Clutch pedal position sensor 1118-3720015 (E-GAS) Lada Kalina, Granta, Priora

The clutch pedal position sensor is installed on VAZ cars with an electronic gas pedal; it is installed on the clutch pedal bracket; in order to see it, you just need to look under the steering column. The VAZ clutch pedal position sensor facilitates the process of starting movement, helps to eliminate speed dips and jerking of the car when switching a manual gearbox. The clutch pedal position sensor helps reduce fuel consumption. Its normal position is open, that is, it turns on only when the clutch pedal is pressed.

Manufacturer: Avers LLC, Togliatti

Contents: Switch 1118-3720015 — 1 pc. Protective casing 1118-3720024-10 — 1 pc. Fastening screw 1-0076690-01 — 2 pcs. Spring 1118-1602179-00 1 pc.

Applicability: Lada Priora 2170, 2171, 2172 Lada Kalina 1117, 1118, 1119 Lada Granta 2190, 2191

When ordering, in the “Order Comments” line, indicate the model and year of manufacture of your car.

The clutch pedal sensor is installed on vehicles with an e-gas system, providing a signal to the electronic control unit to inform about the open position of the propeller shaft and drive. It provides a normally open limit switch, allowing pedal input control and providing the following benefits:

- increased flexibility in controlling engine operating modes (no jerks or drops in speed);

- simplifying the start of movement;

- reducing fuel consumption by turning off its supply at the moment of pressing;

- possibility of adjusting ignition timing.

Symptoms of device malfunction

The following symptoms indicate problems with the clutch pedal position sensor:

- a sharp change in engine speed (drop or increase) when pressing the clutch pedal;

- “pecking” of the car while changing gears.

Malfunction of the clutch pedal sensor 1118-3720015 (e-gas) Lada Kalina, Granta, Priora is automatically detected by the electronic control unit. The CheckEngine indicator lights up immediately, indicating an error. Please note that a problem with the clutch pedal sensor may be associated not only with its failure, but also with the following problems:

- open circuit or short circuit;

- Incorrect clutch pedal height.

If an error appears indicating problems with the clutch pedal sensor, or the symptoms listed above occur, then you first need to eliminate the last two points. This will allow you to get by with a little blood if necessary. At the same time, if the problem still lies in the clutch pedal sensor, then you need to purchase a new device. It is inexpensive and will not break a serious hole in the budget even with unscheduled repairs.

The popular Priora was designed in the spirit of the times, so the computer even controls such a unit as the clutch. The electronics do not control the process of turning the clutch on and off, but the clutch sensor on the Priora, installed under the clutch pedal, collects information about the position of the pedal. This data enters the electronic engine control unit and is used to optimize engine operation depending on the driving mode, and also makes it possible to use cruise control on the car.

How does the electronic engine management system work?

The electronic engine control unit controls most of the vehicle's components, with the exception of the steering and suspension. ECU programs have presets (tables), on the basis of which optimal operating modes are calculated. Many sensors installed on a car read information about speed, movement, engine speed, mechanisms and drives. Based on the tables, the ECU changes the ignition mode, activates additional functions and regulates the composition and amount of the air-fuel mixture entering the cylinders.

Removal and installation

Replacing the brake pedal sensor on Kalina is done with an adjustable wrench set to “19”. The sensor itself is located above the brake pedal under the steering column. Conventionally, the withdrawal stages can be divided into 5 stages:

- Before starting work with an electrician, it is recommended to disconnect the negative wire (terminal) from the battery.

- Then you need to switch to the driver's side of the car. For ease of operation, it is recommended to move the driver's seat in the direction opposite to the dashboard.

- Find the location of the sensor. Find contact with wires. Press and hold the 2 plastic tabs located on either side of the chip. Pull the plug out of the sensor connector.

- Hold the wrench in your hands and loosen the lock nut. The sensor can then be unscrewed freely.

- The installation process is similar to the uninstallation procedure, except that you will need to make changes (adjustments), the process of which is described in detail in the previous section.

Functions of the Priora clutch sensor

Data about the current operating mode of the clutch mechanism is important for engine control. If the clutch is disengaged, it is necessary to reduce the amount of fuel and reduce the engine speed. It is optimal to do this based on the current speed of the car, without idling. A driver, especially an inexperienced one, may make mistakes, which leads to increased load on the engine and clutch. The on-board computer, based on the readings of the clutch sensor, regulates the engine operating mode, setting the optimal speed. In addition, the clutch sensor on the Priora, in combination with the speed sensor, allows the computer to evaluate the performance of the unit and report problems.

Installation of a clutch sensor on a Priora is allowed:

- reduce fuel consumption;

- make driving easier and more fun;

- check the serviceability of the clutch;

- extend clutch life.

Therefore, the functionality of the sensor affects the service life of the units, fuel consumption and is extremely important for the proper functioning of the ECU.

Operating principle of the Priora clutch sensor

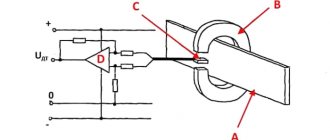

What is a Priora clutch sensor? The operating principle of the device is no different from a simple limit switch. When the pedal is not pressed and the clutch is engaged, the sensor contacts are open. When the transmission clutch is depressed, the limit switch closes, sending a signal to the computer to disengage the clutch disc and pressure plate.

The clutch sensor is installed on the pedal mount so that the toe of the pedal touches the limit switch.

The sensor design is simple and reliable, but this does not exclude the possibility of breakdowns and malfunctions in its operation.

Drive faults

| Malfunctions | Diagnostics | Elimination |

| When changing gears the car “stops” | Disconnecting the block with wires, checking for changes after disconnecting the DS | Replacing the DS with a new one, since the structure cannot be repaired |

| Uncharacteristic increase/decrease in engine speed when the clutch is disengaged | Connecting a new, working DS | Replacing the DS with a new one |

| P0830 "Check Engine" - clutch sensor error on the dashboard | Connecting a new, working DS | Replacing the DS with a new one |

Each type of drive has its own specific disadvantages. It is worth noting that many problems with clutch operation are related to the drive.

Cars often use a mechanical cable drive. The main malfunctions of a cable-driven clutch are as follows:

- violation of regulation;

- rope break;

- snacking.

The cable is adjusted using a nut, which allows you to change the length of the braid relative to the cable itself. If adjusted incorrectly, the cable becomes too tight or weakened, which leads to incorrect transmission of the driver's force to the mechanism.

Cable breakage is usually due to corrosion. With this malfunction of the clutch, its functioning completely stops.

Description of the clutch pedal sensor

What kind of device is this and how to replace it is below.

Purpose, location and operating principle

The clutch sensor is installed directly on the clutch pedal. It influences engine control via the electronic accelerator pedal and provides a convenient and flexible control scheme for machine operating modes. It itself is like a minor switch that has on and off modes.

Typical malfunctions and methods for their elimination

If the controller does not pick up signals from the clutch, there is a risk of error code 0830. This problem usually occurs due to a faulty clutch sensor or a short circuit or open circuit. To correct this state of affairs, it is necessary to identify the reasons. That is, inspect the contacts for cracks or corrosion.

Tool for replacing Lada Kalina

Replacing the clutch release bearing

If the bearing still needs to be replaced, you will have to perform the following sequence of actions:

- dismantling the gearbox;

- disconnecting the ends of the spring clamp from the coupling;

- removal from the bearing guide sleeve;

- disconnecting the spring holder;

- removing the bearing from the coupling and installing a new part.

Before installing the parts on the guide bushing, their surfaces must be generously lubricated with grease.

last up to 150,000 without problems , but they often have to be replaced every 50,000 km due to driver errors and bad roads, which destroy the entire car, including the clutch.

How to understand when it's time to change the clutch

Mechanical clutch is a mechanism whose operating principle is based on the action of sliding friction. Often the term "clutch" is used to refer to one of the components of a vehicle's transmission that is used to connect the engine flywheel to the transmission. Depressing the clutch pedal temporarily disconnects power transmission from the engine.

The clutch mechanism is necessary so that you can move away smoothly without jerking. The speed of the car begins to increase only at a certain minimum number of engine revolutions. The clutch is also used when it is necessary to match the speed of the car and the number of revolutions of the crankshaft, that is, it ensures a smooth transfer of torque from the engine to the gearbox and, if necessary, completely disconnects the gears of a manual gearbox from the engine drive mechanism for a few moments.

There are several types of clutch. Often these are one, two or more friction discs pressed tightly against each other or against the flywheel using springs.

When the driver presses the pedal, the clutch discs are separated and an air gap appears between them, the clutch is disengaged at this time, and no torque is transferred from the engine to the gearbox. When the pedal is released, the pressure springs return the discs to their original position and again come into close contact; the torque of one of the driving discs is transmitted under the influence of friction to the driven disc.

The clutch is one of the most important parts of a car. Various types of these mechanisms are classified according to the control method, the type of friction operating in a given case (dry friction or wet friction), the number of disks, etc. As engine power increases, torque increases; accordingly, double-disc clutch units are used, which have a longer service life.

Sooner or later, clutch discs wear out and require replacement. A failed clutch can cause other parts of the vehicle to fail, such as the gears in the gearshift mechanism, or even prevent the vehicle from moving down the road.

How to understand when it's time to change the clutch

If you hear a loud noise from the release bearing when you release the clutch, it means it is worn out. Clutch wear results in higher and more expensive fuel consumption due to significant loss of engine power in this car group.

One of the clutch malfunctions is slipping of the discs when the pedal is released freely. When sliding relative to each other, the discs become very hot, which leads to rapid deformation or rupture of the discs. Friction linings burn, a specific smell is heard in the car interior.

How can you independently check faults in the clutch system without going to a gas station, as they say, in a popular way? The driver may notice disc slippage first in high gears. In this case, the engine speed increases, but the driving speed does not increase. Having noticed this state of affairs, it is necessary to take action as the process develops, intensifies and, ultimately, reaches a point where the car simply cannot move when engaging first gear.

How long does the clutch mechanism last? The answer to this question is ambiguous. After all, the durability of this mechanism depends not only on the quality of workmanship, but also on the experience and driving technique of the driver himself. According to the unspoken rule of motorists, discs are replaced after driving eighty to ninety thousand kilometers. But these indicators can deviate in any direction.

How else can you tell when it's time to replace the clutch?

The following “symptoms” can be listed:

· The clutch is engaged, i.e. the clutch is not completely disengaged. This can be seen by a loud squeaking noise when changing gears while the vehicle is stationary;

- · The car jerks even when the pedal is released fairly smoothly;

- · The clutch pedal is pressed all the way, but does not return to its original position;

- · When the clutch is engaged, strong vibration occurs.

It will be a shame to find yourself somewhere in the middle of the intended path, so do not put clutch replacement on the back burner.

If you have some experience, a special tool called a caliper will help you measure clutch wear. By following the instructions and having a lift, you can measure the thickness of the disk without disassembling it.

Replacing a clutch often requires removing the transmission. In general, it should be noted that replacing a clutch is a rather labor-intensive procedure, so if you don’t have the time, experience, great desire or anything else, then you need to go to a gas station. The procedure will not be cheap. But we do not recommend saving on this. It may be cheaper and better to replace the entire clutch (basket, discs, bearings) and lubricate the clutch release fork. Choose reliable manufacturers and reliable auto parts outlets.

What is an electronic clutch?

Like any electronic system, the electronic clutch has its own control unit, which processes the received signals and transmits instructions for performing mechanical actions. In addition, this type of clutch combines various input and actuator devices.

Input devices include the clutch pedal unit and input sensors. The latter are the gas (accelerator) pedal location sensor and the gearbox lever location sensor. Although, according to car enthusiasts, there are many more of them, since the car moves without jerking, and the on-board computer tells you which gear is best to engage.

As for the electronic clutch system (not the pedal part), it has its own control unit. It receives and processes signals from input devices and transfers control to execution by the mechanical part. The unit interacts with the engine control system. This suggests that the car will have keyless entry or similar technology.

The executive part of the mechanisms is represented by an electrohydraulic drive (actuator), which stops the movement of the clutch fork based on a signal from the control unit.

Electronic clutch or also known as eCS - Electronic Clutch System is considered a promising development by Bosch. According to the manufacturer, such an electronic clutch brings a manual transmission closer to an automatic transmission. Unlike an automatic transmission, when using the eClutch system, only the clutch operates in automatic mode.

Thanks to the design and operating principle of the electronic clutch, it can be used not only on conventional cars, but also on the manual transmission of hybrid cars. Unfortunately, Bosch is still keeping many of the nuances of how the electronic clutch works secret.

From the name itself we can conclude that the mechanism is easy to use, does not require much effort to change gears and smoothes out the moment of gear engagement as much as possible. Thus, jerks between gears are eliminated.

Possible breakdowns

Since the sensor is a kind of limit switch that works on/off, there are two options: pressing the pedal and releasing the pedal. Inside the sensor there is a special spring-loaded plastic, which can explode over time and therefore the return mechanism of the sensor will not work, which will lead to a constant closure of the contact and the ECU will receive a signal that the clutch pedal is in an inoperative state and is constantly pressed.

Also, the sensor control circuit is connected to it by soldering; most often, the wires are separated from each other by soldering, breaking the circuit. Upon inspection, it is quite easy to identify such a problem.

Carrying out an inspection

To perform the procedure for checking the brake pedal sensor on a Grant, you will need to turn on the ignition, then press the brake pedal, paying attention to the brake lights - do they come on? The pedal should then be released, again focusing on the brake lights, which should now go out. If the brake lights do not light up, you should check the sensor itself, and also see if voltage is supplied from the battery to the wiring harness block.

During the test, circuit 1-4 must be closed and circuit 2-3 must be open. Then press the rod, usually chain 2-3 should close and chain 1-4 should open.

Similar sensors are installed on other VAZ models - Priora, Kalina and others, so the solution to the problem for these models will be exactly the same.

Replacement instructions

The clutch transmits torque from the gearbox to the engine. The transmission is carried out thanks to the clutch cable, which connects the power unit to the gearbox and provides starting, gear shifting and braking. Thanks to the linkage mechanism, the car is set in motion.

Which clutch should you choose?

There are several types of clutch that differ:

- operating principle: electrical, mechanical and combined;

- working environment: air and oil bath;

- mechanism: groups of closed and alternately closed mechanisms;

- number of disks: single, double and multi-disk;

- number of springs: one or more;

- two streams.

The clutch is a complex mechanism, so before you replace it yourself with a Lada Kalina, you should carefully study the design and features of the mechanism.

VAZ 1117, 1118 and 1119 are equipped with 190 and 200 mm clutches. The diameter can be determined based on the number of starter mounting bolts. For 190 mm there are 3, and for 200 mm there are 2. Includes clutch disc, pressure plate and release bearing. The most famous brands: Valeo, Sachs, Luk, VIS, Kraft.

When using a unit of other models, you should pay attention to the flywheel, the type of which is determined by the number of starter pins. There are two of them in the Lada Kalina, and three in the VAZ 2108. The clutch life depends on the components and operating conditions. A high-quality unit can last for 100 thousand kilometers.

If you have problems with the clutch on the road, it is best to call a tow truck or tow the car with another vehicle, otherwise this may lead to transmission failure.

Tools

To replace the clutch, the car must be raised, since some of the work is performed from below. To do this, you can use an elevator, overpass or inspection pit. From the tools and materials for the DIY replacement procedure, you need to prepare:

When removing the transmission, the oil must be drained. If the work is done independently, then all the fat must be drained. If you have an assistant, you can drain some of the liquid from the threads so that the oil does not flow when they are disconnected.

Types of clutch on Kalina

, 1118 and 1119 two different types of clutch are installed at 190 and 220 millimeters. Determining the diameter is very simple, just pay attention to the number of starter mounting bolts. There are 3 of them by 190 mm and 2 by 200 mm. Regardless of the manufacturer, you will almost always find the clutch disc, pressure plate and release bearing assembly.

If you encounter problems with the clutch on the road, you need to have the car towed by a tow truck, as further movement may damage the transmission.

Preparatory work

It is no secret that work on replacing the clutch is carried out through disassembling the gearbox, so it is necessary to take care in advance of the presence of an inspection hole or overpass. We will also need the following tools and materials:

- New clutch kit.

- Set with tools.

- Hex key.

- Jack.

- Rags.

- Screwdriver.

- Container for draining oil.

- (if it is needed).

- Lamp for illuminating hard-to-reach places.

Step-by-step clutch replacement process

The first step in the work must be done under the hood of the car.

- Disconnect the power and negative cable from the battery, and then remove it.

- Then remove the air filter housing along with the corrugation.

- Remove all cables from the starter.

- We disassemble all the cables going to the gearbox and to the power supply.

Go to work under the car

We remove the gearbox and start working on the clutch.

If you are not confident in your abilities, you should not start this type of repair and you need to contact an auto repair shop for the most professional help.

Review of Manufacturer Prices

Technical parameters of the roller: 100 x 60 x 20 mm, weight 0.05 kg.

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| VAZ 11180-1602266-00 cable lead | From 250 | 25 – 35 |

| 11180-1602210-00 cable assembly | From 300 | —/— |

| 21901-1602210-00 cable assembly | From 300 | —/— |

| 1118-3720015-00 DS | From 370 – 450 | —/— |

*prices are current as of October 26, 2018.

- Toad - switch 1118-3720015 – 1 piece;

- Housing 1118-3720024-10 – 1 piece;

- Screws 1-0076690-01 – 2 pcs;

- Spring 1118-1602179-00 – 1 pc.

Replacement algorithm

- It is necessary to remove the ripples from the air filter housing.

- Disconnect the terminals and other wires from the battery, remove the battery itself during repairs.

Exploded view of the engine compartment and battery.

- Unscrew the starter power supply wiring.

- From the control point it is necessary to remove the cable and wires, and also disassemble the motor protection.

Disconnect the gear shift lever.

- Clean the entire surface of the gearbox mounting to the engine and unscrew it.

We tie the box to the crossbar so that it does not fall.

- Remove the engine mount or lift it up.

- We unscrew the shafts from the gearbox using crabs.

We remove the wheel, lever and take out the transmission so that you can move the box without draining the oil.

- Move the transmission slightly away from the engine without removing the element, allowing you to begin replacing the clutch.

An engine mount is required because the mounting mounts have been removed and are shared between the engine and gearbox.

- Remove the bolts connecting the flywheel housing to the clutch disc. Press the flywheel itself with a screwdriver, while the bolts should gradually rotate in a circle.

After pulling out the box, a gap is formed that allows you to remove the clutch basket.

- Remove the disc and set it aside, even if it is in good condition. Inspect the flywheel for dents, scratches or other damage.

The clutch is old: the seals are finished and the disc is already worn with rivets.

- Install new parts or a new clutch part.

Before installing new parts, lubricate the clutch fork.

- When working with the basket, you need to “center” the disk inside. To do this, the driven element is inserted and then the pressure sheath. The spindle helps simplify the task, and when installing the elements, you need to fill the new basket, insert the centering piece into the disk and insert the flywheel.

A plastic bushing is used for alignment (some manufacturers include it in the clutch kit).

- Tighten the bolts evenly in a circle to secure the transmission to the engine.

- Connect the cable and wiring and make changes to make the entire system work properly.

Even when the first signs of a clutch malfunction appear, it is recommended to start purchasing spare parts and quickly prepare to replace the entire set.

Minor problems are always easier and cheaper to fix than major component repairs.

Symptoms of replacement

Mechanical damage can be seen only after removing the clutch from the car, but its wear can be understood by some changes that have appeared in the operation of the mechanism.

Complete replacement is recommended by the manufacturer for the following symptoms:

- Lead starts, in other words, engine power decreases.

- Slippage appears and engagement is incomplete.

- When changing gears, extraneous sounds, jolts or clicks appear.

- Sometimes the grip is lost.

- Vibrations occur when you press the clutch pedal.

When you press the clutch pedal, it falls through without effort, and with the engine running, it is impossible to engage the gear.

This is the most honest mistake. Occurs when the transmission clutch is damaged.

— the clutch cable is torn / the hydraulic drive is damaged (repaired by replacement and adjustment).

- the clutch fork was cleaned and put on the hinge (repaired by replacement or welding and adjustment).

The smell of burnt pads.

This is a very unpleasant and peculiar smell. This cannot be confused with anything.

This usually happens when starting from a stop, when trying to accelerate at high speed and when driving uphill. The reason lies in severe wear of the clutch disc. There is nothing left of its friction linings. It looks something like this:

If your car is very, very old or Chinese, the springs in the clutch basket may be worn out, but I have never seen this happen in practice.

You cannot drive for a long time with this malfunction, since slipping quickly wears out the basket and flywheel.

The only solution is to replace the clutch disc. In this case, it is advisable to replace the launch pad. Since they last about the same, they are inexpensive, and replacing them requires removing the transmission.

When driving in high gears, when you sharply press the gas pedal, the vehicle speed does not change, but the engine speed increases.

The reasons are exactly the same as in the previous case: wear of the friction linings of the driven disk.

It’s just that when driving at speed, the engine compartment and underbody are well ventilated and you can’t always smell it.

Sometimes the cause of such clutch failure is an oily clutch, but this is extremely rare.

When you press the clutch pedal, you hear a hum, noise, or grinding noise.

The reason, in most cases, lies in the wear of the thrust bearing. Depending on the design, it is modified or filled with lubricant (mainly on old machines).

You can drive for a long time with this malfunction; it is not very comfortable from an acoustics point of view. It is also important to understand that there is a possibility that the bearing will seize completely.

A guaranteed solution to the problem is to replace the thrust bearing.

A temporary solution to the problem, for example, when selling a car, is to weld the bearing in refractory grease.

It is important to understand that the work of removing and installing a gearbox is many times more expensive than replacing a release bearing.

If you hear an unpleasant “high” squeak when you press the clutch, the release bearing is completely jammed and needs to be replaced urgently; if this is not done, you will also replace the clutch basket.

If the squeaking and rattling noise is quiet, the bearing in the flywheel may have broken. But in my practice the problem arose only once. It is usually changed when the clutch basket is removed or during an engine overhaul. This is generally necessary to better preserve the gearbox input shaft bearings, its oil seal and increase the service life of the clutch disc.

Vibrations when starting off and/or when changing gears.

Vibration is usually caused by the clutch disc. Damper springs usually break or wear out:

Or the friction linings are partially destroyed:

It happens that the clutch basket itself breaks:

If your car is equipped with a dual mass flywheel, this could be a problem.

The most unlikely scenario is that the clutch release pads are installed incorrectly. The likelihood of this is extremely low, since clutch baskets with cams have not been installed on cars for 25-30 years (except UAZ).

Only removing the gearbox and disassembling the clutch will help localize the problem.

Gears are shifted with great effort, and a grinding noise is heard when shifting.

These symptoms indicate that the clutch is not disengaging completely. These clutch plates are not completely separated and the clutch plate continues to rotate.

This may be due to:

- air in the transmission hydraulic coupling (it is necessary to remove air from the system and eliminate the causes of air ingress).

- deformation or extreme wear of the clutch fork (can only be eliminated by replacement; it is useless to correct the fork).

- Incorrect clutch adjustment (adjust according to instructions).

- by melting the release pad from the plastic casing, this is especially the case for Chevrolet Niva owners. (The solution to the problem is to replace the thrust bearing).

Signs indicating the need to adjust the clutch on a Lada Kalina

Among the obvious symptoms, such as: problems with gear shifting, extraneous sounds when pressing the clutch pedal, poor clutch and not fully disengaged clutch, there are other signs that indicate the need to adjust the Lada Kalina clutch. To identify them, do a simple test.

- The engine must be completely turned off.

- Press the clutch pedal several times and listen for any abnormal sounds when pressed, such as rubbing, squeaking, clicking, etc.

- Pay attention to the presence of bindings when pedaling. If you can't feel it with your foot, try pressing the pedal with your hand and check the stroke.

- If the pedal jerks or sticks while driving, the clutch will most likely need adjustment.

Other signs of the need to adjust the clutch of your Lada Kalina:

- Take a ruler and check the distance from the floor of the car to the outside of the pedal.

- Press the pedal all the way down until it touches the floor.

- Release and check the distance again, if it exceeds 14.6 cm, the pedal stroke needs to be adjusted.

- If: the full pedal stroke is 14.6 cm, the bottom cable moves freely relative to the release fork lever by more than 2.7 cm, there is an eccentricity of the driven disc pads of more than 0.5 mm and the distance between the pads and rivets is less than 0.2 mm - The clutch needs to be adjusted or completely replaced.

Replacing the clutch sensor on the Lada Grant: expert advice

The clutch pedal position sensor on the Lada Grant is fixed on the clutch pedal bracket. To see it, just look under the steering column at the base.

Violation of vehicle operating conditions leads to premature wear of the sensor and incorrect engine operation.

To restore the machine's performance, it is necessary to replace the clutch sensor (hereinafter referred to as DS).

The process is not complicated, but it requires increased attention and precision from the repairman. Do not damage the vehicle's electronic control unit.

Sequence of actions to independently replace the clutch sensor on a Lada Granta car

Necessary tools, materials:

- screwdriver with a short arm, flat and Phillips bits for unscrewing screws;

- new sensor;

- flashlight, other device as additional lighting.

Clutch sensor replacement algorithm:

- We install the machine on a flat platform. We provide unobstructed access to the front doors.

- Move the front driver's seat back all the way. We open the hood, “reset” the battery terminals to avoid a short circuit in the circuit.

- We climb under the steering column and remove the DS (chip).

- Use a Phillips screwdriver to unscrew the base – the board. It is fixed to the pedal bracket with two screws.

- Remove the latch; it is located on the opposite end of the sensor block.

- Remove the DS block holder.

- We troubleshoot the spring mechanism and inspect the integrity of the board fastening. If there are no defects or damage, insert the new DS block.

- We assemble the structure in reverse order.

Self-replacement of the clutch pedal position sensor on the Lada Grant is completed.

Note to the driver. Before installing a new sensor, check its functionality with a multimeter. The process will take a minute, and you will be confident that the equipment is in good working order.

Malfunctions: symptoms, diagnostics, elimination

| Malfunctions | Diagnostics | Elimination |

| When changing gears the car “stops” | Disconnecting the block with wires, checking for changes after disconnecting the DS | Replacing the DS with a new one, since the structure cannot be repaired |

| Uncharacteristic increase/decrease in engine speed when the clutch is disengaged | Connecting a new, working DS | Replacing the DS with a new one |

| P0830 "Check Engine" - clutch sensor error on the dashboard | Connecting a new, working DS | Replacing the DS with a new one |

Frequent causes of failure of the clutch sensor on the Lada Grant

Software disabling the clutch sensor on the Lada Grant

After replacing the DS with a new one, reset the error code. This can be done either with a standard on-board computer or with an ELM-327 scanner (version 1.5).

The standard on-board computer does not always remove system errors. For high-quality car prevention and diagnostics, purchase a modification of the ELM-327 scanner.

The process of self-adjusting the clutch on a Lada Granta car

On domestic cars of the Lada Granta family, in addition to the electronic clutch unit, a cable mechanism is installed. One end is fixed at the base of the pedal, the other on the gearbox drive lever.

In addition to the automatic tensioner on the cable, the manufacturer has provided a mechanical nut adjuster.

- We place the car on a flat platform, open the hood, and squeeze the parking brake lever.

- We remove both terminals from the battery to avoid a short circuit in the circuit.

- We remove the adsorber - air flow sensor, block - air filter module.

- On top of the starter in the engine compartment we find the clutch fork.

- Use pliers to pull the tip forward.

- Using a caliper, measure the distance from the fork to the plastic disk - the rim. Ideally, the distance is 27 mm. If there is a discrepancy, we make an adjustment.

- Press the clutch pedal 4-5 times and repeat the measurement for objectivity.

- We measure the free play of the clutch pedal; it should not exceed 146 mm. If the distance is increased or decreased, the cable must be replaced; it is stretched.

Note to the driver. We carry out maintenance of the clutch mechanism on a Lada Granta car every 20,000 km.

Review of Manufacturer Prices

Technical parameters of the roller: 100 x 60 x 20 mm, weight 0.05 kg.

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| VAZ 11180-1602266-00 cable lead | From 250 | 25 – 35 |

| 11180-1602210-00 cable assembly | From 300 | —/— |

| 21901-1602210-00 cable assembly | From 300 | —/— |

| 1118-3720015-00 DS | From 370 – 450 | —/— |

*prices are current as of October 26, 2018.

- Toad - switch 1118-3720015 – 1 piece;

- Housing 1118-3720024-10 – 1 piece;

How to properly adjust the clutch on a Lada Kalina with your own hands?

- Open the hood and remove the air filter.

- Locate the cable lug and pull on it to ensure maximum tension on the cable.

- Use a caliper to check the distance between the fork and the drive. If the distance is greater than 2.7cm, turn the screwdriver on the tip wire to adjust the size.

- While adjusting the distance, press the clutch several times and check the clearance again. If there is a shift, correct it again. You need to do this until you get the desired result.

If you still have not been able to adjust the clutch on Kalina, contact a specialist or make a complete replacement. Even if you were unable to adjust the clutch, you are unlikely to have to deal with replacement.

Purpose, types

The purpose of the clutch is to briefly disconnect the engine and gearbox so that the gear ratio in the box can be changed, as well as ensuring a smooth start to movement.

There are several types used on cars:

- frictional (also mechanical);

- hydraulic;

- electric.

The most widespread is the friction type. It is used together with mechanical and robotic ones. In automatic and CVT transmissions, the torque converter plays the role of clutch.

We will not touch on the clutch of automatic and CVT transmissions for now; we will focus on the friction clutch, since it is common in passenger vehicles.

Release bearing wear

Release bearing wear manifests itself as follows.

When you press the clutch pedal you hear a loud noise. The mechanism begins to work and applies a load to the deformed bearing, hence the sound.

In addition, another indicator is strange vibrations that occur when the car is moving. If necessary, the release switch is replaced. Hydraulically driven release bearings have many other problems. The clutch pedal becomes very soft and stops working, and the brake fluid leaks. And the clutch also stops working. A good clutch works like this: torque is transmitted very smoothly. The car handles smoothly on the road, without jolts or drifts. There are no unnecessary sounds when changing gears. The pedal is pressed easily, the machine does not make any extraneous sounds.

Operating principle

The release bearing's job is to connect and disengage the clutch when you press the pedal inside the car. The operating principle of the part is quite simple:

- the driven disk is pressed against the flywheel by a pressure disk, due to which clutch is ensured;

- the pressure on the pressure plate is provided by a diaphragm spring, the inner petals of which are acted upon by the clutch release bearing;

- the movement of the bearing, which initiates the separation of the discs, is ensured by the clutch fork.

Release bearing in a car clutch system

The role of the clutch sensor

It would seem, but what does the clutch have to do with it? And here's what to do about it. When the clutch engages, it makes sense to slow down the engine. But not at the minimum, but in accordance with the speed of the car. This is not always available to a pilot, especially a novice. And here the computer will come to the rescue. In response to a signal from the clutch sensor, it can independently regulate the engine speed.

Important! In addition, in combination with the Priora speed sensor, the ECU can receive information about clutch maintenance.

Summarizing the above, we can say that the presence of a sensor on the clutch allows you to:

- save fuel;

- make driving easier;

- monitor the serviceability of the clutch;

- increase its duration.

Therefore, its functionality is an important factor in the Priora control system.”

How to change the clutch sensor on a Priora

Well, the widespread computerization of cars has reached such a unit as the clutch. No, the electronic unit does not yet control the process itself, but it already controls this process. To do this, a sensor is installed under the clutch pedal to monitor the progress of the clutch.

In a modern car, all process control, except for the rotation of the steering wheel, and even then, is entrusted to the computer, or Electronic Control Unit (ECU). It contains a program with many different tables.

In general, the ECU receives data about the state of the car, speed, revolutions, and activated mechanisms from a large number of sensors.

Based on the results of these observations, the ECU, using these tables, includes certain ignition modes, fuel supply and other executive functions.

It would seem, what does the clutch have to do with it? And here's what it has to do with it. When the clutch engages, the most sensible thing to do is to reduce the engine speed. But not to idle, but according to the speed of the car. This is not always available to the driver, especially a beginner. And here the computer will come to the rescue. Reacting to the signal from the clutch sensor, it can independently adjust the engine speed.

Important! In addition, in accordance with the Priora speed sensor, the ECU can obtain information about the serviceability of the clutch.

Summarizing the above, we can say that the presence of a sensor on the clutch allows:

- saves fuel;

- make driving easier;

- monitor the serviceability of the coupling;

- increase its service life.

Therefore, its serviceability is an important factor in the Priora control system.

In principle, this is the simplest switch. In the position when the clutch is disengaged and the pedal is not pressed, the sensor circuit is open. If you press the clutch drive, the limit switch of the sensor closes and the signal “clutch is on” is sent to the ECU.

It is located on the clutch pedal mounting assembly, where the very tip of this pedal is located opposite the sensor end switch.

Since this element is connected to the ECU, it reacts to its failure first of all. That is, it gives peculiar signals that are reflected on the instrument panel and are noticeable in the behavior of the Priora when driving.

- turning on the “Check Anger” light;

- twitching when starting to move;

- a sharp drop or, conversely, an increase in speed when the clutch is engaged.

There can be three malfunctions in total: a breakdown of the sensor itself, a break or short circuit in its circuit, and incorrect adjustment of the position of the limit switch on the pedal.

Attention! Only Prioras, which have an electronic throttle, are equipped with such a device. Cars with a regular throttle cable do not have one. It is also available for all-wheel drive VAZ. It must be remembered that these are two types of sensors, and they are not interchangeable!

In general, the “Check” warning lamp lights up in cases where the ECU has not received a signal within 2 seconds when starting from a stop or during four shifts on the move without a signal. Accordingly, the signs mentioned above appear.

And only after that remove it. This is a simple procedure. The clutch sensor is attached with only two self-tapping bolts, and it is not difficult to remove it with a short, shaped screwdriver. Well, then, on the spot, decide whether to start going to retail outlets in search of a new unit, or try to restore the old part. Well, put it in its place.

After finishing work on the Priora, do not forget to reset the ECU error memory.

Clutch pedal position sensor VAZ

On the latest models of VAZ cars equipped with an electronic accelerator pedal, a clutch pedal position sensor is installed. Let's consider why it is needed, the principle of operation and possible malfunctions.

Where is the clutch sensor installed on VAZs?

The clutch pedal position sensor on VAZ cars is installed directly on the clutch pedal bracket; this can be seen by looking under the steering column.

What is a clutch sensor used for?

The clutch pedal position sensor is one of the elements of the engine management system with an electronic accelerator pedal. This sensor provides a more flexible control scheme for engine modes. It simplifies the process of starting movement, eliminates “dips” of turns and jerking of the car when changing gears in a manual transmission, and also allows you to reduce fuel consumption.

By providing the engine controller with information about when to engage and disengage the clutch, the clutch pedal position sensor allows you to reduce or increase engine speed at the right time, as well as adjust the ignition timing.

Working principle of the clutch sensor

The clutch pedal position sensor is a regular limit switch with two positions: “on” and “off”.

It is usually in the open position, which means it only engages when the clutch pedal is depressed.

Clutch position sensor malfunctions

The following symptoms may indicate a malfunction of the clutch pedal position sensor:

- "Pecking" of the car when changing gears

- a sharp increase or decrease in engine speed when the clutch is disengaged

In addition, if the clutch pedal position sensor is faulty, the engine controller corrects error 0830 “Clutch Pedal Sensor Error” and the “Check Engine” indicator lights up on the instrument panel.

Error 0830 is corrected if the motor controller does not receive a signal from the clutch sensor:

- within 2 seconds after changing gears while driving

- after four gear changes at speeds over 10 km/h and engine speed over 1000 rpm

The main reasons for error 0830:

- malfunction of the clutch sensor itself

- short circuit or break

- Incorrect clutch pedal height

Signs of a malfunction of the Priora clutch sensor

This sensor is connected to the car’s ECU; accordingly, the first sign of a breakdown is the reaction of the control unit in the form of the appearance of a corresponding signal on the dashboard. The nature of movement and operation of the car engine also changes. Symptoms of malfunction are as follows:

- The “Check Engine” light is on;

- when starting to move the car jerks;

- When you press the clutch pedal, the engine speed rises or falls sharply.

The warning lamp on the instrument panel lights up if the computer does not receive a signal from the clutch sensor within 2 seconds from the moment the vehicle starts moving or within 4 seconds when changing speed while the vehicle is moving.

The sensor has a very simple design, so there are few reasons for failure:

- faulty sensor contacts;

- break or short circuit of the wires going to the sensor;

- Incorrect installation of the sensor near the pedal.

Important: the clutch sensor is installed only on Priora models equipped with an electronic throttle. If the car is equipped with a regular throttle cable, there is no clutch sensor. Also, when replacing a sensor, you should focus on its model. Sensors from all-wheel drive VAZ and Priora sensors are not interchangeable.

Repair and service

On the latest models of VAZ cars equipped with an electronic accelerator pedal, a clutch pedal position sensor is installed. Let's consider why it is needed, the principle of operation and possible malfunctions.

Adjusting the brake pedal sensor Kalina

If the sensor is working properly and incorrect operation of the internal combustion engine continues to bother you, try adjusting the product yourself

Please pay attention to the following characteristics:

- The sensor must be twisted clockwise until the brake pedal begins to move down. After this, you will need to unscrew the product slightly and secure its position with a fastening nut.

- The result should be such that when there is no action on the pedal, the sensor rod is recessed into the body, and when the pedal is pressed, on the contrary, it is completely disengaged.

- As for the working gap, it is adjusted by two cubes (one at the top, the other at the bottom). The adjustment is carried out using the upper nut, which is tightened, and the lower nut, on the contrary, is unscrewed. The entire process is carried out until, when the brake pedal is pressed, the button is completely recessed into the body. However, you should not go overboard with the adjustment, in other words, you should leave a slight gap or lag in the path (about 2 to 5 millimeters).

Clutch sensor price

On many VAZ cars with an electronic accelerator pedal there is a connector for this sensor, but there is no sensor itself. It's unclear whether they forget to install it at the factory or remove it carelessly. The second option is also quite possible, since this sensor is still in great short supply. It costs an average of 350 rubles, but it is almost impossible to find it on the open market.

Viburnum clutch pedal end cap

Clutch pedal position sensor 1118-3720015 (E-GAS) Lada Kalina, Granta, Priora

The clutch pedal position sensor is installed on VAZ cars with an electronic gas pedal, it is installed on the clutch pedal bracket, in order to see it, just look under the steering column . The VAZ clutch pedal position sensor facilitates the process of starting movement, helps to eliminate speed dips and jerking of the car when switching a manual gearbox. The clutch pedal position sensor helps reduce fuel consumption. Its normal position is open, that is, it turns on only when the clutch pedal is pressed.

Manufacturer: Avers LLC, Togliatti

Contents: Switch 1118-3720015 – 1 pc. Protective casing 1118-3720024-10 – 1 pc. Fastening screw 1-0076690-01 – 2 pcs. Spring 1118-1602179-00 1 pc.

Applicability: Lada Priora 2170, 2171, 2172 Lada Kalina 1117, 1118, 1119 Lada Granta 2190, 2191

When ordering, in the “Order Comments” line, indicate the model and year of manufacture of your car.

The clutch pedal sensor is installed on vehicles with an e-gas system, providing a signal to the electronic control unit to inform about the open position of the propeller shaft and drive. It provides a normally open limit switch, allowing pedal input control and providing the following benefits:

- increased flexibility in controlling engine operating modes (no jerks or drops in speed);

- simplifying the start of movement;

- reducing fuel consumption by turning off its supply at the moment of pressing;

- possibility of adjusting ignition timing.

Symptoms of device malfunction

The following symptoms indicate problems with the clutch pedal position sensor:

- a sharp change in engine speed (drop or increase) when pressing the clutch pedal;

- “pecking” of the car while changing gears.

Malfunction of the clutch pedal sensor 1118-3720015 (e-gas) Lada Kalina, Granta, Priora is automatically detected by the electronic control unit. The CheckEngine indicator lights up immediately, indicating an error. Please note that a problem with the clutch pedal sensor may be associated not only with its failure, but also with the following problems:

- open circuit or short circuit;

- Incorrect clutch pedal height.

If an error appears indicating problems with the clutch pedal sensor, or the symptoms listed above occur, then you first need to eliminate the last two points. This will allow you to get by with a little blood if necessary. At the same time, if the problem still lies in the clutch pedal sensor, then you need to purchase a new device. It is inexpensive and will not break a serious hole in the budget even with unscheduled repairs.

The popular Priora was designed in the spirit of the times, so the computer even controls such a unit as the clutch. The electronics do not control the process of turning the clutch on and off, but the clutch sensor on the Priora, installed under the clutch pedal, collects information about the position of the pedal. This data enters the electronic engine control unit and is used to optimize engine operation depending on the driving mode, and also makes it possible to use cruise control on the car.

Diagnostic features

To diagnose the operation, you must first call the contacts individually, and then in pairs. If pins 2 and 3 are disconnected, this may indicate that they are faulty, especially since the other pins are making loud noises (video by Stas Garage).

To diagnose the work, you must first visually inspect it to see if there are any cracks or breaks. Then test the contacts to determine if there is a short circuit or break in the wire. In the event of a break, short circuit or corrosion of the wires, dismantle the part. How this simple manipulation is performed is below.

The most common causes of clutch system failure

The human factor can lead to premature failure of this unit. There are several factors that contribute to shortened clutch life:

- Aggressive driving style. Do not constantly press and release the clutch pedal - this will quickly cause the friction linings to fail.

- Driving with increased loads.

- Incorrect towing. Inexperienced car owners often keep the pedal halfway when towing. It is also not recommended to tow vehicles that are much heavier than your vehicle.

- Drive with the clutch pedal pressed to the floor.

- Sharp and too smooth start at high speeds.

- Many beginners often keep the clutch depressed during short stops (for example, at a traffic light). This should not be done, since in this position the release bearing is under constant load and this leads to its premature failure.

The clutch resource is quite long and ranges from 100 to 150 thousand km. When used correctly, the mechanism is quite reliable, and reaching the top bar is quite possible.

Sources

- https://auto-nota.ru/pro-motor/datchik-scepleniya-kalina.html

- https://avtoarsenal54.ru/ustrojstvo/datchik-stsepleniya-kalina-priznaki-neispravnosti.html

- https://vestaz.ru/boltaetsya-pedal-stsepleniya-na-kaline/

- https://LedStrong.ru/remont/datchik-scepleniya.html

- https://dmsht.ru/stseplenie-kalina-1-8kl-kakoe/

- https://korean-car.ru/menaem-sceplenie-na-lada-kalina-svoimi-rukami-ne-snimaa-korobki/

- https://autobryansk.info/priznaki-iznosa-sceplenija-kalina.html

- https://kekso.ru/avtovaz/priznaki-neispravnosti-sceplenija-lada-kalina/

- https://kalina-2.ru/otechestvennie-avto/kak-opredelit-chto-pora-menjat-sceplenie

- https://SpecTorg.su/dvigateli/datchik-pedali-scepleniya-kalina.html

- https://motorchina-online.ru/test-drajv/datchik-hoda-scepleniya.html

- https://artel55.ru/obzory-i-testy/zamena-datchika-scepleniya-granta.html

- https://LakkRoll.ru/regulirovka-kontsevika-pedali-tormoza-kalina/

- https://autogrm.ru/blog/kak-proverit-sceplenie.html

Causes and symptoms of release bearing failure

The reason for the breakdown of this part is uneven loads on it at the moment when the clutch is depressed, and it goes back along with the driven disk. For this reason, holding the clutch pedal for a long time while the gear is engaged is strictly not recommended. In principle, this is a reliable and durable part, and it most often fails among novice motorists.

The most important symptom of bearing wear is the appearance of a slight knocking sound when the clutch pedal is depressed . If the sound appeared in the summer, this is almost a guarantee of future problems, but if it came along with frost, there may be an elementary change in the linear dimensions of the bearing cup due to a drop in temperature outside. The release bearing in most cars has an undeniable advantage - high strength, so even if noise appears, you can afford to do nothing for a while and watch to see if it gets worse.