The question of whether it is possible to drive without a mass air flow sensor is of concern to many car enthusiasts. The fact is that in modern cars special electronic devices are responsible for equipping the working mixture. The technical parameters of the mixture depend on the ratio in which fuel and air will be mixed.

Depending on how much air has passed through the damper, the electronics understand how much fuel should be supplied to the car. In this case, the structural part that is responsible for determining the air flow through the throttle valve is the mass fuel flow sensor. Consequently, the mass air flow sensor is an important part of the mechanism, which indirectly determines the quality of the working mixture.

Principle of operation

The sensor consists of platinum filaments (which is why it is not cheap), through which an electric current is passed, heating them. One thread is the control thread, air passes through the second, cooling it. The sensor produces a pulse-frequency signal, the frequency of which is directly proportional to the amount of air passing through the sensor. The controller records changes in the current passing through the second, cooled filament and calculates the amount of air entering the engine. Depending on the frequency of the signals, the controller sets the duration of operation of the fuel injectors, adjusting the ratio of air and fuel in the fuel mixture. The readings of the mass air flow sensor are the main parameter by which the controller sets fuel consumption and ignition timing. The operation of the flow meter affects not only the overall fuel consumption, mixture quality, engine dynamics, but also, indirectly, the engine life.

Symptoms of a problem

A malfunction of the mass air flow sensor can be indirectly judged by the following symptoms:

- The CHEK ENGINE lamp comes on;

- The car accelerates slowly (stumbles);

- Unstable engine operation at idle;

- Engine bad;

- Increased fuel consumption;

- The engine stalls while driving when changing gears.

Dirty air flow sensor (side view) The symptoms described above can be caused by other reasons, so it is better to accurately check the mass air flow sensor at a service station using specialized equipment. If you don’t have time, don’t want to, or don’t feel like spending money, you can check the performance of the mass air flow sensor yourself with high, but not 100% reliability.

Dirty DMRV (top view)

What happens if you turn off the mass air flow sensor?

Let's start with the fact that when the flow meter is turned off, the engine goes into emergency operation mode. What could this lead to? Depending on the car model and, accordingly, the firmware, the engine will stop (as on Toyota), increase fuel consumption, or... nothing. Judging by numerous messages from auto forums, experimenters note increased agility after shutdown and the absence of failures in engine operation. No one has carried out careful measurements of changes in fuel consumption and engine life. Whether it is worth trying such manipulations on your car is up to the owner to decide.

Features of failures

What all pedal failures have in common is that when you press the pedal, the engine does not respond in a timely manner, and therefore does not gain momentum. Such failures can appear in different situations and the behavior of the machine can also be different.

So, we can highlight:

- Short dips while driving (no more than a couple of seconds) followed by a quick response from the engine.

- Dips during acceleration.

- Dips at idle speed.

- Prolonged failures, as a result of which the car stalls.

- Jerking, characterized by a series of alternating short dips and subsequent jerks.

There are not many reasons for this phenomenon, so finding and eliminating them will not be difficult for an experienced driver.

Gas pedal dips

In 99% of cases, failures can be caused by one of the following reasons:

- clogged injectors;

- damage to the fuel system;

- injector damage;

- wear of temperature sensors;

- errors in the ECU;

- failure of spark plugs.

If you notice even minor changes in the “behavior” of the engine, you should end the trip as quickly as possible and visit a car service center or perform independent diagnostics and repairs. Continuing to drive a car with dips is not only harmful to the car itself, but also extremely dangerous.

Diagnostics of mass air flow sensor

Difficulties in self-diagnosis of a flow meter are caused by the fact that it is a capricious device. Taking readings at the number of revolutions specified in the manual often does not give results. The readings are normal, but the sensor is faulty. Here are several ways to diagnose the performance of the sensor:

- The easiest way is to replace the mass air flow sensor with a similar one and evaluate the result.

- Check without replacement. Disconnect the flow meter. Unplug the sensor connector and start the engine. When the DMVR is disabled, the controller operates in emergency mode. The amount of fuel for the mixture is determined only by the throttle position. At the same time, the engine keeps speed above 1500 rpm. If the car becomes “faster” during a test drive, then most likely the sensor is faulty

- Visual inspection of the mass air flow sensor. Remove the corrugated air intake tube. First, carefully inspect the corrugation. The sensor may be working properly, but the reason for its unstable operation is cracks in the corrugated hose. If the surface is intact, continue the inspection. The elements (platinum threads) and the inner surface of the corrugation must be dry, without traces of oil and dirt. The most likely cause of the malfunction is contamination of the flow meter elements

. - Checking the mass air flow sensor with a multimeter. The method is applicable for Bosh mass air flow sensor with catalog numbers 0 280 218 004, 0 280 218 037, 0 280 218 116. We switch the tester to measure DC voltage, with a measurement limit of 2 Volts.

All of the home diagnostic methods described above do not provide a 100% guarantee of the reliability of the result. A reliable diagnosis can only be made using special equipment.

Replacing the air flow sensor

To replace the sensor with your own hands, you need to prepare a shaped screwdriver and a “10” key.

The replacement procedure consists of the following steps:

- First you need to turn off the ignition and open the hood.

- Then you need to disconnect the negative terminal on the battery.

- At the next stage, you need to loosen the clamp with which the corrugation is attached to the mass air flow sensor.

- Next, remove the corrugation from the pipe.

- Then you need to bend the comb and disconnect the sensor connector.

Disconnecting the sensor connector

Then, using a key set to “10”, you need to unscrew the sensor mounting bolts to the air filter housing. Now you can remove the mass air flow sensor. Installing the sensor yourself is done in the reverse order.

Thus, if the car stalls and has all the signs of a breakdown of the mass air flow sensor, then before you start repairing it, you should check the level of its signal, it should not be low, perform a full diagnosis of the car and repair all faulty components and parts.

It is important to undergo regular vehicle inspections and perform timely maintenance, then the parts and components will last longer.

Do-it-yourself prevention and repair of mass flow sensors

The service life of the mass air flow sensor can be extended by timely replacement of the air filter and monitoring the condition of the piston rings and seals. Their wear causes excessive saturation of crankcase gases with oil. An oil film getting on the sensitive elements of the sensor kills it. On a sensor that is still alive, lost readings can be restored by the “Max air flow sensor corrector” program. With its help, you can quickly change the mass air flow sensor calibrations in the firmware. The program is easy to find and download without problems on the Internet. The luftmassensensor reiniger mass air flow sensor cleaner can help revive a non-functioning sensor . To do this you need:

- Remove the sensor from the engine as described above.

- Spray the product thoroughly and generously onto the sensitive element.

- Wait until any remaining dirt has drained away.

- Dry the sensor well before installation. For prevention, the procedure can be repeated before each air filter replacement.

How to restore the mass air flow sensor?

The optimal solution for problems with the mass air flow sensor is to replace the faulty sensor with a new one. But since the cost of the device is about 2500-3900 rubles, many owners are trying to “revive” the old part.

There are four recovery methods:

- installation of additional resistance;

- blocking part of the air supply channel to the thermistor with aluminum tape;

- updating the engine control unit firmware;

- washing the sensor body and housing from dirt.

Installing additional resistance

Additional resistances are installed in the circuit connecting the sensor to the control unit. When an electric current passes, the voltage decreases, which can be brought to the required limits. The resistance value is selected experimentally. Most often, a 1 kOhm resistor is soldered to the yellow wire and a 15 kOhm element to the green wire.

Blocking part of the air supply channel

The repair principle is based on partially cutting off the air supply to the thermistor. Due to this, less intensive cooling is ensured and it is possible to bring the voltage value to the state of a working device. The cross section is selected experimentally with voltage monitoring using a multimeter. In some cases, owners block the supply channel by 70-80%. Aluminum tape is used for gluing.

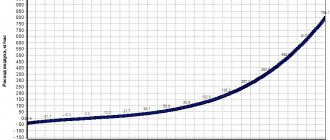

Correcting the firmware of the engine control unit

An adjustment means a change in the calibration or operating schedule of the mass air flow sensor stored in the unit’s memory. The dependence graph is constructed in such a way that at a sensor voltage of 0.996 volts, the flow rate is considered equal to zero. But if the sensor fails and the starting voltage is 1.055 volts, then the control unit considers the air supply to be 1.8 kg when the engine is not running. Changing the graph using the MAF Corrector utility will allow you to set the flow rate to 0, which will improve engine performance. This method can be recommended to owners who are well versed in the control unit software.

Do-it-yourself cleaning of the air flow sensor

The air volume sensor is cleaned after it is detected that it is not working correctly. The procedure is performed by partially disassembling and removing the device body with active elements. At the same time, the body is washed and cleaned from remaining leaves and dirt deposits. In many cases, washing the air flow sensor on a VAZ 2114 does not help restore the device’s parameters.

Mechanical methods of cleaning the mass air flow sensor on the VAZ 2114 are prohibited, as is blowing dust with compressed air.

What products should be used to clean the sensor?

To clean sensors, there are special liquids supplied in pressurized aerosol cans. An example of such a product is a special air flow sensor cleaner Luftmassensor-Reiniger from Liqui Moly. There are similar liquids from other manufacturers. You can wash the sensor with a mixture of 70% isopropyl alcohol and 30% distilled water, after warming the device to 60-70 ºС with a hair dryer.

When washing the mass flow sensor it is prohibited:

- try to clean the sensor with cotton balls, hard objects and brushes;

- use household cleaning products;

- Use carburetor cleaners based on acetone or ether.

Cleaners based on heavy petroleum products, for example, WD40, will remove plaque from working parts, but will leave a greasy film that must be washed off with isopropyl alcohol. The use of ether-containing substances is not recommended due to the destruction of the compound filling and electronic components.

Algorithm of actions

Sequence of steps when washing the mass air flow sensor:

- Remove the sensor together with the housing from the engine air duct. The device is attached with a clamp to the channel and two bolts to the air filter housing.

- Unscrew the two screws securing the sensor to the housing. The bolts have a star head, but many owners unscrew them with pliers.

- Wash the measuring thermistors and the air passage channels with a cleaning agent. If the cleaning method with alcohol is used, the removed sensor is heated with a stream of warm air and placed in a container. The alcohol-water mixture is also heated to 60-70 degrees.

- Dry the sensor.

- Wash the sensor housing with warm soapy water. Rinse under running water and dry.

- Assemble the sensor and install it in place.

Is it possible to drive without a mass air flow sensor, what problems will arise?

The question of whether it is possible to drive without a mass air flow sensor is of concern to many car enthusiasts. The fact is that in modern cars special electronic devices are responsible for equipping the working mixture. The technical parameters of the mixture depend on the ratio in which fuel and air will be mixed.

Depending on how much air has passed through the damper, the electronics understand how much fuel should be supplied to the car. In this case, the structural part that is responsible for determining the air flow through the throttle valve is the mass fuel flow sensor. Consequently, the mass air flow sensor is an important part of the mechanism, which indirectly determines the quality of the working mixture.

Removal and replacement

If the VAZ 2114 air sensor was checked, and the check confirmed incorrect operation, then you should think about replacing it. Experts do not advise rushing to throw away a part, even if it is not working correctly. Sometimes it happens that after cleaning the contacts it starts working again

It’s worth paying attention to this possibility if you don’t want to replace the part.

When it is not possible to revive an existing part, you should go shopping. A new part will not be cheap, it is an expensive pleasure. That is why experienced technicians advise initially checking the functionality of the old sensor before spending your savings. To replace the product, you will need to prepare a flat-head screwdriver, as well as a 10mm wrench.

The sequence of actions should be as follows:

- Initially, the ignition is turned off, the hood is opened, and the negative terminal is removed from the battery.

- Now you have to determine where exactly the sensor is located. Usually there are no difficulties with its location. In the engine compartment you can see the air filter unit; it is made of plastic. This sensor is located on its rear part; it is usually mounted on the air filter pipe.

- Next, the clamp made of metal is removed and the product is connected to a corrugated hose through which air is supplied.

- You will need to pull off the corrugated hose.

- Next, the contact block is removed, and it should be taken into account that there is a button on the bottom of the plug. When pressed, the spring wedge is released. This is necessary to freely pull out the block.

- A pre-prepared 10mm wrench is needed to unscrew the bolts one by one; they are used for fixing. By the way, the second of them is located on the lower part of the case.

- All that remains is to remove the sensor.

Features of the mechanism

Before answering the question whether it is possible to drive without a mass air flow sensor, it is necessary to understand the constituent features of the device. The device is located in the air intake duct, immediately behind the filter. The block from the channel network is responsible for connecting to the control unit. In some modern vehicles, a different connection technology is possible.

It would seem that the operation of the damper is simple. The gas pedal is pressed, opens, the required volume of air is drawn in, the damper closes and a smaller amount is admitted. But in practice things are different. When driving a vehicle, the driver constantly changes the performance by pressing the gas pedal, therefore the engine does not function equally. Whirls occur and air cannot enter in the same volume, making calculations difficult.

The mass air flow sensor differs in design. You can ride with anyone as long as it fits the car. Highlight:

- mechanical;

- ultrasonic;

- thermal-anemometric.

The latter are used only on domestic VAZ vehicles. There will be a penalty if you use other components.

The devices are multi-component, but there are no moving parts. This fact explains the stability of operation even in difficult weather conditions and a long service life. It is not possible to repair it; it is easier to purchase a new one. The sensitive element is a nickel mesh or platinum wire. The characteristics depend on the manufacturing company. A wire that transmits an electric charge is connected to a small structural part. The element heats up above the air temperature, can reach 100 degrees Celsius. For nickel units the maximum threshold is 75 degrees, and for platinum units - up to 100 degrees.

The equipment required for the machine consists of the following elements:

A constant pulse of electricity is required in order to cool the elements affected by the air flow. Direct determination of the air entry rate, that is, its volumetric characteristics, is determined by the degree of how the required current indicators change.

How to check the mass air flow sensor

This device is quite complex and expensive, which will require care when rejecting it. It is better to use instrumental methods, although situations may be different.

Method 1 - external inspection

The location of the MAF along the air flow path already behind the filter should protect the sensor elements from mechanical damage from flying solid particles or dirt.

But the filter is not perfect, it can be torn or installed incorrectly, so the condition of the sensor can first be assessed visually.

There should be no mechanical damage or visible contamination on its sensitive surfaces. In such cases, the device will no longer be able to give correct readings and intervention will be required for repair.

Method 2 - Power off

In unclear cases, when the ECM cannot clearly reject the sensor and switch to bypass mode, this action can be performed independently by simply turning off the engine and removing the electrical connector from the mass air flow sensor.

If the engine operation becomes more stable, and all its changes remain only typical for software bypass of the sensor, for example, an increase in idle speed, then the suspicions can be considered confirmed.

Method 3 - test with a multimeter

All cars are different, so there is no single way to check the MAF with a multimeter voltmeter, but using the example of the most common VAZ sensors, you can show how this is done.

The voltmeter must have suitable accuracy, that is, be digital and have at least 4 digits. It must be connected between the instrument ground, which is on the mass flow sensor connector, and the signal wire using needle probes.

The voltage of the new sensor after turning on the ignition is quite a bit short of 1 Volt, for a working mass air flow sensor (Bosch system, Siemens is found, there are other indicators and methods) it is approximately in the range of up to 1.04 volts and should increase sharply when blowing, that is, starting and set of revolutions.

Theoretically, it is possible to test the sensor elements with an ohmmeter, but this is already an activity for professionals who know the material well.

Method 4 - scanning with Vasya Diagnostic scanner

If there are no prerequisites for displaying an error code yet, but suspicions about the sensor have formed, then you can view its readings through a computer-based diagnostic scanner, for example VCDS, which in Russian adaptation is called Vasya Diagnost.

The channels associated with the current air flow (211, 212, 213) are displayed on the screen. By switching the engine to different modes, you can see how much the MAF readings correspond to the required ones.

It happens that deviations occur only during a certain airflow, and the error does not have time to appear in the form of a code. The scanner will allow you to look at this in much more detail.

Method 5 - replacement with a working one

The mass air flow sensor is one of those sensors whose replacement is not difficult; it is always visible. Therefore, it is often easiest to use a replacement sensor, and if the engine operation returns to normal according to objective indicators or scanner data, then all that remains is to purchase a new sensor.

Diagnosticians usually have replacements for all such devices available. You just need to make sure that the replacement device is exactly the same as required for this engine according to the specification, appearance alone is not enough, you need to check the catalog numbers.

Is it allowed to travel?

You can drive without a mass air flow sensor - yes, but you should carefully assess the situation. When devices fail, the driver does not always have a spare one with him in his emergency kit. Also, sensors for some types of cars are extremely difficult to find, especially when it comes to brands of foreign cars.

In the event of a planned or emergency shutdown of the device, the vehicle operates in emergency mode. Only the throttle valve is responsible for preparing the air-fuel mixture. The state of affairs cannot be called correct, since it provides ideal performance indicators, quickly breaks down and leads to breakdown of the constitutive parts of the mechanism. What will happen if you drive without a mass air flow sensor for a long time, it is clear that the car will become unusable.

When operating in emergency mode, only the damper determines fuel consumption. There is high fuel consumption. There will be no fuel savings, which is extremely unprofitable in Russian realities. The crankshaft rotation speed will be at least half a thousand revolutions per minute. There are no gradations.

You can determine whether the sensor needs to be replaced yourself. To do this, the device is turned off and only the throttle valve reads the readings. If, in the absence of equipment, the vehicle moves quickly, then it is faulty and requires replacement.

Source

Dips during acceleration

Most often, in the VAZ 2114 car, failures when pressing the gas injector occur during acceleration.

If you are faced with a similar situation, then the search for its problem should be carried out in the following sequence:

- If the spark plugs are oxidized or covered with soot, they should be cleaned with a cloth with kerosene or fine sandpaper (or replaced if they cannot be restored). In addition, the composition of the fuel mixture should be adjusted, since very often the cause of soot on the spark plugs is precisely its incorrect composition.

Carbon deposits on a VAZ 2114 spark plug

- Check the condition of the armored wires (to do this, their insulation should be measured using a megohmmeter and, if necessary, replaced with new ones).

- Check the condition of the throttle valve. If it is contaminated with plaque, it should be thoroughly cleaned (even a slight layer of plaque greatly affects the proper operation of the damper).

- Check the condition of the air filter, and in case of severe contamination or damage, replace it with a new one (it is worth remembering that the filter directly affects the correct composition of the combustible mixture, and therefore it should be checked periodically even during normal engine operation).

- If, after completing the above steps, the cause could not be found, then you should dismantle the fuel pump and check its functionality. At the same time, the fuel filter should be checked and, if necessary, replaced.

- Check the computer for errors (this can be done using a diagnostic computer. If it is not available, you will have to contact a car repair shop).

- Conduct diagnostics of the injectors and, if necessary, clean them (clogged injectors are the most rare cause of failures, but at the same time they are quite difficult to do on your own. If you cannot clean them yourself, you will have to contact a car service).

Checking the injectors of the VAZ 2114

If on your VAZ 2114 failures occur when you press the gas injector while driving, then using the above plan you can easily find the causes of this phenomenon and be able to eliminate it.

What happens if you turn off the car's mass air flow sensor

Modern internal combustion engines, both gasoline and diesel, operate under the “guidance” of an electronic control unit (ECU). It controls all engine systems and, based on the data received, forms a fuel-air mixture. As you know, neither gasoline nor diesel fuel burns on its own. Vapors mixed with oxygen in the air ignite. To prevent the process from turning into an uncontrollable fire, it is necessary to accurately calculate the proportions of fuel and air. The stoichiometric, that is, ideal ratio, is 1 part of the mass of fuel and 14.7 parts of the mass of air.

How to comply with consumption standards

The dosage of the liquid component is easy to ensure. The pressure, the diameter of the gas line, and the throughput of the fuel injectors are known. By opening the injector valve for a certain time, the ECU controller can fill the combustion chamber of the cylinder with exactly as much gasoline as is required to form the mixture. How to measure the mass of incoming air?

To generate data on the amount of air, injection cars are equipped with a mass flow sensor. It converts information from physical (kg/hour) to electronic, in the form of varying voltage at the sensor output. There are even special calibration schedules for the engine ECU.

How the flow meter works

The first copies of the sensors worked on the principle of a pitot tube in an airplane. The incoming air mechanically deflected the petal connected to a variable resistor. The changing resistance provided approximate information about the intensity of air flow. The technology was subsequently improved, and today the vast majority of cars have thermal anemometric sensors.

Regardless of the car brand, they look approximately the same.

The housing is a hollow cylinder, the diameter of which corresponds to the air duct of the intake manifold. It contains an electronic group consisting of various sensors and a heating device. An electronic control and data reading circuit is made in a single housing.

- Two resistors in series are connected in a bridge circuit and should show the same resistance. One of them is variable, the second is reference. A variable resistor is made of platinum wire and changes resistance as the temperature changes.

- To synchronize with the reference, the wire is heated until the resistance values match. When blown with air flow, the platinum wire cools and the resistance changes. The resistor heats up (at the command of the control unit), for this purpose a certain voltage is applied to the contacts.

- The value of this voltage is recorded by the engine ECU controller with an accuracy of 1/1000 volt, and based on a calibration graph, it converts the data into air volume.

Battery and contacts

If the starter turns less and less well, then most likely the battery is discharged. If there is anything, check the battery charging and electrolyte level (if necessary, add distillate). You can also rent a battery from a neighbor's garage. If with another device your car starts with half a turn, then that’s definitely the problem.

Think:

Is it worth buying a new one or can this one be restored? Or perhaps it simply does not take recharge from the generator? Then check all electrical connections for loose contacts and oxidation. What is found is to be cleaned and reattached. And look at the generator itself.

What happens if you turn off the mass air flow sensor on your car?

On auto forums there are a lot of posts from keyboard “experts” on the topic: “I drive without a mass air flow sensor, the power has doubled, I can kill everyone at a traffic light.”

Of course, these statements have nothing to do with reality. It is impossible to increase power with a disabled mass air flow sensor.

- Firstly, without information from the sensor, the ECU will not be able to form the correct proportion of the fuel mixture, and combustion efficiency will decrease. The driver, compensating for the lack of power, will press on the accelerator, increasing gasoline consumption. As a result, the fuel will simply fly out into the pipe, without giving the car the required dynamics.

- Secondly, when we disconnect any important sensor (and the mass air flow sensor is one of these), the ECU switches the engine control to emergency mode. That is, in principle, you can drive a car, but only slowly and to the nearest service station.

Information: It is not the mass air flow sensor that is directly related to the environment, but the lambda probes. It is the disabling of these sensors that, in principle, will lead to an increase in engine output with a deterioration in exhaust toxicity. Only then will you need to reflash the ECU controller.

We clean the DMRV ourselves

After we have discussed methods for diagnosing the sensor, as well as means for cleaning it, let’s move on to the most important question - how to clean the air flow sensor on a VAZ 2114 yourself?

First, you need to disconnect the block that supplies the power wires - to do this, you just need to press the button on its lower part, and then pull it towards you. You also need to unscrew the two fastening screws connecting the air flow sensor to the air filter (for this you will need a 10mm wrench).

After this, you should use a Phillips screwdriver to unscrew the screws located on the sensor casing in the area where the block with wires is attached - having done this, you will be able to disassemble the casing itself and remove the sensor out.

Flushing the air flow sensor

We wash all elements of the sensor responsible for its sensitivity - the contacts and wire of the temperature sensor - with a spray from a can (if it is a carburetor cleaner or VeDe-shka). At the same time, you should strictly monitor the jet pressure - to do this, you need to keep the sprayer at a distance of at least 15 cm from the sensor.

After half a minute, this operation can be repeated, after which wash all areas where the first composition was applied using a syringe with a solution of ethyl alcohol. After this, all that remains is to assemble the sensor in the reverse order and mount it in place.