03 February 2016 Lada.Online 91 641 1

Is the car jerking, loss of agility or the engine is difficult to start? One of the reasons for such malfunctions may be related to fuel pressure. Let's look at the instructions for measuring pressure in the fuel rail, as well as features that may arise during this activity.

Checking the fuel pressure is carried out similarly for all Lada cars (Granta, Kalina, Priora, Largus, Vesta, Niva 4x4 and XRAY), because All these models have the same type of engines.

Removing and disassembling the fuel module

We are carrying out work to replace the fuel level indicator sensor, fuel pressure regulator, strainer and fuel pump.

Relieve the pressure in the power system (see “Replacing the fuel filter”). Disconnect the wire terminal from the negative terminal of the battery. Inside the car, lift the rear seat cushion (see “Removing the rear seat”) and bend the sound insulation valve that closes the hatch cover in the floor of the body under the rear seat. Use a Phillips screwdriver to unscrew the two screws securing the hatch cover...

...and remove the cover. Lifting the wire harness block clamp...

...disconnect the block from the fuel module cover connector.

By pressing the spring clamp, disconnect the tip 1 of the tee from the fitting of the fuel module cover. By squeezing the clamps (in the direction of the arrows) of tip 2 of the fuel supply tube, disconnect the tip from the fitting of the fuel module cover.

Using a 10mm socket with an extension, unscrew the 8 nuts securing the pressure plate of the fuel module. Remove the spring washers and the ground wire from the tank neck studs.

Remove the pressure plate.

Carefully, trying not to damage the fuel level indicator sensor float, remove the fuel module from the tank. We drain the remaining fuel in the module into a previously prepared container.

If replacement is necessary, remove the ring plastic spacer.

Please note: when installing the spacer subsequently, its cut must coincide with the protrusion on the fuel module cover.

Remove the rubber sealing gasket. We close the hole in the fuel tank to prevent foreign objects from getting into it. We disassemble the fuel module on a workbench. If it is necessary to replace the o-rings of the fuel pressure regulator or the regulator itself...

...disconnect the tip of the ground wire from the terminal on the regulator body.

Using a screwdriver, remove the fuel pressure regulator mounting bracket.

Using pliers, remove the regulator from the module cover socket.

Remove the two rubber sealing rings of the regulator. Install the fuel pressure regulator in reverse order. We replace the regulator O-rings with new ones. Before installing the regulator O-rings, apply a thin layer of engine oil to the O-rings. To replace the fuel gauge sensor or fuel pump, the fuel pressure regulator does not need to be removed. From the inside of the module cover...

...use a screwdriver to press out the fixing plate of the common wire block...

...and disconnect the wire block from the cover connector. By pressing the latch...

...disconnect the wire block from the fuel pump. To remove the fuel level sensor...

...we release the two sensor latches...

...and move the sensor along the grooves of the housing towards the cover.

Remove the fuel level indicator sensor with wire blocks. Install the fuel level indicator sensor in the reverse order. When replacing the fuel pump, it is better to remove the fuel level sensor to avoid damaging it.

Use a screwdriver to pry up the drain tube... ...and disconnect it from the module body.

There is a retaining ring located in the groove of one of the guide posts of the module cover. We remove it by prying it with the blade of a slotted screwdriver.

By pressing the four latches of the pump holder...

...remove the fuel module cover assembly with the holder and the fuel pump.

Remove the spring from the guide post of the cover.

...remove the strainer.

Remove the lock washer from the slot in the strainer housing.

Using a screwdriver, press out the plastic latch of the holder...

...and use your finger to push the fuel pump out of the holder. We heat the plastic corrugated tube on the pump nozzle over a container of boiling water...

...and remove the tube from the pump connection. The car is equipped with a BOSCH fuel pump 0580454035.

A valve is installed in the fuel module housing to prevent fuel from leaking out of the housing. We assemble and install the fuel module in the reverse order. When installing the strainer, pay attention to the condition of the lock washer; if it is dented, it must be straightened or replaced. When installing the fuel module into the tank...

...arrow 1 on the fuel module cover should be directed backwards (towards the trunk). Arrows 2 on the fittings of the fuel module cover indicate the direction of fuel movement. We put the tips of the tee and the fuel pipe onto the fittings of the module cover until the latches click. Before closing the hatch cover in the floor of the body under the rear seat, it is necessary to check the tightness of the fuel module connections. To do this, connect the wire terminal to the “negative” terminal of the battery and turn on the ignition.

FakeHeader

Comments 28

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

Thanks, I'll take a look today

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

Do you have a photo? I don’t understand, we have an absorber under the hood and only the hose from it goes to the tank

Do not confuse the adsorber with the separator.

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

To prevent this from happening, you need to install fender liners!

:))))) God forbid, advise some grandfather. It must be assembled on the assembly line as expected and this will not happen

fender liners without screws novline, I installed these and everything is good! There seems to be information about them on the drive too, I advise you to look!

For some reason I am not a supporter of these mud collectors.

Rdt. When the gas is released, the pressure should not fall below 3.8 by 4 points. The RTD releases the pressure, and when the engine is stopped, the pressure in the fuel rail should not drop sharply to 0. It should remain at 2-2.5-3 bar (with the internal combustion engine not running)!

did you change the fuel filter?

Change the gas station, did you change the fuel too? check adsorber electromagnetic sensor

I changed the gas station, the same fuel (in the tank and fine cleaning)

it means the star is coming to the catalyst

Kats cut out, firmware for Euro2

DMRV means))) damn there are a lot of reasons for “being held by the ass”!

The pressure was restored, another pump was replaced, the reason “does not work” was the licked key of the kv star, the damper was loose and gave incorrect readings

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

The RTD on the Priora releases pressure above 4 atm, right?

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

It’s impossible to find a diagnostician during the day, they’ll charge 2k for checking (whether they’ll find it or not is unknown)

My friend lives in Surgut. Also a diagnostician. Has scanners and programs. If it is not very far from you, I recommend it. He won’t take extra, and he won’t take money for unresolved problems.

If I find anything here, in the rage I might roll it to Surgut

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

Before changing the RTD, you should check the BN; it breaks 15 times more often than the RTD. You need to measure the fuel pressure head-on, directly. It should be at least 7-8 atm. If this is the case, the RTD is changed (if the corrugated hoses in the module are in good working order and there are no leaks) If the pressure is 1 11 m

Is the car jerking, loss of agility or the engine is difficult to start? One of the reasons for such malfunctions may be related to fuel pressure. Let's look at the instructions for measuring pressure in the fuel rail, as well as features that may arise during this activity.

Checking the fuel pressure is carried out similarly for all Lada cars (Granta, Kalina, Priora, Largus, Vesta, Niva 4x4 and XRAY), because All these models have the same type of engines.

Signs of a malfunctioning fuel pressure regulator

The fuel system of a modern car is a complex mechanism consisting of many parts and is one of the main systems. The fuel system contains many moving parts, one of which is the fuel pressure regulator. The flow of gasoline into the combustion chamber requires constant maintenance of a certain pressure, so this operation requires a special unit that is connected to both the combustion chamber (injectors) and the fuel system (via a valve).

However, over time, with constant and long-term operation of this unit, certain problems arise in the form of malfunctions, which can lead to certain problems in operation.

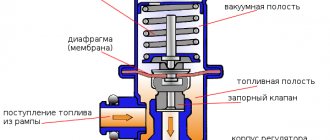

Components

This part consists of several main elements:

- Diaphragm valve is the main part of the regulator and is connected to the fuel supply system and combustion chamber (injector rail). In most domestic models (such as VAZ 2115, 2110, 2114 and Lada Priora) this unit is presented in a similar configuration, since the fuel supply systems of front-wheel drive vehicles of this family have a similar design. Therefore, the quality of breakdowns for these machines is similar;

- Pipes connected to the valves and combustion chamber on one side and, through other valves, to the fuel line on the other. The device in the VAZ 2107 models is somewhat different due to an older and unreliable design. When using equipment for rear-wheel drive, old components of an outdated design are used (the valve may work unstable when operating in a carburetor engine and the wrong choice of fuel mixture enrichment) so its design is somewhat different, although problems arise.

How to choose a good quality fuel filter for Lada Priora?

When purchasing, you need to rely on the markings on the filter. This will help eliminate the problem of purchasing an item that does not match the parameters and type of connection.

Many motorists are interested in what kind of fuel filter is installed on the Priora and whether it is necessary to buy its analogue. The standard cleaner is Salut, but it can be replaced with another domestic or foreign consumable.

Most Priora drivers prefer products from BIG and SCT companies. They are distinguished by high cleaning quality and affordable cost.

The gasoline filter from Mann was well noted for the Lada Priora. But its price category is much higher and not every owner of domestic transport will be able to purchase the product. And, despite excellent reviews, the element will have to be changed according to the recommended mileage.

The Priora gasoline filter from MAHLE is distinguished by good quality lint-free inner paper. The price of the consumable is high, but it guarantees reliable operation of the car throughout the entire period of use. The domestic cleaner Nevsky attracted buyers with its low price. If worn-out elements were correctly replaced, there were no complaints about its operation.

After choosing a purifier, you need to take into account the specifics of its installation. First you need to find out how to change the fuel filter on a Priora carefully and quickly. Then you can begin repairs and restore your car. A mandatory step will be to check the correct installation.

Source

Failure

The design of this unit is quite simple to operate, but the valve can also fail.

This will entail certain negative consequences and the main signs will be:

- Increased fuel consumption due to partial failure of the element . When the valve unstably performs its functionality, the pressure in the rail and the fuel system drops, there is an excess supply of gasoline to the combustion chambers, which causes significant fuel consumption. This also entails, in addition to increased gasoline consumption, increased wear of the element, which will ultimately lead to complete failure of the part;

- Unstable engine operation at idle speed . If the fuel supply is poor, the engine cannot reach its optimal level of operation, so the idle air regulator operates unstably. If there is insufficient pressure and the fuel pressure regulator fails, its supply either stops or fuel flows freely through the system. This can also cause the engine to start poorly, which requires increasing the load on the starter, also causing wear. This effect manifests itself during mechanical wear of the valve, when the failure of one part of it ensures poor pressure balancing between the fuel and air;

- The crankshaft cannot maintain a constant speed level. This effect is dangerous because this malfunction can involve many elements of the system, and the malfunction of this regulator is an indirect cause of such a breakdown. Unstable operation of the crankshaft not only disorganizes the driver, but also reduces engine life (albeit slightly);

- Deterioration of engine power qualities . If the fuel supply is poor, the engine cannot fully realize its potential when moving, so its performance decreases. This causes a deterioration in the dynamic qualities of the motor and affects its service life;

The video shows signs of a malfunctioning fuel pressure regulator:

Tips for motorists

Interruptions in the operation of the engine of the VAZ-2118 Lada Kalina passenger car become very noticeable in idle mode (the engine jerks), as well as when trying to quickly gain speed (the engine does not pull). There are many reasons why an engine may start to work like this. They can be connected both to ignition and power systems, and to gas distribution and crank mechanisms.

It is unlikely that it will be possible to determine immediately what caused the interruptions in engine operation. Therefore, according to the established driving tradition, the search for such a malfunction begins with checking the spark plugs and high-voltage wires. Initially, they check the reliability of the fit of the tips of the high-voltage wires on the spark plugs, and the breakdown of the high-voltage wire to ground is very clearly visible in the dark, naturally with the engine running.

If everything is in order with the high-voltage wires, then you will have to unscrew the spark plugs one by one and check them for the presence of a spark between the central and side electrodes. You need to start this work with a well-warmed-up engine, this will make it easier for you to remove the spark plugs from the cylinder head. Be sure to use a feeler gauge to check and, if necessary, adjust the gap between the electrodes, since an increased gap can lead to misfiring when the engine is running.

Also pay attention to the color of the central electrode insulator, because if there is black carbon on it, the spark plug will not work normally

The engine will operate intermittently in the event of a malfunction in the power system associated with the failure of one of the injectors to inject fuel into the combustion chamber or the pressure in the rail drops below the required level. Considering that the injectors on the Lada Kalina are electromagnetic, and if with the engine running you begin to de-energize their solenoid valve one by one, then by the changed nature of the engine operation you can find a faulty injector. A decrease in pressure in the fuel rail is possible either due to a malfunction of the pressure regulator, or is associated with a malfunction of the fuel pump. But in order to determine this you will need a pressure gauge.

Malfunctions of the gas distribution and crank mechanisms can lead to a drop in compression in one of the engine cylinders. This may be due to leaky valves, as well as breakage or coking of the compression rings.

Due to the fact that the operation of the injection engine is controlled by a controller, and it is located under the interior heater radiator, if it is not sealed, antifreeze begins to drip onto the controller body and if moisture gets inside, malfunctions may occur in its operation, leading to unstable operation engine.

The car became unstable. Although when you start it, it runs normally at high speeds, as soon as it warms up it starts to twitch, not that it shakes, but it’s really noticeable, the steering wheel is already shaking from vibrations. In addition, the engine lost some traction, not much, but noticeably. The check does not light up.

I did the following: - Replaced the spark plugs and Armored wires, also threw in another coil. - Replaced the mass air flow sensor (the old one was dead) - replaced the IAC and TPS and cleaned the throttle (during disassembly I saw a small axial play of the flap, tightened it, I don’t know if it could be from it such an effect?) -Replaced the fuel pump, mesh and filter, as well as the RTD. -I went for diagnostics, there were no errors, the indicators were normal, the mixture in the lambda was a little lean. As a result, I cleaned the lambda. I also tried to drive without a lambda, the check did not light up and there was no difference. — Compression is 13 everywhere (maybe valves? Although the previous owner says that he recently adjusted them) — We also checked the receiver for air leaks — Replaced the DPKV — I looked at the marks on the timing belt It seems to be in place, but there is no mark on the flywheel, I installed it using the old-fashioned method, by unscrewing the spark plug and finding TDC. DPKV hits the 20th tooth. But when the camshaft gear is shifted by 1-2 teeth in both directions, there is practically no difference in the operation of the engine.

The crankshaft pulley also moves a little (+-1 mm), although it has always been like this and it did not affect the operation.

Fuel pressure regulator: diagnostics, repair, replacement

Modern cars are equipped with electronic fuel pumps; mechanical ones are found only in cars manufactured before 2000. The task of this component is to ensure an uninterrupted supply of fuel. Everything functions well at high engine speeds, but problems arise when moving to low and idle speeds. Increased pressure damages fuel supply hoses and other system components. The fuel pressure regulator protects against such consequences. If there are malfunctions in it, this can be determined by several signs.

Design and operating principle

The regulator (RTD) consists of a housing, a valve, a diaphragm and a spring, which are located on the fuel rail, in the fuel return hose of the power supply system, or directly in the tank (if the car does not have a recirculation system). The purpose of the product is to send excess fuel back to the tank. When the engine speed increases, the resulting vacuum opens the valve slightly, and the excess returns to the tank.

Location of the fuel pressure regulator in the fuel supply system

Replacing the fuel hose on a Priora

"Attention. The vehicle's fuel system is under pressure even when the vehicle's ignition is turned off (residual pressure remains)

Therefore, before carrying out work related to maintenance or repair of the fuel system, it is necessary to relieve the pressure!”

Now let's look at how to change the fuel hose on a Lada Priora. In order to dismantle the product you will need:

- The first, preparatory stage of the work will be releasing pressure. To do this you will need to remove the rear seat. Unscrew the fastening points of the metal hatch and remove it. Unplug the power plug from the fuel pump connector.

- Move into the car interior. Start the engine and let it run until all the fuel runs out and it stalls.

- After that, try to restart the engine, allowing the starter to operate for 3.4 seconds.

- Open the hood. Find the fuel hose.

- Now we need to find the connection point between our hose and the inlet metal tube, which enters the engine compartment from under the bottom of the car. Next, you need to press on the special plastic fastener and, holding it in this position, pull the hose in the opposite direction.

- To disconnect the second end, you will need to find the metal tube connected to the fuel rail. In this case, the connecting fastening is different from that indicated in the previous step. You will need a 10mm wrench, with which you will need to unscrew the special fastening nut.

- When installing a working product, do not forget to install new o-rings, which serve to seal the connecting points. It is prohibited to use old rings, and install new ones only when the ambient temperature is above zero.

Measures to extend service life

Fuel hoses of the Lada Priora, as on other cars, are exposed to various negative conditions (friction, bends, temperature changes). To extend their performance characteristics, it is recommended:

- carry out periodic inspection;

- place the product subject to increased friction in a protective corrugation.

With timely diagnostics and replacement of components and components, you will avoid fuel fires and other negative consequences.

Signs and Symptoms of a Malfunctioning Fuel Pressure Regulator

- the engine stalls at idle;

- engine power is greatly reduced;

- when accelerating, it is not possible to achieve normal dynamics;

- the car reacts poorly to pressing the gas pedal;

- fuel consumption suddenly increases greatly;

- the amount of carbon dioxide emissions increases;

- the crankshaft rotation speed changes.

All these problems arise due to the fact that the regulator becomes clogged or completely clogged over time. Another common cause of failure is weakening of the spring, leading to a strong decrease in pressure. In the absence of normal pressure, fuel supply decreases, power decreases and controllability deteriorates. Such problems are especially common on Ladas - Kalina and Priora, as well as on cars of the 2110, 2112, 2114, 2115 series.

To check the part, you need to carefully inspect it itself, the vacuum hose and all connections. Any leaks found must be corrected. It is also recommended to check the membrane. Disconnect the tube that goes from the RTD to the receiver and shake it. If no gasoline comes out from inside and there is no strong odor, then the membrane is in order.

RTD in diesel engines

Diesel vehicles running on the Common Rail system are also equipped with a pressure regulator. It fits into the fuel rail or is located on the high pressure fuel pump housing. The principle of operation is approximately the same. A special valve diverts unused fuel into the return line, preventing excessive loading.

FakeHeader

Comments 28

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

Thanks, I'll take a look today

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

Do you have a photo? I don’t understand, we have an absorber under the hood and only the hose from it goes to the tank

Do not confuse the adsorber with the separator.

Look in the rear left arch, there is a separator tank, there is a valve on top of it inserted through an elastic band. This valve flew out, and I washed the rust and sand fuel system three times until I accidentally discovered a valve dangling in the arch and a hole from it in the separator tank, everything that was on the road flew into it

To prevent this from happening, you need to install fender liners!

:))))) God forbid, advise some grandfather. It must be assembled on the assembly line as expected and this will not happen

fender liners without screws novline, I installed these and everything is good! There seems to be information about them on the drive too, I advise you to look!

For some reason I am not a supporter of these mud collectors.

Rdt. When the gas is released, the pressure should not fall below 3.8 by 4 points. The RTD releases the pressure, and when the engine is stopped, the pressure in the fuel rail should not drop sharply to 0. It should remain at 2-2.5-3 bar (with the internal combustion engine not running)!

did you change the fuel filter?

Change the gas station, did you change the fuel too? check adsorber electromagnetic sensor

I changed the gas station, the same fuel (in the tank and fine cleaning)

it means the star is coming to the catalyst

Kats cut out, firmware for Euro2

DMRV means))) damn there are a lot of reasons for “being held by the ass”!

The pressure was restored, another pump was replaced, the reason “does not work” was the licked key of the kv star, the damper was loose and gave incorrect readings

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

The RTD on the Priora releases pressure above 4 atm, right?

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

It’s impossible to find a diagnostician during the day, they’ll charge 2k for checking (whether they’ll find it or not is unknown)

My friend lives in Surgut. Also a diagnostician. Has scanners and programs. If it is not very far from you, I recommend it. He won’t take extra, and he won’t take money for unresolved problems.

If I find anything here, in the rage I might roll it to Surgut

Change the RTD... The pressure should be 3.8 But in general, before changing anything, you need to do diagnostics and not mindlessly change everything from one extreme to another

Before changing the RTD, you should check the BN; it breaks 15 times more often than the RTD. You need to measure the fuel pressure head-on, directly. It should be at least 7-8 atm. If this is the case, the RTD is changed (if the corrugated hoses in the module are in good working order and there are no leaks) If the pressure is 1 11 m

Is the car jerking, loss of agility or the engine is difficult to start? One of the reasons for such malfunctions may be related to fuel pressure. Let's look at the instructions for measuring pressure in the fuel rail, as well as features that may arise during this activity.

Checking the fuel pressure is carried out similarly for all Lada cars (Granta, Kalina, Priora, Largus, Vesta, Niva 4x4 and XRAY), because All these models have the same type of engines.

How to check on VAZ and foreign cars

To determine a breakdown, the following procedures are performed:

- The fitting plug is unscrewed - the element that controls the fuel pressure.

- The O-ring is inspected - if it is damaged, this component must be replaced.

- The spool is removed from the fitting.

- The engine starts, the pressure in the regulator is measured with a pressure gauge.

- The information received is compared with that specified by the manufacturer.

You can check the performance of the RTD yourself, even without tools. To do this, just pinch or disconnect the valve and study the intensity of the stream. A pressure gauge will give a more accurate result. It should be connected between the fitting and the fuel hose, having first disconnected the vacuum hose. The measurement is taken at idle speed. The information obtained depends on the car model - for example, in a VAZ 2110, the pressure indicator should start at 0.3 and gradually increase to 0.7 Bar.

Fuel pressure regulator with connected pressure gauge

Has your blood pressure changed? You may have connected the pressure gauge incorrectly. Check the connection. If everything is correct, it means the regulator has become unusable.

Where is the fuel pressure regulator located and how does it work (video)

What are the consequences of malfunctions in the operation of RDTs?

Over time, the engine starts more and more poorly. Fuel begins to come out of the cracks, which leads to a strong increase in its consumption. When the pressure changes unevenly, the dynamics of movement are disrupted, surges occur, and the car jerks during acceleration.

Is it possible to repair a failed part? In most cases, no, you have to completely change it. Repair units are almost always non-separable. Some experts suggest repairing the component, but this is dangerous. It is better to buy a new regulator - fortunately, it is inexpensive.

Determining violations in the operation of RTDs is not a very difficult task, which can be handled independently. Remember that this part of the machine needs to be checked periodically. By detecting the problem in time, you will protect important car components from rapid wear.

Signs of a malfunctioning fuel pressure regulator

Every engine fuel system contains a fuel pump. Electric fuel pumps have recently been installed in gasoline engines; mechanical models are already outdated and are no longer used on modern vehicles. Mechanical fuel pumps live out their days on cars produced in the last century.

The performance of the electric fuel pump must be such as to ensure uninterrupted fuel supply at any engine speed and under any load. But what to do when the engine is running at idle or low speed, and a small portion of fuel is required? After all, the pressure that is created in the engine power system for heavy loads will be excessive at idle speed. And excess pressure can lead to disastrous results - breakage of fuel hoses or other damage. For normal operation of the fuel system, there is a fuel pressure regulator.

Resetting pressure in the Priora fuel system

A device such as the fuel pump in LADA Priora always maintains the required pressure in the system. When the car is already in the pit, this very pressure needs to be released, otherwise fuel will spill.

Replacing the filter with a new one in Lada Priora

So, you know where the element that needs replacement is located, first place a container under it. On one side, squeeze the plastic clamp, and on the other hand, press the spring clamp and remove the tubes from the fittings. Handle the plastic retainer carefully; this product is very fragile. If fuel does not flow, then the container can be removed. Using a wrench, loosen the clamp bolt holding the filter to the bracket and remove the contaminated element. Look at the condition of the rubber O-rings located at the tips of the fuel pipes. If the rubber is torn or cracked, the rings must also be replaced. The ring itself is located quite deep in the tip. When removing the ring, the plastic of the retainer may break. In this case, you will need to replace the entire fuel pipe. Install the filter in the reverse order of removal.

It is important to make sure that the arrow on the body coincides with the direction of movement of the fuel. Carefully tighten the clamp nut. Place the fuel hoses on the filter fittings, making sure that the clamps on the protrusions snap into place. Checking functionality Place the container under the new filter again. At this stage, turn on the ignition of the LADA Priora and wait for the electric gasoline pump to raise the pressure in the system. Start the power unit. Inspect everything carefully for tightness of connections.

If fuel drips anywhere, it is solely due to the O-rings. Still, it is extremely difficult to determine the defect of these rubber seals by eye. Under no circumstances should fuel leak. And if it appears, then everything needs to be disassembled and the rings replaced, and if necessary, then the fuel pipes along with the tips too.

What is a fuel pressure regulator?

The fuel pressure regulator (FPR) is a vacuum valve that transfers excess fuel through a return hose into the fuel tank. The RTD is a housing that contains a valve, a membrane and a spring. There are also three terminals in the housing: two terminals for the passage of fuel through the regulator, the third is connected to the intake manifold. As engine speed increases, the vacuum created in the manifold (at the third terminal) overcomes the force of the spring and moves the membrane, thereby opening the valve slightly. Excess fuel gets access to the second outlet and goes back to the gas tank. An RTD is often also called a check valve.

As a rule, the check valve is located on the fuel rail; it can also be embedded in the fuel return hose of the power supply system.

Causes of fuel pressure regulator malfunctions

RDT may fail for several reasons. For example, defective parts are found on Russian-made cars. There are significantly fewer defects on foreign models, but you can purchase a defective RTD by purchasing a non-original spare part.

Mostly the check valve breaks down due to natural aging. Let's say this can happen after a hundred thousand mileage or more. It should be noted that check valve failures are not common. Most often, in an RTD, the membrane dries out over time, less often the valve jams, and even less often the spring breaks or weakens.

Sensor failure may occur due to low-quality gasoline. For example, in winter, fuel was filled with water, and water got into the regulator. If the fuel filter is not replaced on time, dirt gets into the parts of the power system, including the regulator. In this case, the RTD valve most often jams. It’s hard to imagine what could happen to the spring, but apparently, it still breaks sometimes.

Characteristic symptoms of fuel pressure regulator malfunctions

By what signs can you determine that an RDT is not working:

- the engine is very difficult to start, you need to turn the starter for a long time and at the same time keep the gas pedal pressed in order for the engine to start;

- The engine idles unsteadily or the speed is very low, the engine often stalls. At the same time, it does not gain power at all; when trying to accelerate, it results in a deep failure;

- The spam engine changes speed sharply, this is especially noticeable at idle:

- Fuel is leaking from the fuel hoses. Attempts to tighten and replace clamps and replace hoses do not help.

How to check the fuel pressure regulator for serviceability

The fuel pressure regulator is not an electrical sensor and cannot be checked using instruments. It should also be taken into account that the RDT cannot be disassembled or repaired. Someone writes that the fuel check valve can be repaired. I would like to see what it looks like and where you can buy a repair kit. Typically, RTDs are inexpensive, and even for that reason they would not be worth repairing if they were repairable.

WHAT MAY INDICATE PROBLEMS WITH THE SENSOR

For some reason, the developers did not program into the motor control unit a check function and error messages when this device fails. Therefore, to determine problems with px, only external manifestations in the behavior of the car’s engine are applicable. You can observe the following behavior of the power unit:

- The appearance of floating engine speed;

- Stopping the engine while the vehicle is moving;

- Engine failure when driving in neutral gear.

When diagnosing, it is also necessary to take into account the fact that such “symptoms” of the disease also belong to some other sensors of the power unit.

Also sometimes there are increased idle speeds. This device may also be to blame. High idle speeds can be caused by an “extra” amount of working mixture when the cone needle does not completely fit into its seat. The reasons for this phenomenon may be the formation of carbon deposits or the entry of foreign small particles into the air flow. You can find out what speed the VAZ 2114 should be at idle from the machine’s operating instructions. It is recommended to set the idle speed to 750-800 rpm.

Signs of a malfunctioning fuel pressure regulator

The fuel system of a modern car is a complex mechanism consisting of many parts and is one of the main systems. The fuel system contains many moving parts, one of which is the fuel pressure regulator. The flow of gasoline into the combustion chamber requires constant maintenance of a certain pressure, so this operation requires a special unit that is connected to both the combustion chamber (injectors) and the fuel system (via a valve).

However, over time, with constant and long-term operation of this unit, certain problems arise in the form of malfunctions, which can lead to certain problems in operation.

Components

This part consists of several main elements:

- The diaphragm valve is the main part of the regulator and is connected to the fuel supply system and the combustion chamber (injector rail). In most domestic models (such as VAZ 2115, 2110, 2114 and Lada Priora) this unit is presented in a similar configuration, since the fuel supply systems of front-wheel drive vehicles of this family have a similar design. Therefore, the quality of breakdowns for these machines is similar;

- Pipes connected to the valves and combustion chamber on one side and, through other valves, to the fuel line on the other. The device in the VAZ 2107 models is somewhat different due to an older and unreliable design. When using equipment for rear-wheel drive, old components of an outdated design are used (the valve may work unstable when operating in a carburetor engine and the wrong choice of fuel mixture enrichment) so its design is somewhat different, although problems arise.

Failure

The design of this unit is quite simple to operate, but the valve can also fail.

This will entail certain negative consequences and the main signs will be:

- Increased fuel consumption due to partial failure of the element . When the valve unstably performs its functionality, the pressure in the rail and the fuel system drops, there is an excess supply of gasoline to the combustion chambers, which causes significant fuel consumption. This also entails, in addition to increased gasoline consumption, increased wear of the element, which will ultimately lead to complete failure of the part;

- Unstable engine operation at idle speed . If the fuel supply is poor, the engine cannot reach its optimal level of operation, so the idle air regulator operates unstably. If there is insufficient pressure and the fuel pressure regulator fails, its supply either stops or fuel flows freely through the system. This can also cause the engine to start poorly, which requires increasing the load on the starter, also causing wear. This effect manifests itself during mechanical wear of the valve, when the failure of one part of it ensures poor pressure balancing between the fuel and air;

- The crankshaft cannot maintain a constant speed level. This effect is dangerous because this malfunction can involve many elements of the system, and the malfunction of this regulator is an indirect cause of such a breakdown. Unstable operation of the crankshaft not only disorganizes the driver, but also reduces engine life (albeit slightly);

- Deterioration of engine power qualities . If the fuel supply is poor, the engine cannot fully realize its potential when moving, so its performance decreases. This causes a deterioration in the dynamic qualities of the motor and affects its service life;

The video shows signs of a malfunctioning fuel pressure regulator:

Installing a new sensor

Before removing, be sure to relieve the fuel pressure in the rail.

To do this, turn off the power to the fuel pump and start the engine. Or carefully unscrew the spool valve from the fitting in the ramp (this option will be more suitable if the internal combustion engine does not start at all). Next, you work according to this scheme: Disconnect the negative terminal from the battery. Disconnect the hose from the vacuum valve of the VAZ 2114. Unscrew the nuts and drain the gasoline. Please note that there may still be gasoline under pressure in the fuel system

Therefore, take precautions. Fix the tube and washer. Unscrew the bolt screwed into the clamping element. Remove the clamping element. Unscrew the nut that holds the drain hose and pressure sensor. Remove the bolts connecting the fuel rail to the pressure sensor. Dismantle the pressure regulator in the system. Install a new device in the reverse order.

As you can see, there is nothing complicated. The main thing in repair is to imagine what this or that element of the system is responsible for. And then you can quickly give an accurate diagnosis based on the signs

Install the new device in the reverse order. As you can see, there is nothing complicated. The main thing in repair is to imagine what this or that element of the system is responsible for. And then you can quickly give an accurate diagnosis based on the signs.

Sport fuel pressure regulator

The fuel pressure regulator VAZ 2110 2114 2112 2115 is used to maintain a continuous pressure difference across the injectors. When the pressure in the intake pipe increases, the pressure regulator increases the fuel pressure, thereby compensating for changes in engine load, and when the pressure in the pipe decreases, it lowers the fuel pressure and drains the excess back into the tank through the valve.

Fuel pressure regulator VAZ 2110 2114 2112 2115

A faulty fuel pressure regulator VAZ 2110 2114 2112 2115 can lead to engine damage, so you should be very careful about this important component of the car. The following signs indicate that the fuel pressure regulator requires repair or replacement:

The following signs indicate that the fuel pressure regulator requires repair or replacement:

• the engine of VAZ 2114, VAZ 2115, VAZ 2110, VAZ 2112 began to run unsteadily and unevenly;

• idling also causes a lot of problems - the engine constantly stalls, in addition, the crankshaft also behaves strangely - it rotates at an increased or decreased frequency (also at idle);

• the engine power of these models of VAZ cars decreases sharply, it does not “pull” as before, but begins to “freak out” during acceleration, and warms up more slowly, the movement becomes uneven, dips, jerks and other inadequacies appear;

• fuel consumption for both the VAZ 2110 2112 and the VAZ 2114 2115 is growing every day, just like the amount of exhaust vapors and fuel combustion products emitted into the atmosphere.

Checking the fuel pressure regulator on a VAZ 2114 2115 2110 2112 is not difficult, provided that you have the necessary tools, even a beginner can do it on their own. To do this, you will need a pair of keys (a 5-point hex and a 24-point regular wrench), you also need a pressure gauge, you can take a tire gauge.

If the pressure check did not show any deviations from the norm, then the problem is not in the fuel pressure regulator, but in another component of the VAZ car. Note: normal pressure is considered to be 284–325 kPa when the engine is running and plus 20–70 kPa when the vacuum hose is disconnected from the pressure regulator.