Repair / From Autoclub

- Pump repair manual

Preparatory stage - removing the part - How to remove and change the impeller

Video: technology for dismantling the impeller

- Video: repairing a hull crack

The water pump of the cooling system on classic VAZ 2101–07 models is not reliable. On average, the mileage of a part is 40 thousand km, after which it fails and must be replaced. But for the skilled Zhiguli owner there is another way - to remove and repair the pump, replacing worn or broken elements: oil seal, bearing or impeller. If this approach is close to you, then before starting work you should study the detailed instructions for restoring the “classic” pumping unit.

Pump VAZ 2107

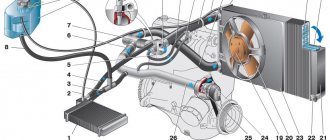

The water pump (VAZ 2107 pump) is no different from the units installed on other “classic” models. This is a housing (cover) with a shaft with an impeller installed inside. The movement of the coolant is ensured by the movement of the impeller blades rotating on the shaft. That is, it is a centrifugal type pump.

Torque is transmitted to the shaft from a pulley mounted on the engine crankshaft through a belt, which at the same time rotates the car’s electric generator. On older VAZ models, the pump pulley was used for another function - for attaching a fan for forced cooling of the radiator. But the VAZ 2107 is equipped with an electric cooling fan, so this part is missing.

Features of the cooling system of classic Lada

The cooling system of the VAZ 2107 is actually no different from other engines built on the basis of the Fiat 124 engine. It is not our plan to describe its operation and design, however, the pump bears the main load and is responsible for the circulation of the coolant. Despite the simplicity of the water pump design, it is subject to a whole bunch of requirements, and failure to comply with at least one of them can cause an antifreeze leak or disruption of its circulation. As a result, the motor will overheat with all the ensuing consequences.

VAZ 2107 pump malfunctions

This unit has a fairly simple design, so the faults are not too varied: a coolant leak or a bearing failure.

They are often connected, but the consequences of these two breakdowns should be separated. In the first case, a critical decrease in the antifreeze level and engine overheating is possible. It will be possible to drive some distance, you will have to add antifreeze (if there is none, water). In the second case, the bearing may jam, which will lead to a break in the pump belt and a complete lack of engine cooling. In this case, you will not be able to continue moving.

In both cases, an immediate replacement of the VAZ 2107 pump is necessary, since this unit cannot be repaired.

Replacing the pump

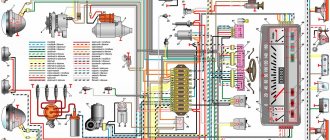

Before you begin replacing the pump, you must drain the coolant from the radiator and engine. To do this, you need to remove the radiator cap and sequentially unscrew the cap on the radiator and cylinder block, exposing the container to drain the antifreeze. When the cooling system is empty (or the coolant level is below the pump mounting level), you can begin replacing the pump. To do this, you need to perform the following operations:

- remove the generator belt by first loosening the nut and reducing its tension;

- loosen the nut securing the generator and move it closer to the splash guard;

- Using a 13mm wrench, unscrew the bolts securing the pump pulley and remove it;

- unscrew and remove the coolant supply pipes;

- unscrew the pump and remove it from the cylinder block;

- remove the sealing gasket (it must be replaced when removing the pump);

- unscrew the 4 nuts on the pump and disassemble it;

- install a new pump pump with o-rings (they, like the sealing gasket, cannot be used twice);

- Reassemble all parts in reverse order.

Features of pouring antifreeze (antifreeze)

After replacing the VAZ 2107 pump, all that remains is to tighten the alternator belt and fill in the coolant. The latter will need about 10 liters.

To add antifreeze without creating air locks in the cooling system, you should do the following:

- position the car so that the front is higher than the rear. Then the heating radiator will be lower than the other elements of the system.

- disconnect the thin hose of the cooling system going to the carburetor or throttle valve (depending on whether the carburetor or injection type of engine is installed on the car);

- open the plugs on the expansion tank and radiator;

- make sure that the drain plugs are installed and carefully tightened;

- pour antifreeze (antifreeze) into the radiator using a watering can;

- push the rubber hoses of the cooling system with your hands, expelling the air (the fluid level will drop);

- fill the radiator to the brim and close the cap;

- pour coolant into the expansion tank and close it;

- start the engine, warm it up to operating temperature;

- With the engine running, squeeze and release the cooling hoses several times to remove remaining air from the system;

- add fluid to the expansion tank to the recommended level.

- install the hose going to the throttle and tighten the clamp.

Final stage

And at the end of this epic there will be installation of the generator belt and pouring antifreeze into the system. If everything with the belt is extremely clear and simple, then with refueling several questions may arise. One of the main ones is how many liters of antifreeze are in the VAZ 2107, what is the volume of the cooling system?

This question is often of interest to drivers, since they need to know which canister of liquid to buy in the store. Take 10 liters, this will be enough, there will even be a lot left for refilling. The price of a canister of antifreeze of this volume will be about 800 rubles. But the price of a liquid called “antifreeze” (green or red) is one hundred rubles more expensive.

And now let’s talk about how to properly fill fluid into a VAZ 2107. In particular, this guide will help you if you are having an emergency or scheduled fluid change. So, it is advisable to install the car correctly - the front part is slightly raised.

Purpose of the VAZ 2107 pump

A water pump is a device whose main mechanisms are a shaft and an impeller. The pump shaft is driven by transmitting torque from the engine crankshaft. Torque is transmitted through a pulley and a belt drive, which connects components such as the crankshaft and the generator.

On VAZ 2107 cars of the carburetor type in the first years of production, the pump pulley is also used to attach the forced cooling fan. Modern VAZ 2107 models of injection and carburetor types are equipped with electric cooling fans, so there is no need to drive the fan.

The pump ensures the circulation of coolant in constant mode after starting the car engine. If the pump does not function, the cooling cycle will be disrupted, which will lead to excessive overheating of the motor and failure. It is very important to replace the pump in a timely manner, otherwise the consequences will be fatal.

Water pump problems

The pump has a fairly simple design, so identifying faults is not difficult. Malfunctions may be associated with failure of the bearings, and there may also be a leak of coolant due to wear of the sealing seals. Such problems have various types of consequences:

- If there is a coolant leak, the antifreeze level will decrease and the engine will overheat. If coolant is leaking, you can compensate for its deficiency by adding antifreeze or water. If a fluid leak occurs, it is important to promptly identify this type of failure.

- When the bearings jam, the consequences of this phenomenon cause the belt to break. In this case, continuing to move is strictly contraindicated.

Replacing the pump on a VAZ 2107 car, injector or carburetor, if the above reasons occur, is mandatory. At home, you can repair the VAZ 2107 pump yourself. How to do this is shown in the video below.

However, experts do not recommend resorting to repairing the product, since it is much easier and more efficient to replace the pump than to buy a repair kit and carry out repair work. It is especially important to pay attention to the integrity of the main pump components.

What is needed for replacement

To replace the pump, you will need to use the necessary tools. These tools include:

- Keys for 8,10,13 and 17.

- A container to drain antifreeze from the system.

- Screwdriver.

The first step is to drain the coolant from the system, and only after that can you begin to replace the device. The process of replacing a water pump does not present any difficulties, but when performing work it is important to follow a clear sequence. We will look further at how the fluid is drained and the pump is replaced on a VAZ-2107.

How to remove a pump from a car: step-by-step instructions

To replace the water pump on a VAZ 2107, you need to drain the coolant. This is done by removing the cap from the radiator, as well as sequentially unscrewing the plug on the radiator and cylinder block. After draining the antifreeze, you can begin work on replacing the water pump. Step-by-step instructions for replacing the pump on a VAZ 2107 car:

- When loosening the nut securing the generator housing, remove the belt.

- Using a key set to “13”, you need to unscrew the bolted connections that secure the pump pulley. After unscrewing the bolts, it should be dismantled.

- Unscrew the fastenings of the coolant supply pipes and then remove them.

- Carry out the process of unscrewing the bolted connections by which the pump is fixed, and then dismantle it.

- After the pump is dismantled, it is necessary to replace the sealing gasket. The old gasket must be changed.

- Unscrew the 4 fastening nuts of the pump, and then disassemble it.

- Install the new pump along with the O-rings. O-rings and gaskets cannot be reused.

- Now you can assemble all the parts in the reverse order of removal.

From the instructions described above, it is clear that the process of replacing the pump is not particularly difficult. Before resorting to such actions, you should find out how to check the water pump. Checking the serviceability of the water pump involves performing the following procedures:

- Antifreeze leak detection. If the water pump fails, a coolant leak will inevitably occur. The location of the water pump housing should be inspected.

- The occurrence of extraneous noise. If the device makes strange noises, then this is the reason that it will soon need to be replaced.

- Formation of excessive vibration. Excessive vibration indicates bearing failure.

- System contamination. If you do not replace the antifreeze for a long time, this will certainly cause the pump to fail.

Is it possible to eliminate a pump leak on the way?

The loss of some antifreeze on the road is indicated by an increase in the temperature of the coolant and a decrease in the level in the expansion tank. If you have located the leak and are convinced that the pump is to blame, you can try to fix the problem. Failures that cause antifreeze leakage are as follows:

- The joint between the flanges of the pump and the cylinder block has lost its tightness, antifreeze is leaking from under the gasket;

- a crack has formed in the pump body;

- the housing was destroyed by the impact of the impeller.

You can insert a wedge into the hole in the housing from the front side and coat it with cold welding.

As a rule, problems with a leaking water pump are critical and are quite difficult to fix on the road. Try to tighten the leaking gasket by tightening the 4 pump mounting nuts, which will require removing the generator drive belt and pulley. Don't overdo it - it's easy to strip the threads on Ø8mm studs.

Try to seal a small crack with a chemical composition - cold welding. If possible, tape the patch to the body with something so that it does not fall off, add water and get to the garage. It will not be possible to seal a large hole from the impeller; you need to look for an option to tow the car or call a tow truck.

Video: repairing a hull crack

From a financial point of view, pump restoration is more profitable than a complete replacement; the savings are about 50% of the cost of a new part. Considering how often minor breakdowns occur on Zhiguli cars, such a difference in price plays a role. The technology for replacing the bearing and oil seal on the VAZ 2101 water pump is also suitable for other cars equipped with a classic engine: VAZ 2121 Niva and its modifications, Niva-Chevrolet.

Design features and procedure for self-replacement of the water pump on various modifications of Gazelle cars

Replacing the pump yourself on a Niva Chevrolet: quickly, efficiently and with your own hands

Pump VAZ 2107

On cars with a liquid cooling system, including the VAZ 2107, one of the main elements responsible for maintaining the operating temperature of the engine is the pump. Thanks to this unit, the circulation of coolant is ensured. If problems arise or if the water pump fails, the normal operation of the power unit is disrupted, which can lead to serious consequences and expensive repairs.

Purpose

The operation of the pump is aimed at continuous circulation of coolant (coolant) through the engine cooling jacket. The antifreeze is heated under the influence of the rubbing elements of the power unit, and the necessary pressure in the system is created by a water pump. The liquid is directly cooled in the main radiator, after which the coolant again enters the cooling jacket. If circulation is interrupted for at least 5 minutes, the motor will overheat. That is why it is so important to monitor the proper operation of the node in question.

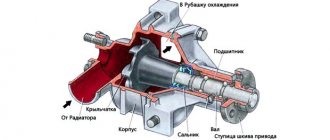

Pump design

On the VAZ 2107, as on many other passenger cars, the pump has almost the same design. The unit consists of a housing with a central shaft located inside, on which the impeller is fixed. The shaft is secured against axial displacement by means of a bearing, and the tightness of the structure is ensured by an oil seal that prevents coolant leakage. There is a hole in the pump cover through which the shaft comes out, where the pulley hub and then the pulley itself are attached to it. A belt is put on the latter, which on the “seven” rotates the generator and pump from the crankshaft. On modern cars, the pump rotates via a timing belt.

Where is

On classic Zhiguli models, the pump is located on the front of the power unit and is attached not to the block, but through a separate housing. By opening the hood, you can easily notice both the pump pulley and the assembly itself.

Which pump is better

For the VAZ 2107, water pumps with catalog numbers 21073–1307010, 2107–1307011–75 and 2123–1307011–75 are suitable. The last two options have an enlarged impeller and a slightly reinforced structure. Initially, these pumps were produced for Niva. The slightly higher cost of such pumps is fully justified by the better performance.

On “Sevens” equipped with both injection and carburetor engines, the same water pumps are installed, and their repairs are carried out in the same way.

The product in question is produced today by many companies, but the most popular are:

At the car market you can find pumps with impellers made of different materials: plastic, cast iron, steel. Products with plastic impellers, which are equipped with embossed and elongated blades, receive positive reviews. Elements made of cast iron are characterized by lower performance, and as for steel ones, they are susceptible to corrosion and are quite often fake.

The pump can be purchased either complete with a housing or separately. If the housing is not damaged, then it is enough to replace the pumping part. If the design has serious flaws or is completely broken, then you cannot do without replacing the housing.

Video: which pump to install on the “classic”

Malfunctions of “classic” water pumps

In older Zhiguli models, the engine is cooled using a special non-freezing liquid - antifreeze, circulating from the engine water jacket to the main radiator. The fluid is forced to move through the system by the rotating impeller of the pump built into the front part of the power unit. It is driven by the crankshaft via a belt drive.

The pump and generator pulley rotates with a belt from the crankshaft

To understand the causes of pump malfunctions, you need to know its structure. The part consists of the following main elements that perform certain functions:

- a housing with a flange serves for hermetically sealed fastening to the engine;

- the shaft is necessary for attaching the impeller and drive pulley;

- roller bearing ensures shaft rotation;

- an impeller with blades pumps coolant;

- hub - fastening element of the drive pulley;

- the seal prevents antifreeze from seeping into the bearing;

- The locking screw secures the bearing race inside the housing.

The cause of pump failure is usually the roller bearing and oil seal.

The pump is not screwed directly to the cylinder block, but to the second housing, where the thermostat pipe fits.

The vast majority of water pump malfunctions occur due to wear of two elements - the oil seal and the bearing. Owners of “classics” have to deal with the following breakdowns:

- antifreeze leaking through the oil seal and pump shaft;

- increased shaft play due to bearing wear;

- an impeller broken due to emergency contact with the surface of the second housing (occurs with increased shaft play);

- jamming of bearing rollers and breaking of the shaft into 2 parts;

A shaft with a broken end can be pulled out and replaced with a new one. - cracks and breaks in the housing as a result of shaft misalignment.

Due to bearing wear, the impeller begins to touch the housing and breaks a hole where all the antifreeze goes

All of the listed problems can be eliminated by replacing the corresponding elements, provided that the housing itself is not broken. In this case, the pump is replaced entirely.

Signs of a pump malfunction

Sooner or later, problems arise with the pump and the unit fails. This may be due to both the high mileage of the car and the installation of a low-quality product. Therefore, it is worth considering what malfunctions may occur with the pump and what to do in this or that case.

Oil seal leak

It is quite easy to detect coolant leakage through the oil seal: a puddle usually appears under the car. If the sealing element is damaged, for example, as a result of wear, antifreeze will get to the pump bearing, as a result of which the lubricant will be washed out of the device, and the part itself will soon collapse. To prevent this from happening, it is necessary to periodically inspect the car and eliminate possible problems.

Appearance of noise

If extraneous noise is heard from the pump area while the engine is running, this indicates an imminent breakdown of the unit. The most likely cause of noise is failure of the bearings or weak fastening of the impeller. In any case, the part needs to be dismantled, subsequently damaged, repaired or replaced.

Video: how the pump on a VAZ makes noise

Decreased performance

Whatever antifreeze is used in the cooling system, it is a chemical substance. Over time, erosion occurs in the pump housing or impeller, which can lead to a decrease in the flow of pumped liquid. As a result, the motor may overheat with all the ensuing consequences. Therefore, if the coolant temperature sensor on the instrument panel begins to exceed +90˚С (operating temperature), it is worth thinking about a possible replacement of the pump or, at least, a revision of this unit.

Increased vibration

If increased vibration comes from the pump area, first of all you need to inspect the pump housing in the bearing area: sometimes cracks may appear on it. It would also be useful to check the correct installation of the generator belt, pump pulley and fan. If faulty parts are found, replace them.

How to check the pump yourself

Today there are three popular ways to check your pump:

1. Warm up the engine to 90-95 degrees and pass the upper hose that goes to the radiator. If a pressure surge is felt at the moment of release, the pump is working normally. Be careful not to get close to the fan blades.

2. Pay attention to the drainage hole, which is located on the pump. If the oil seal no longer performs its functions, then a leak may appear from this hole.

3. Listen for extraneous sounds while the engine is running. If a clear hum is heard, then there is a high probability of bearing failure. Many people confuse this noise with normal belt slipping.

To confirm (or refute) your fears, try pumping the pump pulley. If there is play, then there are problems with the bearings.

Pump repair

If it has been determined that the pump needs repair or replacement, you first need to prepare the necessary tools for work:

- a set of keys;

- container for draining coolant;

- flat or Phillips screwdriver.

Removal

After preparing everything you need, you can start disassembling:

- Open the hood and drain the coolant by unscrewing the corresponding bolt on the cylinder block and the plug on the radiator.

- Remove the generator belt by loosening the top fastening nut and reducing the tension.

If the pump is replaced without a housing, then there is no need to remove the nozzles and tube (points 5 and 6).

Disassembly

Repair work will require disassembling the water pump. The procedure is carried out in the following order:

- Dismantle the impeller, having first clamped the pump in a vice.

- The shaft is knocked out.

- Remove the oil seal.

Video: how to disassemble a pump on a “classic”

Bearing replacement

To replace the bearing, you will need to disassemble the pump and knock the shaft out of the housing. On the “classic”, the bearing and shaft are one part. Therefore, if one of the parts fails, the entire product is replaced. In order not to make a mistake when buying a pump shaft for a VAZ 2107, you need to take the old part with you, since the axles can differ in both diameter and length, which the seller does not always know about.

The shaft is changed in the following order:

- Using a puller, press out the impeller.

Replacing the oil seal

Due to constant contact with antifreeze, the oil seal sometimes fails, which leads to a leak. To replace the part, it is necessary to dismantle the impeller and knock out the shaft and bearing. To do this, you can use an old axle, which is inserted with the opposite end into the pump hole.

Then the shaft is driven in by striking with a hammer until the oil seal comes out of the housing. The new sealing element is inserted and pressed into place using a suitable adapter.

Replacing the impeller

If the impeller is damaged, for example, the blades are broken, then the part can be replaced. Damage usually occurs upon contact with the housing due to severe wear of the shaft or bearing. Regardless of the material of the impeller, the part is attached to the axle by pressing. To replace the plastic impeller you will need:

- Having secured the shaft on the reverse side in a yew, use an M18 tap with a pitch of 1.5 mm to cut the threads inside the impeller, having previously lubricated the tool with engine oil.

- Screw a special puller into the hole and tighten the outer bolt.

- By rotating the head of the inner bolt clockwise, press out the impeller and remove it from the shaft.

- The metal impeller has threads cut from the factory, so the part is simply pressed out with a puller.

When reinstalling, the part is pressed onto the shaft using a hammer and a suitable attachment, avoiding damage to the blades. You need to make sure that the lower part of the impeller rests against the ring on the oil seal, after which it needs to be seated 2-3 mm inward. This will ensure a tight fit of the rotating part to the ring.

Video: how to remove the impeller from the pump shaft

In most cases, owners of VAZ 2107 and other cars do not repair the pump themselves, but simply replace the part.

Installation

Assembly and installation of the unit is carried out in the reverse order. The only thing you should pay attention to is the gaskets - it is recommended to use new ones. In addition, the connections between the pump and the pipes are coated with sealant. When the part is installed, add antifreeze. In order to prevent the formation of air pockets, disconnect the thin hose of the cooling system from the carburetor (on a carburetor engine) and ensure that the antifreeze flows out of the hose and fitting, after which the connection is made. Start and warm up the engine, inspect the pipes for leaks. If everything is in order, the repair can be considered successfully completed.

Replacing or repairing the pump on a VAZ 2107 yourself is within the capabilities of every owner. The only thing is that in some cases special devices will be required. Otherwise, a standard set of tools will suffice. To ensure that the pump operates for a long time, it is recommended to select the part from trusted manufacturers.