Signs of wear on joints

The silent block of the rear beam is a rubber-metal hinge. The part serves as an elastic insert between the car components. It consists of two bushings, between which there is a seal made of rubber or other elastic material. Recently, polyurethane has become widespread. A gasket made of elastic material allows you to dampen vibrations between components and not transfer vibrations to the car body.

The silent block of the rear beam is used not only for connecting suspension units to each other. The element is also attached to the anti-roll bar, at the mounting points of the gearbox and engine of the car. But the suspension has the most severe operating conditions due to dust, dirt, moisture and active movement of parts, so replacement is done regularly.

Rubber bushings are not items that will last forever. Usually they last for 100 thousand kilometers, but due to harsh operating conditions, the replacement period may come earlier. After half this period, it is necessary to check the suspension. This is the only way to understand the degree of wear of the unit and determine whether it needs to be replaced.

Visual inspection procedure:

- drive the car into a pit or lift it with a jack;

- clean the suspension mounting points from dirt;

- carry out an inspection.

The rubber insert must not have cracks or tears. Signs of this kind indicate that it is time to replace the silent blocks of the rear beam. A worn part will subsequently affect handling, and this, in turn, will affect the safety of the car owner and others.

Sometimes the part wears out earlier, especially when driving off-road. The degree of wear can be assessed by the behavior of the car.

Signs of wear on silent blocks:

- when driving in a straight line or when braking, the car pulls to the side;

- increased wear of rubber on the sides;

- increased vibration when driving;

- creaking or knocking in the suspension area;

- the suspension began to work harder.

The presence of one or more signs means that it is time to service the suspension. Delay can be costly. Untimely replacement will lead to loss of control in a critical situation, as well as accelerated tire wear. The hinge seats will also be damaged and then the lever will have to be replaced - this will increase the cost of repairs.

Metal parts of the part break extremely rarely. The rubber gasket usually wears out.

Reasons for premature replacement:

- Long-term use, which leads to drying out of the rubber seal and loss of properties.

- Interaction with chemicals. Oil and gasoline destroy rubber.

- Incorrect installation.

Premature wear indicates that the cause needs to be found and eliminated. Otherwise, the replacement procedure will soon have to be repeated. Oil leaks will be clearly visible, and installation should be carried out strictly according to the instructions and connections should be checked.

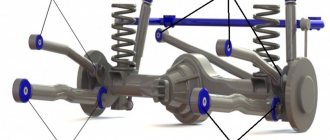

In a car, the wheels are attached to the power part of the body using levers. In order for the suspension to smoothly handle all road irregularities, the following conditions must be created:

- The wheel, under the influence of a spring, must move up and down on the lever, so it is screwed to a steel axle rigidly fixed to the spar.

- To absorb small potholes in the road surface at the junction of the chassis and the body, an elastic gasket is needed. Otherwise, the driver and passengers will begin to feel vibration transmitted from the wheels.

Accordingly, silent blocks are needed for a movable and at the same time springy connection between the body part and the entire suspension of the car. They are the same gasket that softens small impacts and allows the lever to work out large irregularities.

On each side, the suspension rests on body elements at 2 or 3 points. In the first case, it is mounted on a lever and a strut, in the second - on two levers and a shock absorber. As many attachment points as there are, so many pairs of silent blocks are used as softening pads.

The second name for a rubber-metal part is a dry hinge. It characterizes the ability of silent blocks to work without lubrication - only due to the elasticity of the insert between two steel bushings. At the same time, the turning radius of the lever is limited by the ability of the rubber or polymer to twist. But for the working stroke of a car suspension, this radius is quite enough.

Now about the specific points where dry hinges are located:

- The main place mentioned above is the attachment of the upper and lower arms. The strength element of the body - the spar (standing under the wheel arch) has a protrusion with a hole into which the axle is inserted in the form of a long bolt. Rubber-metal hinges, pressed into the eyelets of the lever, are placed at the edges of the axle and secured with nuts.

- The small silent block is located at the lower point of attachment of the strut to the steering knuckle.

- On shock absorbers, the hinges are placed on both eyes - top and bottom.

- Parts are also used at the support points of torque rods and anti-roll bars.

DETAILS: Replacing brake fluid and bleeding the ABS modulator Lexus RX300

The rear suspension of modern cars most often has a multi-link or torsion bar design. In both cases, levers mounted on silent blocks are involved. So hinges are used not only in the front suspension. Even on cars with a continuous rear axle beam, rubber-metal products are used to install rear linkages and shock absorbers.

The silent block is considered a fairly reliable part of the car's chassis. Lever joints last from 50 to 150 thousand km, depending on driving conditions and the condition of roads in a particular area. On jet rods, these parts serve no less, but on shock absorbers, struts and anti-roll bar they last up to 50 thousand km.

Silent blocks have one unpleasant feature - it is quite difficult for an ignorant motorist to diagnose their malfunction as a result of wear. You should have an inspection ditch, a tool, and most importantly, practical skills at your disposal. To detect play on a lever or strut, you need to know exactly how to hang the wheel and where in the car to place the pry bar in order to swing this or that suspension element.

There are a number of signs that indirectly indicate worn dry joints:

- a dull, quiet knock when driving over small potholes;

- dull knocks coming from one side when making a sharp turn indicate problems with the stabilizer joints;

- the car deviates from a straight line on a flat area, lateral wear is visible on the tires;

- deep cracks in the rubber filler or misalignment of the lever, detected during a visual inspection from the pit.

The listed symptoms cannot directly indicate the non-working condition of the silent blocks, unless the rubber began to fall out in pieces and the wheels were noticeably warped. Ball joints and tie rod pins can produce dull knocks, while products with cracks in the rubber may turn out to be quite serviceable.

Self-replacement

Before replacing the pillows, their condition must be diagnosed. The condition of any silent units is checked during installation: it should be subject to resistance that simulates the movement of the engine during operation. If:

A simplified way to replace silent blocks back

beams

VAZ

2108, 2109, 21099, 2110, 2111, 2112, 2113,

2114

, 2115.

- rubber gaps are visible

- The silent block of the bushing refers to the seams,

- the motor moves easily when pressed and beats the protection,

- broken support bracket,

the element must be replaced. Even if signs of wear are not noticeable (for example, the rubber cracks but does not tear), it is better to replace them with a set. Quiet blocks lose their elasticity over time and begin to work poorly.

Standard and reinforced mounts for the VAZ 2114 are available for sale. The second type uses a harder rubber compound, but they are more durable only in quiet driving mode. Fans of sudden starts and brakes will have to change one every 15-20 thousand, they can live with other drivers for 50 thousand km. This is the answer to the question of how much is supported.

VAZ 2114 engine front suspension

The supports of the VAZ 2114 can be completely replaced independently, without resorting to a car service. It is more convenient to use a pit or a span, but you can do without them. To do this, the car is captured and placed on stops (bricks or stumps). If the crankcase is installed, it must be removed.

Replacing the front support. You need to coat the pan with oil. First, head 17 unscrews the 4 bolts securing the bracket to the engine crankcase, then the block cover. To remove the bolt, it is necessary to use the jack in such a position that the engine does not press on it with all its weight

When installing a spare part, it is important to lubricate the silent block bolt well: not only the threaded part, but also the body. It is in contact with the metal sleeve, so it may stick

Side engine mount VAZ 2114

Replacing the correct mount is similar to the difference that it is better to block the engine rather than the transmission. Another option is to install a jack in the area of the oil filter housing. It is attached to the engine crankcase with three bolts. Another trick is that the right pillow needs to be changed together. Without a side stop, the engine moves up, not down. The socket will not help here, so an assistant must apply pressure to it so that the plug of the silent device can be blocked.

Replacing a rear strut is the most difficult undertaking when done without a pit or lift, which requires some auto work skill and persistence. It is located at the intersection of the engine and transmission, so you will have to work in a confined space. In addition, when unscrewing the bolts from the housing, the key may rest against the gearbox housing.

Post Views: 9

PURPOSE AND DESIGN FEATURES OF THE BUSHING BLOCK

There are one more element in the design - silent blocks. These small-sized parts with a simple design play a fairly important role. Their task is to dampen vibrations and prevent their transmission between the components of the suspension. They are connecting elements of the structure; connections of a number of parts are made only through silent blocks. That is, these parts are directly involved in the main task of the suspension.

Silent block refers to rubber products used in the construction of a car. At the same time, it is a consumable material, which, as a result of wear and tear, is simply replaced, since it cannot be repaired.

The design of this part is very simple and includes only two main components:

- metal clips;

- and a rubber spacer between them.

Thanks to the use of rubber, it is possible to dampen vibrations and vibrations received from one component of the suspension, and not transfer them to another.

Outwardly, it looks like a massive bushing that fits into a special seat in the suspension element, but in essence it is just an elastic hinge that connects the parts into one unit. Thanks to the hole in the inner frame, the element in which it is installed to another component of the suspension or body is fastened.

There are also silent blocks, in which only the internal clip is used in the design, and the role of the external one is played by the seat itself in the suspension element.

Right choice

The choice is made after diagnosing the malfunction or during a planned replacement. It is necessary to understand what role the part plays in the suspension. Its task is to dampen vibrations that inevitably arise due to unevenness on the road.

Vibrations during movement are transmitted to the suspension springs, where they are partially damped by shock absorbers. The vibration then spreads to the frame through the connecting nodes. It is partially damped by silent blocks due to the presence of a soft base between the bushings. Therefore, the quality of the base must be of a high level.

Advantages of polyurethane:

- The service life is increased by 5 times. This allows replacements to be made after long mileage intervals and the suspension to be loaded more aggressively.

- Increased thermal stability. Polyurethane tolerates temperature changes well. The material works just as well in cold weather as at high temperatures.

- Thanks to the dense structure of the material, vehicle handling is improved.

Rubber and polyurethane are equally popular. Drivers themselves choose what to focus on. With rubber spacers you can get increased riding comfort, but improved handling can only be achieved with polyurethane. But in the latter case, comfort decreases, which is especially felt by passengers.

When purchasing a part, it is better to consult a specialist in the store. The fact is that vibration isolators are difficult to distinguish from each other in appearance - they are almost similar. But their outer diameter is sometimes slightly different, which will cause installation difficulties.

DETAILS: Replacing silent blocks on a VAZ 2110 Photo instructions on how to change silent blocks on a VAZ 2110

Tools and materials

Tools you will need:

- Spanners (take a full set at once);

- Socket wrenches;

- Vise;

- Chisel;

- Hammer;

- Puller;

- Silent blocks.

There are several important nuances:

- to take silent blocks from repair kits intended for models 2108-2112 . You will simply waste your money because they are not suitable for the fourteenth VAZ model.

- The easiest way to purchase a puller is at auto parts stores. But you can ask your friends for it.

- You can make a device for pressing in a new silent block yourself. To do this you will need a 170mm M12 bolt, a bushing, a washer and a high nut. But if you have the opportunity to use a full-fledged, real tool, do just that.

How can I check the silent block?

How can you determine whether this part needs to be replaced or not? As a rule, silent blocks can last up to one hundred thousand kilometers. But under road conditions such as ours, it is necessary to carry out an inspection after fifty thousand kilometers.

It is possible to realize whether the suspension silent block has worn out only by your own sensations. If the car’s handling has become worse, or the actions to turn the steering wheel have become “wobbly” with a huge delay, then such criteria are an accurate sign of a worn-out silent block.

However, in order to be sure of this, you should visit a car service center or check the rubber-metal joints yourself. A visual inspection of silent blocks is carried out in the following way: you need to drive into a hole and visually look at a silent block that is clean and free of dirt.

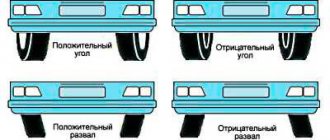

The rubber portion does not need to have cracks or tears. It is best to know how the new part should look before starting to inspect the silent block. An indirect indicator may be to consider a bent camber/toe, if it is established that it was previously correct.

Photo report with comments

The catalog number of these silent blocks is as follows: 17-06-104 (If anyone decides to buy one, the colors, hardness and prices for them are also different).

And now, after a few months, I finally decided to replace it in early June. As always, I was prepared for this task both spiritually and physically, and in order to make my work easier, I spilled the nuts a week in advance. I also bought clips and washers of different diameters at a building materials store and assembled a type of puller for all occasions.

And at the auto parts store I bought two bolts and two nuts to replace the old ones. So, there are these silent blocks:

Left-hand side

Right side

The first thing I decided to do was start on the left side. The nut, of course, didn’t work, even a week’s soaking with water didn’t help, but I wasn’t confused and was ready for such a turn. I picked up a grinder and sawed off half of the nut, and then simply knocked off the remains with a chisel.

I jacked up the car and safely lifted the beam out of the eye.

Then I put on my puller and started turning it, but no matter how wrong it was, the silent block had turned sour that it didn’t want to get out of anything.

I had to trim its edge a little and, after straining, after half an hour it finally gave up. The main reason for souring is the rust that formed inside the seat, well, in principle, there is nothing to be surprised about.

After the silent block was removed, I decided to clean the entire seat and process it. I did everything slowly and with conscience, so that such problems would not arise in the future. Using abrasive rollers, I completely cleaned off the rust, then treated it with zinc. I let it dry for a while, and then went over it again with cutters. The result is a completely clean and shiny seat, without sinks.

Next, I started pressing in the new silent block. I did everything according to my old tradition: I sprayed the silent block itself and the seat with silicone grease, and then simply pulled it in using a puller. Everything went fine, the silent block went in like clockwork.

On the spot

Then all that was left was to insert the beam into the eye and screw in a new bolt. I jacked up the beam with a second jack and in this way got into the seat. Of course, I had to sweat a little, I didn’t manage to get it the first time, because it’s inconvenient to do it alone, but after a few minutes everything fell into place.

I lowered both jacks and smoothly moved to the second side. Fortunately, the nut on the right side unscrewed quite easily and did not have to resort to the help of an angle grinder. I jacked up the car and pulled the beam out of the eye.

It’s not entirely clear from the photo, but the inner metal sleeve was already spinning inside the silent block in the same way as the silent block itself in the eyes, because it was visible that it had been rubbed with rubber. Then I started pressing out. To my surprise, the silent block came out of its seat very easily, killing literally 3-4 minutes, not to mention on the opposite side, although it may have already filled my hand.

Next, using the same technology, I cleaned the seat and pressed in a new silent block.

Then he tightened the bolt, lowered the car and, after swinging it a little towards himself by the towing hook, tightened the nuts. That's all, the work is finished, here are also photos of stock products.

Now regarding the income from this work. Of course, I didn’t expect that anything would increase or decrease, but I noticed a couple of nuances:

- Firstly:

the rear suspension has become softer, that is, there is no breakdown over serious bumps, it floats less, although I didn’t notice this before, so everything can be learned by comparison. But now with the new silent blocks I noticed complete composure, but don’t forget about the installed rear body amplifier, which makes a big contribution to the operation of the rear of the car. - Secondly:

I noticed such a small plus in this, in our city there is such a section of the road where you have to go down the mountain and, turning smoothly, continue straight ahead, but there are such patches, well, you know what, like flat cakes were put on, well, Well, before, in this turn at speed, the back of the car would jump up as if by chance, but now it drives smoothly, the rear part seems to be steering itself at this moment, a cool feeling!

Dismantling and installation process

Installation begins after purchasing the parts. You will need a tool - wrenches for removing the beam and suspension arms, a hammer or sledgehammer.

Step by step guide:

- The car is driven into a pit or overpass. You can lift the wheel with a jack, but it is so inconvenient to work with the suspension - you have to work lying down. The jack foot should not be in the same plane as the beam bracket.

- Dismantle the suspension beam. Be sure to remove the handbrake cable when doing this.

- The brackets have special brackets that hold the brake system hoses. The staples are removed.

- The old silent block of the beam is dismantled. Garage conditions require the use of a hammer or sledgehammer. You should work carefully so as not to damage the seat, otherwise there will be problems with installing the new part.

- The seat is cleaned of dirt and graphite lubricant is placed there.

- Install a new part. Replacement of the silent block of the rear beam is done so that there are no gaps or holes. Pressing is done with careful blows of a hammer.

- Reassemble the beam in the reverse order.

The replacement is complete and you can drive the car immediately. During assembly, you should check the installation of each part and only then proceed with assembling the next one. The silent block of the front beam is changed according to the same scheme.

Dismantling the old gum is done with 3 - 4 strong blows with a sledgehammer. You should hit strictly in the center of the part, without deviating to the side from the vertical axis. The edge of the clip is bent using a chisel to facilitate dismantling.

Experienced craftsmen use a piece of tube to press out the silent block of the rear beam. It is important that its diameter is slightly smaller than the same parameter of the seat. The tube is placed against the part and hit with a hammer. In a few blows the part will be removed without unnecessary operations.

Having removed the silent block of the rear beam, check the seat. There should be no chips or cracks on it. If there are any, the part should be replaced. Otherwise, the new silent block will not fit as it should.

Replacing silent blocks. Step by step description

Replacing silent blocks must be done on an overpass; a lift or inspection pit will do.

- Using 19mm wrenches, unscrew the nuts from the mounting bolts of the rear beam, which is fixed to the bracket. It is necessary to remove the fixing bracket on the left side and disconnect the brake pressure regulator rod from the beam.

- You need to pull out the bolt and slightly raise the car with a jack, and move the beam eye down. A wooden block must be inserted between the body and the beam.

- Use a hammer to knock out the silent block.

- Before installing a new silent block, you need to lubricate the silent block and the beam eye with a soap solution. Next, using the device shown in photo No. 1, you need to press in the silent block.

- Remove the wooden beam, lift the eye of the beam with a second jack, guide it into the bracket and insert the bolt.

That's all! The hardest part is over. The bolts securing the beam to the body bracket must be tightened with the car completely lowered to the surface.

Reasons for failure and what breaks in the silent block

It is quite difficult to imagine the metal parts of the silent block breaking. If they say that the silent block has broken, it means that the rubber component of the part has started to tear or has already broken. There are three reasons why silent blocks fail:

- Long service life, as a result of which the rubber dried out, lost elasticity and began to crack and tear

- Chemical attack on the rubber part. For example, too much oil got on the silent block, which corroded it.

- Incorrect installation. Tightening the silent block bolts should only be done when the car is on its wheels, and not suspended. But, alas, many car repair shops do not follow this rule; as a result, the wheel tightened under the canopy is at the extreme point, and when it stands on the wheels, the silent block is strongly twisted and the rubber will tear over time, without even a third of its life. Another subtle point is the installation of a silent block with partitions. Such silent blocks can be installed in a strictly defined position, and if it is installed incorrectly, the silent block will fail very quickly.

We diagnose the condition of silent blocks ourselves

- Machine creaks in the rear left side of the car body while in motion. The driver can increasingly hear a dull creaking sound, as if small and frequent impacts are being made on the rubber. They are especially activated when the car is overloaded and overcomes obstacles on the road, in particular high artificial bumps, or follows paving stones. The so-called “rubber” squeak is also detected at high speeds when performing sharp maneuvers. In such cases, an experienced driver will analyze the situation and think about how to change the front struts on a Passat B3, and what new equipment is worth purchasing. Problems should be diagnosed as soon as possible, because if, in addition to cracks and chips, ruptures appear on the silent block, then it is difficult to predict the behavior of the machine, and repairs will require large financial costs.

- The creaking of a car without a running engine. The most common diagnosis among car enthusiasts is to park the car on a flat surface, go to the trunk and lift the body with your hands, holding the rear left wheel arch. And if you suddenly hear a creak, then one question arises: how to change the silent blocks of the rear beam of the Passat B3, who to turn to for help if you lack knowledge in the field of repairing foreign cars.

- Deterioration in vehicle maneuverability. You notice that the brake pedal has become worse, as if it is falling somewhere, sluggishly responds to the driver’s demands, and sometimes does not work 100%.

- Cracks and chips on the rubber inserts of the silent block. External damage is noticeable only during a visual technical inspection, when the car is on an overpass and there is an opportunity to evaluate everything in the inspection pit. It’s difficult to find, other equipment elements get in the way, but the task is still doable.

Silent block diagnostics

Thus, it is possible to recognize problems in a car if you are vigilant and want to keep your vehicle in good condition at all times. With the help of a specialist or on your own, it’s not difficult to figure out how to change the rear struts on a Passat B3.

DIY puller

Dismantling and pressing in a new part are difficult stages of work, especially the last one. Therefore, the installation of silent blocks of the rear beam should be performed using a special device - a puller. You can make it yourself or ask a friend. With it you do not need to hit the parts with a hammer, so damage cannot be caused.

DETAILS: Electric headlight corrector: installation || Electric headlight corrector on a VAZ How to remake and install electric headlight corrector on a Classic VAZ 2104 0507

Device options:

- Small vices. They are put on the suspension part, and a tube is placed under one of the sides. It is important to install the second part so that it presses on the body of the part. But a piece of wood is installed between the vise lip and the part.

- Homemade device from scrap materials. This option involves turning and welding. Make a clamp from metal plates or improvised means. A hole is drilled in the base, where a nut is usually welded. A bolt is installed here, which serves as a press.

- Purchase of factory tools.

The option with a vice is the simplest and most reliable. A factory product costs money. If they are not there, but you have the skills and parts, then you can make the tool yourself. It is important that it can withstand high loads.

What you need for garage repairs

- Purchasing new silent blocks, the required size and category

- Purchasing a new fastening system, because most often old bolts may be ineffective or damaged during cleaning and installation.

- Prepare a jack and small wooden beams to fix the vehicle at the required height.

- Find or borrow from friends tools for pressing in the silent block, or choose improvised means that can be used to remove the product from the grooves without damaging the levers and boxes.

- A whole set of open-end, socket, and ring wrenches is formed. You never know how your vehicle repairs will end.

- You will also need a hammer, standard automotive tools, and rags so that the replacement of the rear silent blocks of the VAZ 2114 can be carried out without surprises.

How to replace silent block

As a rule, the silent block is first screwed to one part or pressed into it, which mates with its outer shell, after which the part is put in place and screwed with a bolt threaded through the internal bushing of the silent block.

Knowing how the silent block is installed, it is not difficult to guess that it is removed either by knocking it out or unscrewing it. When knocking out or pressing out, it is very important not to damage the mating plane of the silent block and the suspension element, since the silent block may then not fit tightly or not be pressed in.

When installing, pay attention to how the silent block should be positioned, since not all silent blocks can be placed arbitrarily. If the silent block has a design with partitions, it must have a strict operating position. If you ignore the strict installation position, the load on the partitions will be too great and the silent block will fail.

Tightening of the suspension with connections through the silent block is carried out exclusively in the “vehicle with its wheels on the ground” position, since the suspension must take the working position before tightening. If you ignore this rule, the silent block will twist and its service life will be significantly reduced.

How to replace rear silent blocks on a VAZ 2114

Preparatory stage.

Initially, the repair site and vehicle are prepared. It is necessary to drive the car onto an overpass or use an inspection hole. It's good to fix it in place and let the car cool down. It is recommended to move all cables, pipes, wires passing nearby so as not to damage them during routine repairs of the machine. It is also important to thoroughly rinse the area where the hinge is located, clean everything from dirt and open access to the fastening system so that nothing interferes and replacement is possible rear silent blocks of VAZ 2114. Fixing stage. The car is installed well, raised on a jack, a place is prepared for repairing the vehicle, wooden blocks are also used to fix some parts of the car

If you are afraid of damaging parts of the brake system and engine, you can dismantle them for a while. Direct replacement of rear silent blocks on a VAZ 2114. Gradually unscrew all the nuts. If necessary, the fasteners that have frozen forever are cut off with a grinder. The metal parts of the hinge are lowered to allow access to the rubber or polyurethane layer. Then, using a chisel and a hammer, the damaged part of the hinge is removed from the niche. A new part is installed in the freed space, which can be clamped in a vice at the time of installation. This is how the replacement of the rear silent blocks of the VAZ 2114 is completed.

It is recommended to carry out a wheel alignment diagnosis at the end of the repair work; this will be more reliable. We observe the behavior of the machine for several days; if the alarming signs disappear, it means that you have discovered the correct location of the problem and fixed it in time. The “stuffing” of a car is complex and consists of small parts, but never discount them. Clearly understand: if it is vital to replace the rear silent blocks on a VAZ 2114, then act, look for opportunities to put the vehicle in order. Transform the powerful “steel horse” into a source of supreme pride! Don't lose sight of a single detail, not a single little thing!

Wheel alignment

What can result from untimely replacement of silent blocks?

What can happen if the silent blocks are not replaced in time? Most likely, more than one driver asked this question. If this part is very seriously worn out, then this can lead to the car pulling away at speed, or in other words, at speed the car will be thrown from side to side.

Another significant sign of wear on rubber-metal joints is considered to be uneven wear on the tires of the car. There is no need to start replacing silent blocks, as there may not be very good consequences. For example: the landing zones for attaching the hinges may be destroyed, which will result in a complete replacement of the front suspension arm assembly.

Front arm

Replace the silent blocks on the front suspension arm of a VAZ 2114 with your own hands. To do this, try to strictly adhere to the instructions we offer.

- Place the car on the inspection hole.

- Remove the engine protection, if equipped.

- Unscrew the bolt nuts from the front arms.

- Using a 17 key, remove the fasteners of the front stabilizer strut, which secures it with the lever.

- Knock out the bolt.

- Loosen the wheel bolts, jack up the car and remove the wheels.

- Use a 24mm wrench to remove the brace nut. To avoid having to exert enormous force, first clean the fastener with a wire brush and treat it with WD40. This should help completely unscrew this nut.

- Then remove the two ball joint bolts from the steering knuckle to remove the arm.

- Problems often arise with this nut. It is rarely possible to remove it easily. A good way out of the situation is to remove the lever with a crab and a stretcher. To do this, slightly loosen the extension nut near the crab and remove the three bolts securing the crab and the body. Now remove the entire assembly and, in a more comfortable position, begin to unscrew the problematic nut. The most extreme method is heating or using a chisel.

- You managed to remove the lever. First of all, replace the silent block of the extension. Dismantling the old element is carried out using the most ordinary chisel. Be sure to clean the lugs and take a new suitable silent block.

- It's up to the vice. The silent blocks are pressed one by one into your lever. It is usually not possible to seat the element completely, so the lever should be placed on a flat floor or a sturdy table. The silent block must be installed using a hammer. A few accurate and fairly strong blows should be enough.

- Using the method without using a vice is very risky. Such measures are resorted to either by self-confident specialists or by those who do not mind experimenting with their car.

- Now we change it on the front lever. The first priority is to get rid of the old silent block. If it was completely broken, you just need to remove the bushing and remove the remaining rubber elements of the silent block from the eyes.

- If this method is not relevant, the silent tape will have to be pressed out. You already have a puller.

- The new element is pre-treated with water diluted with any soap, dish gel or simple liquid soap.

- Use the press-in tool to place the new part in its rightful place.

- The fastening bolts should be tightened gradually. The silent block can be twisted at the same time, so try to hold it with a screwdriver.

- Alas, the process of replacing silent blocks on the front lever is much more complicated than in the case of a stretcher.

POLYURETHANE OR RUBBER BUSHING BLOCKS, WHICH IS BETTER?

If the car has rubber bushings and silent blocks in the suspension, which can be replaced with polyurethane parts, then you will only improve the characteristics of the suspension and its operation. Polyurethane silent blocks will last at least 5 times longer than rubber parts.

Polyurethane silent blocks improve the car's behavior on the road, reducing unwanted deformations in the suspension and eliminating the “squeezing” effect typical of rubber parts. This means that the suspension always operates in the mode intended by the designers.

If you want to improve handling, polyurethane silent blocks are what you need. If you calmly move from one point to another, then choose ordinary silent blocks.

WHERE ARE THE BUSHING BLOCKS LOCATED?

FRONT ARM BUSHING BLOCKS

In the front suspension, silent blocks are used in the levers; through them, a movable and elastic connection of the levers with the wheel hub and with the car body is carried out. Silent blocks are often used at the junction of the anti-roll bar with the lever, if this is structurally provided for. It can also be used at the bottom of the shock absorber strut, where it is attached to the hub.

In the rear suspension, silent blocks can be installed on levers (longitudinal and transverse), at the point where the torsion beam is attached to the car body, and in shock absorbers.

In general, the number and location of installation of these rubber elements depends on the design of the car's chassis. For example, consider the location of silent blocks on a VAZ-2110 car. And let's start with the front suspension where these joints are used:

- in the transverse arms (at the place of their attachment to the body);

- at the ends of the anti-roll bar (its attachment to the wishbone);

- in the shock absorber struts at the bottom (the place where they are attached to the wishbone);

- in the extension of the transverse lever (at both ends - at the point of its connection with the lever and with the cross member);

In total, there are 5 silent blocks installed in the front suspension on one side only, and the same number in the other part of the suspension.

Rear suspension

Sometimes it is also necessary to replace the silent blocks on the rear suspension of a VAZ 2114 car. They are not as susceptible to wear as in the case of the front control arms, but the fact remains.

The sequence of your work in this situation will be as follows:

- If there is no lift, slightly loosen the bolts on the wheels, install a jack, raise the car and completely remove the wheel.

- It is advisable to place some supports under the beam. Both simple bricks and a second jack will do. It all depends on what you have at your disposal.

- Now you need to remove the bolts that are attached to the shock absorber and the car body.

- Proceed carefully to avoid damaging the threads.

- The bolts are knocked out, the beam moves down or slightly back. This will allow you to get to the desired silent blocks.

- They are dismantled with a puller.

- New suspension elements are installed in a similar way to the silent blocks of the front control arms. To help them sit in their nests better, use a soapy solution.

- Reassemble the entire disassembled structure in reverse order.

- During the disassembly and assembly process, pay attention to the remaining components to which you gain full or partial access.

- As practice shows, performing certain repairs allows you to study the condition of related components, assemblies and parts of the car, identify emerging problems in a timely manner and eliminate these breakdowns or what may lead to this.

Should you try it if you have no experience at all? Most likely not. But this experience must come from somewhere, right?!