Dismantling and assembling suspension components of the VAZ 2115 Lada

The front struts on VAZ 2114-2115 cars wear out much faster than the rear ones, and this is due to the fact that the front part of the car bears a large load, since the main units are located there. If the shock absorbers are leaking, or are starting to leak heavily in potholes, then it would be best to completely replace them. Many people are used to dealing with such problems at a service station, although if you try a little, you can do it all on your own. The main thing is to have all the necessary tools and equipment at hand. Below is a detailed list of everything:

- spring ties

- ball joint or steering wheel remover

- pliers

- hammer

- keys for 13 and 19 as well as similar heads

- crank and ratchet handle

- breakdown

I recommend that you first familiarize yourself with the video, which will be presented below, and then read my photo report on the work done.

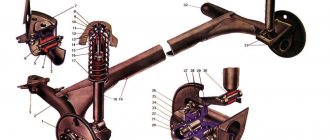

Rear suspension

For the rear suspension, it is better to replace the silent blocks by removing the beam, although this can also be done directly on the car. The installation of the rear rubber bushings is identical to that on the front beam. Pressing out and installation is best done using a mounting device.

However, if it is not there, then the especially “stubborn” ones will be knocked out of the rear silent bars of the VAZ 2110 by holding the part in which they are located in a vice. A mandrel is used, sometimes even sawed.

A faulty rear suspension manifests itself by the appearance of a characteristic knocking sound from the rear. Details: https://vazweb.ru/desyatka/podveska/zadnyaya-podveska.html

Both rear silent blocks are oriented along the lever and pressed flush against the end of the eye.

Front suspension device

The main element of the front chassis of the VAZ 2114 is the shock absorber strut, which is designated as number “9”. It is attached to the steering knuckle with two bolts. Compared to the rear system, the front suspension has a more complex design, which can be understood by the number of parts. Number “11” indicates a bolt that passes through the holes of the rack bracket; it has an eccentric washer and an eccentric collar. When the steering gear turns, the top bolt turns. The result is that the car turns. Most often, shock absorber struts fail, since they do the main job.

Parts and components of the front suspension of the OKA VAZ 1111 car

The VAZ car under the symbol 1111 with the name Oka is a subcompact type of compact city vehicle.

Due to its size, this vehicle is one of the most successful solutions for driving in modern big cities.

The general design of the VAZ 1111 is made using standard technology, independent front suspension, transverse rear beam and front-wheel drive.

The Oka car has an independent front suspension of the MacPherson type. This assumes the presence of a shock absorber strut, which is contained in the steering mechanism. The VAZ 1111 suspension consists of several units:

- two steering knuckles and hub mechanisms with bearings;

- two shock-absorbing struts;

- two lower transverse levers with silent blocks and ball joints;

- two lower longitudinal levers with conical bushings;

- steering rack with rods and steering tips;

- stabilizer bar;

- axle shafts with CV joint mechanism;

- stretcher.

Each of these units carries a different functional load, complementing each other in operation, which explains the good reliability of the VAZ 1111 suspension.

A more complete picture of the work can be presented by breaking it down into individual units. This will give you an understanding of what the Oka car is like as a whole and its front suspension.

Front shock absorbers

The strut with shock absorbers is the most heavily loaded unit. It is entrusted with the functions of monitoring the adhesion of the wheels to the road surface and participating in the control of the vehicle. The Oka is a fairly light machine, so the serviceability of this unit plays a very important role.

The strut is a hollow glass with a knuckle attached to the knuckle of the hub mechanism, into which the shock absorber liner is inserted and secured with a lock nut.

To impart rigidity, it is provided with a support platform for a spring, which gives the Oka machine the necessary vertical stability parameter.

The strut is attached to the car body using a support platform that contains a bearing called a thrust bearing.

This bearing allows the shock absorber to turn after the wheels and at the same time dampens the angle of inclination of the body to the rigid rod.

The lower part of the mechanism is secured to the steering knuckle with two bolts, one of which adjusts the camber angle of the wheel.

Thanks to this design, the stand with a shock-absorbing insert for the VAZ 1111 is very simple, reliable and extremely functional.

Lower control arms, stabilizer bar and steering rack

The purpose of the transverse lower arms is to hold the chassis mechanism in a vertical, stable position. They are attached at one end to the hub and the other to the subframe. It is attached to the steering knuckle through a ball joint; it is designed to rotate the hub. The ball joint is one of the most quickly failing parts of an Oka car.

The silent blocks pressed into them give the levers a small stroke along the axis of attachment to the subframe. They provide the necessary vertical play of the entire chassis, which ensures a stable position of the car on the road.

The longitudinal lower arms are necessary to hold the chassis in the longitudinal plane. They are attached with one side to the transverse arms, and the other to the subframe.

With the help of conical bushings located at both ends of the arms, the chassis of the Oka car provides the necessary longitudinal play.

The tapered bushings of this unit are quite reliable due to the insignificant load and they are changed very rarely.

Despite the fact that the chassis is independent, a stabilizer bar is designed to stabilize its functioning. It combines the entire chassis into a coherent mechanism. The stabilizer is held on the front part of the body and on the transverse lower arms. At the mounting points, the stabilizer is equipped with rubber bushings that provide it with the necessary play.

The main turning mechanism of the VAZ 1111 is a steering rack equipped with rods and ends. Steering tips are installed in the fist and are the main connecting link between the steering wheel and the wheels of the car.

Steering knuckle, hub and CV joint axle shafts

The steering knuckle is the center of the front chassis, to which all other parts are connected. It does not have any moving parts in its design, except for the wheel bearing pressed into it.

This bearing ensures rotation of the hub with the wheel on. The rotational force of the hub is transmitted by an axle shaft with a CV joint mechanism at both ends.

The axle shaft is driven by a gearbox and is equipped with a CV joint, which makes it possible to turn the wheels of the car while driving.

/ Chassis vaz 21144 front suspension diagram.md

Chassis VAZ 21144 front suspension diagram - Design features of the chassis of the VAZ 2114

The design of the VAZ 2114 chassis - rear and front suspension Front suspension How is the VAZ 2114 chassis repaired? Review of the front suspension on the VAZ-2114: detailed repair diagram, individual elements and description Design of the front suspension of the VAZ 2114 VAZ-2114: front and rear suspension

The chassis of the car includes two suspensions - front and rear. During operation of the machine, most of the load falls on the chassis. The quality and comfort of the ride, as well as the safety of the driver and passengers, depend on the condition of the front and rear suspensions. The main function of each suspension is to eliminate vibrations and soften the ride. Also, the tasks of the chassis include reducing roll when turning, ensuring a smooth ride, and providing high information content for the driver in the city and on the highway. On the roads of the CIS countries, the chassis is subject to excessive load, since the condition of the road surface leaves much to be desired. As a result, motorists often turn to car service centers. Things are better with VAZ, since they have more modern systems compared to previous Lada models. Many motorists choose to solve the problem on their own. But in order to understand what has gone wrong, you need to know the suspension structure. The image below shows all the main elements of the rear suspension that can fail. The parts are fastened together by welding. The axles of the rear pair of wheels along with the brake elements are screwed to the flanges. Bushings are installed on the rear suspension arms at the front. One end of the spring rests on the support through a rubber gasket, and the other on the shock-absorbing cup. A complete disassembly of the rear suspension is required if the motorist decides to lubricate all the parts or change them. Most often you need to get to a specific element and replace it. The analysis proceeds as follows: Components of the VAZ rear pillar IMPORTANT. The shock-absorbing spring must be removed using special ties. If they are not used, serious injury may occur as the iron spring is under high pressure. It is attached to the steering knuckle with two bolts. Compared to the rear system, the front suspension has a more complex design, which can be understood by the number of parts. When the steering gear turns, the top bolt turns. The result is that the car turns. Most often, shock absorber struts fail, since they do the main job. Removing Springs Using Ties When removing the bolts that secure the ball joint to the steering knuckle, you must use a socket wrench. Otherwise, the protective cover of the hinge may be seriously damaged, resulting in additional costs. In the case of the front suspension, its assembly proceeds in the reverse order, with the exception of a few features. When installing the mounting bracket to the VAZ body, you need to make sure that the threads of the bushings are not damaged. To do this, you must perform operations carefully. Also, longitudinal displacement of the cushions on the bar must not be allowed. This can happen during installation of the anti-roll bar. A complete set of VAZ chassis elements. VAZ rear suspension diagram. The main parts of the rear suspension are highlighted in color. Components of the VAZ rear pillar Diagram and explanations for it. Removing springs using ties. Select the model VAZ OKA Kalina Granta Priora Niva Vesta Largus Year of manufacture Calculation of tire pressure by car make. Calculation of tire sizes by car make.

How it works and works

The front suspension of the VAZ 2112, inherited from the legendary 2108–2109, has not undergone any major changes, and decades of operation have shown that the capabilities of this system are more than enough for a car with an engine power of up to 150 hp. With..

MacPherson strut

The basis of the front suspension of these cars is a MacPherson strut, also known as the “Swinging Candle”. It consists of:

- shock absorber struts;

- springs;

- steering knuckle.

All parts are combined into one structure, which is held on top by a support bearing, which takes on the weight of the machine, and on the bottom by a lever with a ball joint, which ensures rotation of the rack around its axis. The eccentric bolts that secure the steering knuckle to the shock absorber strut determine the camber angle of the wheels; by turning the eccentric, this parameter is adjusted.

The entire structure rotates at two points - the ball joint and the support bearing, and the constant velocity joint (CV joint) shaft passes through the hole in the steering knuckle. This design of the front suspension of the VAZ 2109 solves the main problem of front-wheel drive cars - combining the normal operation of the spring and shock absorber with the ability to rotate the shaft that rotates the wheels.

Qualified chassis repairs

Before the invention of the “swinging spark plug,” the main type of front suspension was a design with two trailing arms, between which a steering knuckle was located on kingpins or ball joints.

The advantage of this scheme was its high reliability and efficiency, but it was extremely difficult to pass a shaft through it to turn the car into a front-wheel drive one; the levers often collided with it and could be bent. On SUVs with a driven front axle, a bridge was used with CV joints installed at the edges, while the spring or spring, as well as the shock absorber, were attached to the steel/cast iron body (stocking) of the bridge. This scheme showed itself well on army equipment, but due to its high metal consumption and high cost, it was not used even on the legendary Niva.

That is why the MacPherson strut was an ideal solution, because it protected the drive shaft, and also ensured that the fist rotated to the required angle, and its production was much cheaper than the production of other circuits.

Other elements

In addition to the MacPherson strut, the front suspension includes:

- levers;

- ball joints;

- guy wires with brackets;

- anti-roll bars;

- stabilizer bars;

- pillows;

- silent blocks.

The arm with the ball joint and spacer creates a triangle, the two sides of which (the back of the arm and the front of the support) are attached to the body using brackets. Silent blocks are installed in the rear and middle parts of the lever, that is, rubber or polyurethane bushings that ensure free rotation of the parts inserted into them. The back of the lever is inserted into the bracket and secured with a bolt, so the lever moves up and down freely, but does not leave its place.

The extension at the front is fixed with a bracket, which is bolted to the body, and at the back it is inserted into the hole in the middle part of the lever closest to the front edge through a silent block. This design allows you to adjust the castor, that is, the angle of inclination of the stand relative to the vertical axis.

A stabilizer bar is attached to the hole in the lever farthest from the ball joint, which is also equipped with a silent block. The edge of the stabilizer is inserted into the upper part of the rod, equipped with a silent block, and its middle is screwed to the body through shock-absorbing pads.

These elements work as follows: a ball joint connects the lever to the rack, due to which the latter takes on the weight of the machine and rotates freely around its axis. The resistance to up and down movement depends only on the stiffness of the strut, that is, the shock absorber-spring pair.

When both wheels rise or fall at the same time, only the MacPherson strut works, but if the height of the wheels is different, then the stabilizer experiences a torsional effect, and therefore acts as a torsion bar.

That is, the greater the difference in height between the wheels, the more the stabilizer twists, which increases its resistance to torque. Its rigidity is sufficient not only for a quiet ride, but also for cornering at high speeds, because the stronger the centrifugal force deflects the body, the stronger the stabilizer resists this, reducing the roll angle. This is how the front suspension of the VAZ 2115, as well as all other front-wheel drive cars from AvtoVAZ, works.

Rear suspension

The design of the rear suspension of the VAZ 2114 car, as well as other VAZ 2108–2115 cars and their descendants, is much simpler, although the general principle of operation is the same. Its basis is a beam, which performs several functions at once:

- connects wheels and springs with shock absorbers (struts);

- holds the wheels in a certain place, so that they do not catch on the wheel arches;

- reduces lateral roll during turns.

This part is made of relatively thin metal, compared to the anti-roll bar, but due to its shape with stiffening ribs, it turns into a torsion bar with not very high elasticity. When the rear wheels are simultaneously raised or lowered, the beam performs only the function of a lever, forming a triangle with the body and racks, in which:

- one vertex is a bracket with a silent block connecting the beam to the body;

- the second peak is a flange to which both the wheel hub axle and the lower part of the rear pillar are attached;

- the third vertex is the place where the upper part of the rack is attached to the body.

When the Lada drives over an obstacle, the wheel rises and compresses the strut spring, transferring the impact energy to the body through it. As the wheel rises, the spring resistance increases, so that even a sharp blow turns into a smooth rise, and the shock absorber resists any movement, but most strongly when the wheel is lowered. This prevents the wheel from accelerating too much and, having hit the ground, bouncing off it again.

Types of pendants

When driving through an obstacle, the length of one of the sides of the triangle and the angle between the other two sides change, and when the wheels rise to different heights, the rear beam twists. Due to its elasticity, bending resistance increases as the height difference increases, which reduces lateral roll in corners, but it is much less effective than a front-mounted stabilizer.

Disassembling and replacing the front suspension: instructions

- The VAZ 2114 is installed on a viewing hole or raised on a lift. The car must be set to the parking brake. It is necessary to remove the wheel caps, loosen the mounting bolts and unscrew the hub nut. Having secured the front of the car, you can remove the front wheels.

- Next, you need to remove the ball joint pin, which is located in the swing arm of the front strut. The next step is to remove the front stabilizer link (number “24”) from the front suspension arm (number “22”). Next, the stretch marks from the body (30) are removed. Next, you need to completely disconnect the ball joint that is attached to the steering knuckle.

- Now you can remove the front suspension arm. To do this, you need to disconnect it from the body bracket (28). Afterwards the lever is removed along with the bracket and the extension (29, 30). It is also necessary to remove the bolts that secure the pads to the steering knuckle.

- In front of the driver there will be a caliper assembly. To avoid problems with it, you do not need to completely remove it; you need to hang the caliper on a hook in such a way that there is no load on the main hose. The next step is to press the spline shank out of the front wheel hub.

- From the side of the engine compartment, you need to remove the protective fist (“41”). To do this, unscrew the telescopic strut nuts and then remove the solid front suspension strut. It should be together with the wheel hub and steering knuckle. The other front suspension strut is removed in the same way. Next, the racks are removed from the rod.

Features of replacing silent blocks of front levers

So, you have decided that replacing the silent blocks of the front control arms is inevitable. You shouldn’t immediately rush to the service station.

With proper preparation and the necessary tools, you can do the job perfectly on your own. The main thing is to act in the following sequence:

1. Prepare the necessary equipment and tools for work.

You will need:

- Set of socket and socket wrenches,

- special device for pressing,

- hammer,

- vice and chisel.

2. Buy the necessary replacement parts. Here you can choose two options: silent blocks “Balakovo” or “SEVI”.

3. Install the machine on an inspection hole or overpass. If your car has a crankcase protection, remove it.

4. Unscrew the nuts that secure the front arms. Next, using a “17” wrench, unscrew the nut from the bolt that secures the stabilizer to the lever.

Now all that remains is to get the bolt itself. It is unlikely that you will be able to do this by hand, so you can tap it with a hammer.

5. Remove the bolts on the front wheel, lift the desired side with a jack and move the wheel to the side.

6. Proceed to the next task - unscrewing the nuts of the guy wires. This task is one of the most difficult.

Here you can't do without a key with good leverage. In addition, before you start unscrewing it would be a good idea to treat the nut with WD-40 (this will greatly simplify the task).

7. After removing the nut, pull the ball joint and move it away from the steering cam. There are a couple more bolts there - unscrew them and remove the lever.

Attention! Point 8 applies to the VAZ 2109 and similar ones, on the VAZ 2110 there are no crabs, the extension is attached to the cross beam, it also has a silent block, as in the picture, if it is broken, it also needs to be replaced.

8. If you still cannot unscrew the extension nut, then dismantle the lever together with the “crab” and the extension – this will be much faster and easier (just slightly unscrew the nut near the “crab” and twist the three bolts that secure the “crab” to car body).

After this, you can continue to “struggle” with the extension nut, but in a more comfortable position.

9. Dismantle the silent blocks of the extension using a regular chisel and thoroughly clean the eyes from dirt.

10. Press in new silent blocks using a vice and hammer. As a rule, a few precise blows are enough for the knot to sit in place.

You can “put” the silent lock in place without a vice, but in this case you may need a sledgehammer. But remember that in this case there is a danger of damaging the node itself. So, it's better to use a vice to be sure.

11. Change the silent block on the front arm. The best option is if the old node is already broken. In this case, its extraction is not difficult.

All you need to do is take out the metal sleeve and use a screwdriver to remove the excess rubber. If this does not work, then press out the assembly.

12. Lubricate the new silent block thoroughly with soapy water (you can use dishwashing detergent) and put it in place.

During the pressing process, constantly monitor the edges of the silent block

If they start to curl up, carefully straighten them with a screwdriver.. 13. Put everything back in the reverse order.

Put everything back in reverse order.

13. Return everything to its place in reverse order.

That's all. Replacing silent blocks on a VAZ 2110 car is a job that you can easily handle on your own.

The only problem is the selection of a special tool for pressing out silent blocks.

But if you set yourself a goal and believe in success, then you will succeed. Good luck on the roads and of course no breakdowns.

Sources

- https://vaz-russia.ru/remont-vaz-2110/zamena-saylentblokov-perednih-ryichagov-na-vaz-2110-vaz-2112.html

- https://luxvaz.ru/vaz-2110/50-zamena-perednih-saylentblokov.html

- https://remontavtovaz.ru/vaz-2110/instrukciya-po-zamene-sajlentblokov-perednix-rychagov-na-vaz-2110.html

VAZ chassis repair

The working chassis of the VAZ is a soft ride and excellent handling of the car. To maintain the suspension in excellent condition, we recommend regularly inspecting it at a car service center, since it is in this case that specialists will be able to identify deviations from normal performance at an early stage and, as a result, eliminate the problem that has arisen.

The masters of the Exclusive technical center are experienced professionals in their field. They will be able to do a complete diagnosis and repair of the VAZ running gear. All work is carried out using high-precision equipment, and components are replaced using original spare parts.

About VAZ cars

The largest car manufacturer in Russia. The plant was built on the initiative of the Chairman of the Council of Ministers of the USSR Alexei Kosygin in the 1960s. . Equipment and technologies for it were purchased from the Italian concern Fiat. During the Soviet Union, its model range consisted of the following brands: Zhiguli, Niva, Oka, Sputnik, Samara. Today it produces various modifications of cars under the general name Lada, and also assembles Nissan and Renault cars, since these global brands have a controlling stake in VAZ.

Initially, VAZ cars were designed to saturate the domestic market of the USSR. They were affordable, reliable and easy to repair. At the present stage, these qualities have been supplemented by comfort and ease of operation, thanks to many additional options and modern functional equipment. At the same time, the price remained very affordable.

Types of work when repairing the chassis of a VAZ car

Repair of a VAZ chassis may include the following types of work:

- suspension overhaul

- VAZ beam replacement

- bridge replacement

- replacing axle shaft

- replacing VAZ springs

- replacing the support bearing

- replacing the strut support

- VAZ CV joint replacement

- spring repair

- subframe replacement

- cardan repair

Our car service center on Vasilyevsky Island repairs VAZ chassis of all the following models:

- Lada Kalina 1117/1118/1119

- Lada Samara 2113/2114/2115

- Lada Priora (Lada Priora 2170/2171/2172/21728)

- Lada Granta

- Lada Largus

- VAZ 2104

- VAZ 2105

- VAZ 2106

- VAZ 2107

- VAZ 2108

- VAZ 2109/21099

- VAZ 2110

- VAZ 2111

- VAZ 11113 Oka

- VAZ 2114

- VAZ 2115

When contacting the site, you will receive a 5% discount on your first visit to the service center.

Disassembling and replacing the rear suspension: instructions

A complete disassembly of the rear suspension is required if the motorist decides to lubricate all the parts or change them. Most often you need to get to a specific element and replace it. The parsing proceeds as follows:

- The VAZ 2114 is installed under an inspection hole, or, as an option, on a lift. In the luggage compartment, the rear and side trims and the seat belt retractor are disconnected. Also in the luggage compartment there are fastenings for the racks to the car body. They need to be loosened; there is no need to unscrew them completely.

- Next, the fastenings of the rear wheel pair are loosened. To do this, you need to remove the hubcaps and then completely dismantle the wheels. Reliable jacks should hold the car at this time; they are usually installed on each side.

- Now it is necessary to dismantle the brake system cables. You need to get them assembled. To do this, the cable fastenings to the suspension arms and the body of the VAZ 2114 are disconnected. Afterwards, the brake drums are dismantled. The cable ends should be removed from the manual drive levers. You also need to disconnect the flanges from the brake flaps.

- Before dismantling the hoses and pipes of the brake system, care must be taken to prevent leakage. Next, you need to dismantle the elastic drive lever, which is used to operate the brake pressure regulator. To remove the lever, you need to disconnect it from the bracket by removing the lock washer, then remove the shackle from the wheel axle.

- The next step is to disconnect the struts (shock absorbers). To do this, remove the rubber cushions, nuts attaching to the body part and the washer. After this, you need to install additional stops for the front wheelset. The rear part should be raised. After this, you can remove the compression stroke buffers, springs and shock absorber covers.

- If you disconnect the body mounting brackets, the entire beam can be detached. The rear suspension along with the struts will lie in front of the motorist. If necessary, you can disassemble the shock absorbers, which is no longer difficult.

How to change daisies on a VAZ 2114: watch the video, study the instructions

Are you planning to implement a solution to the question of how to change daisies on a VAZ 2114, you’ve already watched the video, now are you preparing a sequential instruction for yourself? Then you can pay attention to the following workflow structure

- The machine is installed on a lift or driven onto an overpass to provide access to the front suspension, the elements of which will be used for repair work. Usually, the approach to the silent block is also made difficult by the crankcase protection, which must first be dismantled.

- Next, work with fasteners is provided, but due to the fact that the car has mileage and has been used in different weather conditions, a situation may arise that all the nuts have soured, or the threads are covered with a layer of dirt. What to do? Take a rag or a wire brush with stiff bristles and clean all existing fasteners. If some nut does not give in, then you should use special lubricant WD 40. And start unscrewing the suspension nuts again.

- First, we unscrew the bolts on the wheels, put the car on a jack and stoppers, and then think about how to change the daisies on a VAZ 2114, having previously pressed them out.

- We continue to work with the support and its dismantling. Sometimes it can be difficult to remove the support from the steering knuckle.

- Using a chisel, we begin to press out the silent block itself. Sometimes even fire is used, but in this situation you need to be very careful.

- We thoroughly clean the freed bushing, and immerse the new silent block in water for several minutes and wash it several times with a soap solution. If you use a regular detergent, for example, for dishes, it’s okay, it will also help treat the new silent block. All that remains is to prepare for the climax, deciding confidently how to change the daisies on a VAZ 2114, and recording a video report if necessary.

- We install a vice - this is a good basis for pressing the chamomile. The process comes with a number of difficulties, because the part does not always quickly fit into its seat and force has to be used. A hammer will not hurt in this procedure. We make several precise and sharp blows, making the correct pressing of the part.

- We work carefully with the fasteners, which should be tightened gradually and consistently. We check the tightness of the nuts and make sure that the installation is correct.

- The rack is mounted in place and all final testing is done once the car is on its wheels.

Silent block “daisy” or replacing the tension joint

Thus, the question of how to change daisies on a VAZ 2114 is relevant, and its solution is in demand among car enthusiasts. But, as they say: “it was smooth on paper, but they forgot about the ravines...”. So with car repairs, you can count on half a day of fussing in the garage, but it turns out that even a day is not enough to solve the problem of how to change daisies on a VAZ 2114, unforeseen difficulties and financial expenses will arise.

Replacing silent blocks “daisies” or extension joints on a VAZ 2115,2114,2113,2199,2109,2108

What's included in the front suspension?

The front suspension of the VAZ-2114 consists of many elements, but many motorists have encountered repairing them individually, and not as a whole system. The front suspension assembly is replaced if the car is involved in a traffic accident and almost all of its elements are destroyed.

So, it’s worth considering what the car’s front suspension consists of, to see what elements are included.

Vehicle suspension device

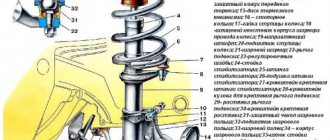

Design and decoding of VAZ-2114 suspension elements:

1 – upper support of the telescopic stand; 2 – upper support cup; 3 – compression stroke buffer with protective casing; 4 – compression buffer support; 5 – suspension spring; 6 – lower spring support cup; 7 – steering rod ball joint; 8 – steering knuckle; 9 – telescopic stand; 10 – eccentric washer; 11 – adjusting bolt; 12 – rack bracket; 13 – steering knuckle; 14 – front brake protective cover; 15 – brake disc; 16 – retaining ring; 17 – wheel hub nut; 18 – splined shank of the wheel drive hinge housing; 19 – guide pin; 20 – wheel hub bearing; 21 – ball joint; 22 – suspension arm; 23 – adjusting washers; 24 – stabilizer strut; 25 – stabilizer bar; 26 – stabilizer bar cushion; 27 – stabilizer bar mounting bracket; 28 – body bracket for mounting the suspension arm; 29 – suspension arm extension; 30 – bracket for fastening the extension; 31 – protective cover of the ball pin; 32 – ball pin bearing; 33 – ball pin; 34 – ball pin body; 35 – suspension strut rod; 36 – outer body of the upper support; 37 – inner body of the upper support; 38 – upper support bearing; 39 – rubber element of the upper support; 40 – travel limiter of the upper support; 41 – protective cap of the upper support; B - zone for monitoring the suspension joint.

Individual elements of the front suspension

Front suspension elements

Front suspension view from below

As can be seen from the figure above, the suspension is quite simple, but all elements are interconnected and for repair and replacement, it is often necessary to disconnect other parts. Therefore, we will consider the main elements of the front suspension separately, and also indicate the main purpose of the part.

Front shock absorber strut

Front shock absorbers

The front shock absorber or front suspension strut is one of the main elements. This part provides shock absorption and absorption of uneven road surfaces. Also, it bears all the force that is in the car, including the load.

Usually, if this element is frequently loaded or incorrectly replaced, it has an increased degree of wear. Therefore, all motorists need to know the structure and operating rules of the shock absorber strut.

Let's look at how the shock absorber strut is designed, as well as all the structural elements:

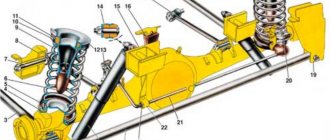

Diagram of the shock absorber strut structure

1 – compression valve body; 2 – compression valve discs; 3 – throttle disk of the compression valve; 4 – compression valve plate; 5 – compression valve spring; 6 – compression valve cage; 7 – recoil valve nut; 8 – recoil valve spring; 9 – recoil valve plate; 10 – recoil valve disc; 11 – throttle disk of the recoil valve; 12 – piston; 13 – bypass valve plate; 14 – bypass valve spring; 15 – plunger; 16 – plunger spring; 17 – rod guide bushing with a fluoroplastic layer; 18 – guide bushing cage; 19 – sealing ring of the rack housing; 20 – rod seal; 21 – oil seal cage; 22 – gasket of the rod protective ring; 23 – rod protective ring; 24 – nut of the strut body; 25 – compression buffer support; 26 – rod; 27 – spring cup; 28 – rotary lever; 29 – rod limit sleeve; 30 – rack body; 31 – cylinder; 32 – drain tube.

Front stabilizer

A stabilizer is a suspension element that provides lateral stability while driving, especially when turning . This part is the least likely to fail.

Detailed suspension repair diagram

In order to disassemble the suspension you will need quite a lot of tools: a set of keys and sockets, hammers, crowbars, pullers, and also screwdrivers.

So, let's look at a brief diagram of how to disassemble the suspension of a VAZ-2114 car:

- The car must be placed on a lift. Of course, you can use the inspection hole, but this is quite inconvenient and not entirely safe, since dismantling will be carried out on both sides at the same time.

- The first step is to dismantle the caps (if any), disks and loosen the wheel bearing fastenings.

- Next, disconnect the ball joint and also remove the steering rod.

- Unscrew the fastening and remove the stabilizer.

- The next step is to dismantle the lever.

- We remove the caliper.

- We remove the outer CV joint from the hub.

- Now you can remove the brake drum from the steering knuckle mountings.

- We dismantle the steering knuckle.

- Remove the shock absorber strut assembly.

- We disassemble the removed parts.

- Assembly is carried out in reverse order.

Thus, the entire suspension assembly can be replaced. If we take time, then complete disassembly of the VAZ-2114 suspension will take approximately 8-12 hours, if no difficulties arise. Some “kulibins” make it easier to speed up the process, and if the suspension to be removed will no longer be installed. It is worth noting that this method is dangerous and contrary to safety regulations, especially if the motorist has never performed this process. Let's briefly look at how the accelerated process occurs:

- Unscrew the stabilizer.

- We dismantle the upper mount of the shock absorber struts.

- Unscrew the steering rod and brake hoses.

- Carefully unscrew the lever mount.

- The suspension feeds downwards in the assembly.

Tuning

Tuning suspension for VAZ-2114

Many motorists, in order to improve the stability and maneuverability of the car, install a sports version of the suspension, both rear and front.

and “DVT-sport” offer a complete version of the front chassis assembly of the sports version. This kit is specially designed for the 2108-21099 and 2113-2115 car families.

It fits perfectly into the seats and is attached to the body without requiring any modifications. The sports suspension has greater stability and maneuverability, and can also withstand a load on the suspension that is 2 times greater than the standard one. The cost of this option is about 30-40 thousand rubles.

Tuning suspension installed on a car

How to replace the silent block of the rear beam of VAZ cars

Hello dear readers of the blog RtiIvaz.ru. Today I want to talk about the silent block of the rear beam - the ease of replacement on VAZ cars when doing DIY repairs.

Silent blocks and various suspension parts from the factory are quite reliable and last a long time. Typically, their longevity depends on how you operate and maintain the car and usually last for 80-90 thousand kilometers. Salentblock find out what it is here.

Let's first look at the signs of wear on the silent blocks of the rear beam. When cornering, the car loses stability and uneven tire wear occurs. Or, when driving over potholes and bumps on the road, impacts appear on the body and an unpleasant creaking sound occurs in the rear of the car.

Unpleasant sounds when driving can also occur due to other malfunctions. Knocks can come from one place and be heard in another, especially as they move along they are heard in the rear of the body. Therefore, first you need a thorough diagnosis of the entire rear and front suspension: you will have to check the struts, bearings, supports, muffler, etc.

Having finally made sure that the rubber silent blocks are extremely worn out, we proceed to replacing them. Fortunately, compared to foreign cars, replacing the silent block of the rear suspension of VAZ “nine” or “ten” cars is distinguished by its simplicity and low cost.

To begin with, let’s buy rubber bushings “fungi”, that is, silent blocks for the rear beam in a car store. For VAZ 2108 cars; 2109; 21099 you need to purchase silent blocks with the VAZ design number 2108-2914054-10, and for VAZ 2110 cars; 2112; 2114; 2115 VAZ design number 2110-2914054 is prescribed.

It is difficult to distinguish these silent blocks of these cars from each other, because they are very similar, but different in outer diameter (see the difference in the photo). You will not be able to install silent blocks from the “nine” VAZ 2109 on the beam of the “tens” VAZ 2110, as they will dangle. But the rubber bushing from the “ten”, if you try, can be pressed into the “nine” beam.

It will be useful: Do-it-yourself modification of the frets of the grant: video instructions

Step-by-step replacement of rear beam silent blocks on VAZ 2108 vehicles; 2109; 21099; 2110; 2112; 2114; 2115:

- 1. Replacement of silent blocks should be carried out on an overpass, inspection pit or lift, installing the machine in a way accessible to you.

- 2. Remove the rear wheel so that it does not interfere.

- 3. On the left side, disconnect the rear brake pressure regulator rod from the beam (see photo number 1.) On the right side, remove the handbrake cable to the side (see photo number 2.)

- 4. Using a “19” wrench, unscrew the nut from the bolt securing the rear beam to the bracket (see number 3 in the photo)

- 5. We remove the fastening bolt with a hammer, and then knock it out with a wrench (see number 4 in the photo.)

- 6. Next, lift the car body with a jack and move the beam eye down

- 7. We insert a wooden block between the body and the beam

- 8. Using a hammer and a drift, knock out the rubber bushings of the rear beam

- 9. Having cleaned the seat from dirt and rust, generously lubricate it with a thick soap solution and also lubricate the rubber bushing itself

- 10. Using a tool, press in the bushing. If there is no device, then we hammer it in with a hammer, hitting the head of any suitable bolt inserted with a washer of larger diameter, but so that the washer fits tightly to the rubber

- 11. Then we pull out the wooden block

- 12. Using a jack, we lift the beam and put on our original fastening bolt, then we attach the nut

- 13. Having placed the rear wheel, lower the car

- 14. Open the trunk door, then sit down on the bumper and press the back of the car as far as possible with all our weight.

- 15. Tighten the silent block mounting bolts until they stop

Actually, the work itself doesn’t seem to be difficult if you have a puller. And if it is not there, what should you do then? Therefore, I am writing for those who repair a VAZ car with their own hands. There is no need to complicate the task if you don’t have a special remover. Listen to the advice of car mechanics: do not fool your head and knock out - hammer in the silent blocks on the beams with a hammer.

Design number of the rear suspension arm mounting hinge: VAZ 2110-2914054

Design number of the rear suspension arm hinge: VAZ 2108-2914054-10

Design number of the rear suspension arm hinge: VAZ 1111-2914054

Video:

conclusions

The installation and repair of the front suspension of the VAZ-2114 is quite difficult and not every motorist can do it. This article examined the design and repair of the front suspension.

As you can see, there is a main group of parts that change when worn out and broken, and there are also a number of parts that are considered consumables and are replaced when the main components are repaired.

It is worth noting that suspension repair has a significant degree of danger, because the fall of one of the elements can lead to injury and even death. Therefore, when performing repair operations you must be extremely careful. Also, many suspension elements are quite heavy, so you need to have an assistant on hand.

Source