Purpose of the VAZ 2107 suspension

The suspension of the VAZ Seven, like any other car, is necessary for safe and comfortable movement. Its design may seem complicated at first glance, but in reality it is not. The front and rear suspensions are a set of elements whose purpose is to provide an elastic connection between the wheels and the chassis of the car. The main function of the suspension is to reduce shock, vibration and jolts that occur when driving over uneven surfaces, which is inherent in roads with poor quality surfaces. It is worth dwelling on malfunctions, repairs and modernization of the rear suspension in more detail.

Front suspension

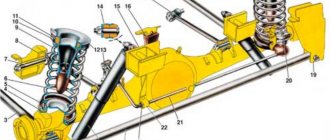

The VAZ 2107 has a double-wishbone independent suspension with an upper and lower wishbone at the front. The first of them is fixed through the mudguard strut, the second - to the front beam connected to the power elements of the body. The upper and lower arms are secured to each other by means of a steering knuckle and ball joints. To rotate the levers, the suspension design includes silent blocks made of rubber and a metal bushing. The softness and smoothness of the suspension is determined by elements such as springs and shock absorbers, and the stability of the car on the road is determined by the anti-roll bar.

The front suspension of the VAZ 2107 bears greater loads than the rear, so its design is made independent

Rear suspension

The rear of the car takes up less load than the front, so the suspension has a simpler design - dependent. The wheels of the rear axle of the “seven” have a rigid connection with each other. Such a system today, although outdated, still has positive aspects - high reliability and ease of maintenance.

Product added to bookmarks!

- Description

- Reviews

Rear independent suspension "AUTOPRODUCT" for VAZ 2108, 2109, 21099, VAZ 2110, 2111, 2112, VAZ 2113, 2114, 2115, VAZ 2170, 2171, 2172 (Lada-Priora).

– loss of contact of the rear inner wheel with the road on turns is eliminated;

– stable contact with different road surfaces and clear control of the vehicle during maneuvers;

– low unsprung mass;

– increased driving comfort.

Original silent blocks "LEMFORDER"

.

Installed on cars with suspension lowered up to -50 mm or with suspension raised up to +15 mm.

Installation is possible only with modification of the muffler bend or with the AUTOPRODUCT direct-flow muffler.

For installation you will need:

– brake pipe, length from 350 mm – 2 pcs.

– corrugated tube with a slit, internal diameter 12 mm or 14 mm, length 210 mm – 2 pcs.

– nylon clamp 5 x 350 mm – 2 pcs.

Rear suspension - description

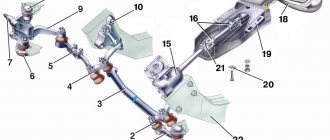

The rear suspension of the VAZ 2107 is practically no different from the mechanism of other classic Zhiguli cars. The dependent design is simple, but has some features. Its main structural elements are:

- springs;

- telescopic shock absorbers;

- rods;

- beam.

Design of the rear suspension of the VAZ 2107: 1. Lower longitudinal rod; 2. Lower insulating gasket of the suspension spring; 3. Lower support cup of the suspension spring; 4. Compression stroke buffer; 5. Bolt for fastening the upper longitudinal rod; 6. Bracket for fastening the upper longitudinal rod; 7. Suspension spring; 8. Compression stroke buffer support; 9. Upper spring gasket ring; 10. Upper spring insulating gasket; 11. Upper support cup of the suspension spring; 12. Pressure regulator drive lever support; 13. Rubber bushing for the pressure regulator drive lever; 14. Shock absorber mounting stud washer; 15. Rubber bushings for shock absorber eye; 16. Rear shock absorber mounting bracket; 17. Additional compression progress buffer; 18. Spacer washer; 19. Spacer sleeve of the lower longitudinal rod; 20. Rubber bushing of the lower longitudinal rod; 21. Bracket for fastening the lower longitudinal rod; 22. Bracket for fastening the upper longitudinal rod to the bridge beam; 23. Spacer sleeve for transverse and longitudinal rods; 24. Rubber bushing for the upper longitudinal and transverse rods; 25. Rear shock absorber; 26. Bracket for attaching the transverse rod to the body; 27. Brake pressure regulator; 28. Protective cover for pressure regulator; 29. Pressure regulator drive lever axis; 30. Pressure regulator mounting bolts; 31. Pressure regulator drive lever; 32. Clip of the lever support sleeve; 33. Support sleeve; 34. Cross rod; 35. Cross bar mounting bracket support plate

Rear beam

The main structural element of the rear suspension is a beam (stocking) or rear axle, through which the rear wheels are connected to each other. With the help of this unit, not only the suspension elements are fixed, but also the rear axle structure - the gearbox and axle shafts - is assembled together.

The main element of the rear suspension is the stocking

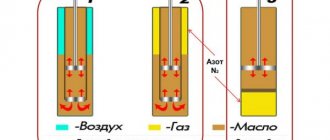

Shock absorbers

The main function performed by suspension shock absorbers is vibration damping, i.e., preventing the car from rocking when driving over uneven surfaces. The presence of such an element and its proper operation directly affects the predictability of the car’s behavior, as well as the comfort of movement and extending the service life of other suspension elements. The upper part of the shock absorber is attached to the power element of the body, and the lower part is attached to the rear axle beam through a bracket and rubber bushings.

Shock absorbers act as elements that dampen vibrations

Springs

Another integral element of both rear and front suspension is the spring. In addition to shock absorbers, it also provides a comfortable ride. In addition, the element prevents the vehicle from tipping over when making sharp turns. By design, the spring is made of a steel rod twisted into a spiral. From below, the part is installed in a special bowl of the rear beam through a rubber gasket that prevents squeaks. The spring element on top also rests against the bowl on the body through the gasket.

The spring, in addition to shock absorbers, is responsible for comfortable movement in the car.

Jet thrusts

The rear axle stocking is fixed to the body of the “seven” using reaction rods. The latter are present in the amount of five pieces - four longitudinal and one transverse (Panhard rod). Longitudinal rods prevent and prevent the bridge from moving back and forth, and transverse rods prevent movement when lateral loads appear. The rods are connected to the rear axle beam through rubber bushings.

Reaction rods of the rear axle keep it from longitudinal and lateral displacements

Bumpers

The rear suspension compression buffers are made of rubber, are inserted into the body holes provided for them and are located inside the springs. An additional bumper is installed above the rear beam and secured to the bottom of the car. The purpose of the buffers is to prevent hard impacts when driving on bad roads when the suspension is fully compressed.

Rear suspension bumpers prevent breakdown during heavy sagging

Replacing a broken spring

To replace the spring (which also cannot be repaired), you need to remove the shock absorber and disconnect it from the roll bar.

After this, you need to loosen the screws of the lower arm, after that it is jacked up, then using a special puller we remove the ball pin. Now you can slowly release the jack, as a result of which the spring weakens and is easily removed from the cup.

Attention! A new spring can be placed in the support bowl only by first tightening it with a special tie. After this, the lower arm is pressed in the same way, then its ball joint enters the steering knuckle

Then you can release the spring from the tie. Shown is a diagram of spring compression using a tie

After this, the lower arm is pressed in the same way, then its ball joint fits into the steering knuckle. Then you can release the spring from the tie. A diagram of spring compression using a tie is shown.

In conclusion, it must be said that a novice motorist is quite capable of monitoring the serviceability of the suspension, the main thing is that he has an overpass or a pit at his disposal.

Malfunctions of the rear suspension of the VAZ 2107

Rear suspension elements do not fail as often as the front ones, but sometimes they also have to be replaced, since even the most reliable parts wear out over time. The breakdown or damage of a particular product is indicated by characteristic signs that allow you to correctly identify the problem and quickly repair the suspension.

Knocks

Knocks in the rear suspension can be of different types and the reasons for their occurrence are also different:

- knocking sound when starting. The malfunction occurs when one of the rear axle reaction rods or the brackets that hold them break. To solve the problem, it is necessary to inspect the suspension, identify the damaged rod and replace it;

- knocking noises while driving. Broken silent blocks of jet rods can knock. Over time, the metal bushing simply begins to dangle in the rubber, and the bridge “walks,” which leads to the appearance of extraneous sounds. The malfunction is treated by replacing the rubber bushings of the rear axle rods;

- knocking noise when the suspension is compressed too hard. This happens when the bump stop is damaged, causing the suspension to “break through.” Therefore, it is necessary to inspect the buffer elements and replace the failed ones.

Video: knocking noises on a Zhiguli when starting off

"Breakthroughs" of the suspension

Such a concept as “breakdown” occurs when the suspension does not cope with its function. There may be several reasons for this:

- rear axle overload. The suspension can often “punch” due to an overloaded rear axle, for example, if the car is heavily loaded. In this case, you need to unload the rear axle;

- breakage or settling of the spring. Despite the fact that the springs are made of durable steel, they still sag over time, especially with frequent transportation of goods. The way out of the situation is to install new or stiffer springs;

- failure of shock absorbers. If the shock absorbers are unable to dampen vibrations, then full operation of the suspension is impossible. The shock-absorbing elements will need to be replaced.

The car is pulled to the side

Sometimes with the suspension of the VAZ “Seven” there are such nuances when the car pulls to the side. Let's list the reasons why this can happen:

- spring breakage or settling. Due to a damaged spring, the car will stand unevenly on the road, which may cause it to move to one side. The spring will need to be replaced;

Damage to the spring may cause the vehicle to pull to one side. - displacement of the rear axle due to wear of the silent blocks of the reaction rods. The appearance of free play in the suspension elements leads to unstable behavior of the car on the road, which indicates the need to replace rubber-metal components.

There can be many more reasons why a car pulls to the side. In addition, a malfunction is possible not only in the suspension, but also in other components, for example, with a flat tire.

Other sounds

Extraneous noises and sounds can come not only from faulty suspension elements, but also from the chassis, which is not always easy to determine with insufficient experience. While driving, a hum from the rear axle gearbox itself may be heard from the rear of the car, which requires adjustment or replacement. In addition to the gearbox, the axle bearings may hum as a result of wear or a small amount of lubricant. When the springs sag, the wheels may touch the plastic wheel arch liners when cornering, if they are installed. They can also simply loosen the wheel bolts if they are loosely tightened, which will lead to extraneous noise. Therefore, each specific case needs to be dealt with separately, where and at what moment this or that sound comes from. Only in this case will it be possible to more accurately diagnose the malfunction.

Rework to strengthen the chassis

The car after a test drive. is it worth buying or not? briefly and honestly

It is also important to treat the studs that are located on the lower arm from corrosive wear. Before tightening the nuts, they must be pre-lubricated. Plastic can be fused onto the tips of the studs. To do this, you can take any plastic thing, cut off a piece, lean it against the tip of a hairpin and melt it.

Additionally, the stabilizer brackets can be strengthened. To do this, it is recommended to weld special steel corners onto them. Then carry out anti-corrosion treatment.

High-quality tuning for the VAZ-2107 chassis makes the car more reliable and easy to use.

The desire for tuning begins with discomfort, when everything is as it should be, but something is still wrong. And the rest of the actions depend on the driver himself - some are completely satisfied with instrument clusters with original scale designs, while others will want to modernize almost every element of the vehicle.

Due to the great demand for tuning of certain elements, stores were simply overflowing with a variety of accessories, auto repair shops had to recruit specialists in tuning of varying complexity, and thematic publications appeared on the shelves of kiosks.

Our article will not be replete with giant pictures, since the focus is on information, not images.

Checking the rear suspension

To check the condition of the rear suspension of the VAZ “Seven”, the only tools you will need are a mounting blade, and the car itself will need to be installed in an inspection hole. Diagnostics consists of the following steps:

- We check the tightness of the fasteners of all elements of the rear suspension, and if loose connections are found, tighten them.

- We diagnose shock absorbers by alternately rocking the rear of the car by the wings or bumper on the left and right sides. After the applied effort, the body should return to its initial position, making just one upward movement. If one of the shock absorbers has lost its properties or traces of fluid leakage have been noticed on the element, both must be replaced. The shock absorber fastenings must be free of play, and the bushings must not show signs of cracking.

To check the rear shock absorbers, rock the car by the rear fenders or bumper. - We inspect the springs. If a sagging part is detected or cracks are detected, both springs must be replaced.

- We check the rear axle rods for damage (cracks, curvature, etc.). To check the condition of the silent blocks of the reaction rods, we insert a pry bar between the bracket and the eye of the rod, trying to move the rod itself. If this can be done, the rubber-metal hinges need to be replaced.

It is quite easy to check the condition of the reaction rods using a mounting spatula.

Selecting New Items

Polyurethane To replace and ensure reliable operation of the car, you need to purchase good silent blocks. Choosing them is not difficult if you know some nuances:

- For the VAZ 2110 model, elements with catalog number 2110 2914054 are suitable. They have the required outer diameter corresponding to this specific VAZ model;

- Do not try to purchase a silent block from a “nine” and install it on your “ten”. Nothing will come of such events, no matter what anyone says;

- Make sure of the quality of the products. Low-grade silent blocks have flooded the market, but their service life leaves much to be desired. Good parts are made from high quality materials that can withstand extreme loads and temperatures.

Garage or service station

All car owners can be divided into two categories:

- Those who carry out most of the repairs themselves in their garage, and only in emergency cases turn to a car service;

- Those who prefer not to touch anything with their own hands, but completely entrust repairs and maintenance to the masters of service stations.

Each of them is right in their own way. Therefore, we have no right to reproach those who do not want to carry out repairs themselves. After all, garage and professional repair of silent blocks, like other components, has its advantages.

STO has the following advantages:

- A high-quality, responsible car service provides a guarantee for repairs performed;

- In the event of a repeated breakdown covered by the warranty, repairs will be carried out free of charge;

- Professionals are professionals; they have extensive experience and knowledge, which allows them to competently perform their work.