STEERING MECHANISM VAZ 2107 - BRIEF DESCRIPTION

The steering mechanism of the VAZ “Seven” has a rather complex design, which ensures reliable vehicle control in different driving situations. The steering wheel is endowed with good information content, which eliminates driver fatigue when traveling long distances. There are some difficulties when turning the steering wheel while the car is stationary. However, as soon as the car starts moving, the steering becomes less rigid and control improves.

The steering mechanism has one nuance - a slight play, which is normal. This is explained by the considerable number of parts in the gearbox and the presence of rods. After modernization, the VAZ 2107 began to be equipped with a safety column, which has a composite shaft. Its design consists of two cardan-type joints, which allow the shaft to fold in the event of an accident. In this way, injury to the driver is avoided.

The steering gearbox is designed to transmit force from the steering wheel to the tie rods to turn the front wheels to a given angle.

Further repairs will not be a problem.

You only need to follow a few rules:

- the worm pair is changed simultaneously, as a set;

- after assembly/disassembly, adjustments need to be made;

- Do not use old oil, but replace it with new lubricant.

After the repair is completed, the gearbox is assembled and mounted in the reverse order.

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

The steering gearbox is a small mechanism designed to transfer rotational motion to translational motion. This means that the gearbox converts the rotation of the steering wheel into a force that shifts it in the right directions, causing the wheels to turn and change the direction of movement of the car.

The gear used in the gearbox is a reduction gear and consists of two elements - a worm and a gear. In addition, the mechanism has a special lever that moves the steering rods in the right directions.

The steering gearbox of the VAZ 2107 is sealed and, which significantly increases its service life and simplifies turning the steering wheel, reducing the effort exerted by the driver.

STEERING GEAR REDUCER DEVICE

Before you begin repairing the steering column, you need to familiarize yourself with its structure, as well as its operating principle. The design consists of the following main elements:

- a unit designed to transmit force from turning the steering wheel to actuators;

- steering column, which turns the wheels to the desired angle.

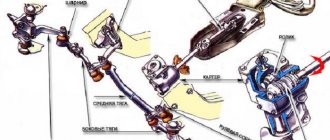

The steering mechanism consists of:

- composite shaft with cardan transmission;

- steering wheel;

- worm type steering gear.

The design has the following components:

- pendulum;

- swing arms;

- steering rods.

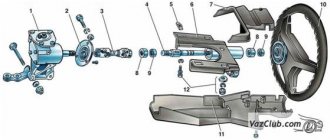

Steering design: 1 - steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Since the outer rods have two parts, this allows the toe angle to be adjusted. The steering functions as follows:

- The driver operates the steering wheel.

- Through universal joints, the worm shaft is driven, through which the number of revolutions is reduced.

- The worm rotates, which helps move the double-ridge roller.

- The secondary shaft of the gearbox turns.

- A bipod is mounted on the secondary shaft, which rotates and carries the steering rods with it.

- Through these parts, force is applied to the levers, thereby turning the front wheels to the angle desired by the driver.

The bipod is a rod that connects the steering gearbox to the steering linkage.

SIGNS OF GEARBOX FAILURE

As the vehicle is used, the steering column may develop problems that require repair. The most common of them are:

- oil leak from the gearbox;

- extraneous sounds in the mechanism;

- It takes a lot of effort to turn the steering wheel.

TABLE: VAZ 2107 STEERING MALFUNCTIONS AND WAYS TO SOLUTION THEM

| Malfunctions | Elimination method |

| Increased free play of the steering wheel | |

| Loosening the steering gear mounting bolts. | Tighten the nuts. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Increased clearance in the engagement of the roller with the worm. | Adjust the gap. |

| There is too much clearance between the swingarm shaft and the bushings. | Replace the bushings or bracket assembly. |

| Increased clearance in the worm bearings. | Adjust the gap. |

| Stiff steering wheel rotation | |

| Deformation of steering gear parts. | Replace deformed parts. |

| Incorrect alignment of the front wheel angles. | Check the wheel alignment angles and adjust. |

| The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| The adjusting nut of the pendulum arm axis is overtightened. | Adjust the tightening of the nut. |

| Low pressure in the front tires. | Set the pressure to normal. |

| Damage to ball joint parts. | Check and replace damaged parts. |

| There is no oil in the steering gear housing | Check and top up. Replace the oil seal if necessary. |

| Damage to upper steering shaft bearings | Replace bearings. |

| Noise (knocking) in the steering | |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance between the pendulum arm axis and the bushings. | Replace the bushings or bracket assembly. |

| The adjusting nut of the pendulum arm axis is loose. | Adjust the tightening of the nut. |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken. | Adjust the gap. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Loosening the nuts securing the swing arms. | Tighten the nuts. |

| Loosening the steering intermediate shaft bolts. | Tighten the bolt nuts. |

| Self-excited angular oscillation of the front wheels | |

| Tire pressure is not correct. | Check and set normal pressure. |

| 2. The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| 3. Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| 4. Wheel imbalance. | Balance the wheels. |

| 5. Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| 6. Loosening the bolts securing the steering mechanism or the pendulum arm bracket. | Check and tighten the bolt nuts. |

| 7. The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| Steering the vehicle away from straight-line motion in one direction | |

| Uneven tire pressure. | Check and set normal pressure. |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Different draft of front suspension springs. | Replace unsuitable springs. |

| Steering knuckles or suspension arms are deformed. | Check the fists and levers, replace unsuitable parts. |

| Incomplete release of the brakes on one or more wheels. | Check the condition of the brake system. |

| Vehicle instability | |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Increased clearance in front wheel bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| There is too much play in the tie rod ball joints. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Increased clearance in the engagement of the roller and worm. | Adjust the gap. |

| Steering knuckles or suspension arms are deformed. | Check the knuckles and levers; replace deformed parts. |

| Oil leak from crankcase | |

| Wear of the bipod or worm shaft seal. | Replace the seal. |

| Loosening the bolts securing the steering gear housing covers. | Tighten the bolts. |

| Damage to sealing gaskets. | Replace gaskets. |

WHERE IS THE GEARBOX LOCATED?

The steering gearbox on the VAZ 2107 is located in the engine compartment on the left side under the vacuum brake booster. If you have insufficient experience, you may not find it at first glance, since it is usually covered with a layer of dirt.

The steering gearbox on the VAZ 2107 is located under the vacuum brake booster on the left side of the engine compartment

Steering column repair

The steering mechanism is subject to constant friction from the elements located inside, which eventually leads to their wear. As a result, repair work or complete replacement of the unit is required.

How to remove a column

Removing and repairing a gearbox is a difficult procedure, but it can be done on your own if you have at least a little experience in car repairs. To perform the operation you will need the following list of tools:

- wrenches 17 (socket and open-end);

- socket heads for 17;

- handle with ratchet;

- mount;

- hammer;

- steering rod puller;

- collar

We dismantle the mechanism in this order:

- Remove the negative wire from the battery.

- Unscrew the fastening and remove the steering wheel.

Video: how to replace the steering gear on a “classic”

How to disassemble a column

You can begin disassembling the gearbox immediately after removing it from the car.

To do this we need a certain list of tools:

- standard set of keys;

- head at 30;

- knob;

- bipod puller;

- vice.

To disassemble the steering column, you must follow these steps:

- Unscrew the bipod nut with a wrench and a socket.

Video: repairing the steering column of classic Zhiguli cars

Gearbox diagnostics

When the unit is disassembled, it is necessary to visually assess the condition of all elements for damage. To do this, the parts are cleaned and washed with kerosene, gasoline or diesel fuel, after which each of them is inspected, trying to identify a possible defect (scores, signs of wear, etc.). The surfaces of the roller and worm constantly interact with each other, so special attention should be paid to them. The bearings of the mechanism should rotate without a hint of jamming. Any damage to the outer rings of the bearings is considered unacceptable. The gearbox housing must also be in full working order and free of cracks. All parts that show wear must be replaced.

Column assembly

Before we begin assembling the device, we apply transmission lubricant to all parts installed inside the unit. Lip seals must be replaced during any repair involving the gearbox. The procedure for assembling the unit is as follows:

- We hit the mandrel with a hammer and drive the inner race of the bearing into the housing.

- We put its internal elements into the bearing cage and insert the worm shaft. We put the outer bearing parts on it, press in the outer ring and attach the cover with gaskets.

When installing the mechanism in place before final tightening of the fasteners, it is recommended to sharply turn the steering wheel left and right several times so that the crankcase self-installs.

Gearbox oil

The lubricant in the steering column of the “Seven” is changed, although infrequently, but it is still worth performing this procedure every 60 thousand km. mileage The mechanism in question uses GL-4, GL-5 oil. The manufacturer recommends using oil of the following viscosity classes:

To replace, you will need only 0.215 liters of the substance. Checking the level and replacing the lubricant is carried out as follows:

- Unscrew the oil filler plug.

Video: how to change the oil in the steering column

Replacing the steering gear

Hello everyone! For a long time, probably more than a year, play began to appear in the steering wheel, naturally I tightened the adjusting bolt, reached the point where I unscrewed it to the maximum, and in addition, I broke off one edge of the screwdriver prose. Not only was there play, there was also a wild grinding and crunching sound when maneuvering in place. As a result, it began to jam and the free play was probably a quarter of a turn, it was scary to drive, I decided to change the gearbox assembly, you can of course buy a repair kit, but I didn’t want to bother.

I disassembled the old gearbox, it turned out that the bearing balls burst due to strong tightening, some in half, some in pieces, that’s the reason for the knocking and crunching, fortunately only on one side of the roller and only half of it, I changed it in time, otherwise it could have jammed on the move. The gearbox costs 3600 hazel grouse, dismantling and installing it yourself, the difficulty was to remove two rods without a puller without damaging the anthers, I did it with a mounting tool and a hammer (for those who don’t know, we pull the rod with a mounting tool and hit the body of the bipod with a hammer, but in no case on the finger, and everything flies out).

There was also an ambush to align the steering wheel and gearbox in the center relative to the wheels, the book says that there should be marks on the gearbox and on the shaft, but I didn’t find them on this new gearbox, I had to remove it, put it on, take it off, put it on until I caught a cent. I assembled everything in 2 hours, drove around, everything works, I drive a little, tighten the adjusting bolt and change the oil, from the factory the oil in the gearbox is up to level, so I installed the gearboxes right away.

Steering wheel play

The appearance of steering play can be caused by two reasons. First, the nut securing the steering wheel to the shaft is loosened. If the nut is not tightened promptly, the splines on the handlebar and shaft will become damaged over time and one of these parts may need to be replaced. The second reason may be wear of the worm gear. To eliminate this malfunction, a special device is provided - an adjusting bolt with a lock nut.

In order to adjust the worm gear, the nut is released, the screw is turned using a screwdriver until the backlash is eliminated, after which the nut is tightened to prevent spontaneous unscrewing. If it is impossible to eliminate the backlash by adjustment, it means that the gearbox needs to be repaired and the worm pair replaced.

To prevent premature wear of gearbox parts, periodic monitoring of the oil level and its replacement is recommended. Level control is carried out as follows:

- Using a 8 key, unscrew the filler plug;

- Use a screwdriver or other object to check the oil level. It should be level with the bottom edge of the filler hole.

- If necessary, add oil using a special supercharger until it begins to flow out of the hole.

To change the oil, unscrew the screws securing the gearbox cover, having previously placed a container under it to collect used oil. Since complete removal of the cap is not required, it is moved to the side and the oil is drained. This operation is best performed on a hot engine. Warm oil has greater fluidity and drains faster. After all the oil has drained out, the cap is screwed into place and new oil is poured into the gearbox using the method described above.

Replacing the VAZ 2107 steering gear

VAZ cars, which are classic models, are distinguished by pleasant reliability. This also applies to the steering mechanism.

It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

The current steering mechanism on the VAZ 2107, a product of the Volga Automobile Company, is quite informative and does not allow the driver to get tired during long trips. There are certain difficulties when turning in a parking lot, but as soon as the car begins to move, the resistance weakens and turning the steering wheel becomes easier.

There is one more nuance - when the steering mechanism is working properly, there is a slight play. But its limit value complies with the traffic rules. This is due to the fact that there are steering rods on the VAZ 2107 and an impressive number of elements in the gearbox.

In general, the steering of the 7 can be considered reliable.

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

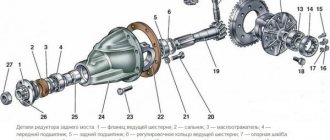

Steering gear housing parts

1 - crankcase; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Details

1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Lubrication

Experienced users often change the lubricant, even in the absence of breakdowns, for the following reasons:

- The standard blue padding is too thick;

- Possible decrease in plasticity in winter;

- it accumulates near the lid and minimally reaches the friction pairs.

Standard gearbox lubrication

Graphite grease with Motul 4100 10W40

Some cars, for example, VAZ 21213 Niva, use transmission oil, as indicated in the official manufacturer's manual for the service station. To do this, the upper crankcase cover has a hole protected by a threaded plug; oil can be added without disassembling the gearbox.

VAZ 21213 gearbox with lubrication hole

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

If any malfunctions are detected, the breakdowns should be repaired immediately.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

We will completely improve the steering!

Everyone prepares for the new year differently. I want to take part in a couple of competitions during the New Year holidays. If you are not afraid of cold garages and colds on your face, then my story is for you.

Whatever one may say, precise control on the track is a very important thing. And in my case, the play on the steering wheel is colossal. I got the car in pretty bad condition. Lately, all I've been doing is eliminating oil leaks from certain components. This time was no exception, and I took up the steering partly because the steering gear was flooding the snow-white asphalt with puddles of dirty oil every time I stopped.

If you do it, do it well. So I removed the steering gear completely from the car. Like all spare parts before this, after removal they look like a piece of oily shit. But in this pile of dirty pieces of iron, some will recognize the steering pendulum from left to right, connected through the middle link to the steering gearbox.

During the inspection, it turned out that I already had a pendulum arm installed on bearings, but it was smashed to pieces and it turns with great effort. And in the gearbox, oil presses from both seals in completely indecent volumes. Unfortunately, simply changing both seals was not at all easy for me. I finished off the gearbox myself and ended up having to buy the entire assembly new. On the left are old, but already washed pieces of iron, and on the right are new spare parts.

This seemed to me not enough and I wanted to install a steering gear bracket. Not many people know, but on domestic classics, the steering gear eventually begins to wrap the spar around itself))) It sounds crazy, but in the most advanced cases it even rips itself out of the spar. At the initial stages, there is a gap in control. This can easily be fixed with a steering gear bracket. In our country there are two large manufacturers of similar pieces of hardware, but neither of them works when purchased without modifications. Therefore, I put this revision aside for now.

neither this one fits

nor competitors' products

Now it's the turn of the wheels. Here we will switch to the newest type of bearings))) I mean that the obsolete cone bearing mechanism in the hub of a VAZ 2107 can be replaced through spacers with the hub (rear) of a VAZ 2108. This will no longer allow you to be smeared head over heels in grease and play on the wheels structurally will disappear. More details in the video, because... Otherwise I'll just overwhelm the whole story with a huge number of photos.

And for dessert my original Chinese RUDDER! This is a very necessary thing indeed. Many people think that such things are staged solely in order to stroke their pride and impress... I don’t know who. Well, for some people in general)) But a good steering wheel with reach and not a large radius is simply necessary on the race track. It is extremely inconvenient to intercept the huge steering wheel. If you take into account that this needs to be done quickly, then the civilian steering wheel simply disappears. I ordered mine from China and bought the spacer here and it is REALLY BAD. Because it is not injury-proof. Those. It doesn't fold when hit - it's a very dangerous thing. So I'll replace it as soon as possible. The steering wheel has a persistent smell of glue, but it performs its functions and I have not yet found any disadvantages, except for smelly hands.

In order not to be unfounded, I decided to test my improvements on the most winding track that can be found in Yekaterinburg. And I liked the result, although I again spent a lot of evenings in a cold garage. The race itself and a detailed story on video. And Andrey and I, who often remain behind the scenes, wish you a good holiday weekend! Maybe someone will even get out on the track during the holidays and give it a blast in their car (sober as glass). See you on the track!!!

Removal and installation of the VAZ 2107 steering gear

An assistant will be required to perform the work of removing and installing the VAZ 2107 steering gearbox.

Removing the steering gearbox from a VAZ 2107 car

1. We install the VAZ 2107 car on an inspection hole or overpass (see “Preparation of the VAZ 2107 car for maintenance and repair”).

2. On a VAZ 2107 car with a fuel injection system, remove the adsorber (see “Adsorber of a VAZ 2107 car - checking the purge valve, removal and installation”).

3. Unscrew the nut of the bolt securing the intermediate steering shaft to the steering gear shaft and remove the bolt (see “Steering shaft of a VAZ 2107 car - removal and installation”).

4. Disconnect the steering rods from the bipod of the steering gearbox (see “Steering rods of the VAZ 2107 - replacement”).

5. Using a 19 mm socket wrench, unscrew the three nuts securing the steering gearbox to the left side member of the VAZ 2107, holding the bolts from turning with a wrench of the same size. Holding the steering gear, remove the bolts.

6. Remove the steering gear shaft from the universal joint fork of the intermediate steering shaft. 7. Turn the bipod of the steering gearbox until it stops at eye A of the gearbox housing. This will make it easier to remove the steering gear from the VAZ 2107.

8. Turning, take out the steering gear upwards.

Step-by-step adjustment of the worm gear.

In order to independently adjust the steering gear of a VAZ 2107 car, you need a flat screwdriver, a 19mm wrench, the help of another person and follow the step-by-step work: