

- Black

- Black

- Straight

- High voltage wires

- Fan controllers

- Adapters

- Rem. kits

- Sensors

- Turbines Actuators

- American AN10

- Tape

- Metal reinforced

- Car Alarm Keychains

How much can you lower a car?

I know this question is now on the minds of many readers, rejoice guys:

The average lowering rate is from 20 to 35 mm, very good, now you don’t need to cut off the coils, you can lower your car simply by unscrewing the lower stop. In terms of ground clearance, this can give simply stunning figures. Fluctuations can range from 20 to 100 mm. Although when cutting springs, many achieve a lowering of 30 - 50 mm.

If your car is “pumped” and you need to perform at any shows, such as drifting or other sporting events. In just a couple of hours the car drops to the required ground clearance. After the show, it can be raised to a normal “sane” size and move around the city perfectly.