When the owner purchases a new car, he has an undeniable advantage, because he can feel and remember how each component or unit works, which is in an unworn condition. After some mileage, the happy owner of a new Lada Kalina already has a clear idea of how a good car should function. Over time, almost all components are subject to natural wear and tear and the first breakdowns begin to occur. This is immediately noticed by the owner, and all his efforts are concentrated on eliminating the defect that has manifested itself.

How to remove a plug from the Kalina cooling system ⋆ I Love My Lada

A sealed cooling system ensures that the heater will work properly and the engine will not overheat, since the antifreeze circulates stably. However, as soon as an air lock appears, the efficiency of the cooling and heating system comes to an end. We’ll figure out how to remove an air lock from the cooling system of the Lada Kalina right now.

Signs of an air lock in the Kalina cooling system

The cooling system in all modern engines must be as tight as possible. Old engines did not have an expansion tank and the coolant was poured directly into the top can of the radiator. This was due to low requirements for the quality and composition of antifreeze, as well as unpretentious materials from which cylinder blocks, heads and other cooled engine elements were made.

Lada Kalina cooling system diagram

Be that as it may, in a sealed cooling system, the slightest amount of air can cause a disruption in the circulation of antifreeze and, as a result, overheating of the engine, boiling of the liquid and disruption of the heater. In short, if we notice that:

- the engine overheats under light loads and the ambient temperature is not too high;

- the stove does not blow hot air, but slightly warm air, even when the engine temperature gauge is in the red zone;

- The heater radiator is leaking, there are other places where antifreeze is leaking,

THIS IS INTERESTING: How to convert an air conditioner to climate control

you can be sure that a plug has formed in the cooling system. At the same time, we are confident that all components of the cooling system work like clockwork. Namely, the water pump, thermostat, heater radiator and cooling radiator, nothing leaks anywhere.

Where did the air lock come from in the radiator of the Lada Kalina stove?

Any leak in the system or improper replacement of the coolant can easily lead to the formation of an air lock in the radiators, pipes or in the water jacket.

Airing of the cooling system occurs as follows - when antifreeze leaks from the pipe or radiator, air is slowly sucked in and occupies the free volume in the system. This does not happen immediately, but when enough air bubbles have accumulated, the cork is ready for use.

Typically, air collects at the highest point of the cooling system. On Kalina this is the throttle assembly heating system.

This is where air collects in most cases.

In addition, air can easily form due to the use of low-quality antifreeze. This is explained simply - good liquids boil extremely rarely, for this they need to be heated to at least 140-160 ˚С, which is almost impossible.

Low-quality antifreezes and everyone’s favorite antifreeze can boil already at a temperature of about 100 ° C, and this, as we know, is almost the operating temperature of the Kalina engine.

When boiling, like any liquid, antifreeze releases air bubbles, which again accumulate and form a plug that prevents circulation.

Any leakage leads to an air lock.

And one more, most unpleasant moment. It is not air that may enter the cooling system, but exhaust gases. This indicates that the head gasket has given up its life and has burned out, gases have broken into the cooling system and formed a plug. In this case, there is only one treatment - replacing the cylinder head gasket and finding out the causes of the burnout.

Let's sum it up

As you can see, an air lock in the cooling system is a significant obstacle to the normal functioning of the cooling system in the LADA Kalina car. It can not only cause the stove to become ineffective, but also cause more significant damage to the engine. Eliminating this negative phenomenon is not difficult, especially since now you know how to pump air, but the best measure would be timely and periodic diagnosis of the engine cooling system. It consists of checking the refrigerant level, the tightness of the circuit (reliability of clamps) and the functionality of the thermostat (control of heating of the lower radiator pipe).

Why does air get into the Kalina cooling system?

One of the benefits of buying a new car is that from the very beginning you can see, feel and remember how the car works when everything is working properly.

While the car is new and unusual, it is difficult to say what works correctly in it and what does not. After three to four thousand kilometers, a picture of a normally working machine automatically forms in your head. If something suddenly changes, I notice it immediately. This change does not always indicate a malfunction, but often it indicates its approach.

Something like this happened after about two years of operation.

Visible signs of trouble Typically, the temperature gauge arrow on the instrument panel did not reach the “90 degrees” mark by about 2 mm. Of course, in traffic jams it rose even higher. But when driving, the norm is a little less than 90.

At some point, the picture changed and the arrow began to show a little more than 90. I noted this fact. But there were no other signs of any malfunction.

It was autumn, winter was approaching. Soon I started turning on the stove and made an unpleasant discovery: it was barely heating. And after a couple of days, the murmur of antifreeze in the heater radiator began to be clearly heard...

I spent several days studying the Internet and hardware and now I can tell you the solution to this little puzzle.

The cooling system on the Kalina (and similar ones) has two design defects, due to which at a certain stage of the car’s life air begins to be sucked into it. While there is still not too much air, it slightly disrupts the circulation of the coolant. In order to maintain the heating-cooling balance, the thermostat raises the temperature of the antifreeze.

If nothing is done, air will continue to accumulate in the system and the heater radiator will become air-filled. It stops heating normally. Since she is in the cabin, you can hear “streams babbling” in her radiator.

Design defects:

1. The expansion tank is located below the antifreeze level in the engine.

2. There is no air valve in the expansion tank plug (or it is always inoperative), there is only an emergency pressure valve.

After stopping the engine, the antifreeze begins to cool and compress - a vacuum forms in the cooling system.

Symptoms

Symptoms or signs of airiness are not difficult to recognize. To do this, you just need to pay attention to the uncharacteristic behavior of your vehicle.

Although sometimes it happens that the driver, calmly operating his car, does not even suspect that a harmful air plug has long ago formed inside the cooling system. Signs of such a malfunction are as follows:

- The thermostat breaks. When the fan turns on almost immediately after starting the engine, there is probably a problem in the system. Air sometimes accumulates in the pipes, which provokes circulation only along the internal circuit of the cooling jacket;

- The coolant temperature indicator arrow is in the zero position, even when the engine is warmed up;

- There is a coolant leak. Look under the car to see if there are traces of coolant. This will also help determine where exactly the leak is;

- The engine overheats with enviable regularity. This symptom indicates impaired circulation;

- When the pump operates, extraneous noise occurs;

- The stove is not working properly. It’s not a fact that the reason is precisely airing. But it's worth checking.

If you observe one or more of the symptoms presented, you should check the operation of the cooling system. If you have a new and good foreign car, I don’t recommend going there with your own hands. But everyone decides for themselves.

Plus, keep an eye on the dashboard icons for signals. They will tell you if the engine is overheating, and more.

Causes

Since everything is clear with the signs, you can move on to the reasons why your injector may experience airing in the cooling system.

There is no point in fixing the problem until its causes have been identified. Otherwise, you can disassemble half the machine without achieving the desired result. And it doesn’t matter whether you have a Gazelle, a new Solaris or some Mercedes S-Class.

Airing often occurs due to:

- depressurization;

- incorrect addition of coolant;

- malfunction of the air valve;

- formation of suction due to the pump;

- cooling fluid leaks;

- mechanical damage to system elements;

- normal wear and tear;

- failure of the cylinder head gasket;

- incorrectly performed previous repairs.

Having dealt with the source of the trouble, you first need to get rid of the cause of the airiness. And only then you should proceed directly to the procedure for removing the airlock.

If you were unable to figure out the reasons on your own, it is better not to continue to study the ins and outs of your vehicle on your own. Contact a good car service center, where specialists, using professional and precise equipment, will carry out all the necessary diagnostic measures.

Consequences

If an air lock is detected in the automotive cooling system of an 8-cl engine or any other engine, there is no point in postponing repairs until later.

Since the circulation of cooling fluid in the car is disrupted, very soon the engine itself and all associated equipment will begin to suffer. The engine will not cool properly, and operating the car at elevated temperatures leads to extremely rapid wear of the elements.

There is one additional problem that does not seem so serious. But only before the cold weather sets in. If the system becomes airy, the stove will not be able to properly heat the interior. And therefore you will be very cold.

Additionally, an air lock leads to increased fuel consumption, breakdown of various sensors, and overheating. As a result, everything ends with a major overhaul. Believe me, removing the air is much easier and cheaper than repairing the engine.

The stove blows cold at low speeds: causes and solutions.

We always say that everything in a car is interconnected, therefore, if one of its elements breaks down, the source of the problem must be looked for in everything that is directly or indirectly connected with this element. The cooling system is no exception. It can produce cold air at idle under the following circumstances:

there is too little coolant in the expansion tank;

This is perhaps the most common option. Agree, even though we know that the amount of antifreeze in the system needs to be checked before each trip, we don’t always do this. As a result, the coolant level may become critically low, that is, insufficient to cope with its functions at low speeds.

What to do: check the coolant level in the expansion tank and, if necessary, top up to the required level.

air pockets have formed somewhere;

In cases where work has recently taken place that requires replacing or partially draining the antifreeze, the reason that the heater is blowing cool may be air pockets formed inside the tubes, which simply do not allow the coolant to circulate normally.

What to do: put the front of the car on a hill, unscrew the cap from the expansion tank, start the car and wait until it warms up - you will notice bubbles appearing as soon as they pass - turn off the car, wait until it cools down a little (so as not to get burned) and return the cap to place.

pump is faulty;

Another problem that may cause warm antifreeze to not reach the heater is a faulty water pump.

What to do: detecting this problem is often quite simple by the characteristic knocking and rumble. If you haven’t noticed one, watch your vehicle; if it gets very hot, even to the point of boiling, remove the pump and disassemble it. If the impeller lives its own life or does not spin at all, replace it or the entire water pump.

radiator tubes are clogged

A very common option, along with an insufficient level of coolant: salts and dirt gradually accumulate on the walls of the tubes supplying coolant to the radiator during operation, and over time there are so many of them that hot liquid cannot even pass through them. As a result, the radiator remains cold, as does the air passing through it.

What to do:

Option 1: Flush the system. To do this, drain the coolant present in it, and in its place, fill in a special cleaning composition or a concentrated solution of citric acid. Start the engine and let it warm up to operating temperature. Drain the cleaning solution and add fresh coolant.

Option 2 (usually used only if the previous method was ineffective). Replace the tubes and radiator.

coolant supply is cut off;

Almost every modern car is equipped with a tap that allows you to shut off the supply of antifreeze to the heater. It allows you to avoid the risk of overheating the interior in the warm season, but at the same time, being a weak point of the heating system, it can create additional troubles.

What to do: check the position of the tap and open it if necessary. If the faucet is jammed, it must be replaced.

A little advice: if you own a VAZ car, we advise you to pay a little extra and purchase a faucet not of domestic production, but of the Audi brand - with it you will not have to replace it every six months.

low coolant temperature;

The last situation in which the heater can give off cold is cold antifreeze. And it can be like this in two cases:

- it's too cold outside, so on short trips the engine simply doesn't have time to warm up

What to do: insulate the engine compartment.

- The thermostat has broken down - it is stuck in the open position, as a result of which the coolant “drives” in a large circle, not allowing it to warm up properly.

What to do: check and, if necessary, replace the failed part.

Removing an air lock from the Lada Kalina cooling system

According to reviews of many car owners, the Lada Kalina car is recognized as one of the warmest cars of domestic production.

It is very warm in the car in winter, the interior is evenly heated and the rear passengers in the car are comfortable, since the hot air from the stove is supplied to the feet of the rear passengers in full and is not “lost” in the air tunnels of the ventilation system as in cars 2109 and 2110.

If one day it became cool inside the Lada Kalina car, and instead of the usual hot air, cold air began to blow from the stove, then there was a problem in the car’s engine cooling system.

Before removing the plug, it is first recommended to check the entire car engine cooling system (SOD), since the cause of ineffective operation of the SOD and a cold stove can be not only an air lock in the system, but also a breakdown or deformation of the pump impeller, kinks in the pipes, or incomplete opening of the thermostat . Only after checking the entire cooling system should you begin to remove the air lock.

Signs of an air lock in the engine cooling system

- An air lock creates an obstacle in the cooling system, due to which antifreeze or antifreeze cannot circulate and evenly cool a running engine.

- Reasons for the appearance of an air lock in the engine cooling system:

- — Air may enter the system when replacing or adding coolant.

— In the engine cooling system, there is a leak in external air due to weak compression of plastic fittings, loose clamps, a leaking radiator, a leak in the pump and a faulty expansion tank cap valve.

One of the signs of a plug in the ODS is the gurgling of coolant under the instrument panel when the engine warms up.

To remove the plug, you need to loosen the clamp and remove tube 3 or 22 from the heating of the throttle assembly

— The cylinder head gasket (cylinder head) was blown. As a result of the breakdown, a coolant leak is visible from under the cylinder head. Exhaust gases escape from under the cylinder head, you can see the bubbling of antifreeze, the formation of an emulsion in the expansion tank, and white steam in the car exhaust.

An air lock in the SOD can form in both the small and large circulation circles. The disadvantage of Kalina's SOD is the location of the expansion tank in a large circle.

As a result, until the thermostat opens completely, it is difficult to remove the airlock. Therefore, in the cold season, “gasification” helps, as a result of which the car warms up faster, and when the engine reaches a temperature of 101-105 degrees.

The thermostat opens a large circulation circle and the air exits into the expansion tank.

Removing the air lock is only possible through the highest point of the cooling system. The method of understanding the front of the car, accelerating and letting the engine run for the Lada Kalina is not effective, because... in a closed system, air can only escape through the expansion tank. Rather, it will be more effective to lift the left side of the car, where the expansion tank is located, to release air from the SOD.

For Kalina cars with a throttle assembly, there is an easier and faster way to remove the plug from the SOD. To do this, you need to loosen the clamp and remove any tube from the heating of the throttle assembly.

Remove the cap from the expansion tank and blow into the expansion tank until antifreeze flows out of the removed tube. Then we put the tube back on the heating fitting of the throttle assembly and tighten the clamp. There is a second way to remove the traffic jam.

To do this, you need to warm up the engine a little and turn it off, without unscrewing the expansion tank cap, loosen the clamp and remove the tube from the throttle assembly. As a result of the increased pressure in the SOD, the antifreeze will flow out of the tube on its own.

We put the tube on the fitting and tighten the clamp. That's it, the plug has been removed, since the throttle assembly is the highest point of the SOD of the Lada Kalina car.

Temperature sensor Lada Kalina with electronic pedal

On Lada Kalina cars with an electronic gas pedal there is no throttle assembly. Therefore, there are several ways to expel an air lock:

- Using a wrench or a 19mm socket, unscrew the coolant sensor from the thermostat, having first disconnected the wiring harness from the sensor. We wait for antifreeze to flow from the hole; for efficiency, you can blow into the expansion tank, tighten the sensor, and connect the connector with wires.

- Instead of the coolant sensor, you can remove the thin hose (if equipped) from the thermostat fitting. We wait for coolant to flow from the hose; if the plug prevents coolant from escaping, blow into the expansion tank. As soon as the antifreeze flows, put the hose back on and tighten the clamp.

engine, viburnum, lada, cooling, plug

Solving the air problem

Experts identify 3 main ways to solve the current situation.

Option 1. It is necessary to remove the hose from the heating and open the cap on the expansion tank. Then cover it with a rag (it must be clean) and blow. When antifreeze begins to come out from the removed tube, the hose must be quickly inserted back and tightened with a clamp.

It should be said that coolant is poisonous and should not be swallowed under any circumstances. After the manipulation, the air lock disappears.

Option 2. In this case, it is necessary to warm up the engine - this will increase the pressure. Then the viburnum engine is turned off and the hose is removed according to the first option. There is no need to touch the tank lid; it is in the closed position. When antifreeze runs out of the hose, you need to quickly put it back on and tighten it. Caution should be exercised during operation as the antifreeze may be hot.

Option 3. How to remove air in this case? After the engine has cooled, it is necessary to remove the hose from the reservoir that goes to the cooling system. Then it is filled with coolant and the plug is tightened. The hose must be placed in an empty canister, and the tube from the air pump must be put on the nozzle.

This way the pressure is pumped up; during this process you need to monitor the liquid level. If necessary, it must be topped up, but no more than 2-3 times.

How to expel air if the situation constantly repeats itself? You can use any of the described methods, but it is recommended to check all system connections for leaks. Thus, Kalina will never become airy.

Top 5 modifications to Lada Kalina

Hi all. This means that two years have passed since I owned this car, and as much as I remain satisfied with it, I have 5 life hacks for you that will help you when operating this car.

Well, I think that thanks to these life hacks, your car will also make you happy. Because the car, in this case, is mine for the sixth year, 2006, and there were some problems that it would be advisable to eliminate immediately.

Something is not a jamb, something, well, more has been done to improve it. Well, I still want to share with you, maybe this video will be useful to someone. So let's go.

- Lifehack No. 1

- Suspension

- The stove doesn't heat well

- Mirrors

- Tunnel of shelves

Lifehack No. 1

This is Kalina's ECU, that is, almost all of Kalina's owners have probably encountered it; those who haven't, they already know about the drawback in the location of the ECU. Initially, Kalina's ECU is located here under the panel.

Refinement of the cooling system on the Lada Kalina

Refining the cooling system on the Lada Kalina will help solve the problem of airing and the formation of traffic jams. There are several ways to eliminate this defect. The ineffective operation of the unit is associated with its design features. The operation of the engine cooling system (ECS) is associated with the interaction of various elements. The temperature of the power unit determines the passage of coolant through the large and small circles. At the first stage, the coolant circulates without passing through the radiator; after reaching the required temperature and the thermostat is activated, the liquid passes through the radiator. The normal functioning of the engine and stove depends on the correct operation of the system.

Causes of ODS malfunction

Refinement of the cooling system on the Lada Kalina

can be produced either in-house or at a car service center. However, in the latter option, experts usually recommend replacing or repairing the thermostat, which is not always practical or effective. The main causes of problems in the cooling system:

- Coolant leak. It is recommended to check the clamps and integrity of the radiator. If necessary, elements are replaced or repaired. You can check the circulation of refrigerant in the system by making sure that liquid enters the tank. If this does not happen, you should replace the pump or clean the SOD with special means;

- Failure of the thermostat or its elements;

- Contamination of radiator honeycombs;

- Fan malfunction;

- Presence of air pockets in the system.

Traditional Troubleshooting Methods

To solve the problem of airing, you should open the expansion tank, start the engine, press the gas pedal several times until the sensor arrow reaches the red zone. If the fan turns on, you need to squeeze the gas all the way several times and turn off the ignition. If this method is ineffective, the following procedure is used. The plastic motor protection is removed, the clamp is lowered and one of the fitting tubes is dismantled. The expansion tank cap is opened and the system is purged until coolant begins to pour out of the removed tube.

A standard modification to the cooling system involves installing a new 6-hole thermostat, coolant filter and heater valve. To maximize coolant flow and minimize the risk of overheating, you will need to install an additional pump.

Traditional methods of improvement

In the version with an electronic gas pedal, the cooling system is looped with a hose that was previously used to heat the throttle assembly. Using an additional hose, tee and clamps, a connection of a smaller diameter is mounted to vent the system. The air vent is installed as close as possible to the thermostat using a tee cut into the supply hose to the radiator.

The second end of the air outlet element is connected to the steam outlet near the RB fitting (using another tee). This modernization made it possible to achieve a stable temperature of 90-95°C when driving around the city, with the stove starting to warm up at 50°C. The costs for additional elements (refilling refrigerant, tees, clamps and 1 m of hose) amounted to about 600 rubles. It is worth noting that before the upgrade, the sensor showed the engine temperature was more than 100°C, while cold air was blowing from the stove.

Second way

modification of the SOD consists of installing a hydraulic intake on the steam outlet. To do this, a regular tube from a dropper is inserted into the steam exhaust channel with constant immersion in the coolant and touching the bottom of the tank. While cooling, the liquid will be drawn into the outlet hose according to the principle of communicating vessels, which will protect the system from the formation of air locks. Alternatively, you can combine both methods.

Let's sum it up

As you can see, an air lock in the cooling system is a significant obstacle to the normal functioning of the cooling system in the LADA Kalina car. It can not only cause the stove to become ineffective, but also cause more significant damage to the engine. Eliminating this negative phenomenon is not difficult, especially since now you know how to pump air, but the best measure would be timely and periodic diagnosis of the engine cooling system. It consists of checking the refrigerant level, the tightness of the circuit (reliability of clamps) and the functionality of the thermostat (control of heating of the lower radiator pipe).

The Lada Granta passenger car, which is considered one of the most affordable in the world, is equipped with a “stove” (or simply a heater) that is standard for VAZ cars. Typically this unit works very well, but problems can still occur. Therefore, if the Lada Granta stove does not heat well, then there must be reasons for this that simply need to be discovered.

Technical features of the system

Expansion tank

The unified layout and closed design of the engine cooling system (SOD) of the Kalina are also characteristic of other VAZ models. The system is designed to remove thermal energy from heated engine elements using antifreeze or other coolant.

The SOD consists of the following functional parts.

- Cooling radiator. Reduces coolant temperature due to the flow of cold air masses.

- Fan. Used for rapid cooling of antifreeze in the Kalina cooling system.

- Expansion tank. Designed to compensate for the volume of coolant (coolant). The need for this unit is related to the expansion/constriction property of the coolant.

- A pump or centrifugal pump, which is responsible for the forced circulation of antifreeze through the appropriate channels.

- A thermostat whose task is to regulate the volume of antifreeze in the Kalina cooling system.

- Temperature sensor involved in SOD control.

The operation of the cooling system is based on the close interconnection of various parts, elements and sensors, including devices that are designed to measure oil temperature. The passage of coolant in a large or small circle depends on the engine temperature. In the first case, antifreeze passes through all components of the SOD, except the radiator. With such circulation, the thermostat is closed. As the engine temperature rises, this element gradually opens. The antifreeze, having passed a large circle, enters the radiator. The latter device is cooled by oncoming air masses. If this is not enough, a signal is sent to the ventilated unit, which begins to forcibly direct air masses to the cells.

The cooled liquid enters a small circle. Next, taking into account the engine temperature, the antifreeze automatically circulates in a small or large circle. At the same time, the optimal operating temperature is maintained, which should be in the range of 95-105°C. This factor has a direct impact on the performance of the Kalina stove. In this case, it will not be able to supply warm air masses into the cabin.

https://youtube.com/watch?v=qX3qBD0IXFI

If there are any doubts about the operation of the ODS, you need to diagnose the car, finding out the causes of the malfunction. You can fix the breakdown either with your own hands or with the help of a car mechanic.

First, it is recommended to check the antifreeze level in the system. To do this, you will need to open the hood and inspect the expansion tank. It should be filled to 1/2 of the total volume. If necessary, antifreeze is topped up or the coolant is completely replaced. In the latter case, you will need to drain the old antifreeze. If there is a fluid leak, you need to inspect the engine compartment.

How to remove air from the engine cooling system?

The process of removing an air lock on cars is almost the same, be it Kalina, Priora, Granta, Hray, Vesta, VAZ 211(0-5), 2101-2107, Opel, Daewoo Matiz, Nexia, Nissan Almera, Gazelle Business, Audi 80-100 , BMW E39, Peugeot, Chevrolet Cruze, Skoda, Mazda, Mitsubishi Lancer, Suzuki Grand Vitara, Niva, UAZ, Volkswagen, Ford, Renault Duster, on Chinese Lifan and even on premium class cars.

There are several options for removing an air lock from the cooling system:

Option #1:

- Remove the plastic casing from the internal combustion engine. Why do you need to unscrew the filler cap to fill the oil? Remove the trim. After removing the casing, you need to close the neck to avoid the ingress of various kinds of objects.

- Find the pipes that provide heating for the throttle assembly.

- Remove any one pipe.

- Unscrew the cap of the expansion tank.

- Cover the neck with a clean piece of rag or tightly connect the hose and blow into it.

Thanks to this method, air and the general system are bleed. You need to blow until liquid flows out of the disconnected pipe. Then, immediately put the hose back in place.

Option #2:

- Start the engine and let it run for about 15 minutes.

- Turn off the engine.

- Disconnect any pipe on the throttle assembly.

- We do not touch the tank lid; it must be closed.

- Wait until the coolant starts to flow out.

- Place the pipe in place and tighten it tightly with a clamp.

To use this option, it is advisable to wear thick rubber gloves and overalls, because the temperature of the liquid is about 90 degrees.

Option #3:

- Place the car on a steep incline with the front end facing up (the steeper the better).

- Set the handbrake.

- Place wheel chocks (chocks) under the wheels.

- Unscrew the plugs from the expansion tank and the cooling radiator.

- The car should run for about 15 minutes with this setting.

- The antifreeze will gradually descend into the system, and the air will escape.

- Add antifreeze and gas.

- When the bubbles end, all the air has escaped.

Method No. 1

- Remove the hose from the throttle body heating.

- Open the cap of the expansion tank, cover the neck with a clean rag and blow into the tank.

- When antifreeze starts flowing from the removed tube, quickly put the hose back in place and tighten it with a clamp.

Attention! Coolant is a toxic substance, so we recommend that you use other methods to solve the problem.

Spoilers

One of the favorite pastimes of novice tuners is to install spoilers in all possible places. Of course, a spoiler is a very useful thing. But getting carried away beyond measure (especially for cars like the Lada Kalina) is not recommended. We remember that this is still not a racing car. We will limit ourselves to the front spoiler, which looks harmonious and fulfills its aerodynamic functions. Gluing it is quite simple and inexpensive.

Wheels:

External transformations include replacing factory wheels with alloy ones, and standard tires with lowered ones. Some lovers of night walks also use LED illumination of the rims and underbody, achieving a truly cosmic effect. Decide for yourself: do you need this?

Design features of the LADA Granta engine cooling system

The LADA Granta engine cooling system is liquid (with forced circulation of liquid), sealed, with an expansion tank. The system is filled with ethylene glycol-based coolant (antifreeze), which does not freeze at ambient temperatures down to -40 'C.

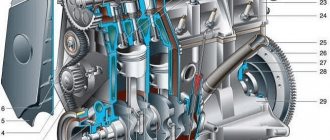

The design of the cooling system of all engines installed on Lada Granta cars is fundamentally the same and is described using the example of a car with a VAZ-21116 engine.

Location of elements of the LADA Granta cooling system:

Rice. 1. Location of the main elements of the Lada Granta cooling system: 1 - water pump (located under the timing cover); 2 — radiator of the cooling system (located under the upper cross member of the radiator frame); 3 — electric radiator fan (located under the upper cross member of the radiator frame); 4 — thermostat; 5 — coolant temperature sensor; 6 - expansion tank

A centrifugal water pump provides forced circulation of fluid in the cooling system of the Lada Granta, is installed on the front plane of the cylinder block and is driven by a timing belt. The pump has sealed bearings that do not require replenishment of lubricant. The pump cannot be repaired; if it fails (liquid leakage or bearing damage), it is replaced as an assembly.

A thermostat with a solid heat-sensitive filler maintains normal operating coolant temperature and reduces engine warm-up time. The Lada Granta thermostat has a main and additional bypass valve. At a coolant temperature of up to (85±2) °C, the thermostat is completely closed and the liquid circulates through a small circuit, bypassing the radiator, which speeds up engine warming up. At temperatures above 85 C, the thermostat begins to open, and at 102 ° C it opens completely, ensuring fluid circulation through the radiator. An electric fan with a plastic impeller ensures air purging of the radiator at low vehicle speeds, mainly in urban conditions or on mountain roads, when the oncoming air flow is not enough for cooling the radiator. To increase operating efficiency, the fan is installed in casing 7 and attached to it at three points through rubber pads. The casing, in turn, is attached to radiator 3 at four points. The electric fan is controlled by the engine control unit, which receives information about the coolant temperature from sensor 5 (see Fig. 1), located in thermostat socket 4.

The radiator is tubular-plate, aluminum, with plastic tanks, two-way, with a partition in the left tank. At the bottom right there is a drain plug 6. The tanks contain inlet and outlet hose pipes to the engine water jacket, as well as a hose pipe connecting the radiator to the expansion tank.

The expansion tank serves to compensate for the changing volume of coolant depending on its temperature. The tank is made of translucent plastic. The “MAX” and “MIN” marks are applied to its walls to control the coolant level; on top there is a filler neck, hermetically sealed with a plastic plug 1 with two valves inside (inlet and outlet), assembled in a single block. The exhaust valve opens at a pressure of 110 kPa (1.1 kgf/cm2), ensuring an increase in the boiling point of the coolant and preventing intense vaporization. When a liquid cools, its volume decreases and a vacuum is created in the system. The inlet valve in the plug opens at a vacuum of about 3 kPa (0.03 kgf/cm*) and allows air into the expansion tank.

Note

The serviceability of the valves of the expansion tank plug is very important for the normal operation of the cooling system, but often when problems arise (coolant boiling, etc.), car enthusiasts pay attention only to the operation of the thermostat, forgetting to check the valves. Leaking of the exhaust valve leads to a decrease in the boiling point of the coolant, and its jamming in the closed state leads to an emergency increase in pressure in the system, which can cause damage to the radiator and hoses. The interior heater radiator is also included in the cooling system using hoses.

The interior heater radiator is also included in the cooling system using hoses.

The design and principle of operation of the cooling system of the “tens” engine.

Any cooling system is designed not only to cool parts, but also to perform some other functions, namely:

- ventilation and air conditioning, heating the air in the heating system;

- cooling air in the turbocharger;

- cooling the working fluid in the automatic transmission;

- cooling the lubricant, or rather the oil in this system.

Design of the cooling system of the VAZ 2110 injection engine.

- Heater radiator

- Heater radiator steam hose

- Outlet hose

- Supply hose

- Coolant temperature sensor (in the cylinder head)

- Pump inlet hose

- Thermostat

- Charging hose

- Expansion tank plug

- Coolant level indicator sensor

- Expansion tank

- Outlet pipe

- Carburetor starter fluid chamber

- Radiator outlet hose

- Radiator inlet hose

- Radiator steam hose

- Left radiator tank

- Electric fan switch sensor

- Fan motor

- Electric fan impeller

- Right radiator tank

- Drain plug

- Electric fan shroud

- Timing belt

- Coolant pump impeller

- Coolant pump inlet pipe

- Coolant supply hose to throttle body

- Coolant drain hose from throttle pipe

- Exhaust coolant temperature sensor

- Radiator tubes

- Radiator core

Method No. 3

- With the engine cooled down, remove the upper hose from the expansion tank coming from the radiator of the cooling system.

- Fill the reservoir to the maximum with coolant and tighten the cap.

- We place the hose in an empty canister, and put a hose from the air pump (for inflating tires) on the tank nozzle.

- We pump up the pressure in the tank with a pump, and at the same time the antifreeze will pour into the canister.

- We monitor the level of coolant in the expansion tank and add it if necessary.

- After 2-3 additions of liquid, we restore all connections.

If air in the cooling system occurs periodically, then the car’s cooling system is not sealed. Check the connections of all system hoses for leaks, as well as the expansion tank cap. See also other photo reports on DIY Lada repairs.