If, when there are interruptions in operation, impossibility of starting, etc., of the UAZ-469B engine, there is a suspicion of a malfunction of the ignition system, then, first of all, it is necessary to check the presence of a spark in the spark plugs.

At the same time, if between the spark plug wires and the engine housing and the high voltage wire of the ignition coil and the housing, a spark breaks through a spark gap of 6-7 mm without interruption, then the ignition system is working.

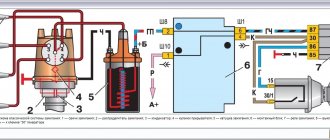

Checking the operation of the ignition system on the UAZ-469B.

If there is no spark between the high voltage wire of the ignition coil and the housing, you need to check the low voltage circuit between the battery and the ignition coil. This can be done with a portable lamp, using it as a control lamp.

If, when switched on between terminal VK-B of the ignition coil and the car body, the light comes on when the ignition is on, then the low voltage circuit is operational. If the light does not light up, you need to check the ignition switch, ammeter and wiring by connecting one wire of the test lamp in series to the ammeter terminals and the AM and KZ terminals of the ignition switch, leaving the second contact of the light bulb connected to the car body.

If the low voltage circuit between the battery and the ignition coil is working, damage should be looked for in the wires connecting the breaker lever with a contact isolated from the breaker body and the movable and fixed panels in the distributor. Breakage of these wires, as a rule, occurs after prolonged use. This malfunction can be identified using the same portable lamp.

To do this, you need to connect one of the legs of the portable lamp plug with a separate wire to the low voltage terminal on the distributor, and the second leg to the car body. Then turn on the ignition and, turning the crankshaft with the starting handle, observe the lamp. When the contacts are opened, the lamp should light up and vice versa. If the lamp does not go out when the contacts are closed, this confirms a break in one of the indicated wires. In this case, it is necessary to remove the distributor from the engine and eliminate the malfunction.

If the low voltage circuit turns out to be serviceable, it is necessary to check the condition of the breaker contacts and, if there is a malfunction, eliminate it. Interruptions in the operation of all spark plugs of the UAZ-469B engine can be caused by wear on the edges of the breaker cam, a reduced or increased gap between the breaker contacts. As well as a break in the wire connecting the movable and stationary plates of the breaker, short circuit of the primary or secondary windings of the ignition coil, a crack in the distributor cap, wear of the distributor cap carbon and a decrease in the capacitance of the capacitor.

Interruptions in engine operation at high crankshaft speeds may be the result of low pressure on the breaker contacts, which is provided by the spring of the moving contact lever. When the tension of the breaker spring is weakened, the force is less than 500 gf, vibration of the contacts occurs, which leads to interruptions in the operation of the ignition system.

If the spark is weak on all spark plugs, then it is necessary to check the fastening of the capacitor to the distributor body. In addition, a weak spark on the spark plugs may occur if, when starting the engine, the starter does not turn off the additional resistor of the ignition coil. This usually occurs as a result of oxidation of the contacts of the starter switch and slip ring.

Checking the technical condition of the UAZ-469B ignition system devices and their repair.

Checking the technical condition and repairing the B7-A ignition coil and additional resistor.

Ignition coil malfunctions include insulation breakdowns and turn-to-turn short circuits of the primary and secondary windings, breaks in the winding wires from the output terminals, cracks in the cover, as well as burnout of the additional resistor.

If the insulation of the windings breaks down, the engine stops and cannot be started. When interturn short circuits and breaks in the wires of the windings from the output terminals occur, interruptions in the operation of the engine occur. When the additional resistor burns out, the engine starts easily with the starter, but when the starter is turned off, it stops immediately.

Since when the starter is turned off, the engine can stop even if the ignition switch is faulty, you need to make sure that after turning off the starter, current is supplied to the VK-B terminal of the ignition coil. A characteristic sign of damage to the additional resistor is also normal sparking when cranking the engine with the starter and the absence of a spark when cranking it with the starting handle.

A burnt-out additional resistor must be replaced. If there is no spare resistor, it can be made from nickel wire NP-2 GOST 2179-59 with a diameter of 0.3 and a length of 740 mm. If the additional resistor comes off at the place where its ends are attached, then it must be soldered using acid-free soldering.

Magneto ignition coil. Checking serviceability and setting the gap.

We often encounter situations where tool users come in with a faulty ignition.

Often it actually turns out to be faulty, but often the ignition coil has nothing to do with the breakdown of the tool. The steps to check the serviceability of the ignition coil are described below. Assessment of the current state of the coil.

Before working on the ignition coil, it is worth checking the serviceability of the entire circuit. Do the following:

- visually assess the absence of cracks and visible defects on the reel body

- contamination of conductive elements and components

- serviceability and insulation of high-voltage wires, wire contacts, reliability of their fastening, absence of rust at fastening points

- check the condition of the spark plug cap: it is often torn off from the high-voltage wire and tried to be restored using “improvised” methods. Remember: any “snot” in this place reduces the quality of the electric arc of the spark plug

- check the serviceability of the spark plug. The quality of our gasoline does not allow the spark plug to “live long”

- Check that the circuit breaker is working properly. This is especially true for Chinese saws and trimmers.

The point of these actions is to exclude from the list of possible faults all circuit elements except the coil. If everything is ok, we move on.

Fuel injection system failures

For proper fuel injection, the electronic engine control unit has to receive and process a large amount of information. Data comes from several sensors. Problems with any of them lead to the impossibility or complication of starting the engine.

For diagnostics, it is recommended to use a special scanner. In its absence, problems can be indirectly determined by inspecting sensors, contact connections, wiring harnesses and checking the condition of fuses.

Similar:

- Porsche Cayenne will not start In order for the Porsche Cayenne engine, like any other internal combustion engine, to start, several conditions must be met: the starter spins the crankshaft to the required speed, there is a spark in the cylinders.

- Lada Priora will not start Lada Priora is a popular Russian car, which, since its appearance, has been actively popularized among car enthusiasts in our country. It is also important that manufacturers pay close attention.

- Nissan Sunny won't start Almost every car owner, while using a car, is faced with a situation where the Nissan Sunny won't start. Without hearing the treasured sound of a running engine, it is important for the driver not to fall into disarray.

- VAZ 2112 will not start. The inability to start the engine on a VAZ 2112 is a standard problem with this model (especially with a 16-valve engine). The best solution to determine the root problem is to use.

About the purpose of the coil

Symptoms of a faulty ignition coil.

When this is the problem. To ignite the combustible mixture of gasoline and air compressed in the working area of the cylinder, a high voltage is required on the spark plug. Its value exceeds 30 thousand volts. The on-board voltage of the car in most cases is 12 Volts. The ignition coil is designed to obtain the required value.

Photo of ignition coil VAZ 2101-2107

This component of the car must be given due attention; if other systems fail, the car can independently reach the parking lot or service center. In the case where there is no spark, this is impossible to do.

You will have to look for a tow truck or call a tow truck.

UAZ-469 no spark. Reel, distributor and...

Causes and Symptoms of faulty spark plugs and ignition coils. Signs of faulty ignition coils

Contactless ignition

check the voltage of 12 volts with the ignition on on the Aleon coil

check the wiresBuble

Check contacts and capacitor Gray

First, wipe the spark plugs and breaker cover with a dry cloth. Wipe the wires and spark plug tips and don’t forget about the ignition coil. Remove the breaker cover and wipe it and the rotor, don’t forget the capacitor either. When you remove the rotor, look carefully at the contact group, it may also be wet. Then you should check the voltage supply to the ignition coil with the ignition on. This is done simply with a test light, one end of the light bulb to ground and the other to the upper terminal of the coil, having previously disconnected the wire that goes to the breaker from this terminal. If the light comes on when the ignition is on, look further. If it doesn’t light up, we look for the cause, a break in the circuit, or the coil “flies”. We put the wire that was removed in place and try to open the contacts with a screwdriver and at this time look for a spark on the central wire; if there is a spark, then just clean the contacts. Bring the center wire to the center of the rotor and try to open the contacts again, there should be a spark between the contacts, but not on the center wire. If in this position a spark strikes from the central to the center of the rotor, then the rotor needs to be changed. Then you will need to wipe the contacts with a clean cloth soaked in gasoline. If the spark is weak or absent, then try replacing the capacitor. This is roughly how electrical engineers look for a claim. Don't be afraid, it's not that difficult. Tinto

Which carburetor is better to install on a VAZ 2101, if everything is original in it and I only want to change the carburetor itself?

Glitch with turn signals VAZ 2101 1976! when I started it and drove off it worked, then it didn’t work, then it started working again)))

In stock there is a VAZ-21011 (1974). There are problems with the paint, it needs to be painted. I want to make a car in retro style.

The door to the VAZ 21012 car closed, the keys are inside, what should I do? how to open?

Tags: UAZ

Comments 54

Above it was suggested to unhook the wiring from the switch from terminal D from the distributor and connect it to ground (previously, instead of the explosive wire, insert a piece of wire into the coil and place it 5-7 mm from ground) with the ignition on - is there a spark? It always makes sense to have a _tested_ distributor cap, slider, distributor sensor, switch and coil with you.

How are you doing, comrade? got out? what happened?

they dragged me)))) after that and I can’t get to it because work keeps me late

How are you doing, comrade? got out? what happened?

I'm blaming the switch, although it's new

Now I’ll say bullshit, but sometimes we don’t even notice the obvious... in the manner of a sudden death. Circuit breakers. Weight. HV wires. Filled it up.

I checked the fuses are intact

Don't you carry a spare switch with you? They sometimes get covered, especially if the mass is bad.

That’s what I don’t drive, now I’ll take half the garage with me for spare parts))))

I still have a Zhiguli, on December 31, when leaving the store, right at the turn the switch burns out, as a surprise. I've been driving ever since.

Do you have a sample? I'll tell you everything point by point

Pull out the central wire from the distributor, lean it against the engine 0.5 cm, turn it with the starter, if there is a spark, check the slider, if not, try to bridge the resistance

The first thing I did was try the central wire to ground and there was no wire. But to bridge the resistance, I’m not very good at electrics.

The box in the photo, the spiral inside, when you start the engine, power goes to the coil from the lock, you release the starter, power goes through the resistance, which reduces the load on the coil.

This happened recently. Cause 100%: the contacts on the contact group were burnt. Those. when you remove the distributor cover you will see contacts (2 pcs). So they got burnt. Cleaning cannot fix it, only replacement (tested).

Do you hear any popping noises when you turn the starter? Is there a spark? Does it catch on? Or completely deaf?

Insert the spark plug wire into the coil and check if there is a spark. If there is one, look at the distributor slider.

no spark, I tried that

Check the distributor. The wiring is attached to it on the side, sometimes unscrewed.

He may be standing, but there is no contact. Hanging on one insulation.

Check the plus on the coil, if not, then the variator, whether there is a plus on it from the ignition, check the plus on the switch, if there is, then take terminal D and poke it to ground, while bringing the high-voltage one from the coil to ground, pulling it out of the distributor. If there is, then the sensor in the distributor has run out, if not, then the switch. PS in practice, when there are breakdowns, most often the variator, then the switch, less often the distributor, and even less often the coil.

Check the plus on the coil, if not, then the variator, whether there is a plus on it from the ignition, check the plus on the switch, if there is, then take terminal D and poke it to ground, while bringing the high-voltage one from the coil to ground, pulling it out of the distributor. If there is, then the sensor in the distributor has run out, if not, then the switch. PS in practice, when there are breakdowns, most often the variator, then the switch, less often the distributor, and even less often the coil.

No spark at trimmer

How to check the ignition coil

September 11th, 2013 admin

Many trimmer owners are faced with a problem when the device simply does not start. One reason for this could be a lack of spark. This usually happens when fuel floods the spark plug. In addition, you need to check the spark plugs for serviceability, as this can also lead to a lack of spark.

The first sign of a faulty spark plug is the presence of a short circuit between its contacts, or, in short, no spark on the trimmer. In addition, the spark plug is considered faulty if it is covered with a black, wet layer.

This layer appears from oil that has entered the combustion chamber. In such a situation, you have two options: either clean the spark plug properly, or buy a new one. Sometimes it happens that the spark plugs are clean, but the problem may be in its insulation, which is often covered with black dry soot. This may be due to a weak spark, too low spark plug temperature, poor fuel quality, dirty air filter or prolonged idling. The solution here is the same - clean the spark plug or replace it with a new one. Moreover, the spark plug should be replaced even if the contacts are sufficiently worn out.

If there is no spark at the trimmer, professionals at the service station will tell you how to solve the problem. Sometimes, the problem may be with the magneto. The magneto may become unusable due to the fact that you could pull the starter cord at a time when the ignition was turned off and the spark plug was not grounded to ground. Such actions can easily damage the magneto. In such a situation, the only way out is to buy a new magneto.

In addition, the problem may lie in the ignition unit. This option can be considered if the spark plug and wire do not have any faults. In such a situation, it is necessary to replace the ignition unit. It can be found attached with two screws to the engine cylinder. To gain free access to the unit, it is necessary to remove the enclosing casing. To correct the current situation, the entire assembly will have to be replaced, since, as practice has shown, replacing individual parts gives insufficient results. If there is no spark on the trimmer, there is only one way to fix it - replace it.

Moreover, sometimes the problem should be looked for in the ignition coil. A lack of spark can result from a coil failure or a fault in the circuit. To check the flow of current into the primary winding of the coil, you can use a light bulb, which must be turned on instead of the coil. Then you need to carefully inspect the breaker contacts. If a strong spark occurs between the contacts at the moment of opening, you can be sure that the capacitor is broken. In this case, you have only one option for further action - replacing the capacitor.

These are the main reasons why there may be no spark on the trimmer.

Published in the Cottage and Garden section

Let's sum it up

The power unit does not start for various reasons, apparently, another is when the fuel pump fuse has failed, in which case the engine will not start. In such a situation, it is necessary to try to find out what the reason may be, and maybe it is the terminals, or maybe computer testing will be required. Also, never underestimate the situation, since a car is a large mechanism, which has quite a lot of rather vulnerable spots, especially under harsh operating conditions.

The spark of the VAZ-2106 has disappeared, reasons for what to do

What to do if there is no spark on a VAZ-2106 car? As is known, this phenomenon leads to the fact that the air-fuel mixture does not ignite and the engine stops starting. Therefore, you will have to look for the causes of the problem without fail.

On VAZ cars, and on the “six” in particular, the spark can disappear due to a variety of malfunctions. But in this article we will describe only the most common of them, and also give useful tips for identifying and troubleshooting problems.

Making sure the spark plugs are working

Most often, the spark disappears due to problems with one of the spark plugs, so we will test these parts first. You can even check it in the field. To do this, it is enough to have a known working candle with you. Testing is performed as follows:

- insert a new spark plug;

- crank the starter and check for a spark;

- If the new part works fine, then we simply leave it in place and start the engine.

In a situation where a working spark plug does not fire, more complex checks will be required.

Checking high voltage wires

After checking the contact spark plugs, we move further along the circuit and test the performance of the high-voltage wires. The instructions below will help you diagnose if the spark disappears on only one of the cylinders:

- swap the wires connected to the spark plugs;

- check for the presence of a spark;

- if it appears on the cylinder to which you transferred the new wire and disappears on the other, then the problem is in the cable. Therefore, the latter will need to be replaced.

In exactly the same way, the integrity of the central wire through which voltage is supplied to the ignition coil is checked. You can also try to press it harder against the transformer and distributor cap to restore contact.

Checking the contacts of the distributor

If after the steps described above the spark still does not appear, proceed to the next stage. We open the distributor cover and inspect the contact groups extremely carefully. It is quite possible that the problem arises due to carbon deposits, which must be carefully removed using a regular knife.

Also at this stage you can check the functionality of the contacts, for which you need to turn the starter several times with the cover open. If all contact groups open normally, then they are working properly. Otherwise, it makes sense to set the correct gap between them.

Understanding the ignition coil

If voltage is not supplied to the contacts of the distributor, then the last step will be to test the performance of the ignition coil. You will need to use an ohmmeter or multimeter to check the primary and secondary windings to make sure that their resistance corresponds to the normal values specified in the car's owner's manual. If there are any deviations, we simply install a new, working coil.

Spark problems on cars with an electronic ignition system

If your car has electronic ignition, then, in addition to all the above steps, you will also need to check the following components:

- voltage switch located under the hood of the car on the left side;

- Hall sensor, which is designed to monitor the magnetic field voltage. In cars with electronic ignition, this device is subject to increased stress and often fails, so it is better to always have a spare part with you.

To avoid problems with electronic ignition on the road, if the spark disappears, you can install a conventional contact system, which will allow you to get to the nearest car service center without incident to have your car professionally diagnosed and repaired.

What to do next

So, the reason why there is no spark from the coil has been discovered. Now we need to decide what to do next. There are two main options:

- repair the faulty element;

- purchase a new coil, and then replace it.

Repairing a unit is a rather complex process. Here it is necessary to disassemble the mechanism into its component elements, then check them for various chips, scratches and other defects, and then clean up the damage. Then you need to restore the shell using glue or a special composition.

To replace the coil, you need to select a model with similar parameters.

It is important to connect the connecting wires correctly, otherwise there is a high risk of overheating and a short circuit. If a spark appears during the test, and the data obtained by the ohmmeter and ammeter are within normal limits, then you should look for a problem in the remaining elements of the ignition system.

To summarize, we can say that several elements are responsible for starting a car engine. At the same time, the main reason here is that there is no spark from the ignition coil. Before solving this problem, it is necessary to understand why exactly this situation arose. You should carefully check the spark plugs, wiring and the coil itself. Having discovered where exactly the problem lies, it is necessary to replace or repair the faulty element. On the other hand, it requires special equipment and instruments, so if you don’t have all this, you should entrust repairs and diagnostics to the hands of professionals .

Chain lubrication system

If there is a significant (small is considered normal) oil leakage, you need to check the tightness of connecting the tubes to the pump fittings. They may fall off or crack. Violation of the tightness of the oil line, in addition to drips, can also lead to insufficient lubrication of the chain. The pump begins to suck in air, which affects its performance. No spark on chainsaw | video in Zaporozhye. Violation of the tightness is eliminated by replacing the tubes or sealing them with sealant.

The most serious failure of the lubrication system is cracks in the oil pump housing. In this case, it will have to be replaced.

Signs of trouble

It is advisable for almost everyone to know about this in order to have a rough idea of what happened to the car, why the power unit “became depressed” or shows no signs of life at all. Knowing this, you can get rid of problems or prevent their occurrence. The most important sign of a problem with this unit is the inability to start the car engine. Moreover, this is equally impossible on both a hot and a cold engine. There will also be characteristic interruptions in the running engine. This may be due to a weak spark being produced by the ignition coil. The engine “troubles”, power and dynamics are lost, and in injection systems a fault signal may appear on the instrument panel.

Problems may arise due to an insulation breakdown; the spark will escape to the ground of the machine, bypassing the spark plugs. It’s rare, but it still happens when the winding turns short-circuit, this will be visible by its heating

It is important for drivers to be able to independently determine the serviceability of the device, which will allow them to independently and quickly eliminate breakdowns. Let's look at how this can be done

If you have a car tester or multimeter, you can easily use them to determine the health of this device.

The photo shows the low voltage coil winding being tested.

Its resistance, depending on the type of product, can range from 300 to 500 Ohms. The high-voltage winding of the device is checked in a similar way. A weak spark due to closed turns is a common occurrence during engine operation.

You can check the serviceability of the device on a power unit with a contact ignition system directly on the engine. To do this, simply remove the high-voltage wire from the distributor and bring it to ground, while simultaneously cranking the starter. A powerful spark discharge must occur between the motor housing and the wire. If the spark is weak or absent, the problem is most likely in the coil.

During such checks, you should also check the functionality of the contact group and the supply of on-board voltage to the low-voltage winding.

The photo shows the device being tested on a car engine.

Weak output from the high-voltage winding may be due to a discharged battery, which happens quite often in cold weather. Whether the ignition coil sparks or not, specialists in workshops check it using special equipment; they can use it to measure the high voltage. Sometimes you can hear, especially from novice drivers, that the ignition coil sparks, but the engine does not start.

In this case, pay attention to the color of the spark produced. It should be powerful and bright, as shown in the photo

Formation of a spark when starting the internal combustion engine

In the case where the color of the spark discharge differs from that shown in the photo, find out the reason for this phenomenon.

At the end of the article, I would like to note that the sources of such problems can be other elements that ensure the performance of the engine.

What to do next

So, the reason why there is no spark from the coil has been discovered. Now we need to decide what to do next. There are two main options:

- repair the faulty element;

- purchase a new coil, and then replace it.

Repairing a unit is a rather complex process. Here it is necessary to disassemble the mechanism into its component elements, then check them for various chips, scratches and other defects, and then clean up the damage. Then you need to restore the shell using glue or a special composition.

To replace the coil, you need to select a model with similar parameters.

It is important to connect the connecting wires correctly, otherwise there is a high risk of overheating and a short circuit. If a spark appears during the test, and the data obtained by the ohmmeter and ammeter are within normal limits, then you should look for a problem in the remaining elements of the ignition system.

To summarize, we can say that several elements are responsible for starting a car engine. At the same time, the main reason here is that there is no spark from the ignition coil. Before solving this problem, it is necessary to understand why exactly this situation arose. You should carefully check the spark plugs, wiring and the coil itself. Having discovered where exactly the problem lies, it is necessary to replace or repair the faulty element. On the other hand, it requires special equipment and instruments, so if you don’t have all this, you should entrust repairs and diagnostics to the hands of professionals .

Methods for checking an injection and carburetor engine in the absence of a spark

If there is no spark on the engine, different diagnostic methods are used:

- checking for ground;

- checking with a digital multimeter (tester);

- using a special tester with a piezoelectric element.

It is recommended to use the ground test only on vehicles with a carburetor. To do this, you need to take a spark plug and bring it to any metal part of the engine (the cylinder block is good). Another person in the cabin should try to start the engine by turning the key in the ignition. This determines the supply of a spark to a specific spark plug.

Important! It is not advisable to use this method to check the spark on injection machines, since they use expensive electrical equipment that can fail due to such “diagnostics”. Using a multimeter allows you to check the spark plugs themselves

The diagnostic principle does not differ from the first method, but the likelihood of damage to the engine ECU is minimized. A special device called a “discharger” allows you to check the spark on a carburetor engine. Using such a device, you can easily determine in which segment of the car’s ignition system there are problems.

Using a multimeter allows you to check the spark plugs themselves. The diagnostic principle does not differ from the first method, but the likelihood of damage to the engine ECU is minimized. A special device called a “discharger” allows you to check the spark on a carburetor engine. Using such a device, you can easily determine in which segment of the car's ignition system there are problems.

If there is no spark in all cylinders, the culprit may be the controller, ignition coil/module, or center wire. First you need to check the condition of the fuses. After this, we check the ground connection and high-voltage wires.

If there is no spark at the coil, you need to check the condition of the central high voltage wire. The presence of damage to the insulating layer, breakdowns and other defects is unacceptable. If they are found, this element must be replaced.

In addition, while searching for a spark, do not forget to check the spark plugs. But it is advisable to do this only after you have reliably established that the spark definitely reaches the spark plugs. The check is performed using the method mentioned above. The spark should be white with a slightly bluish tint. If there is a spark, but it is weak, check the condition of the spark plug contacts. In any case, replacing spark plugs is inexpensive, so it won’t be superfluous.

Troubleshooting the ignition system

Malfunctions of the car’s ignition system are unpleasant because any of them is always accompanied by serious interruptions in the engine’s operation or its complete stop. The main sign of a malfunctioning ignition system is the complete absence or “weak” spark between the electrodes of the spark plugs. What to do if there is no spark, and where to look for it? Read about this and more in our material.

Most often, the spark disappears precisely at the moment when you need to go somewhere. In order not to push the car to the nearest car service center, it is important to understand what the operation of the ignition system depends on, then finding the missing spark will not cause any particular difficulties.

At the end of this article, watch the video instructions for finding a spark in the ignition system of VAZ cars.

And below we propose to get acquainted with the algorithm for searching for a missing spark in a car’s ignition system.

No spark at ignition coil

Why is there no spark on the ignition coil, where to look for a fault?

If there is no spark, it is recommended to first inspect the blocks and wires of the ignition system. If there is water, dirt or oil on the wires or block, wipe them with a dry cloth. Then try to start the engine, maybe this time it will start. If the engine does not start, inspect the high voltage wires

It is important to know that the wires should not be “loose”, they should be neat without breaking the insulation. If any violations are detected in the insulation, the wires are replaced with new ones.

Next, we check all the contacts; to do this, just rub them with your hand. No spark? Then perhaps the fault lies in the spark plugs that do not work, perhaps there is a short to ground, the wires of the low voltage circuit are broken, the ignition coil or the distribution breaker is out of order.

Start looking for a spark in the spark plug wires - remove the tip of the spark plug wire from the spark plug and bring the tip to the ground at a distance of five to eight millimeters (the nearest metal part of the car that is not touched by paint), then turn on the starter for a few seconds.

Pay attention to the starter. When the starter rotates, there should be an uninterrupted bright white spark with a faint blue tint.

If the spark is red, yellow or purple, then we can say that the car's ignition system is in a faulty state. Still no spark? Then check the ignition coil.

To check the ignition coil, you need to pull out the central wire that comes from the coil from the distributor-breaker cover. With the starter rotating, by analogy with the spark plugs, we check the spark from the wire. If a spark appears, then the ignition coil is in good condition, and the fault is most likely in the distributor. If a spark does not appear, then the ignition coil is most likely faulty or there is an open circuit in the low voltage circuit.

Troubleshooting the breaker-distributor

We carefully inspect the cover of the breaker-distributor from the inside. If the cover is in good condition, then it is enough to wash it with gasoline. If cracks are visible on the cover, it is replaced with a new one. To check whether the central carbon contact of the breaker-distributor is “stuck”, just move it with your finger.

To check the integrity of the rotor insulation of the breaker-distributor, you need to lay out the central high-voltage wire from the rotor electrode with a gap, then, with the ignition on, close and open the contacts of the breaker by hand. If sparks appear in the gap, then we can talk about a rotor malfunction. In this case, the rotor is replaced.

To check the low voltage circuit, you will need a “control” 12-volt lamp with a power of no more than 3 watts. The lamp is connected on one side to the low voltage terminal, and on the other side it is connected to the vehicle ground. Then we manually close the contacts of the breaker-distributor and turn on the ignition. If the low voltage circuit is working properly, the control lamp will light up when the contacts are opened, and will go out when the contacts are closed. If the light does not light up when disconnected, then the fault may be in the ignition coil, more precisely, in its primary winding or low voltage wires.

If the light glows both when the contacts are closed and when the contacts are opened, this indicates that the breaker contacts are heavily oxidized (heavily oxidized wires are cleaned and the gap is adjusted), there is a break in the wires that go from the terminal to the lever, a break in the wire connecting the movable interrupter-distributor disk with housing.

No spark from the ignition coil possible causes

A situation in which the engine does not start the first time, or does not start at all, can hardly be called pleasant. Experienced motorists know that any malfunction of the ignition system leads to partial and often even complete failure of the car engine.

So, if your car won't start, the reasons are:

• no current signals are sent to the ignition coil; • fuel does not reach the carburetor; • current from the ignition coil does not enter the distributor; • reason there is no spark from the ignition coil; • no spark passes between the electrodes of the spark plug; • fuel liquid does not enter the combustion chamber ;• the ignition distributor is broken.

The engine may also be blocked by the starter. But before checking the starter, inspect the condition of the electric motor winding; if it is not damaged, then the starter is most likely working

Pay attention to the ignition coil

The ignition coil is the converter of low voltage current to high voltage current in a vehicle's ignition system.

Malfunctions of the ignition coil are expressed by the following actions of the car:

• decrease in engine operating intensity; • problems in starting the engine; • sharp decrease in minimum engine speed, and interruption of its operation when idling the vehicle; • increase in fuel costs.

How to check the ignition coil

Inspect this mechanism for oil stains and cracks. If the surface of the coil is not perfectly clean, wipe off the dirt with a dry cloth, otherwise it may cause high voltage leakage

Also pay attention to the ignition system wires; they must be dry and without external damage. Move the high-voltage wires with your hand and try to start the car

If this does not work, then you will have to check the ignition system more carefully.

To diagnose the condition of the spark plugs, take two high-voltage wires, having first removed them from the distributor cap. Place the wires at a distance of 5-7 mm from the car engine and wait for the reaction. If the system is fully operational, then when the starter is cranked, a blue spark will appear in this gap. If there is no spark or a color other than blue, check the ignition coil.

The coil is checked in the same way. Remove the wire that goes from the coil to the distributor-breaker (distributor), and, by analogy with checking the spark plugs, with the starter running, bring the wire to the ground of the car. If there is no spark from the coil, then it is faulty.

Connect the ignition coil to an ohmmeter to check for breaks in the wires. Check the primary and secondary windings. The absence of holes will be confirmed by the ohmmeter readings: 3 Ohms and 7000 Ohms in the primary and secondary windings, respectively. If the resistance is less than the standard values, then you are most likely in danger of replacing the ignition coil. Check that the coil wires are connected correctly and its insulation. If the wires are tangled together, correct this by untangling them and positioning them correctly. Use an ammeter to check the current in the circuit. To do this, connect the contacts of the distributor and turn on the ignition. The current strength displayed by the device should not be higher than that set for your car. If the current value is greater than the standard value, it means that there is a break in the coil winding caused by a short circuit.

A malfunction in the operation of the ignition coil most often occurs when the ignition system is turned on when the engine is turned off. As a result, the insulation of high-voltage wires overheats, cracks, and crumbles over time, thus causing a short circuit.

If a faulty ignition coil is detected, it can be repaired or replaced with a new one. Repairing the ignition coil consists of separating the mechanism into parts; checking for cracks, chips, scratches; cleaning up damage; restoring the ideal surface of the shell by gluing them with a special compound. Replacing the ignition coil with a new coil with exactly the same characteristics is possible. Connect the ignition coil with the utmost care, take special care to ensure the correct connection of the wires. Otherwise, the contacts may overheat and short circuit.

The appearance of a spark, correct readings of the ohmmeter and ammeter, indicate the serviceability of the unit being tested, and the breakdown of another component of the ignition system. The absence of a spark in the car system can also cause the following problem: the car does not start - the starter turns, there are cases when replacing the ignition switch helps.

No spark from the ignition coil - possible reasons

1 (20%) 1 vote

UAZ Patriot Iveco does not start from the starter. — AutoMastera.net

| Reply Thank you!52 Props Complaint |

Absent Age: 56 years old

RU | Edited by: Pakkard on 26-3-2018 19:36 The pressure sensor can be checked by removing the chip from the injection pump pressure regulator. When the regulator is turned off (on scroll), the pump will raise the pressure in the rail to maximum, that is, until the emergency valve is activated. The sensor will display the pressure in the rail. It’s unlikely that this is the problem; the pressure sensor on F1 is practically eternal. |

borzoi13(26-3-2018 20:00)

Answer Like Dislike Thank you!94 Props Complaint Absent Age: 26 years old

RU | It shouldn’t be pouring into the return line at the starter, it won’t pick up the starter, you should get at least 180 bar so that at least it starts to pick up))) a simple check is a plug on the fuel rail, in place of the supposedly faulty injector! |

Absent Age: 56 years old

RU | 7# |

Source: https://avtomastera.net/thread-7288-1-1.html

If there is no spark, the ignition module

The following symptoms indicate possible problems with the operation of the ignition module:

- at idle speed the engine troits;

- power decreases, the car accelerates poorly;

Engine vibration is most pronounced in two nearby cylinders, and the drop in thrust is more strongly felt during attempts to sharply accelerate the vehicle, that is, when the accelerator is pressed hard and sharply. In such a situation, the “check” light usually lights up on the dashboard of most cars.

If checking the spark plugs and high-voltage wires does not reveal any problems, then the ignition module should be checked with a tester. The test consists of connecting one output of the tester to the module connector, and powering the other to ground. Then the engine can be started. A tester reading of 12 V is evidence that the module is OK. A deviation in the instrument readings from the norm may indicate either the need to replace the module itself or to check/replace the corresponding fuses.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!