The actuator for starting the car is the ignition switch, the work of which is to close and interrupt the electrical circuit. Under the lock panel trim there is a switchgear connected to the electrical wiring through terminals. Changing the key position adjusts the power connection modes. The function of adjusting the circuit closure is performed by the contact group of the ignition switch. The voltage comes from the battery and is distributed among the elements of the vehicle's devices.

The design of the ignition switch consists of the main elements:

- device body;

- turnkey larva;

- locking mechanism;

- ignition switch contact group.

During prolonged use of the vehicle, malfunctions in the operation of the ignition switch are possible - as a result of oxidation of the contacts or mechanical damage to the wiring. It is necessary to periodically replace the contact group of the ignition switch and repair the locking mechanism.

How it works - studying the ignition switch

The operation of the ignition switch is based on a mechanism consisting of a switch, which, when the key is turned in the lock, connects different types of contacts. As a rule, the ignition switch operates in several positions, each of which is responsible for a specific action when starting the car.

The first position is responsible for turning on the instruments on the panel and distributing power consumption throughout the car. The second position is responsible for starting the engine. Well, the last mode is the steering wheel lock. For each position, its own contact group of the ignition switch is activated to one degree or another.

Ignition failure is a fairly rare occurrence and not every motorist experiences this. However, if you can barely get to the nearest service station with a broken tire or a malfunctioning generator, you won’t get far with a broken lock. Let's figure out why this problem can arise and how to fix it yourself.

Vehicle starting problems

Problems with this part of the vehicle (hereinafter referred to as the vehicle) are familiar to many. It also happens that when the key is removed from the keyhole of this system, the car continues to work.

It is interesting that most car owners in such cases, before turning off the engine, engage in reverse gear and move the key to the third position. Then the car stalls.

For those who are ready to spend their free time correcting this situation, I recommend inspecting the ignition switch contacts. With the multimeter you have, things will go smoothly.

The reason is in contacts

To start checking, you need to connect the ohmmeter contacts alternately to the terminals of the ignition switch and, turning the key to different positions, check the activity of these contacts in the lock. When this part of the contacts is in good condition, the resistance tends to zero.

If the values are positive, the reason is obvious: the contacts of the car’s starting system have burned out or become dirty. In this situation, you will need to replace the contact group of the ignition switch - all this can be done easily, but first you will have to disconnect the battery. Otherwise, you are guaranteed a burnt fuse box.

Cause of alarm

Another case not related to the contact group. Try to separate the contact and alarm disconnect connectors, most likely there is a problem here.

If this is the case, then it is recommended to replace the switch with a new one.

The reason is the rear window heating system

Another reason for such a breakdown is the heated rear window, or rather, its switch. To check operation, remove the button from the panel and inspect the hole located on the side of the harness, first disconnecting the wiring.

This is interesting: Take the car to the “shoe” salon!

Insert the key into the lock and monitor the voltage between the terminals and ground. There should be no voltage in the Lock and Acc positions. Replacing the switch will be required if the problem occurs because of it.

Design and principle of operation of the ignition switch contact group

The need to use a contact group in a car’s ignition system is dictated, first of all, by convenience, reliability of the connection and grouping of wires included in the electrical circuit. In addition, the use of a contact group as an intermediate link between the consumer and the ignition switch increases the degree of maintainability of the latter.

The design of the ignition switch installed on classic VAZ models is nothing more than a traditional electrical circuit breaker. The key in this design plays the role of a contact position regulator, capable of performing several standard contact closure options corresponding to certain vehicle operating modes:

- starting the power unit;

- connecting power to electrical devices;

- stopping the power plant

The connection of wires of the “socket-plug” type ensures high reliability of contact, and special fasteners in the plastic housing of the group act as an insulator (distributor) that prevents the occurrence of short circuits. Thus, the contact group of the ignition switch is nothing more than a device that connects all consumers into a single system via electrical wires (see figure).

The contact ignition system used on classic models of VAZ cars can be of two types: generator and battery . The difference between these systems is that one of them has an autonomous power source (battery), which allows the use of electrical appliances when the engine is not running.

The operation of the ignition switch contact group is based on the following principle. Turning the key closes the electrical circuit from the “-” terminal of the battery through the ignition coil to the “+” terminal of the battery. The current passing through the coil is converted into a high voltage pulse, generating a spark discharge at the spark plug electrode. Consequently, turning the key initiates the start of the car’s power unit. The inclusion of other electrical circuits that ensure the functioning of elements of the electrical equipment of the vehicle is carried out by installing the ignition key in the appropriate positions, causing the closure of certain groups of contacts.

Depending on the car model, the same key positions in the ignition switch may correspond to different groups of contacts, and, consequently, different operating modes of electrical equipment. An option is possible in which voltage is supplied at the moment the key is installed in the ignition switch, that is, the key itself closes the circuit that supplies the supply voltage. The functioning of anti-theft and alarm systems, devices that block car doors, etc. is organized in a similar way.

Replacing the ignition lock cylinder on a Lanos with an immobilizer: features of the procedure

If you are the happy owner of a Lanos car that has an immobilizer installed, then the replacement process will be slightly different from that described above. First, let's find out how to check whether your car has an immobilizer. The easiest way is to pay attention to the presence of an LED near the clock, which is shown in the photo below.

After starting the engine, the LED next to the clock goes out, indicating that the immobilizer has accepted the key. If there is no such LED, then the car does not have an immobilizer installed (provided that the clock panel is standard and has not been changed). The second way to check is to make a duplicate key and try to start the engine with it. If it does not start, that is, when you try to turn it in the lock, it will be motionless, then this indicates that you really have an immobilizer (here it is important to understand that if you inserted the key into the ignition with the steering wheel locked, then you should turn steering wheel, try to turn the key without fanaticism).

If an immobilizer is installed in the car, then after you replace the cylinder (according to the instructions described above), you will need to register the key into the system. This can be done by contacting specialists.

However, there is another way that does not require the help of specialists. Its essence is to disassemble the standard and new keys and replace the circuit boards in them. If the key has a chip, then it is dismountable, so you should disassemble both keys and replace the boards in them.

Of course, after performing such manipulations, there will be no need to assign the chip to the immobilizer, and the new key will work with the old chip.

Ignition switch: circuit, device, operation

In order to understand how it works, you need to understand what the ignition switch consists of. Like any other contact electrical device, it has a mechanism that connects and disconnects the electrical wiring circuit. In addition to turning the ignition off, the lock also performs some functions that are activated when you turn the key:

- in position No. 1 - power is supplied to the instrument panel and various electronic devices;

- in position No. 2 - the engine is started;

- in position No. 3 - the steering wheel is locked.

Each of these key positions uses its own ignition switch contact group.

The ignition switch does not break down as often as other parts of the car's electrical equipment. If the ignition system lock is faulty, you can determine the cause yourself.

Pinout of the ignition switch VAZ-2101 - VAZ-2107

The ignition switch on these cars is located to the left of the steering column. It is fixed directly to it using two fixing bolts. The entire mechanism of the device, except for the upper part in which the keyhole is located, is hidden by a plastic casing.

On the visible part of the ignition switch housing, special marks are applied in a certain order, allowing inexperienced drivers to navigate the lock activation mode when the key is in the hole:

- “ ” – a mark indicating that all systems, devices and instruments that are turned on using the lock are turned off (this does not include the cigarette lighter, interior lighting, brake light, and in some cases the radio);

- “ I ” is a mark informing that the vehicle’s on-board network is powered from the battery. In this position, the key is fixed independently, and electricity is supplied to the ignition system, to the electric motors of the heater and windshield washer, instrumentation, headlights and light signaling;

- “ II ” – engine start mark. It indicates that voltage is applied to the starter. The key does not lock in this position. If you release it, it will return to the "I" position. This is done so as not to subject the starter to unnecessary loads;

- “ III ” – parking mark. If you remove the key from the ignition in this position, the steering column will be locked with a latch. It can only be unlocked by inserting the key back and turning it to position “0” or “I”.

How it works

The group of contacts in the ignition switch is a system for connecting wires in the required sequence and order, for this there is a start, ignition and parking position. This ensures correct distribution of on-board voltage from the current source, which in a car is the battery, to consumers. There are many of them in a modern vehicle, these include ignition and engine starting systems, lighting, alarm systems, control, monitoring, and security systems.

The contact group works together with the ignition switch; in some cases, when the ignition switch cylinder is broken, there are options for it to work independently, or an additional start button is installed. Below is shown how the ignition switch of a VAZ 2101-2107 works.

1. Anti-theft rod; 2. Product body; 3. Shaft with splines for turning the contact group; 4. Disk with contacts; 5. Bushing with contacts; 6. Contact connector.

The letter “a” shows the guide for correct assembly of the lock components. As can be seen from the figure, the device circuit is compared with a conventional electrical contact breaker. The key in it acts as a kind of regulator of the order of commutation of certain circuits. The first ignition switching devices were made as one piece, this simplified and reduced the cost of their production, but there was one significant drawback. If the contacts suddenly burned, broke, or oxidized, the lock had to be completely replaced. Therefore, a design for an easily replaceable contact group was developed.

A few words about the principle of operation

Modern cars and trucks have a battery ignition system that uses the battery as the power source. When you turn the key, power supply voltage is supplied to the vehicle’s instrument panel, electronic control unit and other systems of the vehicle’s electrical circuit. A further turn of the key makes a connection through an additional starter relay to start the engine.

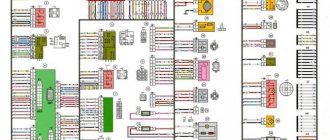

The figure shows the electrical circuit of the ignition switch, which shows the principle of operation of the switch

Almost all switching of consumers is carried out by the contact group of the lock. Different models of machines have switches that differ from each other in their operating algorithm. There are models in which only installing the key supplies voltage to individual systems. Recently, the start button has become widespread, as well as the stop button. This installation allows you to use it instead of a lock, the power unit is started and at the same time the starting circuit is unloaded. The button used should not have a fixed on position.

The same start button is often installed by car owners themselves, especially those who do not have an unloading relay. Typically, a button with the start function has powerful power contacts; only they can relieve the contact group from the starting current of the starter solenoid relay. Switching circuits with high current requires the use of high-quality materials to produce a device that can withstand high temperatures from heating and have good insulating qualities.

Installing the "Start" button

Some VAZ 2106 owners install a button for ease of starting the engine. It is connected via the starter power circuit to the break in the red wire, which goes to terminal 50 of the ignition switch. In this case, the engine starts as follows:

- The key is inserted into the lock.

- Turn it to position I.

- The starter is started by pressing the button.

- When the engine starts, the button is released.

To stop the power unit, you must turn the key counterclockwise. A slightly different option for connecting the button is also possible, so that with its help you can not only start the engine, but also turn it off. For these purposes you will need the following parts:

- headlight relay RS 711;

- starter relay 113.3747–10 or 90.3747–10.

According to the diagram, when the button is pressed, power is supplied to the headlight relay, and after the contacts are closed, to the starter. When starting the power unit, the button is released, thereby opening the contacts of the starter relay and breaking its power circuit. If you press the button again, the contacts of the switching device open, the ignition circuit is broken and engine operation stops. The second option for using the button is called “Start-Stop”.

Even a car owner who is encountering such a problem for the first time can replace or repair the ignition switch on a VAZ 2106. To carry out the work you will need a minimum of tools and following step-by-step instructions. The main thing is to connect the wiring to the lock in accordance with the diagram.

Schematic electrical diagrams, connecting devices and pinouts of connectors

The ignition switch in cars of the VAZ family fails from time to time due to weakening of the contact posts or burning of the contacts inside it. It also happens that the cams of a plastic roller are produced. You can disassemble the lock and clean it, but it’s better to just replace it with a new one, considering that it costs pennies compared to imported locks.

But if connecting the wires together did not result in the starter operating (or it did not turn on the first time), check the solenoid relay on the starter. The contact spots on it may also burn out, which will prevent the circuit from closing normally. Alternatively, you can use a screwdriver to short-circuit the two large terminals on the solenoid relay (before doing this, put the car in neutral and use the handbrake). When closed, the starter should begin to spin vigorously. If this happens, remove and change the solenoid relay. If the starter rotates “sluggishly” when it closes, you will have to remove it and check the condition of the brushes.

All operations are performed with your own hands, without the help of car service specialists. Moreover, the price of an ignition switch on a VAZ2106 is up to 100 rubles. To replace it, you will need to know the pinout of the wires coming from it, for which the editors of the site 2 Schemes.ru have prepared a large reference material.

The ignition switch is designed not only to start the engine - it performs several functions at once:

- supplies voltage to the vehicle’s on-board network, closing the circuits of the ignition system, lighting, sound alarm, additional devices and instruments;

- at the driver’s command, turns on the starter to start the power plant and turns it off;

- turns off the power to the on-board circuit, preserving the battery charge;

- protects the car from theft by fixing the steering shaft.

What you need to know about node malfunctions

They come in two varieties:

- Damage to the lock or its cylinder;

- The ignition switch contact group has failed.

Switch failure is quite a rare occurrence for “branded” parts, which cannot be said about “consumer goods” from China or Hong Kong, which can bring surprises to car owners. We will not consider problems with switches; we will focus on faults of the switching unit. Several factors also indicate breakdowns:

- The machine's electrical consumers do not turn on;

- The engine starting system does not work.

In both cases, to make a final decision on how to fix the breakdown, you should check the serviceability of the unit. This is not difficult to do if you have a car tester and retain your knowledge of electrical engineering. To check, you need an electrical diagram of the lock, which today can be easily found on the Internet. If all this is available, start working.

The photo shows the switching group testing element.

To carry out this “undertaking” you need to have access to its contacts or connector with wires. In some cases, you will have to dismantle the device. This applies to a greater extent to cars of the Zhiguli family of cars. The key is moved to the first position, and the device measures the resistance of the corresponding contacts; the lock diagram will tell you about this. Their resistance should be close to zero. Next, you should take a measurement in the second position of the key. In the stop position, power should be supplied to the car radio, clock and other devices. The diagram will also show all this. If the device readings approach infinity, the group will have to be replaced.

Remember! Cleaning the contacts with fine sandpaper will restore operation in the short term.

During Soviet times, drivers used silver-coated coins to restore contacts; this solved the problem for some time. You can still apply this old-fashioned method today. The contact group of the lock is a delicate thing, so you should treat it with caution.

Replacement

To remove the ignition switch you will need the following tools:

- Phillips and slotted screwdriver;

- Chisel. You will need something thin and sharp;

- Hammer;

- Pliers;

- Key for 10.

This is quite enough. Sometimes, something else may be required. But this is quite rare.

Before work, remove the terminal from the battery. This will avoid short circuit. After which you can begin dismantling work:

- Remove the steering wheel covers. The manufacturer also recommends removing the steering wheel. This is not required, but is advisable;

- The steering column turn switch is removed. To do this, the latches securing it are released and the switch is removed from the column;

- Disconnect the wiring block;

- The bolts holding the lock to the steering column are quite tricky. Their caps break off when twisted. Therefore, it will not be possible to unscrew this fastener with a regular key. To do this, take a chisel and set it at a certain angle. Then, with gentle blows, we tear the bolt out of place, and then you can unscrew it using pliers. The same applies to other bolts, there are 4 in total;

- After this, you can remove the old lock;

- When installing the lock, please note that bolts are supplied with it. According to the manufacturer's idea, their heads break off when tightened to a certain point. Instead, you can use M6 bolts of suitable length. This work has no other special features.

How to extend service life

This is easy to do on those cars where there are no relays for the start or stop position. Installing auxiliary relays yourself helps with this.

The figure shows the connection diagram. Typically, such relays are mounted in circuits “30” and “15” of the lock, which is almost the same for all models. The exception will be the Moskvich and Volga cars, the switches of which are designed slightly differently. 30 Amp relays from the VAZ 2108 or 50 Amp relays from the VAZ 2110 are suitable as auxiliary relays. In “old” models, start buttons are mainly used. In a similar way, the circuit is unloaded along the circuit “30” - “50”. There are options for homemade modernization, when instead of one relay, two devices are installed in a parallel circuit. The circuit becomes somewhat more complicated, but the service life of the relay is extended.

Location

For most domestic and foreign cars, the ignition switch is structurally located in the steering column housing or under the panel of technical sensors. The contact group is located behind the plane of the ignition key cylinder.

It is typical for many vehicles to install the ignition switch on the right or left side of the steering column. Sometimes there are foreign car models where the lock and key are located on the car's dashboard or navigation panel.

This is interesting: 2 methods of cylinder block liner: features of repair work

Procedure for replacing a lock

- Disconnect the battery terminal with the minus sign.

- We put the key in the lock in the “zero position”.

- Use a Phillips screwdriver to unscrew the 4 screws securing the steering column housings.

Installation of the VAZ 2107 ignition switch is carried out in the reverse order:

- Mount the lock until the side latch clicks.

- We attach and tighten the fastening screws.

- We connect the wires and install the steering column covers.

Watch the procedure for replacing the ignition switch of a VAZ 2107 in this video:

Characteristics of a contact group

To begin with, we suggest finding out why an ignition switch contact group is needed, what its structure is and how it works.

Purpose and functions

In essence, KGZZ is used to ensure the connection of all electrical circuits of the vehicle without exception. That is, when the driver turns the key in the lock, the KGZZ closes the contacts, thus allowing the use of all electrical devices without exception.

Device

Diagram of the lock The ignition switch itself is a simple circuit breaker.

When you turn the key, the contacts are adjusted, making it possible to start the engine, power the equipment, and also stop the power unit. If you disassemble the body of the lock itself, you will see that the device itself is located inside it, as well as a large number of wires connected to each other. The wires to the lock come from the battery. The contact group of the ignition switch itself goes directly to the connection point of these electrical devices. To prevent short circuits and to delimit the contact elements themselves, the KGZZ is mounted in a plastic case.

Principle of operation

An automobile ignition system can be either battery-based or generator-based. Their fundamental difference is that battery ignition is equipped with an autonomous power source; accordingly, all electrical equipment can be turned on without starting the engine. As for the generator system, in this case, activation of electrical equipment is possible only after starting the engine.

When the driver turns the key in the lock, the electrical circuit contacts are closed from the negative terminal on the battery to the coil. At the same time, voltage begins to flow through the wiring to the lock, which is supplied to the coil through contacts, after which it returns to the positive output of the battery.

At the moment when the voltage passes through the coil, a very high voltage is generated in it, which is subsequently transmitted to the spark plugs. Ultimately, the contacts close and the engine starts. In addition to the ignition circuit itself, there are other electrical circuits in the car that conduct voltage from the key to electrical appliances. Each of the wires is responsible for connecting the contacts to each other (the author of the video is the Auto Repair and Maintenance channel).

Basic faults

Briefly about the reasons why repair of the ignition switch contact group may be required:

- Overloading of the device, which may be due to the installation of additional devices of increased power, as a result of which a higher voltage will pass through the KGZZ. For some time, the device can cope with this current, but over time, carbon deposits will begin to form on it. It should be noted that this deposit, as a rule, appears precisely inside the contact, and not on its surface, then the only way out is to replace the contact group. To prevent this problem, all additional devices must be connected via fuses or relays.

- Short circuit in the electrical network. If a short circuit occurs, this may also cause high power voltage to pass through the CGZZ, which again will cause its failure.

- Many motorists who changed the KGZZ faced the problem of abrasion of the tracks, as well as the contacts themselves. This problem usually occurs as a result of wear and tear on the lock, but in some cases the cause may be faulty.

- Mechanical failure of contact elements, as well as other components of the group.

- Overheating of the device, which can lead to damage to the design of the CGZZ. Overheating, as a rule, also occurs as a result of increased load on the device. When working in conditions of elevated temperatures, the tracks may move or even break (video author - AlexAvtoKhlam).

Reasons for failure

Malfunctions of the lock elements are reflected during vehicle operation. Problems arise when starting the engine and manifest themselves as:

- intermittent starter operation;

- unusual extraneous relay clicks;

- slow response when changing key positions or complete lack of response.

Sometimes there are situations when the car cannot be turned off. Failure can be diagnosed by examining the elements of the contact group for oxidation.

Mechanical

If the key jams in the lock cylinder, the fault is looked for in the structural elements of the device. The entry of dust particles into the keyhole is accompanied by clogging and premature mechanical wear. In this case, the entire lock will need to be replaced.

Often the problem is the wear of the wire sheath - this happens due to mechanical rubbing against each other.

You should check the tightness of the terminal contacts, and check the cracked insulation for integrity. Replace damaged sections of wiring and tighten the terminals for tight contact.

The internal parts of the keyway also wear out. To increase service life, lubricant is regularly added inside the larvae. A mechanical break in the geometry and wear of the key cannot be ruled out - you will need a spare copy or a duplicate made in advance.

Electrical

The need for premature replacement of the contact group arises when the device is overloaded. Over time, the contact winding elements burn out due to overheating. The resulting internal carbon leads to a violation of the density of the contact spots and the throughput function of the circuit load.

When installing additional sound and light elements, check the devices for matching current strength. Additional devices are connected to the electrical circuit using special relays or fuses.

Replacing the lock contact group

The ignition switch contact group is an element exposed to high temperatures, especially when the vehicle’s power unit is started. This happens as a result of an increase in the temperature of the electrical wire conductor (due to sudden voltage surges), which provokes burnout of the insulating material of the contact group.

Installing an additional unloading relay, which partially removes the load when the engine starts, can protect the contact group from the occurrence of the defect described above. Nevertheless, this phenomenon is quite common among the VAZ “classics”. And the only solution to the problem that guarantees further uninterrupted operation of the ignition system is to replace the contact group .

The process of replacing a contact group is quite simple, and this applies equally to the technical features of the procedure, and to the provision of tools and repair skills. The main point that requires some attention and scrupulousness is compliance with the contact connection diagram. It must be absolutely identical to the old one. In addition, information about the connection diagram is located in the vehicle's operating instructions.

So, we change the burnt-out contact group of the ignition switch:

- Disconnect the battery terminals.

- Unscrew the screws securing the plastic steering column cover and remove it.

- Unscrew the screws (2 pieces) securing the lock.

- We set the key in the ignition switch to position “0”, which ensures that the anti-theft device is turned off.

- When disconnecting the lock from the network, mark the wire contacts.

- Having removed the retaining ring, disconnect the contact group from the lock and replace it.

- Assembling and installing the lock in its original place is performed in the reverse order to that described above.

Diagnostics and replacement

The diagnostic procedure can be combined with device replacement. You can change the KGZZ either in a garage or ask for help at a service station. The first option in this case is more preferable, since replacing the ignition switch contact group is not a particularly difficult task that almost anyone can handle. Moreover, you don’t have to pay for it.

So, how to check and how to replace the KGZZ (the procedure may differ depending on the design features of the car):

- First you need to dismantle the plastic protective cover of the steering wheel; as a rule, it consists of two parts - upper and lower. Using a screwdriver (usually with a Phillips blade), you need to unscrew the bolts that secure the plastic, and then carefully remove the parts of the protection.

- Once you do this, you can gain access to the lock itself. You will need to disconnect the connector with the cable from the socket with the backlight bulb.

- After dismantling the lock itself, you will need to bend the latch that secures the plastic cover. You can use a slotted screwdriver to disconnect. Having done this, you can disconnect all the other fasteners one by one.

- After these steps are completed, you will need to remove the plastic cover from the lock itself.

- Then, when the cover is removed, you will also need to disconnect two more latches in it, this will allow you to disassemble it and gain access to the KGZZ. You can also use a screwdriver at this stage.

- Having done this, you can dismantle the KGZZ itself with the diode elements from the cover. There are convex contact elements on the light source; if they are acidified or have carbon deposits on them, you can try to treat them with fine-grained sandpaper. If necessary, the KGZZ is completely replaced with further installation in the lock. The procedure is repeated in reverse order.

Photo gallery “Changing the KGZZ”

1. Disconnect the latch and remove the cover.

2. Remove the cover from the device.

3. Remove the KGZZ and replace it.

Loading …

Checking the functionality of the ignition switch contact group

Diagnosis of the suitability of the ignition switch contact group is carried out with a device - a multimeter. The contacts are checked for changes in resistance.

Sequence of work

The performance of the part is checked in the following sequence.

- Disconnect the battery (you can only remove the “-” terminal).

- Disconnect the contacts of the wire block.

- The lock connectors are checked in different positions (pairs of contacts of the lower and upper rows).

Multimeter readings

When checking with a multimeter, we look for the following signs and readings of the device:

- Impossibility of measurement (infinity sign) - replacement of the contact group without the possibility of manipulation and repair.

- Fluctuations in the sensor needle (numbers on the screen) indicate intermittent contact. It will be necessary to check the terminals for tight connections and clean them from oxidation.

- Signs of a malfunction of the ignition switch contact group are zero readings on the multimeter.

- The next stage of troubleshooting is checking the electrical wiring for integrity.

You can check the functionality of wiring without a contact group by directly connecting pairs of corresponding wires. If the starter cranks and the engine starts, the circuit line from the battery to the spark plugs is fully functional, and the problem lies in the ignition switch system.

This is interesting: Replacing the front and rear shock absorbers of a Chevrolet Cruze

What kind of damage can occur in the ignition switch?

As mentioned above, practice shows that breakdowns are common to both parts of the lock and often require replacement of one or the other half. Sometimes VAZ 2106 ignition coils can fail

When servicing these elements, you need to know what a non-contact ignition circuit is, and after that you need to disconnect the negative terminal on the battery, except if you check the presence of voltage at consumers.

- Mechanical failure

The most common malfunction of the mechanical part of the locking system is a tight turn of the key; if the connection problem is not solved in time, the key will jam in the lock or break. As a result, you will have to change the entire lock, and such a replacement will require large expenses.

Factory ignition switches from VAZ 2106 cars very rarely break down in this way; such a malfunction is typical for Chinese spare parts, because the cost of the analogue is an order of magnitude lower. Analogs cannot be repaired, unlike spare parts from the LADA automobile plant.

Ignition switch device

The design of the ignition switch depends on the car model. There are two types: with a key and without a key. When cars first began their development, their ignition locks did not have keys. Similar designs were used until the mid-twentieth century, and then they were replaced by conventional models that use a key.

Despite the fact that now there is a revival of push-button ignition locks, the most common type of design remains where the use of a key is required. The most convenient variation of the model is considered to be a flip key.

The design of ignition switches is similar for most passenger cars. The part consists of two main parts. The mechanical one has a cylinder into which the car owner inserts the ignition key. It provides protection against theft. The electrical one comes from the contact unit.

The key has a cylindrical lock, which is responsible for both turning the contact unit and locking the steering wheel. All parts are sequentially connected to each other.

Larva

The part is the part into which the key is inserted to select the desired circuit connection. It is installed in a cylindrical spring, one of the ends of which is fixed to the lock body. The cylinder lock assumes automatic return of the lock in case of unsuccessful start. The part is connected to the leash.

Leash

The part resembles a wide cylinder with a through channel. There are balls at the ends of the radial channel, and a spring is placed between them. The design of the part assumes that the spring allows the balls to fall into the holes on the lock body. Thus, the leash allows you to rotate the contact unit disk and also guarantees the lock’s fixation.

Contact node

The part consists of a contact disk with plates (through which current passes), as well as a stationary block. The last element has about six contacts with leads on the reverse side. Typically, contact plates with a single connector are used.

contact Group

This mechanism is one of the most important parts of the ignition switch, since it is the connecting link between all other components.

The mechanism closes the contacts of the electrical wires in the sequence required for a certain operating mode, which ensures the distribution of current between the devices of the machine. The position of the rotating parts of the contact group corresponds to the position of the key in the lock. The contact group is necessary for more convenient connection and grouping of vehicle electrical networks. The part is indispensable in terms of practicality: using a contact group saves the car owner time and money. The fact is that connecting all contacts directly is extremely inconvenient. If it was necessary to replace any element, the driver would have to climb into the lock body and separately solder each contact. The contact group solves this problem, and its replacement is cheaper.

The key circuit is closed while turning, and electricity rapidly moves from the negative terminal through the wire system, and then from the lock contacts to the induction coil. It generates additional voltage and transmits it to the spark plug. The current then returns to the positive terminal of the battery.

As a result of many years of friction, the elements of the group can wear down, which leads to overheating and burnt contacts. Due to such malfunctions, interruptions in the operation of a variety of vehicle systems are possible. Often, replacing a contact group successfully solves the problem of failure of several systems at once.

How to replace the ignition switch on a Lanos if the key is lost or stuck

There are rare cases when a driver loses a car key or it is simply damaged. It’s good if you have a spare one at home, but if you don’t have one, then the situation is extremely unpleasant.

If the key breaks, then it is easier to make a duplicate, so do not rush to dispose of the broken part (or parts). If the key is broken and part of it remains inside the ignition switch, then try to remove it with pliers. To do this, first switch it to the “Lock” mode, since in other modes it will not be possible to remove it. If you cannot remove part of the key, then you should replace the cylinder, but provided that you can switch the ignition switch to the “ACC” mode. It depends on which part of the key broke.

The most unpleasant moment is when you don’t have the key at all. In this case, there are two ways to solve the problem:

- Drill out the cylinder and replace it.

- Replace the ignition switch housing.

Both methods are not simple, but it is quite possible to implement them yourself without the help of specialists. However, if you have someone to turn to, then it is better to entrust this work to a master. If not, then we’ll proceed to replacing the ignition switch on Lanos ourselves.

If you choose the first option - drilling out the larva, then you will need to use a drill.

This is interesting! When carrying out manipulations, it is necessary to disconnect the negative terminal from the battery.

First you need to remove the decorative steering wheel trim. It will be extremely difficult to do this without the ignition key, because the steering wheel will lock and you will not be able to get to the screws that are located at the end. There are two ways to solve this problem:

- remove the steering wheel lock. This can be done by sharply moving the steering wheel to the side;

- try to remove the screws using screwdriver bits.

Having removed the decorative trims of the steering wheel, you can begin replacing the ignition switch. If you choose the first option, that is, drilling out the cylinder, then use the instructions presented in the video below.

The replacement process is described for the Daewoo Nexia, but the technology is almost identical to the Lanos, Sens and Chance cars. When implementing it, it is important not to damage the lock body, otherwise it will need to be replaced. Before drilling, be sure to disconnect the contact group.

The second method is to replace the ignition switch housing. The process involves performing the following manipulations:

- Disconnect the negative terminal from the battery. Be sure to do this right away so as not to short-circuit the wiring during the work.

- After this, unscrew the screw securing the block and disconnect it from the ignition switch.

- Remove the right steering column switch to gain access to the right bolt securing the ignition switch housing.

- And similarly on the left side.

- The housing is secured with two self-tapping screws. This means that it is impossible to unscrew them with a key or a screwdriver (there are no edges on the head), so you need to use a drill to drill them out or a chisel (core) to unscrew them.

- If you use a chisel, then you need to choose the smallest one. If this is not available, then it is recommended to use a core with a hammer (it is advisable to take a small hammer). With its help, a recess is made in the head (preferably closer to the edge), after which manipulations are made to unscrew the bolt (tapping the core with a hammer), moving it around the circumference.

- It is recommended to make several recess points, which will facilitate the process of unscrewing the bolt.

- Remove the ignition switch and install a new one in its place along with the cylinder and keys.

This is interesting! The body of the original ignition switch for Lanos has the following article number 95710896.

The biggest difficulty when performing the above steps is unscrewing the bolts securing the lock body, as this takes a lot of time. When installing a new product, you can use similar bolts (or new ones that are supplied with the housing).

The video below provides detailed instructions on how to replace the ignition switch on Lanos, Sense and Chance.

Removing a faulty device

We take out the lock and disconnect the wires from the terminals. It is very important that the connection remains unchanged. Press the latch and install the lock. Using a screwdriver, unscrew the 5 screws of the steering column switch housing.

The mechanical part is installed directly in the ignition switch itself. Alternately move the wires from the previous part, choosing the correct contacts. The design of the electronic ignition on a VAZ consists of two elements: The electrical part is a wire terminal fixed at the bottom of the lock with a locking clip. In this case, it is important to remember that the connection diagram plays a huge role, and you should not mix up the wires.

Therefore, the key closes the contacts of the ignition circuit, thereby starting the car engine. Place the steering column cover in place and secure the two parts together.

Illumination of the instrument panel - how is the panel arranged?

Any modern car must have lighting for both the instrument panel and other buttons and switches located on the car’s dashboard. Illumination of the ignition switch is a very common occurrence in imported cars. Our manufacturers have not thought of this, so many drivers improve their iron horse on their own. Such lighting will give your car a special charm at night, and it’s convenient to see where to insert the key.

Photo of the ignition switch illumination

The most optimal and common type of lighting in our time is the illumination of the ignition switch using LEDs.

It is not difficult to install, and its service life is very long. The most important thing is that when choosing such lighting you don’t need to invent anything. Car dealerships, as a rule, sell standard types of backlights that have only one bulb and can only shine at a point. For VAZ cars, they began to produce ready-made elements for illuminating the ignition switch, which are conveniently mounted and do not require alterations or cutouts in the plastic of the car’s steering column.