The fuel pressure regulator is a safety valve that is installed at the end of the fuel rail of the injectors.

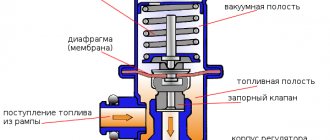

It is serviced together with the ramp. On the one hand, it is affected by the vacuum in the intake pipe and the spring pressure, and on the other, by the pressure in the fuel system. Its main function is to maintain constant pressure in the nozzles.

Attention! The entire process of installing the fuel pressure regulator must be carried out on a cold engine.

Fuel pressure regulator malfunctions

Fuel pressure regulator malfunctions lead to the fact that the engine starts with difficulty, has “floating” idle speed, the car loses dynamic characteristics, and sometimes fuel leaks from the fuel hoses. As a rule, a fuel pressure regulator (abbreviated as RTD) is installed on the fuel rail and is a vacuum valve. In some car models, the RTD cuts into the fuel return hose of the fuel system. To determine that the fuel system malfunction lies in a faulty pressure regulator, it is necessary to carry out a series of simple checks.

Diagnostics

There are a number of methods to diagnose the condition. All of them are simple, even a novice car enthusiast can handle them.

- Visually. This is an option for carburetor engines. Pinch the valve or disconnect it. The fault can be determined by how intense the fuel flow is. The method is simple, but inaccurate.

- Pressure gauge. Install the device between the fitting and the hose, temporarily disconnecting the vacuum hose. The reading on the pressure gauge should rise to 0.7 bar.

- By pinching the hose. Check the RTD by clamping the return line. The pressure gauge should respond immediately. If the engine does not rev up, the governor is faulty. Start the engine by clamping the return line. Watch the speed and listen to his work. If its operation is uniform, the adjustment valve is faulty - it must be replaced.

Where is the fuel pressure regulator located?

To find the installation location of the fuel pressure regulator, let’s figure out what it is and what it is needed for. This will help in further searches and diagnostics.

The first thing you need to know is that there are two main types of RDTs - mechanical (old type) and electrical (new type). In the first case, this is a vacuum valve, the task of which is to transfer excess fuel under excessive pressure back into the fuel tank through the corresponding hose. In the second, it is a fuel pressure sensor that transmits relevant information to the ECU.

Typically, the fuel pressure regulator is located directly on the fuel rail. Another option for its placement is the fuel return hose of the power system. Another option is to locate the regulator directly in the fuel tank on the pump module. In such systems there is no fuel return hose as unnecessary. Such an implementation has several advantages, including simplified design (no extra pipeline), excess fuel does not enter the engine compartment, fuel heats up less and does not evaporate as much.

How does the fuel pressure regulator work?

Structurally, the old-style valve (installed on gasoline cars) has its own body, inside which there is a valve, a membrane and a spring. The housing has three fuel outlets. Through two of them, gasoline passes through the pressure regulator, and the third outlet is directly connected to the intake manifold. At low (including idle) engine speeds, the fuel pressure in the system is low and it all goes into the engine. As the speed increases, the corresponding pressure increases in the manifold, that is, at the third terminal of the RTD, a vacuum (vacuum) is created, which, at a certain value, overcomes the resistance force of its spring. This creates the movement of the membrane and the opening of the valve. Accordingly, excess fuel gains access to the second outlet of the regulator and goes back into the fuel tank through the return hose. Due to the described algorithm, the fuel pressure regulator is often called a check valve.

As for the fuel pressure sensor, it is a little more complicated. So, it consists of two parts - mechanical and electrical. The first part is a metal membrane that bends under the influence of force caused by pressure in the fuel system. The thickness of the membrane depends on the pressure for which the fuel system is designed. The electrical part of the sensor consists of four strain gauges connected according to a “Winston bridge” circuit. Voltage is applied to them, and the more the membrane bends, the greater the output voltage from them will be. And this signal is sent to the ECU. As a result, the electronic control unit sends the appropriate command to the pump so that it supplies only the amount of fuel required at the moment.

Diesel engines have a slightly different fuel pressure regulator design. In particular, they consist of a solenoid (coil) and a rod, which rests against the ball to shut off the reverse flow. This was done for the reason that the diesel engine vibrates very strongly during its operation, which affects the wear of the classic (gasoline) fuel regulator, that is, partial and even complete compensation of hydraulic vibrations occurs. However, its installation location is similar - in the engine fuel rail. Another option is on the fuel pump housing.

What is a check valve

The check valve in the fuel system should only allow fuel to flow in one direction. This is the main purpose of OKDT. When the fuel pump is not working, the device automatically closes the return fuel line to prevent unused fuel from flowing into the tank.

When the valves are working properly, the pressure in the main pipes does not drop for a long time after the engine stops. The small part is calibrated. The design consists of several elements:

- housing with outputs;

- ball-type valve with a seat made of soft metal;

- membrane;

- spring.

Improving the starting characteristics of the internal combustion engine is the main function of the exhaust valve. A working part installed in a certain location in the fuel line maintains the optimal value of the residual pressure.

It is not difficult to understand how a valve installed on a ramp works:

- When the fuel injection pump is running, OKDT does not interfere with the movement of fuel in the forward direction.

- When the fuel pump turns off (when the engine stops), a reverse flow of working fluid occurs in the line.

- The reverse flow of fuel creates pressure, which closes the valve.

- The fuel remains in the line, creating residual pressure.

The operation of the entire fuel system of the vehicle depends on the small device. If there is no residual pressure in the line, it must be created every time the engine is started. The driver is forced to spend extra time cranking the starter.

How to find your device

There are models in which the valve is mounted in the fuel rail housing. A common installation location is the section of the fuel line located between the injectors and the tank.

There are vehicles in which the part is mounted directly into the fuel pump housing. In modern cars equipped with a fuel preheating system, the OKDT housing is located before the preheater. The installation location depends on the make of the machine:

Source of the article: https://moyidorogi.ru/dlya-chego-nuzhen-obratnyj-klapan-na-benzonasose/

Signs of a malfunctioning fuel pressure regulator

There are five main symptoms of a malfunctioning fuel pressure regulator (both types), which can be used to judge the complete or partial failure of this important unit. Moreover, the symptoms indicated below are typical for cars with both gasoline and diesel engines. However, it is worth mentioning that the listed situations may be signs of failure of other engine components (fuel pump, clogged fuel filter), so it is advisable to carry out comprehensive diagnostics in order to accurately determine its performance. So, the signs of a malfunctioning fuel pressure regulator are as follows:

- Difficulty starting the engine . This is usually expressed in a long rotation of the starter with the accelerator pedal depressed. Moreover, this sign is characteristic under any external weather conditions.

- The engine stalls at idle . To maintain its operation, the driver must constantly apply gas. Another option is that when the engine is idling, the speed is usually “floating”, unstable, until the engine stops completely.

- Loss of power and dynamics . Simply put, the car “does not pull,” especially when driving uphill and/or when loaded. The dynamic characteristics of the car are also lost, it accelerates poorly, that is, when trying to accelerate, a deep drop in revolutions occurs at their high values.

- Fuel is leaking from the fuel hoses (rail) . In this case, replacing hoses (clamps) and other nearby elements does not help.

- Excessive fuel consumption . Its value will depend on both the breakdown factors and the engine power.

Replacement

Replacement process

By following the instructions step by step, you can independently remove and install a new fuel pressure regulator without any problems.

- Work on dismantling the device can only be carried out if the engine is cold. If you just drove into the garage, give the car some time to cool down.

- When the engine is running, high pressure remains inside the system, so it must be reduced before work.

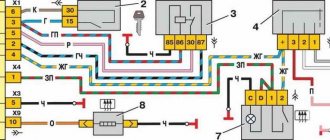

- Disconnect the negative terminal from the battery to avoid electric shock and damage to the wiring.

- Remove the vacuum hose.

- Unscrew the nuts on the drain pipe and gradually reduce the fuel pressure level in this way. Be sure to hold the hose fitting with one hand.

- The tube and the washer are connected to each other by a regular rubber ring.

- The screw that holds the clamping bar is unscrewed.

- Now this very bar can be put aside for a while.

- Slightly unscrew the fixing nut that holds the drain tube and the regulator itself.

- Remove the fastening screws of the regulator holding it to the ramp.

- Carefully remove the nut, which will ultimately allow you to remove the object we are looking for.

- Install the new device by following the reverse dismantling sequence.

Be sure to check the fuel pressure in the injectors with the engine off, ignition on and the electric fuel pump on. During normal operation of the device, the pressure should be about 300 kPa. If the level you checked is below normal, this can lead to disruption of the functionality of the entire engine power system. Therefore, be careful, do the work step by step, and do not forget about the importance of each stage of repair.

Replacing the fuel pressure regulating device yourself is not difficult. Just keep in mind that for optimal engine operation after replacement, you will need to not only follow the sequence of work and do everything as competently as possible, but also use a new, high-quality device as a replacement. The regulator is not expensive, so such repairs will not entail significant costs for your VAZ 2114.

Checking the fuel pressure regulator

Testing the functionality of the fuel pressure regulator will depend on whether it is mechanical or electrical. the old regulator of a gasoline engine . You need to act according to the following algorithm:

- find the fuel return hose in the engine compartment;

- start the engine and let it run for about one minute, so that it is no longer cold, but also not hot enough;

- using pliers (carefully so as not to damage it) pinch the above fuel return hose;

- If the engine was previously “troubling” and running poorly, but after pinching the hose it started working well, it means that the fuel pressure regulator has failed.

How to determine the performance of an injector

In modern injection gasoline engines, firstly, instead of rubber fuel hoses, metal tubes are installed (due to high fuel pressure and for reliability and durability), and secondly, electrical sensors based on strain gauges are installed.

Accordingly, checking the fuel pressure sensor comes down to checking the output voltage from the sensor when the supplied fuel pressure changes, in other words, increasing/decreasing engine speed. This will make it clear whether the fuel pressure regulator has failed or not.

Another method of checking is with a pressure gauge. So, a pressure gauge is connected between the fuel hose and the fitting. Before doing this, be sure to disconnect the vacuum hose. You also first need to find out what normal fuel pressure should be in the engine (it will be different for carburetor, injection and diesel engines). Typically, for injection engines, the corresponding value is in the range of approximately 2.5...3.0 atmospheres.

You need to start the engine and check the readings on the pressure gauge that the pressure is normal. Next you need to give it a little gas. In this case, the pressure drops slightly (by tenths of an atmosphere). After which the pressure is restored. Next, you need to use the same pliers to pinch the return fuel hose, as a result of which the pressure will increase to approximately 2.5...3.5 atmospheres. If this does not happen, the regulator has failed. Remember that you cannot pinch the hoses for a long time!

How to properly check RTD

In order to independently check the pressure in the system, and therefore the correct operation of the regulator, you need to take a pressure gauge, the maximum pressure in which is up to 10 atmospheres. You should not use a device with a larger scale, as its readings will have a serious error.

It connects between the fitting and the fuel pipe:

- first turn off and cool the engine;

- locate the fuel rail under the hood;

- remove the plug from the fuel pressure fitting;

- unscrew the fitting nipple using a spool valve;

- wipe the surfaces if fuel splashes appear under the influence of residual pressure;

- pull a hose with a diameter of up to 9 millimeters onto the fitting and secure it with a clamp;

- Connect the second hole of the hose to the pressure gauge.

Next, you will need an assistant, because the readings from the pressure gauge need to be read at one of four moments:

- when the ignition is turned on, the pressure should be 3 atmospheres;

- at idle speed - 2.5;

- when squeezing the fuel outflow hose - 7;

- with the hose removed on the RTD – 3.3.

If on your VAZ-2115 the measurements show different indicators, then you need to replace the regulator with a new one. To do this, it is enough to detect it in the system, dismantle it, and then return the fuel line to its original state. In the VAZ-2115, the engine of which has 8 valves or another system, the RTD is mounted at the very end of the fuel rail.

It is important to check the integrity of the fuel system. If leaks are detected in it, then the pressure gauge readings should not be trusted. After checking under different conditions, it is worth turning off the engine and looking at the pressure gauge again; the pressure should be within 0.7 atmospheres. If the pressure drops completely, then the problem is definitely in the regulator.

Remember that a regulator will cost you much less than a large-scale repair of the fuel system or engine. It is precisely such global breakdowns that a failed RTD can lead to. The cost of this spare part is from 500 rubles. The final price of the repair depends on which manufacturer’s spare part you purchase. The cheapest parts are stock parts produced in Togliatti, and the most expensive are BOSCH components.

Causes of fuel regulator malfunction

In fact, there are not many reasons why the fuel pressure regulator has failed. Let's list them in order:

- Natural wear and tear . This is the most common reason for RTD failure. As a rule, this happens when the car's mileage is about 100...200 thousand kilometers. A mechanical malfunction of the fuel pressure regulator results in the membrane losing its elasticity, the valve may jam, and the spring weakens over time.

- Defective parts . This does not happen so often, but often there are defects on products from domestic manufacturers. Therefore, it is advisable to buy original spare parts from imported manufacturers or check them before purchasing (be sure to pay attention to the warranty).

- Poor quality fuel . Unfortunately, domestic gasoline and diesel fuel often contain excessive moisture, as well as debris and harmful chemical elements. Due to moisture, rust spots may appear on the metal elements of the regulator, which spread over time and interfere with its normal operation, for example, the spring weakens.

- Clogged fuel filter . If there is a large amount of debris in the fuel system, it will also lead to clogging of the RTD. Most often, in such cases, the valve begins to jam or the spring wears out.

As a rule, if the fuel pressure regulator is faulty, it is not repaired, but replaced with a new one. However, before throwing it away, in some cases (especially when talking), you can try cleaning the RTD.

Cleaning the fuel regulator

Before replacing it with a new similar element, you can try to clean it, since this procedure is simple and accessible to almost every car owner in a garage. Often, special carburetor cleaners or carb cleaners are used for this (some car enthusiasts use the well-known WD-40 for similar purposes).

The most common (and most accessible) thing is to clean the filter mesh, which is located on the outlet fitting of the fuel pressure regulator. Through it, fuel is supplied directly to the fuel rail. Over time, it becomes clogged (especially if low-quality fuel with mechanical impurities and debris is regularly poured into the car tank), which leads to a decrease in the capacity of both the regulator in particular and the entire fuel system as a whole.

Accordingly, in order to clean it, it is necessary to dismantle the fuel pressure regulator, disassemble it, and use a cleaner to get rid of deposits both on the mesh and inside the regulator body (if possible).

Dirty fuel regulator mesh

After cleaning the mesh and the regulator body, it is advisable to force them to dry using an air compressor before installation. If there is no compressor, place them in a well-ventilated, warm room for a time sufficient to completely evaporate moisture from their external and internal surfaces.

Another exotic cleaning option is the use of an ultrasonic unit at a car service center. In particular, they are used for high-quality cleaning of injectors. Ultrasound can be used to “wash” small, stubborn dirt. However, here it is worth weighing the cost of the cleaning procedure and the price of a new mesh or fuel pressure regulator as a whole.

Source

Why is this device needed?

The regulator, responsible for maintaining normal fuel pressure in the system, is in direct interaction with the power unit. According to its location, it can be located in the fuel tank or in the rail (this is where you will be able to find the regulator if you have an injection VAZ-2115). The reason for the failure of this element is often the low quality of gasoline. If you fill up at gas stations with greatly reduced prices, then it is not surprising that very soon the regulator will fail.

Main symptoms of a malfunction

Problems with the regulator can manifest themselves in various ways:

- reduction in engine power (you can notice this when driving downhill or during acceleration);

- problems with starting the power plant (the starter rotates, but the engine does not start);

- Unstable engine operation at idle (you may often stall at intersections).

Even an inexperienced car user can notice these failures. It is important to diagnose your car in a timely manner so as not to spend money on fixing more serious breakdowns later. If you detect these signs in time, you will be able to carry out the repair yourself. Otherwise, you will have to evacuate the car to a service station.

Which way to go

There are two options for eliminating the problem. Take the car to a service station and wait for the repairs to be completed. In this case, you need to shell out a certain amount of money, it’s a pity.

Having knowledge and understanding of the car’s structure, you can carry out repairs yourself. Saving money in person. However, there is a possibility of stepping on a pitfall. Can't deal with the problem.

Then you will have to shell out additional money for repairs in a specialized center, how do you like this prospect? In any case, the decision is yours to make.

Experts recommend not to reinvent the wheel, but to give the car to professionals who will replace it quickly, with a guarantee of quality.

Decide what is more important to you: savings or stable operation of the power unit, good luck to everyone!

Return problem. Where is the check valve, 8 valve, 1.5 engine injector located? Is it in the gasoline pump itself or not??

1.6 8kl. Where is the check valve located? Is it the RTD or on the fuel pump motor itself?

Now 2nd gear won't hold

by Adminrive · Published 03/26/2015

New at a very good price

by Adminrive · Published 04/11/2017

When can fuel consumption increase?

It is worth paying special attention to such a sign of a regulator malfunction as increased fuel consumption.

The car will require more gasoline to operate if the valve in the regulator is faulty or, conversely, it does not hold fuel. In the first case, excess fuel is not returned to the tank; the car owner may notice a pressure above 2.5 kg/cm2. As a result, more gasoline enters the combustion chamber of the engine, which is not completely consumed. If the valve does not perform its functions, fuel “staggers” through the system. The pressure in the fuel system decreases, and as the speed increases, the engine feels a clear shortage of gasoline. The power unit becomes less responsive and powerful. A valve malfunction can be noticed when starting the car for a long time - during the process, the starter has to be turned for a long time until it creates the necessary pressure.

Failure options

The regulator is a simple device from a technical point of view, so there are few breakdowns that can happen to it. In almost all cases it is recommended to replace the RTD.

- Spring. This is the main failure in the RDT. Due to the weakening of the spring, the engine becomes “starved”, there is not enough fuel at high speeds, when the clutch is pressed and during transient conditions.

- Pollution. When clogged, the ability to pass fuel is lost. The engine stops in any operating mode. If the RTD is heavily contaminated, the pressure in the vehicle rises sharply and fuel leaks through the sealing material. The problem is solved by pumping a large amount of fuel into the fuel pump.

- Jammed. The RTD in the ramp may periodically jam. The car twitches.