IA Neftegaz.RU.

Liquefied Natural Gas (LNG) is natural gas artificially liquefied by cooling to -160°C for ease of storage and transportation. LNG is a colorless, odorless liquid whose density is 2 times less than the density of water. 75-99% consists of methane. Boiling point − 158…−163°C. In a liquid state, it is non-flammable, non-toxic, and non-aggressive. For use, it is evaporated to its original state. When vapors burn, carbon dioxide (carbon dioxide, CO2) and water vapor are formed. In industry, gas is liquefied both for use as a final product and for use in combination with low-temperature fractionation processes of APG and natural gases, which make it possible to separate gas gasoline, butanes, propane and ethane, and helium from these gases. LNG is produced from natural gas by compression followed by cooling. When liquefied, natural gas decreases in volume by approximately 600 times.

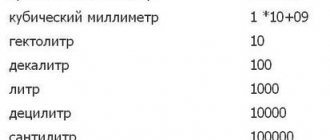

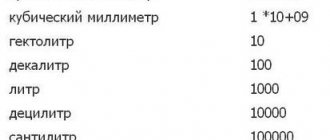

How to convert liters of liquefied gas to cubic meters?

To convert liters of gas to cubic meters, divide the number of liters by 1000. To convert cubic meters of gas to liters, use the opposite rule: multiply the number of cubic meters of gas by 1000.

Interesting materials:

How to clean your iron from plaque? How to clean an iron with a steam generator from scale? How to clean a Tefal iron from scale? How to clean a Tefal iron? How to clean an iron at home? How to clean your iron? How to clean a bathtub covered with acrylic? How to clean a bathtub covered with liquid acrylic? How to clean a refurbished bathtub? How to clean a bathtub with an acrylic coating?

LNG plant equipment

- gas pre-treatment and liquefaction plant,

- LNG production lines,

- storage tanks, including special cryocankers, designed according to the principle of a Dewar flask,

- for loading onto tankers - gas carriers,

- to provide the plant with electricity and water for cooling.

There is a technology that allows saving up to 50% of energy on liquefaction, using the energy lost at gas distribution stations (GDS) when throttling natural gas from the main pipeline pressure (4-6 MPa) to consumer pressure (0.3-1.2 MPa) :

- Both the actual potential energy of the compressed gas and the natural cooling of the gas when the pressure decreases are used.

- additionally, the energy required to heat the gas before supplying it to the consumer is saved.

Pure LNG does not burn, is not flammable and does not explode on its own.

In an open space at normal temperatures, LNG returns to a gaseous state and quickly dissolves in the air. When evaporating, natural gas can ignite if it comes into contact with a flame source. For ignition, it is necessary to have a concentration of vapors in the air from 5% to 15%. If the concentration is up to 5%, then the vapors are not enough to start a fire, and if it is more than 15%, then there is too little oxygen in the environment. To be used, LNG undergoes regasification - evaporation without the presence of air. LNG is an important source of energy resources for many countries, including Japan, France, Belgium, Spain, and South Korea. LNG transportation

is a process that includes several stages:

- sea passage of a tanker - gas carrier,

- auto delivery using special vehicles,

- railway delivery using tank cars,

- regasification of LNG to a gaseous state.

Regasified LNG is transported to end consumers via gas pipelines.

What load can the container withstand?

Standard cylinders can withstand pressures up to 19.6 MPa. In this case, the wall thickness can reach up to 8.9 mm. However, not a single gas distribution or consuming device can withstand such a powerful pressure.

The standard pressure in a 50-liter container is always 1.6 MPa. This pressure indicator is optimal for the operation of all household gearboxes to which stoves, heaters, ovens and boilers are connected.

If you follow simple operating rules, which include vertical storage, installation of vessels in an iron box standing on the north side, as well as distance from wells, windows, doors and the presence of gearboxes, then gas cylinders do not pose any danger to others

Manufacturers of standard containers focus on a pressure of 2.5 MPa, because the vessel must withstand it during inspection, once every five years. If the seams do not hold up, the flask is immediately scrapped.

The locking unit must also withstand a pressure of 2.5 MPa. Although its device allows you to control pressure up to 19.6 units. Cylinders are subjected to this test in exceptional cases; they are usually filled with gas with a pressure of 1.6 MPa.

Steel gas cylinder design

For transportation and storage of light hydrocarbons such as propane, propane-butane or butane, composite cylinders with a capacity of up to 47 liters can be used.

However, more capacious, 50 liter vessels for liquefied hydrocarbons are made of steel. To store other liquefied or compressed gases, only steel tanks of various capacities are used.

GOST 15860 describes in detail the types, characteristics and permissible sizes of gas cylinders for hydrocarbons. GOST 949-73 specifies the parameters of gas tanks suitable for operation, with internal pressure up to 19.6 MPa.

The wall thickness is dictated by GOST standards regulating the design of cylinders. The blanks for steel 50 liter cylinders are seamless pipes made of steel grades: 45, 34CrMo4, 30ХМА and 30ХГСА

Both GOSTs indicate that for safe transportation and storage of gases, each vessel must have the following structural elements:

- Support shoe.

- A body consisting of a shell, lower and upper bottom and a backing ring.

- Information plate.

- Neck.

- Valve or tap.

Modifications are allowed that include a collar, handle/handles and a cap.

In addition to the basic standards for the manufacture of gas cylinders, there are additional standards that manufacturers must comply with.

Supporting documentation includes safety rules: PB 03-576-03 “Rules for the design and safe use of pressure vessels.” They describe in detail the requirements for valves and other auxiliary mechanisms.

Calculation of acetylene in cylinders

The parameters and dimensions of acetylene cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters. The body of an acetylene cylinder differs from the body of an oxygen cylinder in its smaller size.

At a pressure of 1.0 MPa and a temperature of 20 °C, a 40-liter cylinder holds 5–5.8 kg of acetylene by mass (4.6–5.3 m3 of gas at a temperature of 20 °C and 760 mm Hg).

The approximate amount of acetylene in the cylinder (determined by weighing) can be determined by the formula:

Va = 0.07 • E • (P – 0.1)

0.07 – coefficient, which takes into account the amount of acetone in the cylinder and the solubility of acetylene.

E – water volume of the cylinder in cubic dm;

P – pressure in the cylinder, MPa (pressure 1.9 MPa (19.0 kgf/cm2) at 20 °C according to GOST 5457-75 “Dissolved and gaseous technical acetylene”);

0.1 – atmospheric pressure in MPa;

Weight of 1 m3 of acetylene at a temperature of 0°C and 760 mmHg. is 1.17 kg.

Weight of 1 cubic meter of acetylene at a temperature of 20°C and 760 mmHg. is 1.09 kg.

Let's calculate the volume of acetylene in a 40 liter cylinder with a working pressure of 1.9 MPa (19 kgf/cm2) at a temperature of 20°C:

Va = 0.07 • 40 • (1.9 – 0.1) = 5.04 m3

Weight of acetylene in a 40 liter cylinder with a working pressure of 1.9 MPa (19 kgf/cm2) at a temperature of 20°C:

5.04 • 1.09 = 5.5kg

Conclusion (for the case under consideration): 1 cylinder = 40l = 5.5kg = 5.04m3

This gas is available from us: acetylene (C2H2)

Gas Density Table

Table of densities of liquefied propane-butane mixture (in t/m³) depending on its composition and temperature

| Propane/Butane ratio T, °C | −25 | −20 | −15 | −10 | −5 | 0 | 5 | 10 | 15 | 20 | 25 |

| 100/0 | 0,559 | 0,553 | 0,548 | 0,542 | 0,535 | 0,528 | 0,521 | 0,514 | 0,507 | 0,499 | 0,490 |

| 90/10 | 0,565 | 0,559 | 0,554 | 0,548 | 0,542 | 0,535 | 0,528 | 0,521 | 0,514 | 0,506 | 0,498 |

| 80/20 | 0,571 | 0,565 | 0,561 | 0,555 | 0,548 | 0,541 | 0,535 | 0,528 | 0,521 | 0,514 | 0,505 |

| 70/30 | 0,577 | 0,572 | 0,567 | 0,561 | 0,555 | 0,548 | 0,542 | 0,535 | 0,529 | 0,521 | 0,513 |

| 60/40 | 0,583 | 0,577 | 0,572 | 0,567 | 0,561 | 0,555 | 0,549 | 0,542 | 0,536 | 0,529 | 0,521 |

| 50/50 | 0,589 | 0,584 | 0,579 | 0,574 | 0,568 | 0,564 | 0,556 | 0,549 | 0,543 | 0,536 | 0,529 |

| 40/60 | 0,595 | 0,590 | 0,586 | 0,579 | 0,575 | 0,568 | 0,562 | 0,555 | 0,550 | 0,543 | 0,536 |

| 30/70 | 0,601 | 0,596 | 0,592 | 0,586 | 0,581 | 0,575 | 0,569 | 0,562 | 0,557 | 0,551 | 0,544 |

| 20/80 | 0,607 | 0,603 | 0,598 | 0,592 | 0,588 | 0,582 | 0,576 | 0,569 | 0,565 | 0,558 | 0,552 |

| 10/90 | 0,613 | 0,609 | 0,605 | 0,599 | 0,594 | 0,588 | 0,583 | 0,576 | 0,572 | 0,566 | 0,559 |

| 0/100 | 0,619 | 0,615 | 0,611 | 0,605 | 0,601 | 0,595 | 0,590 | 0,583 | 0,579 | 0,573 | 0,567 |

Distinctive features of liquefied gases:

- high vapor pressure;

- have no smell. To detect leaks in a timely manner, liquefied gases are given a specific odor - odorized with ethylmer-captan (C2H5SH);

- low temperatures and flammability limits. The ignition temperature of butane is 430°C, propane is 504°C. The lower flammability limit of propane is 2.3%, butane is 1.9%;

- propane, butane and their mixtures are heavier than air. In the event of a leak, liquefied gas can accumulate in wells or basements. It is prohibited to install equipment operating on liquefied gas in basement-type premises;

- transition to the liquid phase with increasing pressure or decreasing temperature;

- high calorific value. To burn LPG, a large amount of air is required (to burn 1 m³ of the gas phase of propane, 24 m³ of air is required, and butane - 31 m³ of air);

- large coefficient of volumetric expansion of the liquid phase (the coefficient of volumetric expansion of the liquid phase of propane is 16 times greater than that of water). Cylinders and tanks are filled to no more than 85% of their geometric volume. Filling more than 85% can lead to their rupture, subsequent rapid flow and evaporation of gas, as well as ignition of the mixture with air;

- as a result of evaporation of 1 kg of liquid phase of LPG at n. u. 450 liters of vapor phase is obtained. In other words, 1 m³ of the vapor phase of a propane-butane mixture has a mass of 2.2 kg;

- When 1 kg of propane-butane mixture is burned, about 11.5 kWh of thermal energy is released;

- liquefied gas evaporates intensely and, when it comes into contact with human skin, causes frostbite.

Example:

The density of a propane-butane mixture of 60% propane, 40% butane at an ambient temperature of -20°C will be 0.577 t/m3 or 577 kg/m3

striker_truda

Notes of a Traveling Locksmith – Malaga Truth

How much gas is in the cylinder

Oxygen, argon, helium, welding mixtures: 40 liter cylinder at 150 atm - 6 cubic mAcetylene: 40 liter cylinder at 19 atm - 4.5 cubic mCarbon dioxide: 40 liter cylinder - 24 kg - 12 cubic mPropane: 50 liter cylinder – 42 liters of liquid gas – 21 kg – 10 cubic meters.

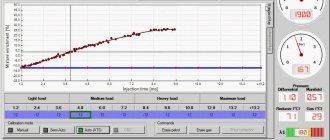

Oxygen pressure in the cylinder depending on temperature

-40С – 105 atm-20С – 120 atm0С – 135 atm+20С – 150 atm (nominal)+40С – 165 atm

Welding wire Sv-08 and its derivatives, weight 1 kilometer along the length

0.6 – 2.222 kg0.8 – 3.950 kg1.0 – 6.173 kg1.2 – 8.888 kg

Calorific value (calorific value) of liquefied and natural gas

Natural gas – 8500 kcal/m3 Liquefied gas – 21800 kcal/m3

Examples of using the above data

Question: How long will gas and wire last when welding semi-automatically with a cassette of 0.8 mm wire weighing 5 kg and a cylinder of carbon dioxide with a volume of 10 liters? Answer: Welding wire SV-08 with a diameter of 0.8 mm weighs 3.950 kg 1 kilometer, which means on the cassette 5 kg approximately 1200 meters of wire. If the average feed speed for such wire is 4 meters per minute, then the cassette will go in 300 minutes. Carbon dioxide in a “large” 40-liter cylinder is 12 cubic meters or 12,000 liters; if you convert it to a “small” 10-liter cylinder, then it will contain 3 cubic meters of carbon dioxide. meters or 3000 liters. If the gas consumption for purging is 10 liters per minute, then a 10-liter cylinder should be enough for 300 minutes or for 1 cassette of 0.8 wire weighing 5 kg, or a “large” cylinder of 40 liters for 4 cassettes of 5 kg each.

Question: I want to install a gas boiler at my dacha and use cylinders for heating, how long will one cylinder last? Answer: A 50-liter “large” propane cylinder contains 21 kg of liquefied gas or 10 cubic meters of gas in gaseous form. We find the boiler data, for example, take the very common AOGV-11.6 boiler with a power of 11.6 kW and designed for heating 110 square meters. meters. The ZhMZ website indicates the consumption in kilograms per hour for liquefied gas - 0.86 kg per hour when operating at full capacity. We divide 21 kg of gas in a cylinder by 0.86 kg/hour = 18 hours of continuous burning of such a boiler on 1 cylinder. In reality, this will happen if it is -30C outside with a standard house and the usual requirements for the air temperature in it, and if outside If it is only -20C, then 1 cylinder will last for 24 hours (day). We can conclude that in order to heat an ordinary house of 110 square meters. meters of bottled gas in the cold months of the year you need about 30 cylinders per month. It must be remembered that due to the different calorific value of liquefied and natural gas, the consumption of liquefied and natural gas at the same power for boilers is different. To switch from one type of gas to another, boilers usually need to change jets/nozzles. When making calculations, be sure to take this into account and take the flow data specifically for a boiler with jets for the correct gas.

Gas cylinder color

Rules PB 03-576-03 state that the outer surface of vessels intended for transporting gases must be painted in the appropriate color. It depends on the type of gas that will be filled.

Red cylinders are provided for butane and other flammable gases. Moreover, for some gases not only a color is provided, but also a corresponding color stripe.

Inscriptions and stripes are applied with durable paints and if they are erased during use, then re-application occurs at filling stations or testing points. That's why gas cylinders always give away their contents.

In addition, the standards establish an identifying inscription that should be applied to the vessel. The word “Butane” must be printed on the butane cylinder, and “Propane” on the propane cylinder. The text color of the inscription on a vessel with hydrocarbon gas is white. Read more about the types of gas cylinders below.

How much does a propane tank weigh?

The volume of the cylinder is at least 50 liters, the permissible mass capacity of liquefied propane gas is no more than 21 kg. The mass of an empty cylinder without taking into account the mass of the locking device, cap and protective rings is up to 22 kg (+- 2.2). How much does an empty 50 liter gas cylinder weigh? 22 kg.

Interesting materials:

In what case does the customer have the right to extend the period for consideration and evaluation of applications for participation in the competition and for how long? In which corner should the pages be numbered? At what age do Indian ducks sit on eggs? At what age is a Rabbit considered an adult? At what age can the sex of geese be determined? At what age can roosters be slaughtered? At what age do you start milking a cow? At what age do women experience a midlife crisis? At what age do people go to high school in Japan? At what age do police officers in the USA retire?

Physical meaning of translation

In a physical sense, everything is quite simple. The translation is carried out in the same way for any gases, liquids or bulk materials as follows:

- 1 cubic meter contains 1000 liters,

- 1 liter equals 0.001 cubic meters

- the table shows the quantity contained in 1 cube (1 cube = 1000 cubic decimeters, etc.).

For example, 15 cubic meters of natural gas used by the meter equals 15,000 liters. When converting these values, the temperature of the fuel, the amount of impurities and other factors do not matter.

Basics of the physical meaning of transformation

The physical meaning of the transformation is not a big problem. In this case, the conversion method for any gas is similar to that for liquids and bulk materials. The calculation is made according to the following method:

1 m³ = 1,000 liters

Accordingly, 1 liter contains 0.001 cubic meters. If the meter shows that natural gas was consumed in the amount of 0.3 m³ during the day, then in liters this value will be 0.3 x 1000 = 300.

Find the side of a cube if its weight is 1 ton and the density of the cube = 6000 kg in cubic meters.

We have prepared a simplified model of the age-sex pyramid, which presents only three age groups, the data about which was given above:. Note: The scale of the pyramid differs from the absolute values given above because each age group contains a different number of years.

As we can see, the Cuban age pyramid has a regressive or decreasing type. This type of pyramid is usually found in highly developed countries. Such countries usually have a fairly high level of healthcare, as well as the level of education of citizens. Due to relatively low mortality and birth rates, the population has a high life expectancy.

In this article: How to find out the values of variables How to calculate density 6 Sources. The density of a body is the ratio of mass to volume. The density value can be used in geology, physics and other natural sciences. This article was produced by our experienced team of editors and researchers, who reviewed it for accuracy and comprehensiveness.

Calculation of oxygen in cylinders

The parameters and dimensions of oxygen cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters.

According to GOST 5583-78 “Gaseous technical and medical oxygen” (Appendix 2), the volume of gaseous oxygen in a cylinder (V) in cubic meters under normal conditions is calculated by the formula:

V = K1•Vb,

Vb — cylinder capacity, dm3;

K1 - coefficient for determining the volume of oxygen in the cylinder under normal conditions, calculated by the formula

K1 = (0.968P + 1) * *

P - gas pressure in the cylinder, measured by a pressure gauge, kgf/cm2;

0.968 — coefficient for converting technical atmospheres (kgf/cm2) into physical ones;

t is the gas temperature in the cylinder, °C;

Z is the oxygen combustion coefficient at temperature t.

The values of the K1 coefficient are given in Table 4, GOST 5583-78.

Let's calculate the volume of oxygen in the most common cylinder in construction: a volume of 40 liters with a working pressure of 14.7 MPa (150 kgf/cm2). Coefficient K1 is determined according to Table 4, GOST 5583-78 at a temperature of 15°C:

V = 0.159 • 40 = 6.36m3

Conclusion (for the case under consideration): 1 oxygen cylinder = 40l = 6.36m3

Table 4. GOST 5583-78.

| Gas temperature in the cylinder, °C | The value of the Ki coefficient at excess pressure, MPa (kgf/cm2) | ||||||||||||||

| 13,7 (140) | 14,2 (145) | 14,7 (150) | 15,2 (155) | 15,7 (160) | 16,2 (165) | 16,7 (170) | 17,2 (175) | 17,7 (180) | 18,1 (185) | 18,6 (190) | 19,1 (195) | 19,6 (200) | 20,1 (205) | 20,6 (210) | |

| -50 | 0,232 | 0,242 | 0,251 | 0,260 | 0,269 | 0,278 | 0,286 | 0,296 | 0,303 | 0,311 | 0,319 | 0,327 | 0,335 | 0,342 | 0,349 |

| -40 | 0,212 | 0,221 | 0,229 | 0,236 | 0,245 | 0,253 | 0,260 | 0,269 | 0,275 | 0,284 | 0,290 | 0,298 | 0,305 | 0,312 | 0,319 |

| -35 | 0,203 | 0,211 | 0,219 | 0,226 | 0,234 | 0,242 | 0,249 | 0,257 | 0,264 | 0,272 | 0,278 | 0,286 | 0,293 | 0,299 | 0,306 |

| -30 | 0,195 | 0,202 | 0,211 | 0,217 | 0,225 | 0,232 | 0,239 | 0,248 | 0,253 | 0,261 | 0,267 | 0,274 | 0,281 | 0,288 | 0,294 |

| -25 | 0,188 | 0,195 | 0,202 | 0,209 | 0,217 | 0,223 | 0,230 | 0,238 | 0,243 | 0,251 | 0,257 | 0,264 | 0,270 | 0,277 | 0,283 |

| -20 | 0,182 | 0,188 | 0,195 | 0,202 | 0,209 | 0,215 | 0,222 | 0,229 | 0,235 | 0,242 | 0,248 | 0,255 | 0,261 | 0,267 | 0,273 |

| -15 | 0,176 | 0,182 | 0,189 | 0,196 | 0,202 | 0,208 | 0,215 | 0,221 | 0,227 | 0,234 | 0,240 | 0,246 | 0,252 | 0,258 | 0,263 |

| -10 | 0,171 | 0,177 | 0,183 | 0,189 | 0,195 | 0,202 | 0,208 | 0,214 | 0,220 | 0,226 | 0,232 | 0,238 | 0,244 | 0,250 | 0,255 |

| -5 | 0,165 | 0,172 | 0,178 | 0,184 | 0,190 | 0,195 | 0,202 | 0,207 | 0,213 | 0,219 | 0,225 | 0,231 | 0,236 | 0,242 | 0,247 |

| 0 | 0,161 | 0,167 | 0,172 | 0,179 | 0,184 | 0,190 | 0,196 | 0,201 | 0,207 | 0,213 | 0,219 | 0,224 | 0,229 | 0,235 | 0,240 |

| +5 | 0,157 | 0,162 | 0,168 | 0,174 | 0,179 | 0,185 | 0,190 | 0,196 | 0,201 | 0,207 | 0,212 | 0,217 | 0,223 | 0,228 | 0,233 |

| +10 | 0,153 | 0,158 | 0,163 | 0,169 | 0,174 | 0,180 | 0,185 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,217 | 0,222 | 0,227 |

| +15 | 0,149 | 0,154 | 0,159 | 0,165 | 0,170 | 0,175 | 0,180 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,216 | 0,221 |

| +20 | 0,145 | 0,150 | 0,156 | 0,160 | 0,166 | 0,171 | 0,176 | 0,181 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,215 |

| +25 | 0.142 | 0,147 | 0,152 | 0,157 | 0,162 | 0,167 | 0,172 | 0,177 | 0,182 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,210 |

| +30 | 0,139 | 0,143 | 0,148 | 0,153 | 0,158 | 0,163 | 0,168 | 0,173 | 0,177 | 0,182 | 0,187 | 0,192 | 0,196 | 0,201 | 0,206 |

| +35 | 0,136 | 0,140 | 0,145 | 0,150 | 0,154 | 0,159 | 0,164 | 0,169 | 0,173 | 0,178 | 0,182 | 0,187 | 0,192 | 0,196 | 0,201 |

| +40 | 0,133 | 0,137 | 0,142 | 0,147 | 0,151 | 0,156 | 0,160 | 0,165 | 0,170 | 0,174 | 0,178 | 0,183 | 0,188 | 0,192 | 0,196 |

| +50 | 0,127 | 0,132 | 0,136 | 0,141 | 0,145 | 0,149 | 0,154 | 0,158 | 0,163 | 0,167 | 0,171 | 0,175 | 0,180 | 0,184 | 0,188 |