Connecting high-voltage wires ZMZ 405, ZMZ 406

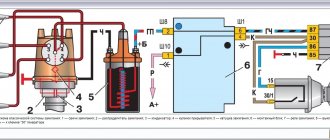

ZMZ carburetor and Euro-2 engines are equipped with a DIS (Double Ignition System) ignition system.

The DIS system uses ignition coils with two high-voltage wires. Each coil operates a corresponding pair of cylinders.

The first coil works with 1 and 4 cylinders, the second coil works with 2 and 3 cylinders.

How to connect the ignition coils?

The ignition coil of cylinders 1 and 4 is located closer to the intake manifold, the coil of cylinders 2 and 3 is closer to the exhaust manifold.

Low-voltage coil wires must be connected to the coil in pairs. The pair of wires for coil 1-4 is slightly shorter than the pair of wires for coil 2-3.

Within the pair, it does not matter which contact is connected to which wire - the coils are non-polar. Also, within the pair, it does not matter which high-voltage wire goes to which cylinder.

Let's look at an example (see photo)

Coil 1 control (cylinders 1 and 4) – green and yellow wires. This pair connects strictly to the coil of cylinders 1 and 4!

Low voltage circuit - polarity is not important - can be connected:

Option 1: The top coil contact is yellow, the bottom contact is green.

Option 2: The top coil contact is green, the bottom contact is yellow.

High voltage outputs – polarity is not important – can be connected:

Option 1: Top outlet for cylinder 1, bottom outlet for cylinder 4.

Option 2: Top outlet for cylinder 4, bottom outlet for cylinder 1.

Coil 2 control (cylinders 2 and 3) – blue and yellow wires. This pair is connected strictly to the coil of cylinders 2 and 3! Further - similar to pair 1-4 - the polarity within the pair is not important.

The determining factor when connecting pairs of low-voltage and high-voltage wires to the corresponding ignition coil is the correctness of their routing. The wires should not be too tight, bent too much, and should not rub against fixed parts of the engine or other wires.

Another article about high-voltage wires ZMZ 405, 406 - read so as not to repeat this mistake.

Source

What are the requirements for spark plug wires?

Any conductor has a certain service life. If the cables are laid in a bundle, have an outer braid and are fixed permanently (protected from vibration loads), the service life is equal to the life expectancy of the car. Another thing is the high-voltage ignition coil wire. It is located in the epicenter of unfavorable conditions: vibration, high temperature (as well as changes in winter), gasoline vapors, therefore high demands are placed on the quality of insulation of high-voltage wires and the core:

- The conductors are exclusively copper (as is known, this material has the lowest resistance), but the protective layer can be silicone or rubber. Other insulation materials, although they have good protection, are not soft enough. Another requirement for high-voltage wires is elasticity. Otherwise, the surface will simply crack due to constant vibration;

- Shell thickness is a compromise. If a breakdown of high-voltage wires occurs, a spark will form between the central core and the motor housing. The voltage will not reach the spark plug, but the presence of a sparking conductor in the engine compartment, to put it mildly, is not useful for the car. The other side of the coin is that a wire that is too thick is inconvenient to install, it is inelastic, which makes installation and maintenance difficult;

- The length of high-voltage wires is another headache for the manufacturer. From Ohm's law it is known: the shorter the conductor, the less losses for electric current. In a car, it is not so easy to place all the interacting components next to each other. Mounting the ignition coil above the spark plug wells is good for electricians, but bad for builders. In addition, it is desirable that the cables be of similar length, so the connection diagram for high-voltage wires is carefully calculated, and replacing the cables with universal ones means disrupting the operation of the entire ignition system on the car.

Connecting high-voltage wires ZMZ 405, ZMZ 406

ZMZ carburetor and Euro-2 engines are equipped with a DIS (Double Ignition System) ignition system.

The DIS system uses ignition coils with two high-voltage wires. Each coil operates a corresponding pair of cylinders.

The first coil works with 1 and 4 cylinders, the second coil works with 2 and 3 cylinders.

How to connect the ignition coils?

The ignition coil of cylinders 1 and 4 is located closer to the intake manifold, the coil of cylinders 2 and 3 is closer to the exhaust manifold.

Low-voltage coil wires must be connected to the coil in pairs. The pair of wires for coil 1-4 is slightly shorter than the pair of wires for coil 2-3.

Within the pair, it does not matter which contact is connected to which wire - the coils are non-polar. Also, within the pair, it does not matter which high-voltage wire goes to which cylinder.

Let's look at an example (see photo)

Coil 1 control (cylinders 1 and 4) – green and yellow wires. This pair connects strictly to the coil of cylinders 1 and 4!

Low voltage circuit - polarity is not important - can be connected:

Option 1: The top coil contact is yellow, the bottom contact is green.

Option 2: The top coil contact is green, the bottom contact is yellow.

High voltage outputs – polarity is not important – can be connected:

Option 1: Top outlet for cylinder 1, bottom outlet for cylinder 4.

Option 2: Top outlet for cylinder 4, bottom outlet for cylinder 1.

Coil 2 control (cylinders 2 and 3) – blue and yellow wires. This pair is connected strictly to the coil of cylinders 2 and 3! Further - similar to pair 1-4 - the polarity within the pair is not important.

The determining factor when connecting pairs of low-voltage and high-voltage wires to the corresponding ignition coil is the correctness of their routing. The wires should not be too tight, bent too much, and should not rub against fixed parts of the engine or other wires.

Another article about high-voltage wires ZMZ 405, 406 - read so as not to repeat this mistake.

Wiring diagram GAZelle 406: device features

Very often, Gazelle owners, when replacing power units from carburetor versions to injection ones, are faced with the need to replace the electronic wiring in the car, since there are severe differences in the electronic circuit.

But a complete replacement is not always justified, since the repair does not affect other electronic devices except the ignition and fuel injection systems.

Accordingly, when planning to replace the engine on a Gazelle, owners give preference to a more modern injection engine, for example ZMZ-4061 or ZMZ-4063.

Typically, GAZelle produced before 2001 and having carburetor versions of power units require six months of repairs.

At that time, a 402 engine was often installed, and the GAZelle for the 406 engine, which appeared in the car plant’s production program in 1998, had its own design features that were not compatible with various types of engines.

Parameters of the main components of the ZMZ-406 engine

The engine is gasoline, four-cylinder, in-line with an integrated microprocessor control system for fuel injection and ignition.

The ZMZ-406 engine is installed on GAZ-3110 Volga passenger cars and GAZ-3302 Gazelle trucks.

The main design features of the ZMZ-406 engine of the GAZ-3110 Volga, Gazelle GAZ-3302 cars are the upper (in the cylinder head) arrangement of two camshafts with the installation of four valves per cylinder (two inlet and two exhaust).

Increasing the compression ratio to 9.3 (instead of 8.2 on the 402 model engine) due to a combustion chamber with a central spark plug, using a system of distributed (alternately in accordance with the order of operation of the cylinders) fuel injection into the intake pipe using electromagnetic injectors (instead of carburetor supply) .

Checking the spark plugs yourself

According to the wiring diagram for engines 405, 406 and 409, spark plugs are used to transfer spark from the switchgear to the engine cylinders. If the operation of the SZ is disrupted, this may affect the quality of the motor as a whole.

To check devices you will need an assistant:

- You need to disconnect the high-voltage wire from the first SZ.

- Using a key, the product is unscrewed from its seat.

- One end of the device from the electrode side should be brought to the engine or metal on the car body, the distance between the electrode and the ground should be about 1-2 mm.

- The assistant then turns the starter to try to start the engine. If at the moment of cranking a spark jumps between the electrode and the body, this indicates that the product is operational. In the same way, you need to check each SZ. Please note that problems with spark supply can also be caused by improper operation of the distributor, as well as damage to high-voltage wires.

Engine Description

Previously, the engine was designed for newfangled power and ignition systems, which were controlled by a microprocessor.

This engine was the first to be equipped with four valves per cylinder, with hydraulic lifters and two camshafts with a double chain drive. An electronic fuel supply system and electronic ignition were also installed.

The four cylinders have an in-line arrangement, a water jacket and controlled fuel injection.

The ZMZ-406 injector runs on A-92 gasoline. Previously, a carburetor version of the 4061 engine was produced, which ran on seventy-sixth gasoline. It had limitations in terms of release.

The unit is unpretentious in maintenance. It has a high degree of reliability. Later, on its basis, ZMZ-405 and 409 units were developed, as well as a diesel version of the engine labeled ZMZ-514.

The disadvantages of the engine include the cumbersome nature of the gas distribution mechanism drive, which is explained by its low quality of workmanship and a number of technological shortcomings.

Design

These parts can come from a wide variety of manufacturers and may have different designs. Candles also differ in materials. By design, these elements are divided into two-electrode and multi-electrode.

So, in a part that is equipped with two electrodes - one central and one side electrode. In the second case there are more than one side ones. A larger number of electrodes allows for higher reliability, durability and efficiency. All this will affect the service life.

Unlike a multi-electrode solution, a classic product has only one electrode, which burns out or breaks during operation. In this case, only replacing the spark plug will help. The Gazelle, which has a multi-electrode element, is more resistant to temperatures.

Carburetor engine

The ZMZ-406 carburetor (402nd engine) has been produced since 1996 and has managed to establish itself as a simple and reliable unit. This device develops a power of 110 horsepower. The fuel consumption of a car with this engine often depends on driving style and operating conditions. The power system of the carburetor unit is quite reliable. With timely maintenance and normal operation, using high-quality lubricants and gasoline, it can travel up to 500 thousand kilometers without serious breakdowns. Of course, with the exception of boring the crankshaft, which is necessary for this unit once every 250 thousand kilometers.

Technical differences

A unit that has exhausted its life is replaced, often giving preference to more modern versions.

Structurally, everything fits into the factory seats, and the differences, for example from the Gazelle Business, appear exclusively in the electronic wiring diagram at the location of the equipment:

- Another form of connecting blocks;

- Another device connection diagram;

- Different voltage.

Supply system

Leaving the carburetor behind, replacing the unit inevitably entails replacing the power system:

- A new gas tank is installed, since the injector must dump excess fuel back, and the ancient tank design is not applicable for this;

- The gas line is replaced (the return line is laid and connection );

- The operation of the injectors is regulated using connecting wiring.

Cooling system

The new ZMZ-406 injection engine is more demanding on the cooling system, therefore during the installation of a new unit:

- An electric fan is installed on the cooling radiator;

- The engine compartment wiring harness is being replaced.

Ignition system

On ZMZ-406 engines, ignition is carried out by igniting the fuel mixture using a microprocessor system. For all engine operating modes, the electronics sets the required ignition timing. It also performs the function of adjusting the working process of the forced idle economizer. Due to the operation of this system, the engine is distinguished by its high economic performance, exhaust gas toxicity standards are monitored, the moment of detonation is eliminated and the power of the power unit is increased. On average, a GAZelle car consumes about 8-10 liters of gasoline per 100 kilometers under average loads. However, if you convert it to propane or methane, the “appetite” of the machine almost doubles.

Replacing wiring

Advice: replacing functional control devices on the panel due to new connectors is not justified.

Therefore, when integrating new wiring, the connection diagram in the connecting terminals only changes, and for alignment you should use the wiring diagram of the new power unit.

It is certainly not impractical to change the entire electrical wiring of the Gazelle when replacing the engine from 402 to 406.

The fact is that on newer versions of Gazelles, the connection diagram of certain devices also changed:

- Gazelle 406 wiring is integrated into the standard electrical system in the engine compartment;

- electronic components and control devices are connected using terminals;

- The voltage and correct connection are checked using testers.

After assembling the wiring into a single whole, its functionality is checked. Subsequently, the operation of the power unit is adjusted.

Conclusions: Replacing a power unit inevitably involves changing the standard electrical wiring of the car. That is why it is important to have a visual aid at hand when carrying out such an operation, and the Gazelle’s factory wiring diagram will allow you to avoid mistakes.

In any car, the ignition system plays one of the main functions. It is thanks to its correct operation that the correct operation of the power unit is ensured both when starting it and during operation of the car. What spark plugs should be used in Gazelle cars, for what reasons can the ZMZ-406 ignition coil fail, and how to install the ignition yourself? You can find answers to these and other questions below.

Ignition diagnostic mode

When the car ignition is turned on, the ZMZ-406 engine diagnostic system automatically comes into operation (the ZMZ-405 carburetor is no exception). The fact that the electronics are working properly is indicated by a light sensor. It should go out when the engine starts.

If the diode continues to light, this indicates a malfunction of the elements and parts of the electronic ignition system. In this case, the breakdown should be repaired immediately.

HOW OFTEN SHOULD I CHANGE GDP?

According to the advice of Avto-VAZ, replacement of high-voltage wires of the VAZ 2114 should be done every 30 thousand kilometers. In practice, motorists rarely comply with these replacement deadlines, since if the wires do not have any mechanical damage, they can travel about 100-150 thousand km.

When the service life is exceeded, the internal resistance of the GDP increases, which has a bad effect on the transmission of the electronic pulse. This leads to problems with ignition and acceleration dynamics, since when there is a delay in the supply of current to the spark plugs, the normal cycle of the engine is disrupted.

READ How to make American cars on a VAZ

Change the wires every 25-30 thousand km and everything will be fine

Injection motor

In terms of technical characteristics and components, an engine with an injection power system is not very different from the carburetor analogue of the 405 model.

With proper operation, this unit is no less reliable and practical than with a carburetor, and in addition has its own advantages:

- Stable idle speed.

- Low level of harmful emissions into the atmosphere.

- The efficiency of the ZMZ-406 injector is much higher than its analogue with a carburetor, since the fuel mixture is supplied in a timely manner and in the right quantity. Accordingly, fuel savings are obvious.

- Improved fuel economy.

- Does not require prolonged engine warm-up in winter.

The only disadvantage of an injection engine is the high cost of repair and maintenance of the system.

Popular foreign analogues

German spark plugs “Gazelle” (405 engine) “digest” well. They are also suitable for the 406 unit. Popular brands include Bosch products with models W8D and WR8D, products from Brisk LR17Y or LR17YC. Champion also produces spark plugs for the Gazelle - models NR11Y and NR11YC. Another popular brand is NGK. This manufacturer's models BPR5E and BPR5ES are suitable for these motors.

Denso also offers two models - W16EXP and W16EXP-U.

If you need a spark plug (Gazelle 4216), then all the brands and models presented will also fit this engine. The main thing is that the model has a long thread.

Block head

All engine modifications were equipped with one head, which complied with Euro 2 requirements. With the introduction of additional Euro 3 requirements, it was refined and improved. It is not interchangeable with the previous model.

The new head does not have idle system grooves; now their functions are assigned to an electronically controlled throttle. The front wall of the part is equipped with holes for attaching the protective chain cover, and on the left side there are ebbs for mounting the intake system receiver brackets. The part has pressed cast iron inserts and valve guides. The latter do not require periodic adjustment, since they are driven by cylindrical pushers with hydraulic compensators. The modernized ZMZ-406 head has decreased in weight by 1.3 kilograms. When installing it on the engine, use a metal multilayer head gasket.

FakeHeader

Comments 15

I read it, even the first time))

And my engine dangles back and forth at idle. CHANGED SPARKLES WIRES COILS MARKS SENSORS ALL