Turbo kit for a VAZ is a set of spare parts for installing a turbocharging system on an engine. The turbo theme is becoming increasingly popular in our country and abroad, and we are constantly continuing to improve our turbo kits. Turbo tuning is one of the best ways to increase engine torque and power. By correctly installing a turbocharger, it is possible to achieve an increase in power by 1.5 - 3 times. And with appropriate engine preparation, it is possible to remove 300 hp from a VAZ engine. and more.

If you want to get a powerful and at the same time flexible engine for the city, then the VAZ turbo kits offered on our website are perfect for you.

Atmospheric tuning is good, but it will never give the performance that you will get by delving into the turbo theme. The article presents a line of turbo kits for VAZ for civilian use for almost all VAZ cars. The kit includes only new original spare parts. The turbo manifold is made of gray cast iron, which gives the kit greater reliability compared to analogues on the market. The turbine on a VAZ is one of the most common engine modifications today. The turbo kit is designed for installation on cars:

VAZ 2108 injector, VAZ 2110 injector, VAZ 2112, VAZ 2113, 2114, 2115, LADA Granta 2190, Kalina 1118, Priora 2170, Lada 4×4 / NIVA (VAZ 21213 - 21214), Chevrolet Niva.

Engines:

VAZ 2112 1.5 16V VAZ 11186/11189 Granta, Kalina, Vesta VAZ 21114 1.6 8V Lada Kalina VAZ 21127/21129 1.6 16V Granta, Kalina 2, Priora, Vesta VAZ 11194 Kalina VAZ 2106 /2121 Niva VAZ 21124 1.6 16V VAZ 21214 1.7 8V LADA 4×4, Chevrolet Niva VAZ 21126 1.6 16V Priora, Granta, Kalina 2 VAZ 11183 1.6 8V Lada Kalina VAZ 21116 1.6 8V Granta, Kalina 2

Turbo kit VAZ 8 valves

• Boost pressure up to 0.5 bar. • Allows you to increase the car's power up to 120 horsepower. • Torque up to 190 Nm. • Does not reduce engine life. • Installation of the turbo kit is very simple, all parts are hinged. • No additional engine modifications are required. • The layout is such that external changes will not be noticeable to the naked eye. • Fast response to the gas pedal. • Maximum boost pressure is already achieved at 2000 rpm. • The engine control program needs to be changed. Equipment:• Steel manifold (lower location of the turbocharger) • Mitsubishi TD04HL turbocharger - 15T style • Gasket between the turbine and the manifold • Exhaust gas flange from the turbocharger • Reinforced oil supply hose • Reinforced oil drain • Antifreeze supply for cooling the turbocharger • Antifreeze return for cooling the turbocharger • Copper seals rings for fittings • Overpressure relief valve • Silicone air line connectors • Air ducts • High performance fuel injectors 192 cc • Cylinder head oil intake bolt • Oil supply bolt for turbocharger • Clamps • Studs • Nuts

PRICE 36,950 P

Purpose of the turbine

The technical characteristics of the VAZ 2106 engine cannot be called outstanding. For this reason, many car enthusiasts are beginning to modify the engines of their “sixes” on their own. Installing a turbine on a VAZ 2106 engine is the most radical, but also the most effective way to increase engine performance.

A turbine is the most radical way to increase the power of a six engine.

By installing a turbine, the driver receives several advantages at once:

- the acceleration time of the car from standstill to 100 km/h is almost halved;

- engine power and efficiency increase;

- Fuel consumption remains virtually unchanged.

How does a car turbine work?

In short, the point of operation of any turbocharging system is to increase the rate of supply of the fuel mixture to the combustion chambers of the engine. The turbine is connected to the exhaust system of the “six”. A powerful stream of exhaust gas hits the impeller in the turbine. The impeller blades rotate and create excess pressure, which is pumped into the fuel supply system.

A car turbine directs exhaust gases into the fuel system

As a result, the speed of movement of the fuel mixture increases, and this mixture begins to burn much more intensely. The standard six engine has a fuel combustion coefficient of 26–28%. After installing a turbocharging system, this coefficient can increase to 40%, which increases the initial engine efficiency by almost a third.

Turbo kit for VAZ 8v up to 250 hp

A set of parts to increase the power of VAZ Samara and Samara 2 cars up to 250 horsepower. Designed for cars equipped with a 16 valve VAZ 2112 / 21124 engine. The declared power is achieved by installing a TD05H-16g turbocharger. Boost pressure 1 bar. The kit consists of the following parts:

| Turbocharger Mitsubishi TD05H – 16G style | 1 | PC. |

| Turbo manifold 16 cl. Subaru flange, budget | 1 | PC. |

| Hairpin M10 | 3 | PC. |

| Bolt M10 x 30 x 1.25 | 2 | PC. |

| Nut M10x1.25 | 8 | PC. |

| Downpipe VAZ, TD04L, budget | 1 | PC. |

| Banjo bolt M10×1.5 | 1 | kit |

| Oil supply hose Clubturbo (length 50 cm) 10-14 mm | 1 | PC. |

| Oil intake bolt from the VAZ cylinder head for supply to the turbocharger | 1 | PC. |

| Copper washer 10 mm | 2 | PC. |

| Copper washer 14 mm | 6 | PC. |

| Banjo bolt M14×1.5 | 2 | kit |

| Antifreeze supply hose Clubturbo 14 mm | 2 | PC. |

| Universal turbine oil drain kit | 1 | PC. |

| Piping VAZ 2110 - 2112, kit with silicone | 1 | PC. |

| Silicone pipe, 28 mm | 1 | PC. |

| Clamp 25/40 | 2 | PC. |

| Blow off Forge | 1 | PC. |

| Front intercooler (700x180x65), inlet 51 mm | 1 | PC. |

| Receiver Clubturbo Trapezium 16v | 1 | PC. |

| Air temperature sensor | 1 | PC. |

| DBP Motorola 6250 (1.5 bar) | 1 | PC. |

| Wiring harness for the transition of mass air flow sensor - DBP + DTV | 1 | PC. |

| Fuel injectors Bosch 430 cc (Set of 4 pieces) | 1 | kit |

| Submersible fuel pump 255 l/h CreditParts GSS342, silver | 1 | PC. |

| Turbo pistons VAZ 2112 F 82.0 mm (set of 4 pieces) | 1 | kit |

| Piston rings 82.0 mm VAZ (1.5/2.0/3.947), set for 4 cylinders | 1 | kit |

| Gasket set for VAZ 2112 engine | 1 | PC. |

| Cylinder head gasket VAZ 2112 | 1 | PC. |

| Oil pan gasket VAZ 2108 | 1 | PC. |

| Hairpin M6*22 | 2 | PC. |

| M6 nut with skirt | 2 | PC. |

| Silicone vacuum hose, 4mm (blue) | 2 | m |

Attention!

Kit for vehicles with manual throttle. Installation will require modification to the car body. After installation, it is necessary to configure the engine control unit. PRICE 67,500P

About the choice of turbocharging systems

Currently, car enthusiasts do not need to design turbines themselves, since a wide range of ready-made systems are available on the aftermarket. But with such abundance, the question will inevitably arise: which system to choose? To answer this question, the driver must decide how much he is going to modify the engine, i.e. how deep the modernization will be. Having decided on the degree of intervention in the engine, you can move on to turbines, which come in two types:

- reduced power turbines. These devices rarely generate pressure above 0.6 bar. Most often it varies from 0.3 to 0.5 bar. Installing a low-power turbine does not involve serious intervention in the engine design. But they also provide an insignificant increase in productivity - 15–18%.

- powerful turbocharging systems. Such a system is capable of creating a pressure of 1.2 bar or more. To install it in the engine, the driver will have to seriously upgrade the engine. In this case, the engine parameters may change, and not necessarily for the better (this especially applies to the CO level in the exhaust gas). However, engine power can increase by a third.

What is meant by modernization

Before it comes to installing the turbine, the driver will have to carry out a number of preparatory procedures:

- cooler installation. This is a device for cooling air. Since the turbocharging system runs on hot exhaust gas, it gradually heats up. Its temperature can reach 800°C. If the turbine is not cooled in a timely manner, it will simply burn out. In addition, the engine may also be damaged. So you can’t do without an additional cooling system;

- The carburetor “six” will have to be converted into an injection engine. The intake manifolds of the old carburetor “sixes” were never particularly durable. After installing the turbine, the pressure in such a manifold increases approximately five times, after which it ruptures.

All of the above points indicate that installing a turbine on an old carburetor six is, to put it mildly, a questionable decision. It would be much more advisable for the owner of such a car to install a turbocharger on it.

In some cases, it is more advisable to install a turbocharger instead of a turbine

This solution has several advantages:

- the driver will no longer worry about the problem of high pressure in the intake manifold;

- there is no need to install additional cooling systems;

- there will be no need to redo the fuel supply system;

- installing a compressor costs half as much as installing a full-fledged turbine;

- Motor power will increase by 30%.

Installation: procedure

Turbocharging an engine is a lengthy process. Plans to “turban for vacation” are practically impossible. Plan your time in advance. If the car is your main one, it makes sense to think in advance about purchasing a temporary means of transportation.

Most turbocharging features are unique to different models of compressors and other equipment. The description below is average and schematic.

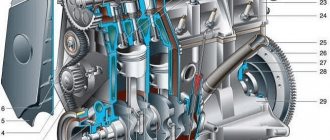

Stage 1. Preparing the motor . The engine is disassembled, a complete inspection of the cylinders, crankshaft, connecting rods, liners and oil pump is carried out, and the block is polished. Pistons are purchased after preparing the cylinders (boring may be required).

The cylinder head is checked (if necessary, the cylinder head is ground), hydraulic compensators and valves can be used as standard.

Stage 2. Assembly of attachments. New injectors are installed and the fuel pump is replaced. VAZ 2114 engines with 8 valves have a number of advantages compared to 16-valve engines. Firstly, there is no need to be clever with the return. Secondly, it is much easier to connect the fuel pressure regulator.

Next, installation of the receiver, installation of the exhaust manifold, fitting of the turbine. If you purchased an intercooler, we find a place for it and install it. We install piping and blow-offs. We are preparing the oil and cooling supply to the turbine. We remove the air flow sensor and install the DBP and DTV system.

Stage 3. When everything is assembled and secured, there is confidence that nothing is leaking anywhere, the most difficult part begins - setting up. All horsepower, Newton meters and fuel consumption depend on the skill of the tuner. There are good turbo specialists in large cities - do not spare money on their services, otherwise a much larger sum will go down the drain.

A good boost is the result of intellectual work and skill. For the results to justify themselves, remember: there can never be too much information. Study the question thoroughly - the result will amaze you.

How is oil supplied to the turbine?

A complete turbocharging system cannot function without oil. So the driver who decides to install a turbine will have to solve this problem. When the turbine is installed, a special adapter is screwed to it (such adapters usually come complete with turbines). A heat dissipation shield is then installed on the intake manifold. Oil is supplied to the turbine through an adapter onto which a silicone tube is first placed. In addition, the turbine must be equipped with a cooler and an air tube through which air will flow into the manifold. Only in this way can an acceptable temperature of the oil supplied to the turbine be achieved. It should also be said here that sets of tubes and clamps for supplying oil to turbocharging systems can be found in spare parts stores.

A set of turbine pipes will save the driver a lot of time

This set costs from 1200 rubles. Despite the clearly inflated price, such a purchase will save the car owner a lot of time, since he will not have to bother with cutting and adjusting silicone tubes.

About the pipes

Pipes are needed not only for supplying oil. Exhaust gases from the turbine also need to be removed. To remove excess gas not used by the turbine, a massive silicone pipe on steel clamps is used. In some cases, a whole system of silicone pipes is used to remove the exhaust (their number is determined by the design of the turbine). Usually there are two of them, in some cases - four. Before installation, the pipes are carefully inspected for internal contamination. Any, even the smallest, speck that gets into the turbine can cause a breakdown. It is for this reason that each pipe is thoroughly wiped from the inside with a cloth soaked in kerosene.

Exhaust pipes are usually made of silicone

When choosing clamps for pipes, you should remember: silicone is not a very durable material. And if, when installing the pipe, you tighten the steel clamp too much, it can simply cut the pipe. For this reason, experienced motorists recommend not using steel clamps at all, but instead using clamps made of special high-temperature plastic. It provides reliable fastening and does not cut the silicone.

Turbo kit for VAZ 16v up to 250 hp

A set of parts for installing turbocharging on VAZ 2110 - 2112 cars. Designed for cars with a 16 valve engine. The installation allows you to increase the car's power to 250 horsepower. The declared power is achieved by installing a TD05H-16g turbocharger. Boost pressure 1 bar. The kit consists of the following parts:

| Turbocharger Mitsubishi TD05H – 16G style | 1 | PC. |

| Turbo manifold 16 cl. Subaru flange, budget | 1 | PC. |

| Hairpin M10 | 3 | PC. |

| Bolt M10 x 30 x 1.25 | 2 | PC. |

| Nut M10x1.25 | 8 | PC. |

| Downpipe VAZ, TD04L, budget | 1 | PC. |

| Banjo bolt M10×1.5 | 1 | kit |

| Oil supply hose Clubturbo (length 50 cm) 10-14 mm | 1 | PC. |

| Oil intake bolt from the VAZ cylinder head for supply to the turbocharger | 1 | PC. |

| Copper washer 10 mm | 2 | PC. |

| Copper washer 14 mm | 6 | PC. |

| Banjo bolt M14×1.5 | 2 | kit |

| Antifreeze supply hose Clubturbo 14 mm | 2 | PC. |

| Universal turbine oil drain kit | 1 | PC. |

| Piping VAZ 2110 - 2112, kit with silicone | 1 | PC. |

| Silicone pipe, 28 mm | 1 | PC. |

| Clamp 25/40 | 2 | PC. |

| Blow off Forge | 1 | PC. |

| Front intercooler (700x180x65), inlet 51 mm | 1 | PC. |

| Receiver Clubturbo Trapezium 16v | 1 | PC. |

| Air temperature sensor | 1 | PC. |

| DBP Motorola 6250 (1.5 bar) | 1 | PC. |

| Wiring harness for the transition of mass air flow sensor - DBP + DTV | 1 | PC. |

| Fuel injectors Bosch 430 cc (Set of 4 pieces) | 1 | kit |

| Submersible fuel pump 255 l/h CreditParts GSS342, silver | 1 | PC. |

| Turbo pistons VAZ 2112 F 82.0 mm (set of 4 pieces) | 1 | kit |

| Piston rings 82.0 mm VAZ (1.5/2.0/3.947), set for 4 cylinders | 1 | kit |

| Gasket set for VAZ 2112 engine | 1 | PC. |

| Cylinder head gasket VAZ 2112 | 1 | PC. |

| Oil pan gasket VAZ 2108 | 1 | PC. |

| Hairpin M6*22 | 2 | PC. |

| M6 nut with skirt | 2 | PC. |

| Silicone vacuum hose, 4mm (blue) | 2 | m |

PRICE 67,500 RUR

How is the turbine connected to the carburetor?

If the driver decides to connect the turbocharging system directly through the carburetor, then he must be prepared for a number of problems that will have to be solved. Firstly, with this connection method, air consumption will increase significantly. Secondly, the turbine will have to be installed near the carburetor, and there is very little space there. That is why the driver should think twice before using such a technical solution. On the other hand, if the turbine can still be placed next to the carburetor, it will work very efficiently, since it will not have to waste energy supplying air flow through a long system of air ducts.

There are two ways to install a turbine next to the carburetor

Fuel consumption in old carburetors on “sixes” is regulated by three jets. In addition, there are several fuel channels. When the carburetor is operating normally, the pressure in these channels does not rise above 1.8 bar, so these channels perform their functions perfectly. But after installing the turbine, the situation changes. There are two ways to connect the turbocharging system.

- Installation behind the carburetor. When the turbine is installed like this, the fuel mixture has to pass through the entire system.

- Installation in front of the carburetor. In this case, the turbine will pump air in the opposite direction, and the fuel mixture will not flow through the turbine.

Each method has both advantages and disadvantages:

- the first method is much simpler. Yes, the air pressure in the system will not be too high. But the carburetor will not have to be seriously upgraded, installing an additional valve for the compressor and additional coolers;

- the second method is much more complicated. The overall pressure in the system will be much higher. At the same time, the CO content in the car exhaust will be lower, and in addition, it will be easier to start a cold engine. But it is more difficult to implement such a connection, since it will be necessary to upgrade the carburetor, as mentioned above.

Turbines based on IHI VF10 compressor

Turbocharger VF22

Subaru has experimented with turbo engine configurations more than other manufacturers. On the same WRXs you can find Garretts, and the famous Apexi, and Mitsubishi. Not the last place in this series is occupied by the American manufacturer IHI, whose superchargers were installed on legendary cars like the Chevrolet Camaro.

VAZ is equipped with many variants of turbines from IHI, including:

- VF22

- VF23

- VF24

These are classic drag racing turbos that boost extremely quickly, already at 2800-2900 rpm.

The VF10 is less powerful than either of these options. Peak power is about 250 horses (rarely, with very professional tuning and a strong reduction in resource - up to 300). By comparison, the 20th and 30th numbers are capable of developing up to 325 or more horses. But for the VAZ engine, the “ten” (as well as the VF11-20 turbines similar to it), according to many turbo experts, is optimal.

When compared with the TD04 and even the TD05, the VF10 will be faster at the bottom, but the turbo lag will be more noticeable. A VAZ 2114 with such a turbine will feel better on drag or in circuit racing with a minimum of long straights.

About connecting turbines to the injector

It is much more expedient to install a turbocharging system on an injection engine than on a carburetor one. Fuel consumption becomes lower and engine performance improves. This primarily relates to environmental parameters. They improve because about a quarter of the exhaust is not released into the environment. In addition, motor vibration will be reduced. The sequence of connecting the turbine to injection engines has already been described in detail above, so there is no point in repeating it. But something still needs to be added. Some owners of injection cars try to further increase the turbo boost. To achieve this, they disassemble the turbine, find a so-called actuator in it and install a reinforced spring under it instead of the standard one. Several tubes are connected to the solenoids in the turbine. These tubes are silenced, but the solenoid remains connected to its connector. All these measures lead to an increase in the pressure created by the turbine by 15–20%.

Construction of turbo-VAZ 2110 (Urban version)

aleksii888

Aborigine

I thought for a long time whether it was worth writing an article about my car, on the one hand, I’m not the first turbo builder, I didn’t set any records, but on the other hand, there is very little information on turbo building for beginners on the Internet, and what is there is very sketchy, without specific examples.

The article is intended for novice turbo builders; motorists and gray-haired tuners are unlikely to find revelations in it. In general, I’ll state the VAZ 2110 2005 before the turbo was built, it was already at a serious stage of atmospheric uprooting, the head was modified, there were “wide” camshafts, a “short” gearbox, forward flow, etc., everything was “like the boys”, but the result of the modifications was not pleasing neither resource nor fuel consumption. And turbo construction began.

Bottom. The 21124 cylinder block is standard, in principle any would be suitable, but this one has oil nozzles, +2.3 mm in height and is thicker than 21083, which is good for reliability. The work on the block is no different from a regular capital, we removed the engine (we pulled it out without a box, as a familiar mechanic aptly described this method - “... through the ass,” it was easier to pull it out with the box), disassembled it, knocked out the oil nozzles and took it to boring. For the first repair 82.4 we sharpened a gap of 4 acres (in order not to break in a year later, it was possible to do 3),

At this stage, we encountered the following difficulties: the oil pump housing burst during disassembly, and we bought the wrong gaskets (pictured above). As it turned out later, the steel gasket for the exhaust was not compatible with our manifold and the standard cylinder head gasket was replaced with a Priorovskaya one, more on that later.

Pistons. The pistons were taken Nivovskie 21213 STK, Nivovskie because they have a thick bottom and can be selected for a lower coolant, STK - since there was only STK on the market, I think both the Kharkov Avtromat and the original VAZ would have gone no worse. The biggest advantage of Nivov pistons is the price. They gave it to a turner to modify it for low fuel life, he took 30 UAH and made a selection with just this money, i.e. crooked to the point of disgrace, all the puddles were different and then I had to manually adjust them for half a day to the weight and volume of the sample. The counters for the valves were made by ourselves with a little rusty clamped in a drill, not aesthetically pleasing, but it all worked out. Regarding the pistons, there was another option to take the TDMK under the 78 knee and reduce the coolant by a lack of income, but it is not known how the TDMK lives on the turbo.

The assembly of the block was no different from the usual one, the tightening torques were the same. The connecting rods and elbow are standard, the ShPG was hung on the scales, ala “. and how much are your tomatoes?” The accuracy is not pharmaceutical, but better than what VAZ posted; a penny coin was used as a weight. After all the modifications to the pistons, it is necessary to measure the volume of the “puddle”, water is not good (checked), we take kerosene, drive the resulting volume into the program for calculating the coolant and in our case we faint from the resulting calculated coolant - 7 (once again I express my gratitude to the turner). Then we buy the Priorov gasket and get 7.6 - which is quite suitable. The Priorovskaya gasket is installed as original, without any modifications (although particularly cunning mechanics charge not very smart clients plus money for this modification)

Head. When assembling/disassembling the heads, we gained valuable experience: M5 bolts (for 8 keys) of which 18-20 pieces turn out to be disposable, this is generally no secret, but we constantly reuse disposable bolts, so these cannot be used, otherwise it will be like ours. So these bolts from repeated unscrewing/twisting become brittle and break off at the head. We broke about five of them while we were assembling them. But if a bolt in your head breaks, then I’ll dictate a recipe for how to pick it out: the bolt breaks off, leaving a couple of mm above the surface, you need to electric weld a piece of iron to this stump, and then unscrew it. When welding, be careful not to overheat the head and not to drip welding somewhere inside; we covered the entire surface with a metal sheet with a hole at the welding site and covered it with wet rags. I used standard camshafts; for a medium-sized turbine, their range is quite satisfactory; if you install a large turbine, then it is also advisable to install the shafts higher, but the phase should not be very wide; Master Motor 52\52, for example, was successfully used by fellow tuners on one machine. In general, if you study the experience of foreign-made turbo shafts, the conclusion suggests itself that our tuned atmospheric camshafts do not fit well, so I decided not to reinvent the wheel and left the standard ones.

How is a turbine checked?

Before installing the turbine, it is strongly recommended to change the oil. In addition, the oil and air filters must be replaced. The sequence for checking the turbocharging system is as follows:

- the turbine should be inspected for oil leaks (this applies to both the part through which oil is supplied and the part through which it drains from the turbine);

- All air ducts are also carefully inspected. None of them should contain dirt or foreign objects;

- if the machine is equipped with a catalyst, then it should also be checked for wear (excessive exhaust from a worn-out catalyst can significantly worsen the operation of the turbine; it simply cannot cope with the large volume of incoming gas);

Knowing the design of the turbine, it is easier to check its performance - Finally, you should check whether the turbine rotor rotates normally. The hum produced by the rotor should be uniform. There should be no extraneous sounds in it: creaking, whistling, etc.

So, installing a turbine on a VAZ 2106 is a long and painstaking process. In some situations, instead of a full-fledged turbine, you can think about installing a turbocharger. This is the least expensive and simplest option. Well, if the car owner has firmly decided to install a turbine on his “six”, then he should prepare for a serious modernization of the engine and serious financial expenses.

Pros and cons of turbine, compressor and naturally aspirated engine

Let's consider all these methods of engine tuning separately.

Turbine

Under the hood of a turbocharged VAZ-2112

In recent years, the installation of turbines on cars of the VAZ family has become quite widespread. And there is nothing unexpected about this, since they are the most common, unlike mechanical inflation (compressor - approx.), because they have a number of advantages.

Firstly, the supercharger is located next to the turbine impeller and is built into the exhaust manifold, driving itself with exhaust gases. Secondly, such an arrangement of components can significantly increase the efficiency of the entire engine, because there is no direct connection between the turbine and the crankshaft, since it does not take power from the engine itself. Experienced auto mechanics call this the main advantage of a turbine over a compressor.

If such designations are difficult for you, in one word, a turbine pumps a lot of pressure into the cylinders and the higher it is, the greater the power.

Turbine disadvantages

However, the turbine has its drawbacks, and these include “turbo lag”. This effect manifests itself in a slow response to pressing the gas pedal, and at low speeds the turbine operation will not be felt at all. The explanation for this is very simple: in order for the engine to begin to gain power and speed, it requires time for the exhaust gas pressure to increase, which would be able to properly spin the turbine. For exactly the same reason, a turbocharged engine is capable of producing maximum power only after 4000 rpm.

Compressor

The compressor engine starts air movement due to a special mechanical supercharger operating using a belt drive. That is, the operation and power of the engine directly depends on the number of revolutions gained and the higher they are, the higher the power. In the design of the compressor, the air mixture with fuel is not only supplied to the cylinders under pressure, but is also capable of blowing through the exhaust and intake valves when they are not completely closed, thereby cleaning them. Because of this design, the engine is always able to operate at full power.

Disadvantages of the compressor

A significant disadvantage of such a modification is the unreliability of the drive belts, which will one way or another break and become unusable, as well as increased fuel consumption, since the compressor is best installed on engines with a large volume, since the efficiency of interaction with them will be much higher.

Atmospheric engine

When talking about an atmospheric engine, many people think of anything but what actually exists.

An atmospheric engine is a regular engine that does not have any supercharging, that is, turbocharged or compressor. However, there are some nuances here too.

The atmospheric engine is both simple and the most complex in its design. Since the ideal fuel-air mixture is supplied to the cylinders of this engine, without any obstacles or resistance in its path. The manifold works perfectly on this engine, the camshaft is adjusted as precisely as possible, the cylinder diameter, piston stroke, and so on are increased. And all this is done to increase the rated power of the engine.

Despite the fact that this is a seemingly ideally built engine, the advantages of which include the strictly accurate response of the gas pedal and a good reserve of power at any speed, it also has disadvantages in comparison with its turbocharged counterpart.

Cons of a naturally aspirated engine

- The first disadvantage due to which you can give preference to the “turbo” is the very high fuel consumption and the high degree of wear of the internal parts of the engine. It is also impossible for a naturally aspirated engine to more than double the stock power, whereas a turbocharged engine can increase it several times.

- Heavily promoted “aspirated” engines only drive at high speeds, which has a negative effect when driving in urban conditions. They also have a high idle threshold, which is also inconvenient for everyday use.

As you can see, all three types of engines have their advantages and disadvantages, but today we will focus on the turbine , since this is the most suitable type of tuning for the VAZ-2112 engine.

Rework during turbine installation

Before proceeding with the installation of the turbine itself, some parts and elements of the engine may require modification:

Compression ratio

New elements are ready for installation.

The task of reducing the compression ratio may be to replace pistons or modify the cylinder head. Please note that when installing a low-pressure turbine, only the pistons can be modified, but for high pressure both are changed at the same time.

Exhaust system

“Spider” and “direct flow” can be installed.

The best way to solve the exhaust system is to replace the manifold and “pants” with the installation of a “spider”. Remember that such systems should only be purchased from trusted sellers, whose products are made of high-quality materials that can withstand the maximum temperatures from turbine operation.

- With low-pressure turbines, after the exhaust pipe of the “pants”, everything can be left unchanged.

- With a high-pressure turbine, the transition to “direct flow” is very noticeable, since the full potential of this type of turbine can be very well revealed.

Injection system

The new injector is different from the old ones.

If the pressure of the turbines is low, it is possible to replace the receiver; fortunately, their choice in modern tuning stores is very wide, but for the older brother, the fuel pump and injectors will need to be replaced with the most efficient ones.

Electronic control unit

You should read about its installation separately.

You should also read the manual about careful installation of this device.

When installing any type of turbine, mandatory firmware of the “brains” will be required. And on a turbine with a total power above 200 hp, it will also be necessary to replace the mass air flow sensor with a DBP (absolute pressure sensor - approx.) and an air temperature sensor (air temperature sensor - approx.). And this is done because the standard sensor is simply not designed for the passage of such an amount of air. Until they are installed, it will not be possible to reflash the ECU correctly.

Lubrication

Any turbine needs lubrication and for this it is necessary to provide it with an oil supply. This is done in various ways, either by installing a special tee in place of fixing the oil pressure sensor and then connecting a special hose to it, or by using an adapter with an outlet for the oil filter. In any case, no matter which method you choose, the oil must be drained only into the pan through a metal tube.

Cooling system

The intercooler is a small radiator instead of a bumper.

To ensure the best cooling of the engine, an antifreeze supply will be required from the general cooling system. And in order to cool the air supplied by the turbine, an intercooler must be installed. When installing low-pressure turbines, many people mistakenly think that installing such a device is not necessary, but in the summer, the standard system simply cannot cope with its responsibilities.

The engine itself will also need cooling, and in the case of the VAZ-2112, installing a double-row copper radiator is ideal. This is quite enough for its optimal cooling.

Bypass valve

The valve in the photo is Blowoff.

The bypass valve is necessary to relieve excess pressure that may arise in the system when the throttle is suddenly closed. And so that it does not break out through the rubber elements and connections and cause them to rupture, such pressure is released into the air. There are two types of valves: Blowoff is a valve that must be installed next to the throttle valve, and Bypass is mounted between the intercooler and the air line.

Wastegate valve

The price of such a device is quite high.

The purpose of such a valve is to allow part of the exhaust gas to bypass the turbine, thereby limiting its speed and reducing its excess pressure at the inlet. They come in two types:

External ones - are installed more often on racing cars, as they have very significant dimensions, and internal ones , which are installed directly on civilian types of wastegate turbines.

High pressure turbine block

- If your goal is to achieve a total power of the VAZ-2112 of more than 200 horsepower , then we will not be talking about installing a turbine to the engine, but about assembling a new engine.

- In this case, instead of a stock block, it is better to install one from a Lada Kalina, since with it and with a correctly selected crankshaft you can achieve an increased volume. Pistons, connecting rods, etc. can also be replaced.

- There are many options for such a design, and it all depends on how much you are willing to invest in such a modification.

Other changes

- Depending on what budget and imagination you have, you can modify the engine in either direction. For example, it may be necessary to install different spark plugs, or a fuel pressure regulator, modified injectors or a fuel pump.

- To install some types of turbines, a change in the design of the front bumper may be required, since there is simply not enough space to install an additional radiator.

Read also: What is the tire pressure on a scooter?

Turbo KIT

Turbo KIT assembled.

In order not to bother with installing a certain type of turbines and equipment for them, it is possible to purchase a special Turbo KIT kit. As a rule, such a kit includes the turbine itself and everything necessary for its installation.

Nowadays, in tuning stores you can see a large selection of similar, varied kits, in which everything is done to make installation as simple as possible.

Turbine prices

It is possible to install a turbine at a service center with about 100-150 thousand rudders in your pocket . This price includes the price of the turbine and components, as well as all work on its installation.

However, it must be remembered that the installation of each model is strictly individual and requires personal calculation.

Self-installation of a turbocharger

Despite the complexity of repairing a turbocharger, there are operations that the owner, with the proper technical skills, can perform independently. We are talking about dismantling and installing the unit. In this case, you should follow some rules to avoid trouble.

- Before installing a repaired turbocharger, thoroughly rinse the oil supply pipe, since the health of the unit directly depends on the oil supply to it. In addition, after repairs, remaining dirt can get inside the unit and initially damage it. In general, when working with a turbine, maximum cleanliness and accuracy should be observed. Before installing the TC on the engine, about 20 g of oil should be poured into the receiving hole, after which it is necessary to rotate the shaft several times to distribute it evenly. You definitely need to change the oil, oil and air filters.

- It is prohibited to use sealants when installing pipes through the gasket. Only new, good quality gaskets should be used. After assembly, you need to start the engine and let it idle for 10-15 minutes. In this case, you need to make sure that there are no oil or coolant leaks through the connections. The turbine running-in period is 1000 kilometers. In this case, you should not exceed the speed above 100 km/h, and also avoid sudden changes in driving modes.

Cons of supercharging

The first and most repulsive is, of course, the price of supercharging for the VAZ 2110. This is followed by a significant increase in wear and tear on engine components due to an increase in power. And although the “ten” engine is extremely suitable for major repairs, it is still not the best that could be. You will also have to use expensive oil for the car’s engine and always carry out maintenance of the turbocharger and engine accurately and on time. You will also have to ensure that the compression value in the engine cylinder is always at the same level, since the appearance of crankcase gases in large quantities can quickly “kill” the turbine.

Principle of structure

It should be noted that now some German manufacturers have such superchargers in their engines. And they are installed, as you understand, in the air intake system. Mercedes, BMW and AUDI were the first to use such superchargers.

The principle here is simple - a powerful “fan” is installed, which creates a pressure of approximately 0.5 atmospheres (and possibly more). Powered by the vehicle's electrical system, it pumps additional oxygen into the engine to increase power. With fuel supply settings, you can achieve a significant increase - about 20 - 30%.

The electric turbine should also be adjusted to certain speeds, for example, at idle it should work slower, and at high speeds, correspondingly faster. It turns out to be almost an ideal system! But what’s the catch, where are the downsides? And you know, they exist.

How to install an air blower yourself

There are several approaches that allow you to install a mechanical air blower on VAZ family cars with your own hands. This means making a device yourself that provides turbo mode or boosting the engine, or using a ready-made KIT kit.

Homemade supercharger for VAZ

With this approach, the mechanical air blower will be decisive. The entire future design depends on it. The main thing is to find an air supercharger from an imported car that meets the requirements, or you will have to use a homemade one. This is also possible, and in this case suitable parts and components from completely unexpected devices, for example, a vacuum cleaner, are used.

When making such a homemade air supercharger, you need to take literally everything into account - dimensions, weight, placement in the engine compartment, how and where the drive pulley and belt will be located, the performance of this device, operating modes (short-term or long-term), the possibility of lubrication and much, much more. Once the compressor becomes clear, it is necessary to calculate the implementation of the turbo mode for the engine.

Here it is necessary to take into account how the fuel and cooling system of the car will be changed, what changes need to be made to its control and how to do this, what pressure will be acceptable for safe operation of the engine when implementing a turbo mode using such a device.

Even the far from complete list of questions shown shows that making a homemade air supercharger for a VAZ of any family, be it 2107, 2106, 2114, 2112, is quite difficult, but possible. An example would be a photo showing that such work has been successfully completed. True, this is not a VAZ, but the fact itself is important - it is possible to make a homemade air compressor in which its drive unit is connected to the engine crankshaft.

Do-it-yourself drive supercharger - from a KIT kit

Yes, there are such kits on sale that allow you to implement the turbo mode in VAZ 2107, 2106, 2114, 2112 cars with your own hands. As a rule, it includes everything needed to assemble and install such a device on a car - the compressor itself, belts, drive unit , brackets and air ducts. What such a kit is like can be seen in the photo below.

The main advantage of this approach to implementing the turbo mode on your car is the simplicity and complete adaptation of technical solutions to a specific option - 2107, 2106, 2114, 2112. As a rule, the manufacturers of kit kits are Chinese manufacturers, which ensures their fairly reasonable price.

As an advantage of implementing the turbo mode in this way, it is worth noting that it is tailored specifically to VAZ cars of one model or another (2107, 2106, 2114, 2112). The advantages of this approach also include the fact that under some conditions, when the level of additional pressure created is not more than half a bar, no intervention is required in the vehicle’s fuel system.

It is inappropriate to describe the procedure for implementing the turbo mode from such a set; each of them has its own assembly instructions. The disadvantages include the country of origin, but it depends on your luck. What the car looks like after modification and how to do it, the video will additionally help you understand.

About installing a compressor using ready-made KIT kits

These systems are complete sets that include a compressor, as well as everything necessary to ensure its joint operation with the VAZ injector engine. KIT kits come in two types.

The first of them is a homemade system, which is manufactured using a homemade method using used compressors removed from foreign-made cars and adapted for installation on VAZ 2107 engines.

The second option involves the use of Chinese factory-assembled kits. Their advantages over hand-made systems are greater reliability and an attractive price. In addition, it is worth noting that adapting such a compressor and everything that comes with it to VAZ cars is much simpler, because it is manufactured specifically for 2107 engines. In addition, KIT kits are distinguished by their simplicity. As a result, almost every car owner with at least basic knowledge of its structure is able to install a compressor without outside help.

It is worth noting that on the market you can purchase both a truly factory kit, which is covered by a warranty, and a cheaper sample. No one can guarantee the stability of such a system.