When using any car, its suspension wears out over time. Domestic car enthusiasts know that repairs to the VAZ 2114 chassis are required quite often due to poor roads in our country. How to repair the front or rear suspension of a VAZ 2114 with your own hands, we will look in detail in this material.

The VAZ chassis consists of front and rear suspensions. When operating a vehicle, they bear the greatest load. Their condition affects the quality and comfort of driving a car, as well as the safety of the driver and his passengers. The main function of car suspensions is to soften the ride and eliminate vibrations. The chassis also reduces roll when cornering and ensures a smooth ride, and also provides high information content to the driver in the city and on highways.

In the CIS countries, the roads are generally not very good, so the VAZ 2114 suspension experiences very high loads. This leads to the need to regularly contact a car service. At the same time, you can save your money by repairing the chassis of a domestic passenger car yourself in a garage. To be able to determine which element has failed, you need to know how the suspension works.

Description of the spare part

The rear beam on the VAZ 2114 is a steel element of the torsion bar suspension that provides connection between the rear part of the car body and the wheels. Gives the car lateral stability . Has a U-shaped section. It has high bending rigidity and low torsional rigidity. The design of the rear beam is simple.

The part consists of two longitudinal-type arms connected by welding. At the stern there are special holders with holes used for mounting shock absorber elements. There are also flanges with holes for fastening the axle of the rear pair of wheels. A malfunction of the rear beam is manifested by the knocking of wheels and abrasions on the body from tires.

We disassemble the front suspension with our own hands

Install the VAZ 2114 over the inspection hole or lift it on jacks or a lift. Be sure to set the parking brake when not using a lift. Remove the wheel caps and bolts, and then remove the wheels.

Next, remove the ball joint pin located in the strut swing arm. In the next step, remove the front stabilizer link number 24 from the suspension arm number 22. Then remove the braces from the body 30 and completely disconnect the ball joint that is attached to the steering knuckle.

Special ties

Remove the front suspension arm by disconnecting it from the body bracket number 28. After this, the arm can be removed with the bracket and extension. You should also remove the bolts that hold the pads to the steering knuckle.

In front of you you will see the assembled caliper. To avoid unnecessary work, do not remove it completely, but hang it on a wire so that the hose is not bent and does not experience stress. Then press the spline shank out of the wheel hub.

From the engine compartment, remove the protective cam number 41 by unscrewing the telescopic rack nuts, and then remove the solid suspension strut. It must be assembled with the wheel hub. In the same way, you need to remove the other front suspension strut, and then remove the struts from the rod.

When removing the bolts holding the ball joint to the steering knuckle, use a suitable socket wrench. Otherwise, you may damage the hinge protection case, which will result in unnecessary costs.

Do-it-yourself assembly of the front suspension of the VAZ 2114 is carried out in the reverse order. When installing the bracket, make sure that the threads of the bushings are not damaged. To do this, carry out all work carefully and do not allow longitudinal displacement of the cushions on the bar. This can happen when installing a stabilizer bar.

What affects the price of a part?

The rear beam for a VAZ 2114 car is sold in different places and the cost of such a part varies widely. The price level is influenced by the following factors:

- Quality.

- Originality.

- Sales region.

- Equipment (levers, torsion bars, etc.).

- Popularity of the manufacturer.

- The need for delivery and its cost.

- Place of purchase.

- Availability of guarantee.

- Seller rating and pricing policy.

- Condition of the part, degree of wear.

Determining the malfunction of the rear shock absorbers of the VAZ-2115

The role of shock absorbers in ensuring the safe operation of a car is often not taken into account by many, especially novice car enthusiasts. And this can lead to unpleasant and even tragic events. If the shock absorber fails, or even partially fails, the car wheel loses contact with the road.

And, as a result of this, the braking distance increases in case of emergency braking. When cornering, the stability of the car deteriorates, the chassis and tires are subject to greater load, which leads to their wear, and so on.

Types of spare parts

By manufacturer you can get a spare part for a VAZ 2114:

- Original (AvtoVAZ plant).

- Non-original (from another manufacturer).

Depending on the condition, the spare part may be:

- Used.

- New.

The part can be purchased:

- According to an advertisement from a private individual, the owner of a VAZ 2114.

- At the car dismantling point.

- In the online store.

- At the car market.

- In a specialty store.

According to the configuration, the beam can be:

- Naked.

- Assembled (complete with torsion bars, levers, hubs and drums).

By payment method you can buy a spare part:

- On credit.

- In installments.

- For personal savings.

You can take a car part from the following manufacturer for the VAZ 2114:

- JP GROUP.

- AvtoVAZ.

How to determine if a shock absorber is faulty

The first thing to do is conduct a visual inspection. Oil stains on the shock absorber itself, boot or rebound buffer warn that it needs to be replaced. Also, uneven tire wear may be an indication of problems with the rear suspension strut.

When driving at a speed of more than 80 kilometers, the car's handling noticeably deteriorates, the steering reacts late to road irregularities, and the car's swaying does not subside.

But the most reliable way is to inspect it at a specialized service station stand.

Approximate prices

A new original rear beam can be purchased in specialized stores for 4500-5000 rubles . The assembled part is sold for 5800-6000 rubles . A non-original new spare part can be purchased for 4000-7000 rubles .

A used rear beam manufactured by AvtoVAZ is sold through private advertisements for 1000-1500 rubles . The assembled part can be purchased for 2000-2490 rubles .

Sequence of work when replacing shock absorbers

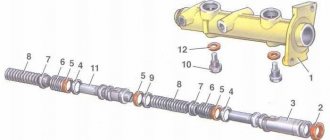

Before dismantling the VAZ-2115 rear shock absorber, you need to remove the plastic plug from the rear strut cup and unscrew the nut securing the rod. To do this, use a special key that simultaneously fixes the rod and unscrews the nut.

After removing the nut and washer with a rubber cushion, jack up the car and remove the rear wheel to gain access to the bottom of the rear strut mount.

Using a 19-mm open-end wrench, we fix the nut, and with a 19-mm socket, we unscrew the bolt, lubricating it with pre-penetrating lubricant, unscrewing and removing the bolt from the hole, and remove the rear shock absorber from its seat. To do this, it is better to use a flat-head screwdriver, carefully prying up the lower part. The strut body is moved to the side, lowered down and the shock absorber is removed.

We take out the remaining rubber gasket inside the glass with the same screwdriver. We disassemble the old shock absorber, removing the spring, rubber bushing, cup, casing, bump stop, and then install these parts in the opposite (reverse) order on the new strut.

When installing the spring in place, the last coil should be in such a position in the lower cup of the rear shock absorber that the end of the spring does not extend beyond the cup. And after the installation of the stand is completed, it should be directed towards the wheel. Before installing the shock absorber, it is recommended to immediately put on the upper elastic band and, so that it does not change its location, use insulating tape to attach it to the coils of the spring.

Upon completion of complete assembly, the rear strut is installed in the reverse order, the upper nut and the lower bolt securing it are tightened.

Source

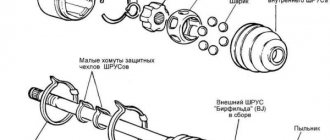

How does the ball joint change?

To do this, you need to remove the front wheel mounting bolts and hang part of the car on a jack. Next, the nut securing the ball element is unscrewed. The support pin is pressed out of the lever. Similar to the previous case, this is done using a puller. If there is none, do not unscrew the nut completely.

Also interesting: Chevrolet Niva pinouts. Wire diagrams

After this, the lever is moved to the side (with a pry bar), and the support is successfully pulled out. A working finger should not move with more than 0.8 millimeters of play in the support. Otherwise, it needs to be replaced, since there is a large output here. Before installing the dirt boot, it is recommended to coat the surface of the support with sealant.

Read news about the new Niva

- The modernized Lada Niva Legend (4x4) 2021 was shown on the Internet

- Lada 4×4 Bronto - sales stopped, new details » Lada.Online - all the most interesting and useful about LADA cars

- Description of the instrument panel Lada 4×4 (VAZ 2121, 2131) » Lada.Online - all the most interesting and useful about LADA cars

- Chevrolet Niva gasoline consumption per 100 km

- Buy LADA (VAZ) 2131 (4×4) 2022 in Rostov-on-Don, low price for Lada 2131 (4×4) 2022 on the Avto.ru website

- Fuses Niva 21214 injector «

- The new large Lada 4×4 Niva “Bigster” 2021-2022 based on the Dacia Bigster was shown for the first time. The SUV has changed beyond recognition

- New Niva Chevrolet Lux 2022 - review of GLC equipment

How does the node work?

The spring works at the same time with the shock absorber strut. These same elements provide support for the wheel and the entire car as a whole. The entire assembly is supported by suspension arms and braces. The entire system does not move in the longitudinal direction. This provides a set of levers that prevent longitudinal movement of the suspension. The steering wheels are used to set the drive wheels in motion.

There are eyes on the racks; tie rod ends are installed in them. With the help of a support bearing, which is mounted in the upper part, as well as a ball joint located in the lower arm, the rack moves around its axis. At the same time, the wheels turn and the car moves in the desired direction. The suspension has a stabilizer that links the two parts and allows them to work as synchronously as possible.

Suspension faults

It should be noted that car suspension repairs can be easily done on your own. The most vulnerable component is the shock absorber struts. They bear the maximum load, since the car is constantly experiencing dynamic forces that are transmitted from the wheels, especially when driving on uneven roads. Moreover, steering rods create lateral loads during turns. Shock absorber struts are the most expensive suspension components. But their reliability is quite high, so most often rubber seals and silent blocks fail, as well as tie rod ends, ball joints, and bearings. All those components that are included in the suspension device of the VAZ-2114.

If repairs have recently been carried out, it is possible that the threaded connections have become loose. Please note that car suspensions use nuts with plastic inserts on the threads. With their help, they are fixed to the bolt. When repairing the front and rear suspension, you must have not only a standard set of keys, but also the following tools:

- For tightening springs.

- Tie rod end remover.

- Puller for ball joints.

- When replacing a wheel bearing, an appropriate puller must be used.

Shock absorber

The shock absorber housing has a steering knuckle to which the tie rod end is attached. The front suspension also includes a hub to which the wheels are attached. At the bottom they are fixed to the suspension arm using a ball joint. To ensure that the drives rotate freely, bearings are used. And to stop the wheels, brake discs, calipers, and pads are used.

Using the bolts that secure the shock absorber strut to the hub knuckle, the camber angle of the wheels is adjusted. The lower arm has been installed on the stretcher. This stretcher has two edges; they are attached to the spar using brackets. A stabilizer is attached to one side of the stretch. Using this mechanism, the two sides of the suspension are connected. This is what the VAZ-2114 suspension consists of; there are no difficulties in the design.