Due to the lack of the required number of guarded parking lots, car owners install not only alarms on their cars, but also secret bolts on the wheels. Fastening elements with non-standard head shapes are called “secret”. They cannot be unscrewed with a balloon tool; fastening can only be done with the special tool that comes with the kit.

How to change a wheel

The wheels, as always, break at the most inopportune moment.

Therefore, you must always be prepared for this trouble. I think there is no point in saying that there should be a working and inflated spare tire in the trunk. Driver's actions to change a wheel:

- Block the car's wheels to prevent it from moving.

- If the car wheels are equipped with hubcaps, then using a screwdriver or the flat end of a wheelbrace, you need to pry and remove the hubcap from the damaged wheel.

- Remove the spare tire from the trunk of the car.

- Using a wheel wrench, loosen the mounting bolts that hold the wheel. In this case, you need to know which bolts you have - left-handed or right-handed. The type of thread determines which direction the wrench should be turned. Typically, right-hand threaded bolts (which should be unscrewed counterclockwise) are used, but sometimes, on the left side of the vehicle there may be left-hand threaded bolts (which should be unscrewed clockwise). Look carefully at the bolts - if the letters “R” and “L” are visible in the center of the bolt, then: R (right) – right-hand thread; L (left) – left-hand thread.

- Place the wheel wrench on the bolt and loosen it until it can be turned freely by hand. Do this operation in a circle with all the bolts. The bolts can be very tight, so if you can't loosen it with your hands, you can use your feet or improvised means (a piece of pipe) to increase the strength or length of the lever.

- Place the jack in its designated location and lift the car so that the wheel rotates freely in the air.

- Install supports and lower the car onto them (the wheel should still rotate freely).

- Unscrew the loosened bolts by hand and remove the broken wheel from the studs.

- Roll the broken tire to the trunk and put it in place of the spare wheel.

- Place the spare tire on the studs and secure it with the bolts.

- Lightly tighten the bolts with a wheel wrench until the wheel is securely in place.

- Raise the car on a jack and remove the jack stands.

- Lower the car to the ground and remove the jack.

- BE SURE to tighten all the wheel bolts! Pull with all your strength - don’t be afraid, you won’t break the thread, but the wheel will be securely fixed.

- Reinstall the wheel cover. To do this, place it opposite the hooks and drive it into place with the back of your hand. Tap it a couple of times in several places to make sure it sits evenly and securely. If this cannot be done, then this can be done later. The cap mainly plays a decorative role, and it is quite possible to drive without it. But it is highly recommended to install the cap in the near future, because... it protects the brake pads and bearings from dirt and dust.

- Don't forget to take all tools and wheel blocking chocks with you.

- Don’t delay repairing a flat tire, otherwise if you have another accident, you will have nothing to replace the flat tire with. A broken tire can be repaired at any tire shop. Depending on the damage, the technician will offer you repair options.

Top of page

Source: vaz-2101-07.ru

Wheel fastening

Wheels become loose for many reasons, but the most common is incorrect tightening of the nuts. Broken studs as a result of loose nuts are common. For the same reason, it often breaks holes on disks and deforms nuts and studs. “Twisting” is also not recommended: if you twist with more force than necessary, the disk and studs can be damaged, and the wheel will come off the vehicle when moving. If you tighten the nut to the recommended torque (which generally depends on the size of the nut), it will not come off. But periodically you should still check the tightness and tighten the wheel nuts.

The forces that hold the wheel rim and hub together are created by the frictional force in the threads of the nut on the stud and the frictional force of the nut on the wheel rim. Before the wheel nuts are securely fastened, they will have to be tightened several times, especially on new wheels, in which the paint layer at the contact points of the nuts and the disk, breaking down, further weakens the friction forces. On a new truck, the tightening of the nuts should be checked after the first 50...70 and 100...150 km, and then at each regular maintenance, the frequency of which depends on the operating conditions: this could be after 15 thousand km, or maybe after just 3 thousand. km.

The fastening of trailer wheels should be tightened more often than the wheels of a tractor, since when moving the trailer tosses from side to side and lateral forces act on its wheels, which “loose” and weaken the fastening of the wheels.

Modern wheels are secured with bevel (older design) or flange nuts. The advantages of fastening with flange nuts are that there is no chamfer at the fastening holes and, therefore, such a defect as wear (“breaking”) of the chamfer is eliminated. In addition, with the same tightening torque, the pressing force of a flange nut is higher than that of a conical nut. When fastening with conical nuts, if the angle of the nut's cone and the chamfer on the disk do not match (when using a non-original nut), the nut may become firmly stuck in the hole and cannot be unscrewed. For flange nuts, it is recommended to apply lubricant between the hex and washer. In this case, it is necessary to ensure that the lubricant does not get on the surface of the washer pressing against the disk and does not weaken the friction force.

Over time, the force with which the mating surfaces are pressed weakens, for example, if the threads are worn. Do not attempt to repair worn wheel stud threads in any way. If the stud or nut is faulty, it should be replaced.

Also, the pressing force of the nut decreases under the influence of vibration or if the surface to which the nut is pressed is covered with rust. But you can’t unscrew a rusted nut, and you can’t move a wheel rim from its place with any force, and sometimes you have to heat up the rusted nuts by welding or even cut off the studs by welding. Therefore, corrosion must be combated in order to be able to replace the wheel.

Corrosion not only weakens the tightening force of the wheel nuts. During the corrosion process, chips and depressions appear on the surface of the disk, thereby reducing the effective thickness of the part and weakening it. The smallest surface defect becomes a stress concentrator. Over time, cracks develop from the cracks. Typically, a regular wheel maintenance program includes removing rust and painting the rims. Once the rust has been removed (eg by wire brushing or sandblasting), the disc should be inspected for signs of cracking or pitting. If corrosion is minimal, the defects can be sanded down, the disc painted and used again, but if serious defects are found, the disc cannot be used.

A torque wrench measures the resistance to rotation of a nut. If the stud is new and there are small burrs on the threads, the torque resistance will be slightly higher than designed. After the nut is unscrewed, the second time the tightening torque on the “clean” thread will be less than the first time.

When tinting the rims, you need to make sure that the paint does not get on the threads of the studs, because when tightening the nuts, the paint will create additional resistance, the torque wrench readings will be incorrect and the tightening force will be insufficient. The layer of paint on the surface of the disk in contact with the nut should not exceed 0.1 mm. A thicker layer of paint can cause weakening of the friction forces and wheel fastening. Some mechanics bolt the wheels on first and then paint the rims and nuts. In this case, the paint protects the exposed threads of the studs from corrosion.

A large amount of rust on the threads of a stud or nut will also create additional resistance and lead to incorrect tightening torque. A few drops of oil applied to the corroded area of the thread can sometimes help solve this problem. However, oil should be applied very carefully - if it gets onto the seat of the nut on the disk, the friction force will weaken, the torque wrench readings when tightening will be incorrect and the risk of the nut unscrewing itself will increase. This applies primarily to wheels that are mounted on studs with conical nuts. However, many drivers do not wait for corrosion to appear on the threads, but always, when tightening conical wheel nuts, carefully apply grease to the threads so that it does not get on the conical part of the nut and into the holes in the disk.

Read also: Forged railings with wood

As a result of play and impacts when the machine moves, the surface of the nut adjacent to the disc may be damaged. Discs and studs are also damaged, and the studs may break off, and the disc often splits.

After making sure that the wheel mounting is in order, you can proceed to checking the wheel bearings and ball joints.

Source

see also

How to check the hub

- 37 0 22k

Wheel bearing grease

- 112 4 125k

Wheel bearing

- 28 0 42k

Hub

- 0 1 69k

Car brake system maintenance

- 20 0 65k

Many will agree that unscrewing the hub nut is an activity that can be punished in court; it is too inconvenient and difficult even for a physically strong person with all the necessary tools. However, since it is not always possible to choose the easiest one (option One, also known as the Main one!) - sending the car to a service station, where they will not only unscrew it but also carry out subsequent repairs. Then you will have to figure out the task yourself, using the easiest and most effective method possible.

Which way does the hub nut unscrew?

Yes, you may very well be one of the lucky ones who won't need any extra effort as the problem with unscrewing the hub nut may simply be a matter of going in the wrong direction.

So, we take the wrench and, when your car is far from new, try, if the nut does not lock, on the left wheel, unscrew the nut counterclockwise, and on the right wheel, unscrew it clockwise. In modern brands, it is usually necessary to unscrew the hub counterclockwise .

Before you start unscrewing the hub nut, do not forget that it comes off when the car is standing on the wheels and the stops are placed under them. On the side from which the nut will be unscrewed, a stop is securely installed.

Although if the nut is located deep and the brake disc is ventilated, then you can try to unscrew it (fixing it with a powerful screwdriver) and only after making sure that the car is securely secured. Remember about personal safety precautions: protect your eyes, do not overdo it, because in the spirit of enthusiasm you can accidentally get hurt or damage the car body.

Unfortunately, in most cases, it is not enough to use a wrench with a large lever; you have to use additional tools and special mixtures. Let's consider the other options.

Design features of car wheel mounting bolts

Product parameters must correspond to the characteristics of a car wheel. The main parameters of bolts include:

Cars

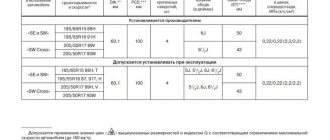

Nuts of types “A”, “B” and “C” are available with six types of small format threads. For M12 the thread pitch can be 1.25 mm, for M12, 14, 18, 20, 22 the thread pitch is 1.5 mm.

Freight

Class “D” nuts are intended for truck wheels. These are M18, 20, 22 hardware with a thread pitch of 1.5 millimeters. The thread direction can be right or left. The size of the wrenches for the nuts is 17, 19, 24, 27, 30 or 32.

The easiest way to unscrew/tear off a hub nut

The easiest way can be considered the following, but it involves completely replacing the nut. Don't worry, any method does not guarantee the safety of this part. To easily unscrew or tear the hub nut out of place (an option for all brands - from VAZ to foreign cars with a groove on the shaft), you need to take:

Unscrewing the VAZ hub nut using a drill

- New nut.

- Drill or screwdriver.

- Drill up to 3 mm.

- Chisel.

- Hammer.

- You need to drill the nut along the groove to counteract it.

- Using a chisel and hammer, simply break the nut and remove it, then replace it.

- If throwing away the nut is not possible, then you will have to sweat - and in the literal sense of the word too.

How to unscrew a hub nut - the delicate way

- Tubular socket wrench - “wrench”. The tool must be made of high-strength steel.

- Powerful screwdriver.

- Iron pipe.

- WD-40.

- Wire brush.

- Clean the threads from dirt using a brush with metal bristles. Now you should soak the hub nut with penetrating lubricant. For example, WD-40.

- We impregnate the hub with the penetrating mixture. You can rest for 10-15 minutes, and then you should put the wrench head on the nut and hit it with a hammer several times, gradually increasing the force of the blow. Just don’t overdo it: the point of this action is to slightly deform the nut, which will make it easier to remove. And immediately after the impacts, you should try to unscrew the hub nut on a VAZ or a car of another brand.

Remove the nut from the car: force method

- Lever made of pipe (length of at least one and a half meters).

- Powerful socket wrench (450 mm).

- Head of the appropriate size.

Place the head of the wrench on the hub nut, insert the wrench and place the pipe on the handle. Gradually increasing the applied effort, we unscrew the part.

As experienced car enthusiasts say, few hub nuts can resist for a long time if you use a Zilov cylinder!

How to unscrew a broken bolt

What to do, what to use and how to unscrew it if a pin or bolt is torn off. Video tips on how to independently unscrew a broken bolt/stud in an engine or manifold. A reliable way to unscrew if the head of a bolt has been torn off Read more

Replacing the rear wheel bearing of a VAZ 2111

To replace the rear wheel bearing on VAZ 2110, 2111, 2112 cars you will need: a “30” socket, “10” and “15” keys, a hammer, duckbills and a long pipe as a lever. See details clearly Read more

A wheel hub is a part designed to mount a car wheel on an axle called an axle. Hub bearings are a key element not only of the hub, but also of the entire chassis of the machine. Read more

Unscrewing the hub nut on a VAZ: “burn, hit and twist!”

Now let’s look at the methods that may be the only effective ones in your case, but that doesn’t make them any less radical, even barbaric.

Strong hammer blows

If you hit the hub, you hit the bearing! If you are going to make a replacement, then go ahead! If you value the bearing, avoid this method.

Warming up the hub nut with a burner. Not recommended!

Using the burner

The law of physics is guaranteed to work, and the body (read: hub nut) will expand. And this will make it much easier to remove the stubborn part. There is one “but”: not only this one part heats up, but also everything else in the area of the burner. For example, a bearing. And it’s better not to allow this. As a more gentle option, we can suggest using a soldering iron and... patience. You'll need it.

Jumping on a lever

A chisel will help you remove the hub nut.

The “method” is fraught with the danger of unexpectedly breaking off the edges of the nut, breaking the key, and so on. Just don't do it.

Take a chisel and make notches on the edges

An increase in diameter, of course, makes the hub nut unsuitable for further use, but it will be easy to unscrew it.

Chemical

Now we will consider methods for those who do not rely on the help of physics, but want to solve the problem with the help of chemistry. Your laboratory should have: kerosene, white spirit, acidified sulfuric acid, zinc, plasticine, hammer, water, sandpaper, wrench, chisel.

Attributes of the chemical method for unscrewing the nut

We moisten the nut and bolt with kerosene (experienced people recommend making a mixture of White Spirit and kerosene), applying a swab to them, it doesn’t matter whether it’s cotton or gauze. After some time - from an hour to a day, and with repeated attempts, you may find that the hub nut can be easily unscrewed. But even here you cannot do without force: at a minimum, you will probably have to work with sandpaper to clean the parts from rust. If even after this things don’t work, you should help with a hammer: tap it on the edges of the hub nut.

If in this case you are not successful, make a small container out of plasticine, secure the hub nut on top, pour water with sulfuric acid into it, and put zinc in the container. A chemical reaction begins that does a very good job of removing rust. Usually a day is enough for even advanced corrosion to go away from a part. Finish the job with a wrench. But this method is valid only in the case when the reason is that the nut is tightly stuck and/or rusted, and if it was simply tightened, neglecting the required tightening torque (to “be sure”), then you just need to tighten it.

What is the result..

As you can see, unscrewing the hub nut is not an easy task, but it can be solved. Please note that the first step is to try to preserve the hub nut by using penetrating fluids such as Vedeshka. Physical efforts to twist the hub should be moderate. And, of course, you should refrain from strong blows and heating with a torch, as methods that can render not only the nut, but also the bearing unusable.

Source: etlib.ru

Preparing to remove wheels

Before starting this whole process, you should set the car to the handbrake, after which you can proceed directly to further actions.

It is useful to have some kind of tool with you, since without it it will be quite difficult. A screwdriver, a wrench and, quite possibly, a secret key will come in handy.

Note! Some wheels use security nuts to prevent theft and require a special wrench to remove them.

When you have all the necessary tools and the car is on the handbrake, the first thing you need to do is remove the wheel nut caps. It should be borne in mind that some caps are held on by bolts. And if you do not unscrew these bolts, the caps will not come off.

Accordingly, you always need to take into account exactly how the caps are secured: with bolts or nuts.

Reasons for self-loosening of bolts and how to avoid it

Home > Articles > Why did the wheel come loose?

Experienced drivers will probably remember from their driving lives cases when suddenly, out of the blue, a wheel came loose. Why does this happen and how can such a situation arise?

Of course, the vast majority of drivers immediately blame the tire fitters, who, in their opinion, did not tighten the wheels. However, this is not always the case and there can be quite a few reasons for spontaneous wheel turning. For example, how could a wheel tightened with a torque wrench with a torque regulated by the car manufacturer be unscrewed? Faulty key? No, the wrench has been checked and the tightening torque matches the reference torque head. But why, even in this case, do the wheels sometimes unscrew?

Tightening torques for popular models

The variety of cars on the Russian market is amazing. But there are certain categories of the most popular models that are more often found on local roads than others.

Let us give examples of the required tightening torques for the most common and popular cars in Russia.

These are just the basic parameters that you should focus on. Certain wheels and fasteners are installed from the factory. But the motorist can replace them. Then the tightening values will change to ones that will differ noticeably from the factory regulations.

Source

How to unscrew a stuck bolt on a wheel if you don’t have a wrench at hand

We live in a world where high technology plays an extremely important role. But you can’t unscrew the bolts in a wheel with an electron microscope or a super-sophisticated smartphone if it’s also rusty and strongly stuck to the wheel.

That is why you should always have a wrench and other tools with you that will help you change a tire on the road. It is worth listening to the opinion of specialists who will help you get out of this sticky situation without losing face or time.

What should a driver have in his trunk?

In addition to the above actions, there are a number of preventive measures in case the need to replace a wheel arises:

- There must be a spare wheel in the trunk or on the body of the car. Its absence can cause a lot of problems, especially in a desert place.

- The tools you will need are a jack and a wheel wrench.

- The tire is inflated using a pump; a pressure gauge is also needed to measure the pressure in the tire.

- It would be useful to have clamps (“shoes”) or wheel chocks for wheels, a hammer for them, and special clothing (gloves, a robe) to protect against dirt.

All devices, especially the jack, which will bear a significant load, must be of high quality. It should be noted that the tools that came with the machine when you purchased it are not always of the proper quality.

What should you do if you don’t have a wrench when you need to unscrew the bolts on a wheel?

The situation, of course, does not often occur. Still, no matter how lazy our drivers are, they still always carry some kind of tool with them.

And to change a wheel, there are always special devices that will help you quickly change wheels. But what if there is no special tool for unscrewing the bolts? What if we also imagine a scenario where the bolts are rusty and only Hercules can unscrew them?

In this case, experts advise the following:

- You can use the old army method of unscrewing rusted bolts . Often in military equipment the bolts are not unscrewed for years, and even a wrench will not help to unscrew the bolts to carry out repairs. So it remains for the army craftsmen to come up with everything on the fly. You can heat the bolts with a strong flame, and in this case the bolts must be subject to even slight physical impact.

- There is an option to use lubricating oil, which will also help you unscrew the bolt without difficulty.

- Some experts advise using not an ordinary impact wrench , but one that has several gears. The more of them there are, the less force the driver can exert on each rusted nut in the wheel, and even a fragile woman can unscrew all the bolts without extra effort.

As you can see, there are not too many options. That is why experts recommend not using wheel bolts and taking tools with you on the road, especially if the driver goes out of town. Changing a wheel is simple, but if you let the bolts rust, the process will become a real pain.

What should I do to prevent rust from forming on wheel bolts?

The topic is quite interesting and extensive, which will help every person who has a car not to get into a difficult situation on the road.

Here you don’t even need to visit a car service center often or change wheels - you just need to periodically lubricate the bolts generously with lubricating oil. The oil will also prevent the bolts from freezing in winter, and at the same time the oil will protect the bolts from rust formation.

Well-lubricated bolts are easier to unscrew and this can be done even without tools if you have a pair of strong hands. Oil is a motorist's best friend.

That is why it is worth using it often for moving elements in a car, in order to protect it from the corrosion process, and to prevent the bolts on the wheels from being unscrewed without strong efforts.

Source: dixnews.ru

Preliminary actions and tools

Knowing how to change a tire on a car yourself is necessary because help in this process is not always available. For example, if a puncture occurs on a country road, vehicle maintenance and repair through car services is not available.

The first preparatory stages depend on where the wheel is being replaced. In any case, you need to check whether the car is on the handbrake, otherwise known as the parking brake. If the car is on the road, then first roll it to the side of the road and put up a warning triangle. It is also advisable to switch gears to first to be on the safe side and turn on the hazard lights.