Disk mass limit for products made from different alloys, using different methods and having different designs.

Data are expressed in pounds (lib).

Disc weight 13×4.5

| Discs | m (kg) | m(lib) | Parameter | By brand |

| 13×4.5 | 4.72 (kg) | 10.41 (lib) | Cast | RS Watanabe EightSpoke F8F |

Caution: due to the fact that different types of disks from different manufacturers can be installed on a car, the above data are averages; actual values for a particular car may differ by 15% in one direction or the other.

A car disk is, in fact, a wheel, its base, which bears the entire weight of the car. Disks are divided into two groups: steel and light alloys.

Steel wheels weigh more, but are much stronger than cast alloy wheels, while forged alloy wheels are stronger than steel wheels and lighter than cast wheels.

For example, for a BMW 7, a steel wheel weighs 9 kg, a cast aluminum wheel weighs 7.8 kg, and a forged aluminum wheel weighs 6.8 kg.

Discs come in different diameters: from 10 to 23 inches. For cars, wheels with a diameter of 13 to 16 inches are mainly used, from 10 to 13 - for ATVs and mopeds, above 16 - for tractors and special equipment.

Weight readings vary depending on the manufacturer and width, the table shows the average values:

| Disc diameter | Weight of one disc in kilograms |

| Steel disc (stamped) | |

| 12 inches (R12) | 4,5 |

| 13 inches (R13) | 5,2 |

| 14 inches (R14) | 6,3 |

| 15 inches (R15) | 7,4 |

| 16 inches (R16) | 8,5 |

| 17 inches (R17) | 12,1 |

| Cast light alloy | |

| 10 inches (R10) | 2,5 |

| 11 inches (R11) | 3,3 |

| 12 inches (R12) | 3,9 |

| 13 inches (R13) | 4,5 |

| 14 inches (R14) | 5,6 |

| 15 inches (R15) | 6,9 |

| 16 inches (R16) | 7,8 |

| 17 inches (R17) | 8,5 |

| 18 inches (R18) | 9,4 |

| 19 inches (R19) | 10,8 |

| Forged alloy | |

| 14 inches (R14) | 4,8 |

| 15 inches (R15) | 5,8 |

| 16 inches (R16) | 6,6 |

| 17 inches (R17) | 7,4 |

| 18 inches (R18) | 8,2 |

| 19 inches (R19) | 9,1 |

| 20 inches (R20) | 10,2 |

From time to time, manufacturers try to break the record for lightness of wheels, since the speed of the car depends on this.

OZ Racing, , R17 6.25, . , 3.

Weight of alloy wheels R12-R23

| Disc diameter | Volume 1pc (m3) | Weight 1pcs (kg) | Volume 4pcs (m3) | Weight 4pcs (kg) |

| 12 | 0.03 | 5.5 | 0.10 | 22 |

| 13 | 0.03 | 6.0 | 0.12 | 24 |

| 14 | 0.04 | 6.5 | 0.14 | 26 |

| 15 | 0.05 | 8.0 | 0.18 | 32 |

| 16 | 0.06 | 9.5 | 0.24 | 38 |

| 17 | 0.075 | 11.5 | 0.30 | 46 |

| 18 | 0.09 | 13.0 | 0.36 | 52 |

| 19 | 0.10 | 15.5 | 0.42 | 62 |

| 20 | 0.12 | 17.0 | 0.49 | 68 |

| 21 | 0.16 | 19.5 | 0.62 | 78 |

| 22 | 0.18 | 23.0 | 0.72 | 92 |

| 23 | 0.21 | 27.0 * | 0.84 | 108 |

* 27 kg is the maximum weight of wheels with a diameter of 23 inches that was found in our catalogs. The weight range of discs of this diameter is very large, from 18 to 27 kg. The weight of R14, R15 and R16 wheels does not differ as much between different manufacturers and models as for wheels with larger diameters, for example, R17, R18, R19, etc.

Attention!

All contents of this site are protected by intellectual property legislation (Rospatent, registration certificate No. 2006612529). Installing a hyperlink to site materials is not considered a violation of rights and does not require approval. Legal support of the site - legal..

ATTENTION!

The exact parameters of such a product are difficult to determine, since each manufacturer uses its own types of raw materials in the manufacture of discs and its own design solutions.

A more significant difference between the estimated and actual parameters is observed for disks with a larger diameter. This is due to the fact that manufacturers use their own unique technologies and different stylistic options.

When determining the cost of transportation, transport companies prefer to base themselves not on the weight of the disks (table below), but on their dimensions (volumes). Such a calculation is more profitable for them. This applies to all types of wheels.

If you need to determine the volume and weight of your tires, go to the Tire Weight section. To calculate the external parameters of the wheel, use a calculator.

?

, , , , . : .

, , .

, W 7 9 , – 7.8 , – 6.8 .

: 10 23 . 13 16 , 10 13 , 16 .

, :

| () | |

| 12 (R12) | 4,5 |

| 13 (R13) | 5,2 |

| 14 (R14) | 6,3 |

| 15 (R15) | 7,4 |

| 16 (R16) | 8,5 |

| 17 (R17) | 12,1 |

| 10 (R10) | 2,5 |

| 11 (R11) | 3,3 |

| 12 (R12) | 3,9 |

| 13 (R13) | 4,5 |

| 14 (R14) | 5,6 |

| 15 (R15) | 6,9 |

| 16 (R16) | 7,8 |

| 17 (R17) | 8,5 |

| 18 (R18) | 9,4 |

| 19 (R19) | 10,8 |

| 14 (R14) | 4,8 |

| 15 (R15) | 5,8 |

| 16 (R16) | 6,6 |

| 17 (R17) | 7,4 |

| 18 (R18) | 8,2 |

| 19 (R19) | 9,1 |

| 20 (R20) | 10,2 |

, .

OZ Racing, R17 6,25 , . , 3 .

How much does a car wheel weigh?

A car disk is, in fact, a wheel, its base, which bears the entire weight of the car. Disks are divided into two groups: steel and light alloys .

Steel wheels weigh more , but are much stronger than cast alloy wheels, while forged alloy wheels are stronger than steel wheels and lighter than cast wheels .

Discs come in different diameters: from 10 to 23 inches. For cars, wheels with a diameter of 13 to 16 inches are mainly used, from 10 to 13 - for ATVs and mopeds, above 16 - for tractors and special equipment.

Weight readings vary depending on the manufacturer and width, the table shows the average values:

| Disc diameter | Weight of one disc in kilograms |

| Steel disc (stamped) | |

| 12 inches (R12) | 4,5 |

| 13 inches (R13) | 5,2 |

| 14 inches (R14) | 6,3 |

| 15 inches (R15) | 7,4 |

| 16 inches (R16) | 8,5 |

| 17 inches (R17) | 12,1 |

| Cast light alloy | |

| 10 inches (R10) | 2,5 |

| 11 inches (R11) | 3,3 |

| 12 inches (R12) | 3,9 |

| 13 inches (R13) | 4,5 |

| 14 inches (R14) | 5,6 |

| 15 inches (R15) | 6,9 |

| 16 inches (R16) | 7,8 |

| 17 inches (R17) | 8,5 |

| 18 inches (R18) | 9,4 |

| 19 inches (R19) | 10,8 |

| Forged alloy | |

| 14 inches (R14) | 4,8 |

| 15 inches (R15) | 5,8 |

| 16 inches (R16) | 6,6 |

| 17 inches (R17) | 7,4 |

| 18 inches (R18) | 8,2 |

| 19 inches (R19) | 9,1 |

| 20 inches (R20) | 10,2 |

From time to time, manufacturers try to break the record for lightness of wheels, since the speed of the car depends on this.

Source

Average disk weight

- OZ Racing has released the world's lightest Alleggerita HLT wheels. So, this model in size 17 inches weighs only 6.25 kg

- The heaviest disks are considered to be those from BelAZ-75710 - one R63 disk weighs about 3 tons.

The relationship between the weight and size of wheel rims made from various materials is well illustrated in the table. The data presented in the table was obtained based on a comparative analysis of the weight and dimensions of more than 4 thousand models of car wheels from various manufacturers. Each mass indicator is obtained by obtaining the arithmetic average of the aggregate masses of disks of the same size (diameter) and the same type (manufacturing material) of many models from different manufacturers.

The difference is in the production technology!

The production technology of cast and forged wheels determined the name of their types. For the manufacture of both the first and second, aluminum alloys with alloying additives are used. The difference lies precisely in the technology, which involves the use of hot die forging, hardening and artificial aging for cast wheels. All these processes allow us to achieve a material structure that will withstand loads well due to its strength and ductility! Thanks to it, forged wheels can be repaired even in situations where cast wheels cannot be restored. Even with strong impacts leading to deformation, forged wheels are not destroyed.

How do they look

Almost everyone can imagine what stamped wheels look like, since stampings are currently the most common car wheels - about 70 percent of cars use them. And also almost all commercial vehicles are equipped with stamps.

Many consider the appearance of stamped wheels to be their main disadvantage. Indeed, they do not have such a variety of designs as their forged and cast counterparts, and they are all similar to each other. Only the colors can differ radically.

Life time

The level of wear resistance of stamped discs is strongly influenced by two indicators:

- disc deformation while driving;

- corrosion.

This is especially evident on bad roads. Since R14 stamping wheels are made of steel, they are much softer and more ductile than, for example, casting. But in this case it plays into the hands of car enthusiasts. If, when it falls into a hole, the casting cracks and becomes unusable, then the dies will simply be dented. This is not difficult to fix. The disk will simply need to be rolled over the rim and you can continue to use it. For minor damage, you can even handle it yourself with a sledgehammer or hammer. Moreover, you can correct it more than once.

Painted stampings

The second important factor that reduces the service life of dies is that they rust. Accordingly, if the disk becomes very rusty, it will no longer be usable. Therefore, it is important to store car wheels in dry, indoor areas. Painting can also slightly prevent inevitable corrosion.

Stamping of car wheels with a diameter of 14 inches

Stamped car wheels are so called because they are made using the stamping method:

- A plate, the central part, is extruded from a steel blank using a stamping press. The stiffeners are pressed through. Holes for the bolts are drilled. The unnecessary edge is removed. The plate is ready.

- Next, the rim is made. A long sheet of steel is cut. Bends into a cylinder. Welded along the seam, the seam is cut off for smoothness. The cylinder is pressed with a press, the shape of the disk is set. The edges are sanded.

- It would be more correct to call such a disk stamped-welded. Since only the central part itself is stamped, and the rim is obtained by rolling, then the two parts are welded.

- At the end, a hole for the nipple is drilled. Covered with paint.

Among the disadvantages are susceptibility to corrosion, high weight, worse balancing, which means worse road stability and controllability.

Where is the maximum wheel load displayed?

The static load on a wheel rim is the total or maximum permissible load on the rim. In English, the parameter is called wheel load capacity. The technical standard was introduced by one of the leading manufacturers of alloy wheels from Italy, WSP. The company's engineers sought to improve the product and developed a system for calculating the strength criterion of an alloy wheel under full load - load capacity (WLC). That is, the manufacturer informs the buyer what load is permissible and safe when using the disks.

Calculations are made using software and 3D modeling. There is a virtual load on the graphical drawing of the disk. The test lasts no more than 5 minutes. During this time, the computer calculates the hardness and structure of the material under the influence of various factors. For example, driving at different speeds with a load on a winding road. After testing, the product is assigned a WLC parameter, measured in kg. Information about the permissible weight is displayed on the back of the disc, in the niche of the spokes. As a rule, next to this parameter you can see marks of expert certification: TUV (Germany), JWL-VIA (Japan).

How to choose original rims

Popular Russian manufacturer of stampings TZSK. Often on the market you can find products from Chinese Trebl, which are not durable. The largest manufacturer of dies is the Ukrainian plant KrKZ. More expensive options for stamped car wheels are also available. For example, these are KFZ stampings, which are more expensive, but of better quality. Wheels of this brand are presented in basic configurations of the Volkswagen and Toyota concerns.

A large number of car models, especially in the basic configuration, are supplied by the factory with stamped wheels. And that motorist who wants to acquire original wheels must look for products recommended by the manufacturer of his car.

VAZ 2113 on original stamps

Parameters and characteristics of stamped discs

R14 stamping is installed on a wide variety of car brands: domestic and foreign cars, cars and trucks. Accordingly, the range of dimensions of stampings on the market is enormous.

And if, as mentioned above, the plasticity of the stamping disks 14 contributes to the safety of the suspension, then heavier weight, on the contrary, reduces the service life of the suspension. Acceleration and braking on heavy stamped wheels is more difficult. Fuel consumption increases due to the heavier weight, but not significantly.

KAMAZ on stamps

Discs

| R | Volume, cubic m – 1 disk | Weight, kg – 1 disk | Volume, cubic meters – 4 disks | Weight, kg – 4 discs |

| R12 | 0,03 | 6 | 0,12 | 24 |

| R13 | 0,05 | 8 | 0,2 | 32 |

| R14 | 0,06 | 10 | 0,24 | 40 |

| R15 | 0,70 | 12,5 | 0,28 | 50 |

| R16 | 0,75 | 13 | 0,3 | 52 |

| R17 | 0,08 | 13,5 | 0,32 | 54 |

| R18 | 0,09 | 14 | 0,36 | 56 |

| R19 | 0,10 | 15,5 | 0,4 | 62 |

| R20 | 0,12 | 17 | 0,48 | 68 |

| R21 | 0,16 | 19,5 | 0,64 | 78 |

| R22 | 0,18 | 23 | 0,72 | 92 |

| R23 | 0,21 | 27 | 0,84 | 108 |

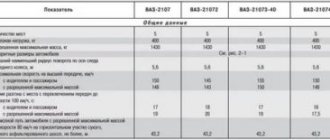

What wheels are suitable for VAZ 2110

Many Lada models have universal basic elements characteristic of a wide variety of modifications of these cars:

VAZ 2110

- device,

- engine volume and power,

- wheelbase,

- pendant,

- braking system,

- wheels and tires.

So, depending on the modification and equipment of the vehicle with different options, the following standard parameters for these products are set at the factory:

- The bolt pattern is 4x98, which is the same for all models of the automobile concern, which means that the wheel is mounted on 4 studs of 98 mm each, as well as the drilling or diameter of the circle along which the holes for the studs are located - 58.6 mm.

- What wheels are suitable for the VAZ 2110? The simplest car configurations, regardless of the year of manufacture, were always equipped with stamped wheels in silver, white or black without decorative overlays with a dimension of 5.0J x 13 ET35, on which summer tires 175/70/R13 were put on.

- Further, all subsequent 3 trim levels with an engine capacity of 1.5 liters were equipped with wheels with dimensions of 5.0J x 14 ET35, 5.5J x 14 ET35 and 6.0J x 14 ET35, and this indicates the capacity of the wheel arches, under which with a constant offset The disk freely accommodated tires 175/65/R14, 175/65/R14 and 175/60/R14, respectively. All of the disks listed were also stamped, but already covered with caps.

- In more expensive versions with an engine capacity of 1.6 liters, wheels with an increased radius in a cast version were installed - 5.0J x 15 ET35 or 6.0J x 15 ET38 with tires 195/60/R15 and 205/55/R15.

- All new models produced by the automaker after 2005 did not use a radius greater than R15. However, in the initial version there were 2 top-end configurations of the brand, which came off the assembly line with wheels that were exclusive at that time. Thus, these cast wheels with designer grilles had parameters of 6.5J x 16 ET33 and 7.0J x 17 ET27, which corresponded to business-class foreign cars, and tires were installed in 205/50/R16 and 215/45/R17, but it could only be safely used in the summer due to its low profile.

You might be interested in About wheel bolts: models with eccentric, for VAZ cars

R13 wheels on VAZ 2110 Important!

The VAZ 2110 has always been a fairly universal car, and the parameters of the wheel arches satisfied radii from R13 to R17 without much difficulty, which allowed car enthusiasts to install original wheel rims from famous manufacturers on their “iron horses” as an option.

see also

Comments 106

Information varies everywhere. So I’m trying to clarify the exact data!

Thank you very much, and especially for your efficiency! And 695 on the KiKa website says 7.3 kg, and 451 6.520 kg. (shop.kolesa-kik.ru/catalo...ross-/37551.html?from=app) At the same time, 695 are written from the replica series and such a weight! Can you tell me what the weight of the factory wheels on the 2022 Grant-Cross is? I called the factory and they can’t tell you, these wheels are not available in the city, so I’m choosing, and you can’t tell me, maybe it’s better to put Slick with studded tires, otherwise She weighs about 10 kg, and where is the best place to buy it?

All original KiK wheels for Grants/Kalinas in 15th diameter weigh approximately 6.5 kg. I think it should be similar for Grant Cross if the manufacturer is KiK. Slik is only slightly lighter. Either on them or on the factory ones, the assembled wheel will weigh up to 15 kg.

Wheel K&K KS451 (Kalina Sport) 6Jx15 ET30, 4x98, DIA58.6: and wheel KS695 (15_KALINA-CROSS) could you tell me the net weight of these wheels, without tires?

Both wheels weigh approximately 6.5 kg.

Yaroslav, thanks for the information!

Thank you for your feedback. Glad the information was useful.

A huge THANK YOU to the authors! The most useful disc weight I've ever seen!

Thanks for your feedback!

Dear, I’m a bit of a novice in this topic, please explain... I have 14 stamps with tires 185-60 r14 on a viburnum. If you put, for example, casting on 13 relatively light and rubber not heavy on 13 175-70, I’ll really notice increased traction and acceleration or so a little? And also the second question is the opposite, if you switch to light 15e (like Kalina Sport 5.5j) + light tires like 185-55 (example stated Kormoran Road Performance 185/55 R15 82V weighs 6.75 kg, I will lose a lot in dynamics and acceleration and fuel consumption ?

Nothing particularly good will happen when switching to 13″ wheels. The increase in traction and dynamics will be almost unnoticeable (more likely even completely unnoticeable), a minimal improvement in rolling is possible (depending on the tires) and a decrease in fuel consumption (up to 0.5 liters, or even less, again depending on the tires). But the taxiing will become much worse.

Likewise, there will be nothing wrong with installing 15″ drives. If the wheels are moderately light and the tires are 185, then the dynamics will remain at the same level, as will the fuel consumption. But the taxiing will improve.

I advise you to take a closer look at 15″x6J with an offset in the range of 30-35, and with 185/60 R15 tires with a load index of 84.

For me, fuel economy is more important than imaginary comfort on bumps! Wow, they said within 0.5 liters. That’s a lot and good! Why do I need the heavy 6j, they are bigger for 195 tires! 5.5j is lighter! And 60 profile tires are heavier? There is a theoretical consumption calculator! gaidi.ru/kalkulyatory/kal…sxod-topliva-kalkulyator/

Everything I wrote is the best outcome. Basically (in about 95% of cases) there are no changes, except for nuances. Therefore, let's take a different route. Tell us what specific tire and wheel options you are considering. And I’ll tell you the effect of installing them.

Well, it depends on what the final size is. The small size is attractive due to the price of tires, wheels and of course fuel efficiency + fast starts without strain! But wide ones don’t know what’s good, except for the type and type of stability on the highway (theory again)… and there are a lot of disadvantages! It’s a small thing for someone to overpay for 0.5 liters per 100, but it’s unpleasant for me, given the already expensive 15 tires and wheels. I wish I could put on the 13s, but they don’t fit the 14 calipers, the casting says it’s going to fit a bit, you need to measure it. Do you have experience to clearly say that at 175-70 r13 it will be much worse than 185-60 r14 for example? Or again depends on the tires, etc. By the way, I consider tires from very cheap ones like Viatti and Kama Breeze to average ones at most for 2200 rubles like Nexen or Cordiant, no more!

Installation of alloy wheels on a VAZ 2107

Alloy wheels are installed in the same way as stamped ones. Difficulties may arise if the diameter or offset of the disc is very different from the standard one. In this case, you will have to change the shape of the wheel arches and fenders so that the wheel does not rub when turning or while driving. Such modifications are very labor-intensive and expensive, so you should think twice before deciding to install wheels of non-standard sizes on a VAZ 2107.

When choosing wheels for a VAZ, you need to look not only at their appearance, but also at the possibility of using them on a particular model. In addition, certain technical characteristics must be taken into account.

The most important of them are:

- bolt pattern;

- diameter;

- departure;

- fastening elements;

- diameter of the centering hole.

Controllability

When the car hits a bump, the wheel takes the impact and transfers it through the shock absorber to the body. In turn, the body with its weight (through the shock absorber) compensates for this impact, and the wheel returns to its original position. The smaller the unsprung mass, the less force is generated by the impact on the body, in addition, less effort is spent when maneuvering. However, if the weight of the body is too small relative to the weight of the wheel (all unsprung elements), then the wheel will not be able to quickly return to its original position, which can lead to loss of control (skidding).

Radius and wheel size R14 4×100

Obviously, each car requires a different wheel size. One of the main indicators is diameter. R14 wheels have a diameter of 14 inches or 35.56 centimeters.

The 4x100 parameter characterizes the bolt pattern. The first index of this marking is the number of bolts (4). The second PCD index is the diameter of the circle passing through the center points of the mounting holes. Measured in millimeters.

There are other important parameters. In particular, the width of the rim, the diameter of the central hole.

Overhang is the distance from the middle of the disk width to the mating plane (the place where the disk comes into contact with the hub). This indicator characterizes how deep the wheel will be after installation on the car.

Each disk has a maximum load.

Basic drive functions

Wheel rims on a passenger car perform a number of important tasks:

- rubber seal around the perimeter;

- ensuring a rigid structure under the total weight of the vehicle;

- transmission of torque to the wheel.

Based on these functions, the car enthusiast can formulate requirements for the disks, as well as their technical characteristics. Any wheeled product must be balanced in size, durable and safe. Only after this can you proceed to drilling wheels on VAZ cars.

Wheel weight: every kilogram matters

Surely, you will not argue that the dependence of the car’s mass, acceleration and braking times are directly related. The heavier the car, the more difficult it is to accelerate it and the longer it will take to stop it, all other things being equal. However, the mass of a car is not a constant quantity. By removing from the trunk all the junk that has accumulated there over several years of owning a car, you can lighten it by 20-30, and often 100 kilograms. It's a lot.

However, not everyone keeps unnecessary things in the car, you might say. And you will be absolutely right. Therefore, let's move on to a more realistic development of the scenario. You can reduce the weight of your car by choosing the right wheels and tires. Moreover, this step will have very positive consequences, because the weight of the rims and tires is included in the total mass of the unsprung part of the car. Moreover, weight has a direct impact on such a parameter as inertia. Now it’s worth understanding the terms so as not to go further into a dead end.

Alloy wheels for fourteen

The production of cast wheels, as their name implies, is based on the use of casting metal alloys into special prepared molds. Engineers use an alloy of aluminum and magnesium as the starting material. It does not rust, does not rot, and is lighter than steel. Let us briefly touch upon the issue of mass. Many are convinced that cast wheels are much lighter than stamped ones. This is partly true, but there are nuances.

Alloy wheels come in a variety of shapes

The fact is that the alloy of aluminum and magnesium is light, but fragile. Therefore, when in the 90s of the last century the first such samples began to appear in the vastness of our country, soon many car owners were faced with a situation where, when driving on domestic roads with a large number of holes, they simply cracked. Manufacturers drew the appropriate conclusions and simply increased the amount of alloy used to produce each disc, thus increasing their mechanical strength. However, this affected the mass, increasing it. Therefore, today the difference in weight between four stamped and alloy wheels is only 10.12 kg . Thus, one should not expect a significant increase in dynamic indicators.