Advantages and disadvantages of self-locking gearboxes on the VAZ 2107

First, let's list the advantages that locking on the VAZ 2107 provides:

- increased traction of the driving wheels in any conditions;

- good cross-country ability in sand, mud and snow;

- improved acceleration dynamics;

- good cornering.

But the locking differential comes at a price:

- handling deteriorates in rear-wheel drive vehicles, which include the VAZ 2107;

- it becomes more difficult to hold the car when accelerating;

- the tendency of the “seven” to skid when cornering increases;

- high friction links appear, which lead to an increase in wear rate and fuel consumption.

https://youtube.com/watch?v=4wzIz1u4QBs

Differential lock on the VAZ 2107. Everything you need to know about it

Previously, when cars moved at low speeds, this problem did not cause any concern, and as a result was not solved. But today, car speeds have increased significantly and a problem arose with rigidly fixing the same torque on two wheels, and as a result of solving this problem, it was necessary to separate the drive wheels.

To separate the wheels, a differential is used, which is based on a planetary mechanism. This mechanism divides the torque equally between the wheels. But what is required from an SUV? Naturally, high cross-country ability on off-road, snowy roads or on ice, and the planetary mechanism underlying the VAZ 2107 differential significantly reduced this figure.

On rough terrain it happens like this:

the torque is given by the wheel, which has a lower coefficient of friction, resulting in a situation where one of the wheels begins to slip, and the other completely stops. The manual differential lock feature does not solve this problem. Moreover, the driver must clearly control the situation manually.

This complication forced the use of automatic differential locking. The advantage of automatic locking is that the driver’s participation in this process is not required, and automation can also help correct his mistakes while driving. Such differentials do not require additional maintenance.

The differential lock on the VAZ 2107 can be carried out by a rigid connection of the rear wheels together, which leads to strict fixation of the same torque on the wheels. The disadvantage of automatic locks is that the load on the differential reaches an extreme when the lock is activated. This drawback was eliminated in screw locks, which are the most common of all types of locks today.

The operation of the screw lock is based on the on/off principle of the lock. This approach to differential locking reduces wear on the transmission and protects it from breakdowns. Also, the steering column is not subject to mechanical shock load when locked.

With screw system

Differential locking greatly increases the vehicle's maneuverability on slippery roads. When driving on an icy road, the following redistribution of torque occurs: the wheel with a low level of road grip receives a low torque, and the wheel with better grip receives more.

The VAZ 2107 with a screw differential lock accelerates faster on slippery roads and snowy terrain, and also has excellent handling when cornering.

- When the lock is turned off when turning, there is a strong jerk. This is due to a sharp reduction in the load on the transmission. When the differential lock is turned on, the wheels crash into the ground with a characteristic noise;

the angle of rotation is greatly limited when the differential is locked 2107;

you cannot lock the differential when driving on normal roads;

When towing and checking the brakes on a stand, you also do not need to turn on the differential lock.

Explanation of operating principle

Translated from Latin, differentia means “difference.” In a car, a differential is a mechanism that distributes torque to the car axles. It definitely exists in every car. A simple differential is called classic, open or free.

Let's imagine that the rear axle gearbox does not have a differential, but there is a single axle, like a tricycle.

Since there is no absolutely linear movement, and the driver's hands almost never lie motionless on the steering wheel, it is clear that the path of the drive wheels will be very similar, but slightly different.

If there were no differential, then the path of the left and right wheels would be the same. Then constant slipping will become inevitable, since a common trajectory is “imposed” on the wheels. This results in increased tire wear and rapid failure of transmission units.

The task of the gearbox is to give the wheels independence and “freedom”, to separate their rigid connection.

How does a classic differential work?

If there is one drive axle (all VAZ classics), then one gearbox is required between the rear wheels, i.e. interwheel. In the case of a full-fledged jeep, there are as many as three differentials - two inter-wheel differentials for each axle, and an additional inter-axle one.

This mechanism (also called a gearbox) is installed in the rear axle housing. The drive gear transmits torque to the driven gear. It is distributed into two gears of the axle shafts, and they rotate the wheels.

Additional gears - satellites are a symmetrical equal-arm lever, and transmit forces equally to the wheels.

When the car moves in a straight line, the satellites do not rotate. As soon as the car slides onto uneven ground or enters a turn, that is, when each wheel has its own path, the satellites begin to rotate and redistribute the torque between the wheels of the drive axle, and to the axle shaft that has less resistance and is easier to spin.

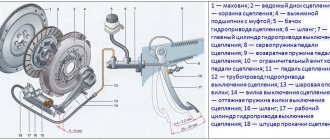

The VAZ differential is shown in the figure below:

8 — axle gear; 9 — satellite; 11 — driven gear of the main gear; 18 — drive gear of the main gear;

This is how the satellites behave and distribute the moment of movement in different areas:

From the analysis of the rotational speeds of the axle shafts and gearbox it follows that:

- If one wheel is stationary, then the free wheel rotates “for two”, and the rotation speed is doubled.

- If one wheel slips, it spins faster and starts to slip, and the second wheel with good grip will receive the same torque, since it is distributed equally, and the differential cannot give it all the traction.

- If the traction of a single wheel becomes less than the resistance to movement, the car will stop.

- In this case, the situation of point 1 arises, the running wheel stops, and the previously slipping wheel sharply increases speed.

- When you try to “add gas,” the speed of the slipping wheel increases.

So, a conventional gearbox does not help the drive axle on slippery roads and on surfaces with high rolling resistance (snow, sand and mud). The cost of a conventional gearbox is about 5,000 rubles.

Eliminate vibration with additional fasteners

Mechanical gearbox, types, types of gears

Vibration in the body is the main “disease” of the Niva; it often occurs due to improper alignment of the transfer case. Most often, vibration occurs on VAZ 21213/21214 cars, since the transfer case is mounted only on two supports on the sides of the body; on the Chevrolet Niva, the transfer case is already installed on three supports.

- driveshafts are poorly secured;

- wheels are not balanced;

- there is play in the cardan crosspieces (vibration is especially affected by play in the rear driveshaft crosspieces);

- The vibration comes from the engine itself.

Vibration when starting off on a Niva can also occur for the following reasons:

- the mounting supports of the transfer case have become loose;

- The rubber on the RK supports themselves broke.

Installing the third support of the transfer case on VAZ 21213/21214 vehicles allows you to reduce the level of vibration of the transfer case; with this support it is easier to center the transfer case. The part can be purchased at auto stores or made yourself. The finished product comes with three long studs (for model 2121); to install the third support on this machine, you will need to unscrew the short studs from the transfer case housing and install new studs from the kit. We carry out repairs as follows:

- dismantle the front passenger seat in the cabin;

- remove the floor tunnel lining;

- in the cabin we move aside the carpet covering the body amplifier (in front of the handbrake lever);

- remove the transfer case (alternatively, you can simply hang it up, but removing the third support makes it easier to install);

- We attach the bracket of the new support to the body of the RC;

- we install the transfer case in place, center it in the optimal position, and fasten the side supports;

- we combine the third support with the body, drill two holes in the bottom;

- Using washers, bolts and nuts (from the kit) we attach the support to the bottom of the body.

In order to install the subframe, the transfer case must be removed. It is more convenient to carry out such work in a pit; we carry out repairs as follows:

- leave the car in neutral gear;

- disconnect the propeller shaft from the transfer case, it is advisable to mark the driveshaft flange and the drive shaft so that during installation, align the driveshaft according to the marks - this way, the occurrence of unnecessary vibrations is eliminated;

- dismantle the muffler mounting bracket;

- remove the gearbox traverse;

- jack up the transfer case, remove the side fastenings of the transfer case;

- We treat the places where the subframe fits to the body with Movil;

- place the subframe on the gearbox studs;

- we mark the attachment points of the subframe on the side members, drill holes, attach bolts to the body;

- we tighten all fastenings, except for the transfer case supports themselves;

- we perform alignment of the steering wheel;

- Finally tighten the transfer case supports.

It should be noted that installing an additional support or subframe on the steering wheel does not always lead to the desired effect; in some cases, vibration only increases.

Search

Welcome! Rear axle gearbox - thanks to this, all the torque is transmitted from the drive shaft and goes to the rear wheels, without a gearbox the rear wheels do not rotate (unless it is a car on the front wheel, which instead of a gearbox with an axle is a normal support at the rear) and a car with the rear wheel will not go anywhere, by the way, there is also a differential inside the gearbox, which is welded a little, and the likelihood that the car slides around the turn increases because if you are looking for information on how to remove the torsion gears and weld it in different ways, we don't advise you to do this for you if the car is used in everyday life, if it is purely for weekend drifting Why not spin with a welded differential, the car actually starts spinning much better, not counting when accelerating, higher speed as the uniform torque is transmitted to both wheels, and the car begins to move without slipping, this is not so noticeable in classics, in front-wheel drive cars it is a more pronounced scoop (it becomes less, if there are excellent tires, then it generally loses) ARE).

The note! To replace the transmission on the rear axle, the tools you will need are wrenches, screwdrivers, and a wrench, and if you have a wrench, they will certainly accumulate to allow you to properly tighten the transmission mounting bolts. then, when the vibrations are weakened, they can sometimes become twisted, and tightening it very tightly will not do any good (you may unscrew the bolts if you suddenly go down when you need to unplug them again), so the bolts must be tightened with a torque that can be realized with wrench!

Result:

Where is the rear axle gearbox located? It is located in the lower rear part of the car, at the bottom it rotates for clarity on a white circle, and this gearbox is connected to each other by axle shafts (indicated by blue arrows, or rather the blue arrows indicate beams, inside of which these are the same axle shafts) that you will removed from the car, since their ends are in contact with the gearbox gears, and therefore the gearbox cannot be removed without disconnecting them (after reading the article, you will understand how to remove the shaft axle from the gearbox, we will explain carefully) in order to clearly mark the location of the gearbox, for clarity, we have also indicated the red arrow where to disable the spell, as you can see next, and this gearbox is worth it because you are no longer confused about finding it.

When do I need to change the rear axle gearbox? The gearbox is changed when the gearbox is badly worn or after severe deformation, which can occur as a result of the gear hitting a stone (at speed this happens, but basically the protection takes the full blow), when the gears wear out inside the gearbox, their spacing between them increases and due to this there is a strong roar and the gearbox may vibrate more than usual while the engine is running, unfortunately the gearbox is not easy to repair, but this may be because if yours is already completely worn out and the new vit . If it's not cheap, try (if you want) to fix the old one by replacing the gears, which are basically unusable, for more information on how to fix the gearbox, read “Rear axle gearbox for VAZ cars.

How to replace the rear axle gearbox on a VAZ 2101-VAZ 2107?

You may also like

The note! When buying a new gearbox, take into account the fact that different classic gearboxes were used on the classic (there were four of them in total), they are the same inside, in fact they are all the same, they are just different gears, the fastest unwinding is the gearbox - from the VAZ 2102. (it has a 4.44 main pair) and a VAZ 2106 car is a 3.9 main pair, the data transmission is interchangeable (in other words, you can put a gearbox from six to a penny and vice versa) and their differences only apply to the main pair, explain that this is a pair, this won't be explained at all, just say that a 4.44 steam engine will accelerate faster, but will have the lowest top speed, whereas a steam engine (meaning similar car power) will accelerate 3.9 times longer, but at top speed speed it will be much higher than a pair of 4.44 transmissions, but it doesn't make sense to install a lot of massive pairs of 4.44 automatic transmissions, because the joke acceleration says that you will also shift rs a lot, but a lot of massive cars don't needs a pair of 4.44 (the car will run in almost 3 gears until 80 and ask for the next gear, and in 5 it will accelerate to a certain speed around 150 and will also make noise, but the engine allows it, but the gearbox does not accelerate anymore, so when choosing it, be be careful and buy new/used power from your car, not faster acceleration or top speed), all these gearboxes are explained in more detail on the classic in the video below:

Video: How to cook a gearbox weighing 2107

Removal: 1) First drain all the transmission oil from the gearbox, by the way, this is an opportunity to change it if you have not filled in new oil for a long time, for more information on how to drain the oil from the gearbox, read the section of the article: everything is explained there and written.

2) Now proceed to disconnect the propeller shaft flange from the gearbox flange, both flanges are secured with 4 bolts (the two bolts are marked with blue arrows for clarity) and nuts (the nuts are screwed onto the end of the bolts, one of the nuts is marked with a red arrow), you will need to unscrew all nuts, and at the moment when the cardan does not rotate, block it (you can press the brake if an assistant or a thick screwdriver is inserted into the hole). green arrow), well, unscrew all the nuts, disconnecting the e Flange driveshaft from the flange box ne edit, then hang a rope from the butt of the driveshaft muffler (if the car is hot, the muffler will also be hot, consider this) or hang something carefully later (we do not recommend this do).

The note! You can mark with chalk or a felt-tip pen on both flanges, if you later reinstall the old transmission, you will just need to later install the driveshaft in the same position as before, or simply disconnect the driveshaft by hanging it on a rope - just like that it stood (in other words, without flipping or rotating), then you definitely didn't go wrong with the reinstallation!

3) You will then have to remove both shafts, just if they are installed the gearbox will not be removed, you can find information on how to remove half the shafts on our website, but this can be found in the article entitled: "Replacing Shaft Seals, and , by the way, if you are already going to remove the shaft axis, then replace the seals in them, if they have already been suggested, so that a little later you no longer have to crawl and the more the hoe rolls.

Why is it brewed?

How to calculate a gearbox for reducing speed

So, we come to the most popular question among novice street racers. A welded differential is made to make it easier for the car to skid just when turning. This phenomenon is called drift. A welded differential is most often done on older rear-wheel drive cars.

This is especially true for the old domestic “classics”, where there is no blocking. What is a differential lock? This function allows you to change the torque transmission on the axle shaft. So, when the lock is turned on, the wheels rotate at the same angular speed. The system acts directly on the rear axle. "Niva Chevrolet" is also equipped with a lock. But this system is quite expensive and significantly affects the cost of the car. Therefore, not every machine has it. What to do in this case? There is only one way out - weld the differential. The procedure is quite simple, and you can do it yourself. The only thing you will need is a good welding machine and a mask to protect your eyesight when working with electrodes.

After all, a bright electric arc greatly affects the human eye. Therefore, do not forget to wear a mask before work.

Nissan Skyline RB25DE+T NEO R34 › Logbook › Welded differential

This is a manifestation of collective farm tuning through the use of a welding machine, other than using obscenities, I cannot remember. Of course, most street racers will stubbornly declare that this is all full 2Way and that’s it, with such a differential only for drifting. This may be true, but traveling with this collective farm every day is simply unrealistic. My opinion is that there is no money to supply LSD, don’t go there, for God’s sake. The car turns from a brainchild of engineering into a metal block with wheels that actively destroys rubber, does not want to turn, and in dampness or snow desperately wants to send you to the next world. In general...after riding with this horror for 3 days, I set out to improve the situation and knock down all the welding from there to a single hairdryer. But that was not the case, having opened the gearbox, we were presented with a picture of such welding barbarism that it would not seem a little (see photo below). The result is the purchase of a new gearbox and the HAPPINESS of driving a car with human controllability)))

Issue price: 12,000 ₽

By

VAZ 2110

How to make a gearbox for a walk-behind tractor with your own hands?

I bought it from a neighbor. Therefore, I had no doubt about the integrity of the body and the very low mileage. The previous owner installed various bells and whistles - such as a rain sensor, parking sensors. But it would be better if he put imported tires instead of all this. Which will provide greater comfort. As for the rain sensor and parking sensors, they don’t work in the cold, because... they are all Chinese. Although in the summer the parking sensors sometimes help.

At first I was very pleased with the car, because... was almost new. But after I drove 30 thousand km in a year. problems started. During acceleration, the differential flew out onto the street! YES, yes gentlemen - DIFFERENTIAL. The crankcase was pierced and the satellite with a broken axle “got to hell” out of the box! And this is with a mileage of only 50,000 km! Although my driving style is not ragged. An autopsy showed that it was cheaper to buy a new box than to repair the old one.

The rack is still knocking. We tried to pull it up, but it didn’t work. The service center said that this is a design flaw in the 16th rack and repairs will not get rid of this problem for a long time. The knock will still appear. As long as it doesn’t jam, I drive. The central locking is worn out - on the doors and trunk.

Before closing the trunk, you need to press the button several times and slam it several times. And recently I accidentally noticed that the rear left door always remained open when the car was armed.

It turned out that the drive and lock rods were covered with dust and the force of the electric drive was no longer enough to close the lock.

What kind of climate control does the dozen have? He generally lives his own life. After starting the engine, it can close the valve itself. Therefore, you have to set the knob to 18 and then turn it to the desired temperature. Recently I was horrified to learn that the mastic on the windshield was applied unevenly. The maintenance ticket just came out under the glass.

To be honest, I don’t even want to invest in a car of this quality.

For reference: I bought the box for 12,000 rubles. + new clutch 2500 RUR + work 1500 RUR. =16,000r.. And for example, on a Subaru Forester, a torque converter costs 18,000r. And where, please tell me, are the savings? And the price of the new 2110 is higher than that of a Chevrolet Lanos in a similar configuration. And after all, those who buy, for example, Lada Priora. Definitely won’t pass for smart!

Author's advice to buyers of VAZ 2110 2001

Gentlemen! Take a closer look at Renault Logan or Chevrolet Lanos. Make smart choices!

- Large and well-designed trunk.

- Good and predictable handling. Excellent feedback at the steering wheel thanks to the caster.

- Good anti-corrosion resistance.

- Maintainability, but just tired of repairing.

- Very unreliable car

- Uncomfortable landing. This is partly due to the very soft seats and poorly thought out ergonomics of the interior space.

A differential is a type of mechanical device that transmits rotation from one element of the gearbox to 2 others with a change in the angular speed of rotation of the main consumers, making their movement independent.

Welding technology

Gearbox for walk-behind tractor: types and self-assembly

So, before us is a bare gearbox with satellites. How to weld a differential with your own hands? Everything is very simple. Using a welding machine, we “grab” the satellites from the inside of the differential housing, as well as from each other. After this, you can apply a full suture. It looks like this.

To ensure the quality of the seam (if a semi-automatic machine is used), remove the slag deposits with a hammer and chisel. If the seam is uneven, process the contact area of the satellites again. Now you can put everything back together and put the gearbox in its place. The car is fully serviceable.

Design and technical characteristics of the gearbox

The rear gearbox of the VAZ 2107 car consists of a massive steel casing with a shank, a driveshaft flange, two main gears mounted at right angles to each other and a self-locking differential.

The main elements of the gearbox are the housing, the main pair of gears and the differential with satellites

Rear gear ratio

The main characteristic of any gear transmission is its gear ratio. It is the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear. The driven gear of the VAZ 2107 rear gearbox has 43 teeth. And the drive gear has 11 teeth. Dividing 43 by 11 we get 3.9. This is the gear ratio on the VAZ 2107 gearbox.

Another important point should be noted here. VAZ 2107 was produced for many years. And over the years, gearboxes with different gear ratios were installed on it. For example, the earliest models of the “seven” were equipped with gearboxes from the VAZ 2103, the gear ratio of which was 4.1, that is, the tooth ratio was 41/10. On later “sevens” the gear ratio changed again and was already 4.3 (43/10) and only in the newest “sevens” this number is 3.9. Due to the above reasons, the driver often has to independently determine the gear ratio of his car. Here's how it's done:

- the car is set to neutral gear;

- The rear of the car is raised using two jacks. One of the rear wheels is securely fixed;

- After this, the driver manually begins to turn the driveshaft of the car. It is necessary to make 10 revolutions;

- By rotating the driveshaft, you need to calculate how many revolutions the unfixed rear wheel will make. The number of wheel revolutions should be divided by 10. The resulting number is the gear ratio of the rear gearbox.

Bearings

The rotation of all gears of the gearbox is ensured by bearings. In the rear gearboxes of the VAZ 2107, single-row roller bearings are used on the differential, and the rollers there have a conical shape. Bearing marking is 7707, catalog number is 45–22408936. The price of a bearing on the market today starts from 700 rubles.

All rear gear bearings of the “seven” are roller, single-row, tapered

Another bearing is installed in the gearbox shank (i.e., in the part that connects to the cardan). This is also a tapered roller bearing marked 7805 and catalog number 6–78117U. Standard VAZ shank bearings today cost from 600 rubles and more.

Planetary pair

The main purpose of the planetary pair in the rear gearbox of the VAZ 2107 is to reduce engine speed. The pair reduces the crankshaft speed by about 4 times, that is, if the engine crankshaft rotates at a speed of 8 thousand rpm, then the rear wheels will rotate at a speed of 2 thousand rpm. The gears in the planetary pair of the VAZ 2107 are helical. This solution was not chosen by chance: a helical gear is almost twice as quiet as a spur gear.

The planetary pair has a helical gear to reduce noise levels

But helical planetary pairs also have a disadvantage: the gears can move along their axes as they wear out. However, this problem is relevant for racing cars, the rear axles of which have exclusively spur gears. And for all the years of production of this car, the VAZ 2107 had exclusively helical planetary pairs.

Correct assembly

When using old parts, only the oil seal and spacer sleeve are changed. When replacing elements of the main pair, it is necessary to use a new spacer washer for the shaft gear and bearing. The washer is selected according to the size, which can be found on the shaft itself. The adjustment ring is mounted and pressed with an attachment onto the inner bearing race.

Requires installation of a spacer sleeve. It is placed in the crankcase. A new oil seal is installed. Next, put on the flange and tighten everything with a new nut. When installing new bearings, the nut must be tightened with a force of 16-200 kgf meter. After running-in, the force will drop to 6. When using old bearings, tightening occurs in the same way as the oil seal.

The differential is assembled and installed in place. If the semi-axial gears had axial play, then thickened washers are installed. After this you can screw on the lids.

A specialized wrench is made to adjust the bearings.

The main pair is adjustable. The nut must be tightened from the main gear until the gap disappears. The shtangel will help measure the gap.

Then the second nut is tightened and tightened a couple of teeth. The first nut has a gap of 0.08-0.13 mm. It will be noticeable if you pick up the gear: a faint knock of teeth will appear.

While controlling the gap, slowly tighten both nuts until they increase by 0.2 mm. This ensures that the bearings are tensioned correctly. Next, the gear is turned by hand and backlash is tested. If it is the same in different positions, then locking plates are installed, tightened with bolts. If this is not the case, then they say that the differential box is deformed, and therefore it needs to be replaced.

Types of limited slip differentials

To eliminate the above shortcomings, a differential was introduced into the vehicle’s transmission, which should also transfer all loads received from the engine to the wheels. On cars of earlier releases, planetary differentials of a classical design with a symmetrical torque distribution scheme were installed.

This differential only partially eliminated these shortcomings. Since the 30s of the last century, research has been carried out on the use of limited slip differentials. They were installed first on sports cars, and then in production SUVs and road cars. The most widely used limited slip differentials are: FRICTION

• self-locking friction multi-disc differential.

Consists of a housing, satellites, satellite axle, output axle shafts, axle shaft gears, disk packages. The discs are alternately connected to the differential housing and the axle gears. The discs are spring loaded. The work is based on the synchronous rotation of the axle shafts with the body on a straight section of the road and the difference in rotation when performing maneuvers. In this case, the clutch comes into operation and supplies additional torque to the lagging gear. Having in their design spring-loaded friction disc packs. They have a static pretension (actuation moment) from 2 to 12 kg/m. Used in motorsports, they wear out quickly and require intervention to restore performance after each race. • self-locking gerotor differential. The design is similar to the differential described above, only instead of springs a pressure piston and a hydraulic pump are installed. The friction discs are compressed by a piston under fluid pressure from one or two gear pumps. The disadvantages are approximately the same as for a spring-loaded clutch • cam (gear) differential. Consists of a separator, an outer sprocket, an inner sprocket, crackers, two axle shafts, a driven gear of the main gear, and a housing. Based on the use of cam (gear) pairs instead of a planetary mechanism. With a small difference in the angular velocities of the axle shafts, the gear pairs rotate mutually, and when they slip, the axles are blocked. Positive aspects: simplicity of design, easy installation, low cost. Negative aspects: harsh operation, low efficiency, increased fuel consumption. In this regard, they are installed mainly on military and special equipment. • viscous coupling. It consists of a housing, a drive shaft, a driven shaft, a package of disks (drive and driven shaft disks), a hub, a pressure plate, 2 annular injection pistons, an annular working piston, and a balancing spring. The operating principle is based on filling the inter-disc space of the clutch with a dinatant liquid, silicone, capable of thickening and increasing in volume as the temperature rises. As the difference in the rotation of the axle shafts increases, the temperature from friction increases, and accordingly, the viscosity of the fluid increases and, as a result, the adhesion of the discs. Advantages: simplicity of design and operation. Disadvantages: low efficiency, cumbersome design, inertness in use. Due to their massiveness, they are mainly used for center differentials. GEAR

• self-locking differential (QUIF). Consists of a housing, satellites of the left and right rows, semi-axial gears (left and right), 2 output shafts. In this differential, the axles with satellites are closed in the housing (in special holes), located in two rows parallel to the axis of rotation of the housing. Satellites from different rows engage each other in pairs with helical teeth. • “torsen” of the first type. Consists of a housing, satellites of the left and right rows, right and left axle gears, 2 output shafts. "Torsen" of the first type. Each axle axis has its own satellites, connected in pairs with the satellites of the other axle axis. The gearing is spur-toothed, the satellite axis is perpendicular to the axle axis.

• “torsen” of the second type. Consists of a housing, a satellite connected to the right axle gear, a satellite connected to the left axle gear, right and left side gears, left and right output shafts. "Torsen" of the second type. Helical gears of axle shafts and screw satellites are used. The axes of the satellites are parallel to the semi-axes.

Search

Welcome! Rear axle gearbox - thanks to this, all the torque is transmitted from the drive shaft and goes to the rear wheels, without a gearbox the rear wheels do not rotate (unless it is a car on the front wheel, which instead of a gearbox with an axle is a normal support at the rear) and a car with the rear wheel will not go anywhere, by the way, there is also a differential inside the gearbox, which is welded a little, and the likelihood that the car slides around the turn increases because if you are looking for information on how to remove the torsion gears and weld it in different ways, we don't advise you to do this for you if the car is used in everyday life, if it is purely for weekend drifting Why not spin with a welded differential, the car actually starts spinning much better, not counting when accelerating, higher speed as the uniform torque is transmitted to both wheels, and the car begins to move without slipping, this is not so noticeable in classics, in front-wheel drive cars it is a more pronounced scoop (it becomes less, if there are excellent tires, then it generally loses) ARE).

The note! To replace the transmission on the rear axle, the tools you will need are wrenches, screwdrivers, and a wrench, and if you have a wrench, they will certainly accumulate to allow you to properly tighten the transmission mounting bolts. then, when the vibrations are weakened, they can sometimes become twisted, and tightening it very tightly will not do any good (you may unscrew the bolts if you suddenly go down when you need to unplug them again), so the bolts must be tightened with a torque that can be realized with wrench!

Result:

Where is the rear axle gearbox located? It is located in the lower rear part of the car, at the bottom it rotates for clarity on a white circle, and this gearbox is connected to each other by axle shafts (indicated by blue arrows, or rather the blue arrows indicate beams, inside of which these are the same axle shafts) that you will removed from the car, since their ends are in contact with the gearbox gears, and therefore the gearbox cannot be removed without disconnecting them (after reading the article, you will understand how to remove the shaft axle from the gearbox, we will explain carefully) in order to clearly mark the location of the gearbox, for clarity, we have also indicated the red arrow where to disable the spell, as you can see next, and this gearbox is worth it because you are no longer confused about finding it.

When do I need to change the rear axle gearbox? The gearbox is changed when the gearbox is badly worn or after severe deformation, which can occur as a result of the gear hitting a stone (at speed this happens, but basically the protection takes the full blow), when the gears wear out inside the gearbox, their spacing between them increases and due to this there is a strong roar and the gearbox may vibrate more than usual while the engine is running, unfortunately the gearbox is not easy to repair, but this may be because if yours is already completely worn out and the new vit . If it's not cheap, try (if you want) to fix the old one by replacing the gears, which are basically unusable, for more information on how to fix the gearbox, read “Rear axle gearbox for VAZ cars.

How to replace the rear axle gearbox on a VAZ 2101-VAZ 2107?

You may also like

The note! When buying a new gearbox, take into account the fact that different classic gearboxes were used on the classic (there were four of them in total), they are the same inside, in fact they are all the same, they are just different gears, the fastest unwinding is the gearbox - from the VAZ 2102. (it has a 4.44 main pair) and a VAZ 2106 car is a 3.9 main pair, the data transmission is interchangeable (in other words, you can put a gearbox from six to a penny and vice versa) and their differences only apply to the main pair, explain that this is a pair, this won't be explained at all, just say that a 4.44 steam engine will accelerate faster, but will have the lowest top speed, whereas a steam engine (meaning similar car power) will accelerate 3.9 times longer, but at top speed speed it will be much higher than a pair of 4.44 transmissions, but it doesn't make sense to install a lot of massive pairs of 4.44 automatic transmissions, because the joke acceleration says that you will also shift rs a lot, but a lot of massive cars don't needs a pair of 4.44 (the car will run in almost 3 gears until 80 and ask for the next gear, and in 5 it will accelerate to a certain speed around 150 and will also make noise, but the engine allows it, but the gearbox does not accelerate anymore, so when choosing it, be be careful and buy new/used power from your car, not faster acceleration or top speed), all these gearboxes are explained in more detail on the classic in the video below:

Video: How to cook a gearbox weighing 2107

Removal: 1) First drain all the transmission oil from the gearbox, by the way, this is an opportunity to change it if you have not filled in new oil for a long time, for more information on how to drain the oil from the gearbox, read the section of the article: everything is explained there and written.

2) Now proceed to disconnect the propeller shaft flange from the gearbox flange, both flanges are secured with 4 bolts (the two bolts are marked with blue arrows for clarity) and nuts (the nuts are screwed onto the end of the bolts, one of the nuts is marked with a red arrow), you will need to unscrew all nuts, and at the moment when the cardan does not rotate, block it (you can press the brake if an assistant or a thick screwdriver is inserted into the hole). green arrow), well, unscrew all the nuts, disconnecting the e Flange driveshaft from the flange box ne edit, then hang a rope from the butt of the driveshaft muffler (if the car is hot, the muffler will also be hot, consider this) or hang something carefully later (we do not recommend this do).

The note! You can mark with chalk or a felt-tip pen on both flanges, if you later reinstall the old transmission, you will just need to later install the driveshaft in the same position as before, or simply disconnect the driveshaft by hanging it on a rope - just like that it stood (in other words, without flipping or rotating), then you definitely didn't go wrong with the reinstallation!

3) You will then have to remove both shafts, just if they are installed the gearbox will not be removed, you can find information on how to remove half the shafts on our website, but this can be found in the article entitled: "Replacing Shaft Seals, and , by the way, if you are already going to remove the shaft axis, then replace the seals in them, if they have already been suggested, so that a little later you no longer have to crawl and the more the hoe rolls.

Sequencing

- Before starting work, 2 bushings are made from bronze or brass according to the drawing given below.

Locking brass bushing for VAZ 2107 gearbox

A pair of bushings in a spring from a valve of a VAZ 2110 car

Axle shaft removed from VAZ 2107

Standard gearbox removed from a VAZ 2107

A pair of bushings is inserted into the VAZ 2107 gearbox

Video: Installing a lock on seven with your own hands

To summarize, it should be said that differential locking on the VAZ 2107 was and remains a very controversial issue. On the one hand, the car's cross-country ability increases, it corners better, and acceleration becomes more dynamic. On the other hand, it is not so easy to keep an accelerated car on a straight line, and its tendency to skid increases. In a word, whether to install it or not is up to the driver to decide.

The Chevrolet Niva is one of the few Russian-made SUVs that, in addition to excellent cross-country ability, can also boast a relatively modern design. Therefore, it still enjoys well-deserved popularity in the market.

The Chevrolet Niva owes its good off-road characteristics to its predecessors - the VAZ2121, namely permanent all-wheel drive, with the possibility of forced differential locking. But before setting up the transfer case and using the gearshift levers correctly, you must first understand how this mechanism works and what happens during its operation.

The transmission of this type of car consists of several main components: cardan, gearbox, transfer case and axles. The main component in the bridge structure is the differential. If it were not there, the wheels would rotate at the same speed, which would lead to wheel slipping and excessive load on the axle. The presence of a differential allows you to avoid destruction of the axle due to the fact that when turning, torque is transmitted to one of the wheels.

The design itself provides for the transmission of torque to the wheel, which experiences less traction with the surface. Therefore, for example, a wheel that stands on ice or sand will spin faster than one that stands on asphalt.

The Niva design provides for the presence of three differentials. This is due to the presence of permanent all-wheel drive in the car. If the same force were transmitted to all wheels, then the car could only move in a straight line. But when turning, the forces between the wheels are distributed unevenly. Accordingly, two bridges connected to each other will invariably experience increased loads that can destroy the structure. There are some SUV models that do not have a center differential installed, but they use other technical solutions, such as clutches or all-wheel drive is not permanent.

How does it work?

There are three differential operating modes in total. So, his work is aimed at moving in a turn, along a road and in a straight line. In the latter case, the car's wheels have equal resistance. Torque from the driveshaft (or final drive) is transmitted to the differential housing. The satellites rotate with it. The latter run around the axle gears and thus transmit torque to the two driving wheels in equal proportions. And since the satellites on the axles do not rotate, the gears of the axle shafts move at the same angular speed. The speed is equal to that of the driven shaft of the main gear.

Repair and adjustment of the VAZ 2107 gearbox

Adjusting and repairing the gearbox requires some skills and careful adherence to technology. It is also necessary to have pullers, stands and special tools. If the above is not the case, you should entrust the work to professionals.

If your qualifications are insufficient, it is better not to start working with the gearbox. Assembly and adjustment work requires fairly high metalworking skills. It is not difficult to disassemble the VAZ 2107 axle, but this is one of the few components of the “Seven” that requires highly qualified maintenance. It is not worth saving on these works.

Disassembling the gearbox is performed in the following sequence:

- unscrew the shank nut;

- remove the flange and remove the drive gear and adjusting rings;

- remove the oil seal, oil deflector, inner ring of the bearing;

- press out the outer rings of the bearings with a puller;

- disassemble the drive gear with the differential (the spacer sleeve in this case must be replaced).

When disassembling the gearbox, it is necessary to put marks on the bearing caps in order to then install them in their original position. To do this, you can use a core (which is more reliable) or a pencil. Marks must be placed on the covers and on the body, so that later during assembly they can be aligned. You should also mark the left and right covers so as not to confuse them.

This can be done this way: on the covers, in addition to the marks opposite the marks on the body, apply numbers or letters with a pencil. The disadvantage of this method is that the marks will be erased when you clean the lid. Therefore, it is safer to simply make marks with a core. For example, one on the left cover and two on the right.

The inner rings with the separator are removed using a hammer and drift. You need to knock out the rings by lightly tapping them in different places. If you hit only one place, you won’t be able to pull out the ring.

Typically repairs consist of replacing bearings or the main pair. These parts most often fail.

The main pair is available in several variations and determines the gear ratio. The higher the gear ratio, the greater the traction; the lower, the higher the maximum speed of the machine. There are three standard versions of the main pair, used on different VAZ models.

| main couple | number of teeth on gears | number of revolutions of the propeller shaft per 10 wheel revolutions | gear ratio | |

| on the slave | on the leading | |||

| 2102 | 40 | 9 | 22,2 | 4,44 |

| 2101 | 43 | 10 | 21,5 | 4,3 |

| 2103 | 41 | 10 | 20,5 | 4,1 |

| 2106 | 43 | 11 | 19,5 | 3,9 |

VAZ 2107 owners sometimes install the main gearbox pairs with a non-standard gear ratio. To increase traction, pairs are set with a larger value, to increase maximum speed - with a smaller one. If the task is to tune a car, you can take this opportunity to change these characteristics of the VAZ 2107.

Reference: the VAZ 2102 axle had the maximum gear ratio (4.44). After this model was discontinued, finding pairs with this ratio became problematic, but as practice shows, the best option is installation on a VAZ 2107 with a 1.5-1 engine ,6 gearboxes with 2103 (4.1 gear ratio). When choosing this gearbox in conjunction with a five-speed gearbox, traction and speed are maintained.

We eliminate the main problems of industrial gearboxes

- 08 November 2016 21:08:00

- Reviews:

Industrial gearboxes are one of the most commonly used equipment. However, their active use can lead to wear of parts and subsequently disrupt the technical characteristics of the unit. The main signs of problems with the gearbox are extraneous noise, vibration, oil leakage, heating or freezing of the housing. How to fix all problems with minimal costs?

Rice. 1 — Main problems of industrial gearboxes

If, when inspecting the gearbox, we noticed that oil is leaking from it, the input shaft does not rotate, and it itself makes sounds that are unusual for it - this is a clear sign of problems. We identify the 6 most common root causes of gearbox problems and offer methods to combat them.

Why does the gearbox get hot?

The root causes of gearbox heating may be:

| Problem: | Solution: |

| - sticking gear | reduce the load on the gearbox until the teeth are worn in |

| — damage to bearings due to wear | bearing adjustment |

| - lack of oil | top up the gearbox with oil |

| - non-recommended oil was filled | change the oil to the recommended one |

| - permissible load exceeded | reducing the load to the recommended |

| — the gearbox and unit shafts are not centered | center the shafts |

| — there is no reliable air circulation for cooling the gearbox | clean around the gearbox, remove all unnecessary objects |

| - contamination of the gearbox | Gearbox surfaces must be clean |

Why does the gearbox howl?

If you hear a loud noise or a sharp knock coming from the gearbox, the root cause may be the following:

— the teeth of the worm gear are damaged (in the worm gearbox)

Rice. 3 - Damaged worm gear teeth

Why is the gearbox humming?

If, in operating condition, the gearbox makes sounds similar to a hum while vibrating, the problem may lie in increasing the permissible vibration level. A special device called a vibrometer will help you accurately determine the vibration indicator.

Rice. 4 — Determining the vibration level with a vibrometer

Causes of increased vibration levels and their solutions:

| Problem: | Solution: |

| — misalignment of gear and unit shafts | align the shafts |

| — the drive base is not rigid enough | increase the rigidity of the base |

| — the foundation bolts of the gearbox, engine or unit are not tightened | tighten foundation bolts |

Why does the gearbox freeze?

The gearbox freezes if you fill it with oil that is not intended for low ambient temperatures. To solve this problem, it is necessary to fill in a special oil, which is universal and suitable for both the summer and winter seasons (for example, TRANSOL-200A oil).

Why is oil leaking?

If you find traces of oil on or around the gearbox, we advise you to immediately inspect the gearbox and take all necessary actions. Oil can flow through the seals and along the plane of contact of the bearing caps to the housing or through the seals. To solve the problem you will need:

Problem: Solution: - the drainage vent is clogged with debris, clear the vent of debris - the bolts are loose, the bolts must be tightened until they stop - the cuff is damaged, replace the faulty cuff

Why does the gearbox output shaft not rotate when the engine is turned on?

The output shafts of the gearbox must always rotate freely. If this does not happen, then the reason lies in the following:

Problem: Solution: - high-viscosity oil is filled, replace with suitable oil - low-power engine, check or replace the engine - gearbox or engine shafts without keys, install keys

Rice. 5 — Installing the key on the gearbox shafts

Detection of one of the above problems is the first signal that your gearbox may soon fail. Further operation of a faulty gearbox can lead to breakdown of its individual mechanisms or lead to a stop in the operation of the entire unit. Therefore, it is very important to do maintenance on the gearbox at least once a month, and also inspect it for oil leaks each time before use.

If you have any difficulties with servicing or repairing the gearbox, we advise you to immediately seek help from specialists. Our company can also help you with this. To use our services, follow the link and leave us a request.

Opening hours and prices at the AvtoVAZ Prototype Museum

Opening hours coincide with the schedule of the entire Technical Park named after. Sakharov. The museum is open daily, seven days a week, from 08:00 to 20:00.

Since the hangar with the prototypes is located on the territory of the park, you must pay a general admission ticket + a ticket to the museum.

- Entrance ticket to the park: adults - 200 rubles, children, students, disabled people - 100 rubles.

- Entrance ticket to the Museum of Prototypes - 50 rubles.

VAZ-1121 (Oka-2), Igor Butyrskii

Excursion services (at park sites):

- group of up to 15 people: adults - 250 rubles, children - 150 rubles.

- individual: entrance ticket + 1000 rubles.

Preferential groups have free access days. For detailed information, please visit the museum's website or call.

The museum has rules of conduct. It is strictly forbidden to touch, climb or sit in cars, or open doors. You cannot cross the fence line, litter, come to the museum with animals, etc. Amateur photo and video shooting is free.

Full price list of Park complex services on the official website

Lada 21109 “Consul”, Igor Butyrskii

How to weld a differential on a VAZ 2107

This. and if you make a hole in the beam, through which in front of the difficult-to-pass section - GRACK - and block the diff by sticking a pry bar.

They don't seem to catch flies. How do you like this idea: - one p/axle is drilled through and a thread is cut in the hole, - a screw with a “feather” at the end “goes” along the thread, - in the “diff unlocked” state, the screw is screwed into this p/axle as much as possible and does not connect her on the other. — if necessary, the driver turns the screw from the outside using a special key, it extends and the pen connects both axes.

(FANFARES, EVERYONE STANDS UP, RUSSIAN ANTHEM, CANNON FIRE, PB BOWS)

Since May 2013, our portal has expanded the thematic sections of the forum for the exchange of experience: subforums Americans, Koreans, Germans, French, Japanese have been added, due to the increase in the fleets of our visitors.

In addition to changing the style, our Chat, Mail, Entertainment and photo/video sections, Literature have become built-in and do not require separate registration. In addition, there are other useful and pleasant innovations that you can all familiarize yourself with when visiting the portal.

You can contact the administration with questions and suggestions in a special section of the forum or through the feedback form.

- print version

- Download/Print theme

- Display Modes

- Switch to: Tree-like

- Standard

- Switch to: Linear

Topic author GvOzD, 21.6.2004, 10:06

Log in to reply to this topic

- Users-2

- 194 messages

- Offline

- Card

- PM

Message added 12/10/2005, 1:08 am

Users-2 4,651 messages 4

- Offline

- Card

- PM

Message added 12/10/2005, 2:53 pm

Users-2 28 messages

- Offline

- Card

- PM

Message added 12/10/2005, 20:31

Users-2 194 messages

- Offline

- Card

- PM

Message added 12/15/2005, 0:30

Users-2 10 messages

- Offline

- Card

- PM

Message added 12/28/2005, 3:26

Users-2,503 messages

Features of different types of blocking. What to choose

Permanent differential locking is only necessary for SUVs, which, like tractors, never drive onto asphalt surfaces.

After installing the disc lock, you will need to constantly adjust it. You will also have to buy special, expensive gear oil. In this type of locking, there is a small constant friction moment, which impairs the vehicle's handling and causes increased fuel consumption and tire wear. When the clutches operate, they wear out intensively, therefore, with frequent driving on a bad road, when the car slips, the unit will quickly wear out. Therefore, the VAZ 2107 differential is usually not blocked in this way.

The viscous coupling has a large response inertia, often overheats or turns on at the wrong time, with a delay. Not suitable for off-road use, but good in urban environments. Due to its complexity and high cost, it is not used for modernizing the “classic” VAZ.

Screw and planetary locks are most suitable for installation on the VAZ 2107. They not only work well in a snowy city, but are also suitable for car enthusiasts traveling along country roads. But such a lock is not suitable for serious off-road use.

Symmetrical differentials

The higher the blocking coefficient, the better the cross-country ability. And when driving on a flat road on asphalt, a large coefficient, on the contrary, worsens the control and dynamics of the vehicle, because the moment of the lagging wheel is several times greater, which helps push the car out of the turn. In this case, there is increased wear of the rubber due to slipping, there is a load on the drive units, the efficiency decreases and fuel consumption increases.

Differential preload is a kind of trade-off between driving comfort and traction power of the car.

Pros and cons of a welded gearbox for off-road use

In the article about the tricycle from the Ural motorcycle, I said that the differential in the Zhiguli bridge is welded. But later a regular differential was installed there. The difference was felt immediately.

Inverted Zhiguli Bridge on a tricycle

So, let’s list the main advantages of a welded differential for off-road use:

- Patency. It is what it is. Due to the lack of torque distribution, cross-country ability is noticeably increased. The likelihood of wheel slipping due to insufficient traction with the surface is reduced, which in itself already worsens this traction. Read more about this effect (static and sliding friction) in the article on types of all-wheel drive (link at the end of this article).

- Straightness of movement. With a locked gearbox, the tricycle tends to go straight in any conditions, which sometimes turns out to be useful. You can, for example, brake by turning the steering wheel. But this effect is more of a hindrance than a help. More details below.

This is where the advantages of the “electric arc” bridge blocking end, and it has no less disadvantages.

- Controllability. More precisely, its absence. Due to the fact that both rear wheels are constantly rotating at the same angular speed, the tricycle turns reluctantly. This is especially problematic during sharp turns and turns. It is more difficult to accurately maintain the trajectory of movement, and if you get into a deep rut, it is almost impossible to get out of it.

- Heavy control. It follows from the previous point. This is especially evident during prolonged lateral rolls, when your hands simply “go numb” from constant tension on the steering wheel.

- Load on the structure. The suspension suffers especially, both front and rear. A couple of times the rear post rods and the mounting of the rear shock absorbers were torn off, and the frame cracked in the area of the steering column. Nothing like this was observed with a conventional gearbox, even during severe operation.

- The welded differential may have a short service life. In the Urals, due to the relatively low engine power (about 35 hp versus 75 hp for the Zhiguli one), the welded bridge served regularly for more than two years without any problems. But when using “electric arc” blocking on a car, and even on asphalt, I think the bridge will not last long.

Conclusion

There was no noticeable deterioration in cross-country ability after installing a conventional differential on the tricycle. Even on a slippery surface, two wheels usually “row”. Only if there is a noticeable difference in traction between the wheels is there really a lack of locking. But handling has improved noticeably, allowing masterful maneuvering in difficult situations. And this, I think, is much more important. Of course, blocking would not hurt, but only automatic or manually activated. But not permanent.

You also need to take into account that the listed pros and cons of a welded bridge are clearly manifested when using it on a tricycle. Those. if, say, you put a welded axle on a car whose wheelbase is much larger, then the handling will not deteriorate so much. And if it is also all-wheel drive, then this effect will be even less noticeable. But it’s better to spend money on self-locking or forced locking if we are talking about a car that will be used not only for off-road use, but also for everyday trips around the city.

Types of all-wheel driveTheory of cross-country abilityTricycle from the UralsFactors affecting cross-country abilitySpecific ground pressure

About contraindications

Before welding the differential, your car must be in full working order. First of all, this concerns the transmission. After all, it is on it that all the torque will be placed. A welded gearbox will significantly increase the load on the transmission shafts. As a result, it will quickly fail

Also pay attention to the quality of the seam. If the welding is done poorly, the weld will soon collapse and a bunch of metal fragments will appear inside the gearbox

The situation is not pleasant. Don’t be lazy to knock off the layer of “slag” on the seam you just made. The better the work is done, the longer the “infusion” will last. She does not have a specific resource. If everything is done correctly, the “infusion” will last forever. It’s more likely that the engine itself will fail or the body will rot over time.