When planning to purchase a new set of wheels for your car, you should never forget about the importance of wheel bolt patterns. A bolt pattern is a combination of various measured characteristics that allow you to select the appropriate set that fully matches the characteristics of a particular vehicle. To take measurements, you can use tools and do the work yourself. An alternative is special compatibility tables. Car owners who have only recently started operating their cars on their own do not fully understand the complexity of choosing wheels for their vehicle. The kits can differ significantly from each other and be intended for completely different cars, although externally it is extremely difficult to find the difference between them.

Method for determining the bolt pattern of wheel rims.

Bolt pattern tables 4×98, 4×100, 4×108, 5×100, 5×108, 5×112

Car make Model 4x98

| VAZ | 2110-12 |

| Classic | |

| Granta | |

| Kalina | |

| Priora | |

| 2108-99 | |

| Alfa Romeo | 145 |

| 146 | |

| 33 Sport Wagon | |

| MiTo | |

| Citroen | Nemo |

| Fiat | 500 |

| Albea | |

| Barchetta | |

| Brava | |

| Bravo | |

| Bravo HGT | |

| Cinquecento | |

| Coupe | |

| Coupe 16V turbo | |

| Coupe BV6 | |

| Doblo | |

| Doblo 4X4 | |

| Fiorino | |

| Idea | |

| Linea | |

| Marea | |

| Multipla | |

| Multipla 2 | |

| Palio | |

| Panda | |

| Panda 4x4 | |

| Punto | |

| Qubo | |

| Seicento | |

| Seicento Sporting | |

| Stilo | |

| Ford | Ka |

| Lancia | Delta |

| Lybra | |

| Musa | |

| Y | |

| Ypsilon | |

| Peugeot | Bipper |

Car make Model 4x100

| Acura | EL |

| Integra | |

| BMW | Z1 |

| Chery | Amulet |

| Kimo | |

| Kimo(A) | |

| QQ6 | |

| QQ6(S21) | |

| Chevrolet | Astra |

| Aveo | |

| Cobalt | |

| COBALT SS | |

| Lanos | |

| Spark | |

| Citroen | C1 |

| C15 | |

| Daewoo | ESPERO |

| Kalos | |

| Lanos | |

| Nexia | |

| Nubira | |

| Daihatsu | Applause |

| Atrai | |

| Atrai 7 | |

| Boon | |

| Charade | |

| Cuore | |

| Coo | |

| Copen | |

| Esse | |

| Gran Move | |

| GRANDE MOVE | |

| Leeza | |

| MAX | |

| Materia | |

| Mira | |

| Move | |

| Naked | |

| Opti | |

| Pyzar | |

| Sonica | |

| Storia | |

| Sirion | |

| Trevis | |

| Tanto | |

| YRV | |

| Dacia | LOGAN |

| SANDERO | |

| Isuzu | Gemini |

| Pa Nero | |

| Piazza | |

| FAW | Vita |

| Fiat | Grande Punto |

| Punto | |

| Geely | MK |

| Otaka | |

| Vision | |

| Great Wall | GWPeri |

| Peri | |

| Hyundai | Accent |

| Amica | |

| Atos | |

| Atos Prime | |

| Getz | |

| i10 | |

| i20 | |

| Solaris | |

| VERNA | |

| Verna Hatchback | |

| Verna Sedan | |

| Honda | Accord |

| Airwave | |

| Beat | |

| Capa | |

| City | |

| Civic | |

| CIVIC VTI | |

| concerto | |

| CR-X | |

| Domani | |

| Fit | |

| FIT SPORT | |

| Freed | |

| Insight | |

| Integra | |

| Jazz | |

| JAZZ 4X4 | |

| Life | |

| Logo | |

| Mobilio | |

| Orthia | |

| That's | |

| Today | |

| Vamos | |

| Zest | |

| Kia | Picanto |

| Rio | |

| Rio II | |

| Shuma | |

| Shuma II | |

| Spectra | |

| Lifan | Smily |

| Solano | |

| Lotus | ELISE |

| EUROPA S | |

| Evora | |

| EXIGE | |

| Mazda | AZ-1 |

| AZ-3 | |

| AZ-Wagon | |

| Carol | |

| Demio | |

| Familia | |

| Lantis | |

| Laputa | |

| Revue | |

| Roadster | |

| Scrum Wagon | |

| Spiano | |

| Verisa | |

| 2 | |

| 323 | |

| MX-5 | |

| MX-5 Miata | |

| MX-5 ROADSTER | |

| MG | TF |

| ZR | |

| ZS | |

| Mini | Mini |

| Clubman | |

| Clubman S | |

| Cooper | |

| Cooper Cabrio | |

| Cooper Cabrio S | |

| COOPER CABRIOLET | |

| COOPER CABRIOLET S | |

| Cooper S | |

| Cooper S Cabrio | |

| One | |

| Mitsubishi | Carisma |

| Colt | |

| eK | |

| I | |

| Lancer | |

| Libero | |

| Minica | |

| Mirage | |

| Toppo | |

| Toppo B.J. | |

| Townbox | |

| Nissan | Be-1 |

| Bluebird | |

| Cube | |

| Figaro | |

| Luchino | |

| March | |

| Micra | |

| Micra C+C | |

| Moco | |

| Note | |

| NX | |

| OTTI | |

| Pino | |

| Presea | |

| Pulsar | |

| Rasheen | |

| Sunny | |

| Tiida | |

| Wingroad | |

| Opel | Agila |

| Agila II | |

| Astra | |

| ASTRA G | |

| Astra H | |

| COMBO | |

| COMBO TOUR | |

| Corsa | |

| Corsa B | |

| Corsa C | |

| CORSA COMBO | |

| Corsa D | |

| Calibra | |

| Meriva | |

| Tigra | |

| Tiger A | |

| Tiger B | |

| TIGRA TWINTOP | |

| Vectra | |

| Vectra A | |

| Vectra B | |

| Vita | |

| Peugeot | 107 |

| Renault | CLIO |

| CLIO 3 | |

| Clio II | |

| Clio II Sport | |

| Clio III | |

| Clio IV R | |

| Kangoo | |

| KANGOO 4WD | |

| Kangoo Compact | |

| LAGUNA | |

| LAGUNA (B56) | |

| Logan | |

| Megan II | |

| MEGANE | |

| MEGANE 2 | |

| MEGANE 2 CC | |

| MEGANE GRAND SCENIC | |

| Megane Scenic | |

| MODUS | |

| Sandero | |

| Sandero Stepway | |

| Scenic | |

| Scenic II | |

| Symbol | |

| TWINGO | |

| Rover | 25 |

| 25 STREETWISE | |

| 400 | |

| 45 | |

| Street Wise | |

| Saab | 9-2 X Aero |

| Saturn | Ion |

| S.C. | |

| Scion | xA |

| xB | |

| Seat | AROSA |

| AROSA (100) | |

| Cordoba | |

| CORDOBA (110) | |

| CORDOBA VT | |

| Skoda | Felicia |

| Subaru | Dex |

| Justy | |

| JUSTY II | |

| Justy III | |

| Justy IV | |

| Pleo | |

| R1 | |

| R2 | |

| Rex | |

| Sambar | |

| Stella | |

| Vivio | |

| Suzuki | Aerio |

| Alto | |

| BALENO | |

| Cara | |

| Cervo | |

| Cultus | |

| Every Wagon | |

| Kei | |

| Ignis | |

| Liana | |

| Liana ll | |

| MR Wagon | |

| Palette | |

| Solio | |

| Splash | |

| Swift | |

| Swift ll | |

| Twin | |

| Wagon R | |

| WAGON R+ | |

| Toyota | Allex |

| Augo | |

| Aygo | |

| bB | |

| Belta | |

| Carina | |

| Corolla | |

| Corolla II | |

| Corona | |

| Corsa | |

| Corolla Verso | |

| Cynos | |

| Duet | |

| Funcargo | |

| iQ | |

| Ist | |

| MR-S | |

| MR2 | |

| Passo | |

| Platz | |

| Porte | |

| Prius | |

| Pro Box | |

| Ractis | |

| Raum | |

| Serra | |

| Sienta | |

| Sparky | |

| Sprinter | |

| Starlet | |

| Succeed | |

| Wagon | |

| Tercel | |

| Vitz | |

| Will | |

| Yaris | |

| YARIS 1.5TS | |

| YARIS 2 | |

| YARIS D4D | |

| Yaris Verso | |

| Volkswagen | Corrado |

| Golf | |

| Jetta | |

| Lupo | |

| LUPO GTI | |

| Pointer | |

| Polo III | |

| Passat | |

| Polo | |

| Santana | |

| Vento | |

| ZAZ | Chance |

| VAZ | Largus |

| TagAZ | Accent |

| Doninvest Assol (L100) | |

| Vortex Corda |

Car make Model 4x108

| Audi | 80 |

| Cabriolet | |

| Citroen | Berlingo |

| C2 | |

| C3 | |

| C3 Picasso | |

| C3 Pluriel | |

| C3 X-TR | |

| C4 | |

| C4 COUPE | |

| C4 Picasso | |

| C5 | |

| DS3 | |

| DS4 | |

| Grand C4 | |

| Saxo | |

| SAXO VTS | |

| Xantia | |

| Xsara | |

| XSARA COUPE | |

| XSARA COUPE VTR | |

| XSARA COUPE VTS | |

| Xsara Picasso | |

| Ford | Cougar |

| COUGAR ST200 | |

| Escort | |

| Fiesta | |

| FIESTA ST | |

| Focus | |

| FOCUS RS | |

| FOCUS ST170 | |

| Fusion | |

| Ka | |

| Mondeo | |

| Puma | |

| SPORT KA | |

| STREET KA | |

| Peugeot | 1007 |

| 106 | |

| 205 | |

| 205GTI | |

| 206 | |

| 206 CC | |

| 206 S.W. | |

| 207 | |

| 3008 | |

| 306 | |

| 306 CABRIOLET | |

| 306 S16 | |

| 307 | |

| 307 CC | |

| 307 S.W. | |

| 308 | |

| 308 CC | |

| 308 S.W. | |

| 309 | |

| 405 | |

| 406 | |

| 406 COUPE | |

| 408 | |

| Partner | |

| Partner Origin VU | |

| Partner Tepee | |

| Partner VU | |

| Volvo | 850 |

| Lifan | Breez |

| Mazda | 2 |

| Saleen | S121 |

| TagAZ | Doninvest Orion (J100) |

5x100

Car makeModel

| Audi | A1 |

| A2 | |

| A3 | |

| S3 | |

| TT | |

| Chevrolet | Cavalier |

| CAVALLIER LS | |

| CAVLIER COUPE | |

| CAVLLIER COUPE Z24 | |

| Sonic | |

| Chrysler | NEON |

| Neon II | |

| PT Cruiser | |

| PT Cruiser Cabrio | |

| Sebring | |

| SEBRING CABRIOLET | |

| SEBRING COUPE | |

| SEBRING Sedan | |

| VOYAGER | |

| Dodge | Caravan |

| Neon | |

| Stratus | |

| Honda | Civic |

| Lexus | CT200h |

| MG | ZT |

| ZT-T | |

| Nissan | Sunny |

| Plymouth | |

| Neon | |

| Pontiac | |

| Sunfire | |

| SUNFIRE GT | |

| Vibe | |

| Rover | 75 |

| Saab | 9-2x |

| Scion | tC |

| xD | |

| Seat | Cordoba |

| CORDOBA (110) | |

| CORDOBA VT | |

| Ibiza | |

| IBIZA (130) | |

| IBIZA SC | |

| Skoda | Fabia |

| FABIA (130) | |

| Fabia II | |

| OCTAVIA | |

| OCTAVIA 4WD | |

| OCTAVIA SRC 4WD | |

| Octavia Tour | |

| PRACTIK | |

| Roomster | |

| Subaru | Baja |

| Alcyone | |

| Exiga | |

| Forester | |

| FORESTER | |

| FORESTER (USA) | |

| Forester I | |

| Forester II | |

| Forester III | |

| FORESTER STI | |

| Impreza | |

| Impreza Anesis | |

| Impreza II | |

| Impreza III | |

| IMPREZA WRX | |

| IMPREZA WRX STI | |

| LEGACY | |

| Legacy Lancaster | |

| Legacy II | |

| Legacy III | |

| Legacy IV | |

| LEGACY SPECB | |

| OUTBACK | |

| Outback I | |

| Outback II | |

| Qutback III | |

| Traviq | |

| XV | |

| Toyota | Allion |

| Avensis | |

| Avensis II | |

| Caldina | |

| Camry | |

| Carina | |

| Cavalier | |

| Celica | |

| CELICA T23 | |

| Corona | |

| Curren | |

| Ist | |

| Opa | |

| Premium | |

| Prius | |

| Matrix | |

| Vista | |

| Voltz | |

| Will | |

| Wish | |

| Volkswagen | Beetle (A4) |

| Bora | |

| BORA(130) | |

| Cross Polo | |

| Corrado | |

| Golf | |

| Fox | |

| GOLF 4 | |

| GOLF 4 (170) | |

| GOLF 4 R32 | |

| Lupo | |

| LUPO GTI | |

| New Beetle | |

| POLO | |

| POLO GTI | |

| Polo IV | |

| Polo Sedan | |

| Polo V | |

| Polo V Sedan | |

| Vento | |

| GAS | Siber |

Car make Model 5x108

| Alfa Romeo | 166 |

| Aston Martin | V12 Vanquish |

| Vanquish S | |

| Chery | M11 |

| Citroen | C5 |

| C6 | |

| Jumpy | |

| XM | |

| Ferrari | 348 GT |

| 348 Spider | |

| 355 F1 Berlinetta | |

| 355 F1 GTS | |

| 355 F1 Spider | |

| 360 MODENA | |

| 360 Spider | |

| 456 GT | |

| 456 GTA | |

| 458 ITALIA | |

| 512TR | |

| 550 Barchetta Pininfarina | |

| 550 MARANELLO | |

| 575 M Maranello | |

| 599 GTB Fiorano | |

| Challenge Stradale | |

| F355 Berlinetta | |

| F355 GTS | |

| F355 Spider | |

| F430 Challenge | |

| F430 Spider | |

| F50 | |

| F512 M | |

| Superamerica | |

| Ford | C-Max |

| Focus | |

| FOCUS 2 | |

| FOCUS 2ST | |

| Focus C-Max | |

| FOCUS CC | |

| FOCUS RS | |

| Galaxy | |

| Kuga | |

| Mondeo | |

| MONDEO ST220 | |

| S-Max | |

| Taurus | |

| Taurus SE/SEL | |

| Thunderbird | |

| Tourneo Connect | |

| Transit Connect | |

| Jaguar | S Type CCX |

| S Type Estate | |

| S-TYPES-TYPE V8 R | |

| X-TYPE | |

| XF | |

| XJ | |

| XJ6 | |

| XJ8 SE | |

| XK | |

| XKR | |

| Renault | AVANTIME |

| CLIO | |

| Clio IV Sport 197 | |

| Clio V6 Evo Sport | |

| ESPACE | |

| Espace III Grand Espace | |

| Espace IV | |

| Kangoo | |

| KANGOO II | |

| LAGUNA | |

| Laguna 5 Stud | |

| LAGUNA II | |

| Laguna II G | |

| Megan II | |

| MEGANE 2 CC | |

| Megane II CC Coupe/Cabrio | |

| Megane II Turbo | |

| Scenic | |

| Scenic II | |

| VEL SATIS | |

| Lancia | Thesis |

| Land Rover | Evoque |

| Freelander 2 | |

| Lincoln | L.S. |

| LS6 | |

| LS8 | |

| MKS | |

| Mercury | Sable |

| MG | XPower SV |

| Maserati | 3200 GT |

| Coupe | |

| Gran Turismo | |

| Gran Turismo S | |

| Peugeot | 407 |

| 407 Coupe | |

| 407 S.W. | |

| 508 | |

| 605 | |

| 607 | |

| RCZ Sport | |

| Volvo | 240 |

| 740 | |

| 760 | |

| 780 | |

| 850 | |

| 940 | |

| 960 | |

| C30 | |

| C70 | |

| C70 Convertible | |

| C70 Coupe | |

| C70 Coupe Cabrio II | |

| S40 | |

| S40 II | |

| S60 | |

| S70 | |

| S80 | |

| S80 II | |

| S90 | |

| S90 (204) | |

| V50 | |

| V70 | |

| V70 (193) | |

| V70 (250) | |

| V70 (300) | |

| V70 I | |

| V70 II | |

| V70 III | |

| V70 XC | |

| V90 | |

| XC60 | |

| XC70 | |

| XC70 II | |

| XC70 III | |

| XC90 | |

| GAS | 3102 |

| 31105 |

Car make Model 5x112

| Audi | 100 |

| A3 | |

| A4 | |

| A4 ALLROAD | |

| A4 Allroad quattro | |

| A4 CABRIOLET | |

| A5 | |

| A6 | |

| A6 Allroad quattro | |

| A7 | |

| A8 | |

| Allroad | |

| RS4 | |

| RS5 | |

| RS6 | |

| Q3 | |

| Q5 | |

| R8 | |

| R8 V10 | |

| S3 | |

| S4 | |

| S5 | |

| S6 | |

| S7 | |

| S8 | |

| TT | |

| TT S | |

| TT RS | |

| V8 | |

| Bentley | Azure |

| Continental | |

| CONTINENTAL GT | |

| MULSANNE | |

| BMW | M3 |

| Chrysler | CROSSFIRE |

| Ford | Galaxy |

| Lamborghini | GALLARDO |

| Gallardo LP550-2 | |

| Gallardo LP560-4 | |

| Gallardo LP570-4 | |

| Mercedes-Benz | A-Class (W168) |

| A-Class (W169) | |

| B-Class (W245) | |

| B-Class (W246) | |

| C-Class (CL203) | |

| C-Class (W202) | |

| C-Class (W203) | |

| C-Class (W204) | |

| CL-Class (C140) | |

| CL-Class (C215) | |

| CL-Class (C216) | |

| CLC-Class | |

| CLK-Class (W208) | |

| CLK-Class (W209) | |

| CLS-Class (C219) | |

| E-Class (W210) | |

| E-Class (W211) | |

| E-Class (W212) | |

| GL-Class (X164) | |

| GLK-Class (X204) | |

| M-Class (W163) | |

| M-Class (W164) | |

| M-Class (W166) | |

| R-Class (W251) | |

| S-Class (W140) | |

| S-Class (W220) | |

| S-Class (W221) | |

| SL-Class (R230) | |

| SLK-Class (R170) | |

| SLK-Class (R171) | |

| SLR-Class | |

| Vaneo | |

| Viano | |

| Vito | |

| W 203 (CLC) | |

| W 204(GLK) | |

| W 212(E) | |

| W129 (SL) | |

| W129 (SL) MILLE MIGL | |

| W140(S) | |

| W140 (SEC) COUPE | |

| W163 (ML) | |

| W163(ML)ML55AMG | |

| W164 (ML) 63AMG | |

| W164(ML) | |

| W168(A) | |

| W169(A) | |

| W170 (SLK) | |

| W202(C) | |

| W203(C) | |

| W203(C)AMG | |

| W203 (C) KOMPRESSOR | |

| W203 (C) SPORT COUPE | |

| W204(C) | |

| W208 (CLK) | |

| W210(E) | |

| W211(E) | |

| W211 (E) KOMPRESSOR | |

| W215 (CL) COUPE | |

| W215 (CL) COUPE 55 A | |

| W219 (CLS) | |

| W220(S) | |

| W221(S) | |

| W230 (SL) | |

| W231 (SL) | |

| W245(B) | |

| W251(R) | |

| W251(R)63AMG | |

| W414 (VANEO) | |

| W638(V) | |

| W638 (VITO) | |

| WX164 (GL) | |

| X 204(GLK) | |

| 300SE | |

| 400SEL | |

| 500SE | |

| 500SEL | |

| 500SL | |

| 600SE | |

| 600SEL | |

| 600SL | |

| A160 | |

| A170 | |

| A190 | |

| A200 | |

| B170 | |

| B200 | |

| C180 | |

| C200 | |

| C220 | |

| C230 | |

| C240 | |

| C250 | |

| C280 | |

| C300 | |

| C320 | |

| CL500 | |

| CL550 | |

| CL600 | |

| CLK200 | |

| CLK240 | |

| CLK320 | |

| CLK350 | |

| CLS350 | |

| CLS500 | |

| CLS550 | |

| E220 | |

| E230 | |

| E240 | |

| E280 | |

| E300 | |

| E320 | |

| E350 | |

| E400 | |

| E430 | |

| E500 | |

| E550 | |

| ML270 | |

| ML320 | |

| ML350 | |

| ML430 | |

| ML500 | |

| ML550 | |

| R350 | |

| R500 | |

| R550 | |

| S280 | |

| S320 | |

| S350 | |

| S400L | |

| S430 | |

| S500 | |

| S500L | |

| S550 | |

| S600 | |

| S600L | |

| SL320 | |

| SL350 | |

| SL500 | |

| SL550 | |

| SL600 | |

| SLK200 | |

| SLK230 | |

| SLK280 | |

| SLK320 | |

| SLK350 | |

| V230 | |

| V350 | |

| Maybach | 57 |

| 57 S | |

| 62 | |

| 62 S | |

| Landaulet | |

| Seat | ALHAMBRA |

| ALHAMBRA (130) | |

| Alhambra Facelift | |

| Altea | |

| Altea Freetrack | |

| Altea XL | |

| EXEO | |

| EXEO ST | |

| LEON | |

| Leon ll | |

| Toledo | |

| TOLEDO (130) | |

| Skoda | OCTAVIA |

| OCTAVIA 4WD | |

| Octavia II | |

| Octavia lll | |

| Octavia Scout | |

| OCTAVIA SRC 4WD | |

| Octavia Tour | |

| Superb | |

| Superb ll | |

| Yeti | |

| Ssang Yong | Actyon |

| Chairman | |

| New Actyon | |

| Volkswagen | Beetle (A5) |

| Caddy | |

| CrossTouran | |

| Cross Golf | |

| Eos | |

| GOLF 5 | |

| GOLF 5 GTi | |

| GOLF 5 PLUS | |

| GOLF 6 | |

| GOLF 6 GTi | |

| Jetta | |

| JETTA 2 | |

| JETTA 5 | |

| JETTA 6 | |

| Passat | |

| Passat CC | |

| PASSAT W8 | |

| Phaeton | |

| PHAETON W12 | |

| Scirocco | |

| Sharan | |

| SHARAN SYNCRO | |

| T4 | |

| Tiguan | |

| Touran | |

| Transporter | |

| Vanagon |

Calculation formula and compatibility tables

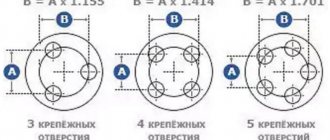

If there are an odd number of holes, one measurement will not work. In this case, you need to measure the distance between the axes of two adjacent bolts, and then apply simple formulas for calculations.

Let's say the distance is equal to some number X. Then, depending on the number of bolts from 3 to 5, the following formulas are used:

- 3 bolts. PCD=1.155*X

- 4 bolts. PCD=1.414*X

- 5 bolts. PCD=1.701*X

The formulas are obtained as a result of simple geometric manipulations; everyone can personally check and obtain more accurate coefficients.

As approximate reference information, you can use the table of compatibility of car models based on the same PCD.

As mentioned above, this cannot in any way mean complete interchangeability of disks, since all their other parameters rarely coincide.

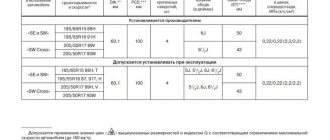

| Disc size according to PCD | The most common cars where it is used |

| 4×98 | Alfa Romeo 33, 155, 164, FIAT 124, 126, Brava, Cinquecento, Croma, Multipla, Palio, Panda, Punto, Seicento, Tempra, Tipo, Uno, Lancia Delta, Lada |

| 4×100 | Old models Audi, Mini, BMW 3, Daewoo Espero, Lanos, Nexia, Daihatsu Charade, Cuore, Grand Move, Honda CRX, Civic, Accord, Integra, Jazz, Kia Spectra / Sephia, Mazda 121, 323, MX5, Mitsubishi Carisma, Colt, Lancer, Nissan Micra, Sunny, Opel Ascona, Astra, Calibra, Corsa, Kadett, Vectra, Zafira, Renault Clio, Espace, Kangoo, Megane, Twingo, Seat Ibiza, Toledo, Skoda Felicia, Suzuki Baleno, Toyota Corolla, Yaris , Volkswagen Golf, Jetta, Passat, Polo, Volvo 440 |

| 4×108 | Audi 80, 100, Citroen BX, ZX, Berlingo, Visa, Xantia, Xsara, Ford Escort, Fiesta, Ka, Mondeo, Peugeot 106, 205, 206, 306, 307, 405, 406, Partner, Saab 900, 9000, Volvo 850 |

| 4×114,3 | Daewoo Matiz, Honda Civic VTEC, Accord, Prelude, Hyundai Accent, Sonata, Mitsubishi Carisma, Colt, Galant, Lancer, Space Wagon, Nissan Almera, Primera, Suzuki Alto, Swift, Volvo S40, V40 |

| 5×100 | Audi A3, TT, Skoda Octavia, Subaru Forester, Impreza, Legacy, Outback, Toyota Avensis, Carina, Celica, Volkswagen New Beetle |

| 5×108 | Citroen XM, Jumper, Ferrari, Ford Focus, Mondeo, Volvo 740, 760, 780 |

| 5×112 | Audi 100 CS, Quattro, Audi A4, S2, S4, A6, A8, Ford Galaxy, Mercedes Benz 280SL, 600SL, SLK, A, Vito, Volkswagen T1, T4 |

| 5×114,3 | American cars, Daihatsu Terios, Honda Odysee, CRV, Lexus, old Mazda models, Toyota RAV4 |

| 5×115 | American cars |

| 5×120 | Range Rover, Rolls Royce |

| 5×139,7 | Lada 4×4, Chevrolet Niva, UAZ |

It should be borne in mind that the wheels that were equipped with the cars could differ greatly depending on the specific modification of the model and the equipment ordered.

What is wheel rim bolt pattern?

Any car owner strives to improve his vehicle by replacing its original parts with new, more efficient ones, improving the appearance of the car through tuning. Wheel rims also undergo changes, because their appearance and production method directly affect the overall appearance of the car.

Larger wheels look more impressive than the original ones. Improving the exterior of a car is a completely natural desire of every owner, but in this case it is important that tuning does not negatively affect the performance of the car. To do this, you should select spare parts that meet the safety requirements and technical characteristics of a particular vehicle. And we need to talk about an attractive appearance only after these requirements are met after installation.

If the required number of bolts can be determined by eye, then the diameter of the holes is much more difficult to determine in this way. This is the main difficulty of loosening.

Features of bolt patterns of different types of disks

Today on the market you can find the following types of wheels for cars:

- stamped (steel);

- cast (light alloy);

- forged.

Steel models have gained popularity due to their modest cost, as well as the ability to straighten dents (they rarely crack and usually do not require expensive welding). Straightening is available for them due to their high strength - such a model will not burst even in a direct collision. The stamping bolt pattern must comply with standard standards.

Cast models are quite light, but not so durable during operation. The bolt pattern of wheel rims, the compatibility tables of which are presented by each manufacturer, must also fit into the standard standard.

Forged models are quite rigid and durable. During operation, they do not burst (it is extremely difficult to even make a dent on them), and are also not subject to the destructive effects of corrosion. In addition, if a forged wheel has a dent, it can be repaired by rolling it in a car service center.

Disc size indicators

There are five main sizes, an error in determining which will result in the impossibility of installing the wheel.

These include:

- number of bolt holes (LZ);

- the distance between them;

- diameter of the circle on which they are located (PCD);

- diameter of the central (hub) window (DIA);

- departure (ET).

The number of windows for bolts on passenger cars varies from 3 to 6. For trucks, this figure reaches 12-15 pieces. Togliatti-made cars have 4 bolt entries. The exception is the Lada Niva, the wheels of which are secured with five bolts each. The number of holes is measured visually by simple counting.

main disk sizes

The most common wheels are found, except for those that came from old FIAT models and some other cars, VAZ PCD 4 x 98 , with 4 and 5 bolts (studs).

The most popular bolt patterns:

- 4×100;

- 4×108;

- 5×100;

- 5×108;

- 5×112.

Although it is difficult to judge the actual prevalence of specific sizes, there are many others used on fairly well-known mass-produced cars.

Naturally, the disc parameters are not limited by the size of the bolt pattern.

There are others, no less important:

- diameter of the central hole;

- width;

- departure;

- disc edge parameters and much more.

This is interesting: When is it prohibited to drive on winter tires?

What do the numbers mean?

- R - Rim diameter (in inches);

- J - Rim width (in inches);

- DIA - Hub bore diameter (in mm);

- ET – The distance between the vertical axis of the rim to the plane where the disc abuts the hub.

Hub Bore Measurement (DIA)

Note: This value may be zero, plus, or, when the disc is very inward, negative.

This parameter is very important, since if it is chosen incorrectly, the disk may not fit in its normal place, even if all other sizes are suitable. How to find out the disc offset is shown in one of the photos above.

Types of departures: negative, zero, positive

- LZ – number of places for fastening the disk with bolts or nuts on a stud;

- PCD is the diameter of the circle in millimeters, along the perimeter of which the mounting holes are located (this is precisely the bolt pattern).

Where is the bolt pattern indicated on alloy wheels: there is complete information on the packaging

Note: There is no place to see this size on the discs unless there is a shipping box.

You have to measure this size yourself, but doing this with a tape measure or caliper is inconvenient. It’s easier to use the calculation coefficients that we presented below.

| Number of fasteners | Coefficient |

| 3 | 1,155 |

| 4 | 1,414 |

| 5 | 1,701 |

| 6 | 2,0 |

| 10 | 3,326 |

As a last resort, you can simply try the disk on the hub and try to tighten the nuts (or bolts).

How to find out the wheel bolt pattern (PCD)

If the disk is not original, but universal, it may have double drilling - for example: 5*100/5*114.3. It can be installed on cars with PCD 5*100, and on cars with PCD 5*114.3.

Universal discs with double drilling

The hub hole on universal discs is usually made larger - for example: 67.1 as for Mitsubishi, which has a bolt pattern of 5 * 114.3.

To put these wheels on, say, a Chevrolet with a 5*100 bolt pattern and a 57.1 hub, you only need a plastic adapter measuring 67.1*57.1.

Adapter rings (hub adapter)

These numbers correspond to the outer and inner diameters of the ring, with which you can change from 67 to 57 hub.

Studying the markings

- Each disk is marked with a set of numbers and Latin letters. To those who were not interested in what it all means, they will seem like Chinese letters. Meanwhile, the marking carries complete information about the disk;

- The first number in the row indicates how wide the disk is in front of your eyes. It is measured in inches;

- The next number after the separator indicates the diameter of the disk. Units of measurement are the same inches;

- The two letters and number following it show the so-called offset (or offset, as you call it) of the disk, and this time it is in millimeters;

- After the letters PCD

(which stands for “

Pitch Circle Diameter

,” which implies international standardization of diameter), there is a number - the slope - a three-digit number. This is exactly the chatter we are looking for.

Let's look at the code:

And what do these mysterious numbers mean? Their decoding is quite simple. The first number shows how many bolts it is attached to. After the fraction sign, it indicates the diameter of the circle along which the mounting holes are made. And if these numbers on the new disk do not match those indicated on the old one, then the problems described above await you.

How to measure the bolt pattern of a disc yourself

In fact, the need for measuring procedures rarely arises. The required parameter can be easily found out from the characteristics of a particular machine, and for any disk it is indicated on the product labeling.

But the designation of a used part may have been destroyed, so you will have to determine the bolt pattern using a ruler.

Measurements should be made with the greatest possible accuracy. It is very difficult, for example, to distinguish a 4x98 disk from a 4x100 one. It often happens that VAZ cars are driven with enlarged PCD rims, which is wrong and very dangerous.

Even if the wheel is centered more or less normally and does not bounce while driving, the lack of complete contact between the chamfers of the fastening bolts and the disk sockets causes high stress in the metal, wear of the holes, fatigue in the wheel bolts and a high probability of losing the wheel while driving.

There are two measurement methods - for an even number of studs and universal.

If the number is even, it is enough to mark the centers of the holes with the greatest possible accuracy and determine the distance between these centers for diametrically opposite bolts.

You will have to use a caliper; a regular ruler will give too much error. For example, on a disk you need to take the size between the edges of the holes, one from the inside, the other from the outside. Since the diameters of the bolt sockets are made with high precision, this will be the desired PCD.

How to measure the drill hole (PCD) of a wheel rim?

Very often we are asked the question of how to correctly measure one of the main parameters of a wheel rim - its drilling (aka PCD). And today we will answer this question in detail.

PCD (Pitch Circle Diameter) - the diameter of the location of the centers of the holes for fasteners on the wheel rim. A couple of examples: 5x114.3 - 5 holes located on a diameter of 114.3 mm; 3x112 - 3 holes, which are located on a diameter of 112 mm; 4x108 - 4 holes with a diameter of 108 mm; 6x139.7 - 6 holes on a diameter of 139.7 mm.

Measuring the drilling of a 4 or 6 bolt wheel rim is not difficult, you just need to measure the distance between the centers of opposite holes.

However, measuring the drilling of a 5-bolt disk is a more non-trivial task, because there are no opposite holes (we consider the opposite hole to be the hole whose chord to the center passes through the center (!) of the wheel disk).

So, to measure the drilling (PCD) of a 5-bolt disk, you need to take two measurements and then add the two obtained values.

Due to its specific nature, we will, of course, carry out measurements on a wheel spacer, and not on a wheel rim, but this does not change the essence at all.

Measurement No. 1: distance from the inner edge of one of the 5 holes to the central hole (DIA) of the wheel rim:

Measurement No. 2: distance from the outer edge of one of the 5 holes to the opposite side of the central hole (DIA) of the wheel rim:

The result of the second measurement is 92.0mm :

We add the two obtained values: 20.0 + 92.0 = 112mm Thus, drilling the wheel rim (spacer-adapter in our case) has a value of 5x112 (where “5” is the number of holes, “112” is the diameter of their centers in millimeters).

Let's consolidate the knowledge gained with one more example. This time we will take measurements not with a caliper, but with a regular ruler .

We measure the distance from the inner edge of one of the holes (any) to the CO (central hole, DIA):

Next, we measure the distance from the outer edge of one of the holes (again, any) to the opposite side of the CO. Make sure that the ruler passes strictly through the center of the wheel rim!

Add: 20.0 + 92.0 = 112mm, i.e. in this case, the value of the measured drilling is still the same 5x112 !

One of the main parameters of wheel rims is the number of mounting holes and their location relative to the wheel axis. The English term PCD, in domestic auto slang called a bolt pattern, contains information about the number of studs or bolts, as well as the diameter of the circle in which their centers are inscribed.

For example, a typical size for VAZ cars will be designated as PCD 4 x 98 .

This is interesting: Why do you need wheel balancing?

How to find out the bolt pattern of a 4-bolt wheel

How to find out the bolt pattern of a 4 or 6 bolt wheel. This method is only suitable for discs with an even number of holes. To do this, you need to measure the distance from the extreme point of two opposite holes. For example, for the VAZ 2104 this parameter is 85 mm. Next, we measure the diameter of the mounting hole; for this model it is 13 mm. We add up both obtained values - we get 98 mm. In total, the PCD of the VAZ 2104 is 4x98 mm. You can make measurements easier by taking measurements directly from the edges of the mounting holes. However, this method is not particularly accurate.

How to understand the bolt pattern on wheels with an odd number of holes

How to find out the bolt pattern of a 5 bolt disc? This method is universal and suitable for measuring PCD with any number of bolts; only the formula is replaced when performing calculations. To take the measurement you will need a caliper. If you use a ruler, the error in your measurements will be too large. Follow the instructions below:

- To take measurements, take two adjacent holes and measure the distance from the nearest edges;

- The diameter of the hole is measured;

- The value of the distance and diameter is added;

What is the danger of incorrect wheel bolt pattern?

It is important to correctly determine the bolt pattern parameters. This action should not be neglected, since it indirectly affects the safety of the vehicle. Installing wheels without taking into account deviations in one direction or another means that the wheel will not be installed accurately relative to the axis. As a result, it will not be possible to achieve the required tightening level.

It is impossible to visually determine the correctness of the bolt pattern. The consequences of incorrect drilling will be revealed later during the ride by the following manifestations:

- there will be strong beating in the wheels;

- damage will be found in the suspension elements and in the steering mechanism;

- the risk of the wheel mounting bolts coming loose will increase.

It can be seen that from a safety point of view the consequences are very serious and can lead to an emergency.

Departure parameter

In the example under consideration, the “offset” indicator is 30. This means that the gap between the center of the width of the wheel rim and the so-called mating plane is 30 millimeters. The last parameter is the plane with which the wheel disk is pressed directly to the hub. Note that the product will have zero “overhang” if they are absolutely identical. The “offset” can be considered positive if there are no points of intersection of the two mentioned planes. If the transfer plane goes beyond it will be negative.

German concerns that produce wheels designate the “offset” parameter with the symbols ET. In the example we are considering, this indicator is positive (YE30). A negative offset will be indicated as ET-30 (with a hyphen). French manufacturers designate this parameter as DEPORT. In other countries, as a rule, the designation OFFSET is used.

The “offset” indicator is no less important than the bolt pattern. It must be taken into account when installing wheels. If “offset” has a negative value, this may cause the element to protrude outward. In this case, when turning, it will rest against the wheel arch. Positive “overhang” implies a preferential location of the disk inside. If you do not take into account the correspondence of the “offset”, it will simply be impossible to carry out installation. This is due to the fact that the suspension elements will prevent this.

Overhang amount

Every vehicle owner strives to make the car original and unique with the help of tuning. A lot of effort and time is spent on selecting disks. Some motorists do not look at the standard markings, ignore the requirements and install low-profile wheels, forgetting that any deviations are unacceptable. Mismatched wheel rims lead to the car becoming unsafe and directly threatening the lives of all road users.

After deciding on tuning, you should not immediately run to the store and buy the wheels you like for your car, but you should consider several important selection parameters. You should not count on the help of consultants in the store; many of them are simply incompetent in matters of choice and try to simply sell the part, especially if they notice that you are interested in it.

To avoid waste of money, you must choose a disk strictly according to its parameters. There are a huge number of myths, and many prejudices have absolutely no relation to the real situation.

Motorists are sure that the offset of a wheel rim is the value that denotes the protruding part of the rim above the body of the vehicle. In fact, the parameter carries a slightly different meaning. Any disk in a car has a mating plane that comes into contact with the wheel hub when installing the disk. As a result, the offset is the distance from the mating plane of the disk to the vertical axis of symmetry of the disk.

Do not ignore the departure parameter. He is directly responsible for driving safety in the vehicle. If you choose wheels with the wrong offset, you increase the risk of accidents and premature wear of the main components. Thus, an incorrectly selected parameter can result in premature wear of the suspension.

Basically, motorists, when choosing wheels for their car, can make three common mistakes:

- They blindly believe the stories of consultants, hoping to receive highly qualified assistance in choosing;

- They ignore information about the markings that are applied to the standard disc from the car manufacturer;

- They make a choice only according to the parameters of appearance, color, geometric features, and other aesthetic factors.

In order to purchase a suitable part, it is necessary to correctly calculate the offset parameter:

ET=ab/2

In the formula, the symbol “a” denotes the distance between the inner plane and the part of the disk that is in direct contact with the hub, and the symbol “b” denotes the width of the disk profile. This information is presented more clearly in the figure:

All data for calculating the offset parameter can be measured manually with a millimeter ruler

The result is obtained in millimeters. The offset can be positive, negative, or equal to zero.

If the offset is positive - the axis is slightly shifted from the place of fastening, zero parameter - the axis and plane are completely consistent and fit tightly, negative parameter - the plane is outside the axis.

Most often on cars there is a positive offset value

Video: wheel spacers

Bolt pattern formulas

To accurately determine whether the kit and car make are compatible, bolt pattern formulas are used that indicate the parameters of the disks. There are abbreviated and full values, but absolutely all parameters are indicated only in the latter.

Full

This formula is used by disc manufacturers who apply the appropriate markings to their products. It looks like: 8Jx15 H2 4x100 ET0 D54.1 and for an inexperienced car owner it is a random set of numbers and letters. In fact, each parameter can be deciphered:

- 8 Jx15 - the first number indicates the width of the rim, the diameter being 15 inches. The X here represents the type of wheel, in this case they are cast or forged. The letter J indicates the possibility of using the wheel only on cars with single-wheel drive - rear or front, because all-wheel drive is designated as JJ.

- H2 - Displays the number of haps, which are otherwise called horse lugs. They hold tubeless tires on the rim and there are products with one hub or without it at all. These elements secure the tire, preventing it from depressurizing, and also help to corner more efficiently.

- 4x100 is a PCD indicator, the first digit in which reflects the number of bolt sockets, the second - the transverse diameter of the circle.

- ET0 - gives an understanding of the disc offset, in this case it is zero. If the number is 40, this is a positive offset, and the designation ET-40 shows a negative offset.

- D54.1 - this designation indicates the diameter of the hub window, the figure is given in millimeters.

The diameter and width of the wheel rim are indicated in inches, while other characteristics are reflected in millimeters.

Abbreviated

The abbreviated digital characteristic is simplified; it contains only two indicators. the 4x98 formula reflects that the wheel has 4 bolts located along a 100 mm circumference. This is the standard bolt pattern of the VAZ 2110; other cars also have circles from 100 to 139.7.

Before purchasing wheels, measure the hub. There may be no differences, for example, a disk with a 98-th circle will visually fit on a hub with a diameter of 100. In practice, such a disk will not fit tightly to the hub, the wheel will be skewed, and safety will be at risk.

Is it possible to install a product with inappropriate parameters?

Disc with centering ring

It is possible to install the product on a car with unsuitable bolt pattern parameters. For this purpose, special rings called centering rings are often used. With their help, you can set a parameter specifically for installing selected disks. This may result in errors in balancing and violation of suspension geometry. Therefore, it is strictly not recommended to carry out such operations, since they can disrupt the performance of the machine in motion.

The bolt pattern is an important parameter that can be used to determine how the disc is attached to the chassis structure. You can measure it yourself or find out from official sources, which is preferable.

Sources

- https://rad-star.ru/pressroom/articles/chto-takoe-razboltovka-kolesnykh-diskov/

- https://ZnanieAvto.ru/skaty/razboltovka-kolesnyx-diskov.html

- https://kolesadom.ru/kakie-byvajut-razboltovki-koles-vylet/

- https://AutoVogdenie.ru/razboltovka-kolesnyx-diskov.html

- https://BlackTyres.ru/informaciya/informatsija-o-diskah/razboltovka-kolesnyh-diskov/

- https://carnovato.ru/markirovka-kolyosnyx-diskov/

- https://kolesa.guru/diski/razboltovka.html

Compatibility tables

No one argues with the fact that bolt pattern can be determined independently using the appropriate tools and special formulas for calculations. But in the current conditions there is absolutely no need for this. To facilitate the selection process, there are special compatibility tables for wheel bolt patterns. The motorist only needs to find the table provided for his make and model of car. It is also very easy to determine the correct bolt pattern using the information provided in the official owner's manual. There is data about all sizes, offsets, diameters and much more. Depending on what diameter of wheels and tires the owner wants to use, the manufacturer makes recommendations for each case.

It is important to understand that all cars have their own restrictions regarding minimum and maximum wheel diameters and tire parameters. It is strongly not recommended to go beyond their limits, as this may result in negative changes in the operation of the suspension, increased wear of parts, and also increased fuel consumption.

There are a number of car owners who ignore manufacturers' recommendations and do not take into account information from compatibility tables. Their goal is to save on the purchase of parts. Therefore, they buy discs that are not quite suitable, begin to widen the hub holes, and make additional slots for mounting bolts. Some go further, changing the location of the wheel-to-hub mounting points. And already in this form the product is installed on the vehicle. In theory, such modernizations have a right to exist. But only on the condition that all calculations and work were carried out as accurately as possible. But it is impossible to achieve this using a makeshift method in a garage. If you drill the holes incorrectly, the wheels will start to beat and the hubs will collapse. And the car’s suspension will very quickly become unusable.

Modifying wheels that do not meet the standards of your car if you want to get a result close to the factory one is extremely unprofitable economically. You will have to spend a significant amount of money on the work. It is much cheaper to purchase wheels that are already fully regulated by the manufacturer, the efficiency and performance of which will not be doubted.

The importance of bolt pattern

Unfortunately, when purchasing, not all car enthusiasts ask themselves how to find out the wheel bolt pattern. Ignoring this parameter can lead to dire consequences. Determining the presence of a problem visually is quite problematic. When tuning their car, many motorists try to select wheels not according to technical parameters, but based on appearance. Often a situation arises in which the discs fit only approximately according to the bolt pattern. On the Internet you can find compatibility tables for disk models from various manufacturers, but you should not trust this data directly. Some experts suggest “adjusting” the car’s parameters to new rims, whose PCD value differs significantly from the standard one. During installation, centering rings are usually used. However, the effectiveness and safety of this method is controversial. Rings can be made of aluminum or plastic. Although manufacturers claim that the materials used are specially designed for loads, the presence of an additional element in the wheel fastening system gives an additional chance of weakening the structure and, if the ring splits, can lead to an accident.

Installing rims with an incorrect PCD indicator can cause:

Increased wheel runout;

Damage to the suspension or steering mechanism;

Wheel loosening while driving.

Even if the wheel is centered, the chamfers of the bolt studs will not fit snugly into the wheel sockets. For this reason, the stress in the metal increases, which accelerates the wear of the holes. In addition, there is always a risk of “losing” a wheel while driving.

Car wheels have a number of geometric parameters, according to which they are selected for the car. And if, at the request of its owner, it is possible to vary, for example, the radius of the rim, then the number of fastening elements and the distances between them in any case remain unchanged.

Let's consider what this or that parameter is, how to determine it, and what types of wheel bolt patterns there are on certain brands of cars.

Device for measuring the distance between bolts on a disk

Device RF-40341 for measuring the center-to-center distances of wheel rims.

A ruler for measuring the distance between bolts on a rim is designed to measure the bolt pattern of car rims and helps measure the distance between the mounting holes. With this tool you can measure the bolt pattern (PCD - mounting hole diameter) of any disk. Regardless of diameter. The measurements are made with high precision, since there are very close values (eg: PCD 4x100 or PCD 4x98), where a difference of 2 mm plays an important role. Installation of disks with incorrect measurements is prohibited.

4 holes: 4 × 98mm 4 × 100mm 4 × 108mm 4 × 110mm 4 × 114.3mm (4.5 inches) 4 × 120mm 4 × 130mm 4 × 140mm

5 holes: 5 × 100mm 5 × 108mm 5 × 112mm 5 × 114.3mm (4.5 inches) 5 × 115mm 5 × 120mm 5 × 120.7mm (4.75 inches) 5 × 127mm (5 inches) 5 × 130mm 5 × 135mm 5 × 140mm (5.5 inches) 5 × 150mm

6 holes: 6 × 114.3mm(4.5 inches) 6 × 127mm(5 inches) 6 × 135mm 6 × 139.7mm (5.5 inches)

8 holes: 8 × 165mm (6.5 inches) 8 × 170mm

A device for measuring the distance between bolts on a disk is currently sold at a price of 960 rubles. The price in retail stores may differ from the price in the online store.

You can order the product with delivery throughout St. Petersburg

, Leningrad region and to any region of Russia. You can also reserve and pick up goods in our stores. For all questions please call..

Source

Marking

As an example, consider the markings of the 9J x20H PCD 5×130 ET60 DIA 71.60 wheel rim:

- The number 9 indicates the width, measured in inches. To convert inches to centimes, the total figure is multiplied by 25.4.

- The letter J indicates the design elements: the shape of the disc flanges. This parameter does not play an important role in the selection.

- The letter X denotes the indivisibility of the disc.

- The number 20 indicates the landing diameter of the wheel product. This indicator corresponds to the fit of a car tire.

- The letter H denotes the presence of one hump or ridge on the rim.

- The abbreviation is PCD 5×130, where the number 5 indicates the number of drillings for fastening the nuts or bolts and the number 130 indicates their PCD diameter in millimeters.

- The ET60 marking indicates disc offset. In this situation the figure is 60 mm.

- The DIA value 71.60 indicates the diameter of the center drill. Typically, DIA corresponds to the fit of the hub and is indicated in millimeters. If the DIA is greater than the hub diameter, then a centering ring is used to install the disc.

The following information is also included with the label:

ISO, SAE, TUV - these abbreviations indicate the organizations that tested the wheel product, similar to the Russian GOST. The standards that correspond to the wheel marking are also indicated.

Maxload indicates the permissible load on a car wheel. This indicator is indicated in kilograms and pounds.

Characteristics of rims using the example of R14 radius

The driver should know that any wheel rim has maximum permissible parameters depending on the diameter of its rim, since indicators that go beyond these limits to a greater or lesser extent simply do not occur in everyday life. If we consider these relationships using the example of a wheel with radius R14, we can identify the following acceptable indicators of all other parameters:

- This dimension is used exclusively for compact low-power cars; the drilling, or PCD indicator, should not exceed 65-70 mm, and, as a rule, is 56.1 mm or 66.1 mm, however, there are also some intermediate diameter options.

- For the same reasons, the wheel is not secured with 6 or more studs, and their length should not exceed 120 mm. Thus, the range of bolt patterns is from 4 to 5 studs with a length of 90-120 mm for each.

- The rim width for such wheels ranges from 4.5-5.5 inches.

Disk options

To determine what the marking means, you need to know the width and diameter of the wheel product.

Drilling or bolting

This is one of the most difficult parameters to study, indicating the diameter of the mounting bolts. Drilling is measured from the center area of the stud to the opposite area where the element is located on the wheel.

Quite often, manufacturers indicate the disc bolt pattern parameters using shot depending on the number of holes for fastening.

Let's assume the figures are 6/222.25. The first number shows the number of drillings for fastening the bolts, and the second number indicates the drilling in millimeters.

Disc offset

This indicator is marked with the English letters ET. What is ET in disks and why is it needed? The indicator indicates the distance from the plane of the wheel product to the middle zone of the rim. The mating surface of the wheel product indicates the pressing plane of the disk to the hub.

Departure parameters can be:

- with zero indicator;

- with negative;

- with positive.

Zero offset indicates that the plane of the disc corresponds to its middle zone. Thus, the lower the indicator, the more the wheel product protrudes from the outside of the car. If the overhang indicator is increased, this means that the disc is deeper into the interior of the car.

It is also necessary to take into account the fact that depending on the width of the product, the overhang indicators differ. Manufacturers indicate in the documentation accompanying the vehicle a smaller offset value for wheels with a large width.

Diameter and other parameters of the disk schematically

What is HUMP(H)?

The hump is the protrusion of a ring on a disc rim. This element is used as protection against car tires coming off. Usually 2 humps (H2) are used for a wheel.

In some cases, a hump may not be used or only one may be used, depending on the vehicle configuration. Types of Humps:

- combined (CH);

- flat (FH);

- asymmetrical (AH).

PCD Disc Parameters

The PCD value refers to the diameter of the circle of the center holes on the wheel rim. That is, this is the diameter of the holes for fastening the bolts.

DIA drive option

The DIA parameter indicates the diameter of the hole located in the center of the disk. Casting manufacturers prefer to create a large DIA center hole diameter. This is done to ensure that the wheels are applicable and universal for all types of cars.

Despite the fact that the size of the hub may differ depending on the vehicle model, the auto disk is installed using an adapter ring or bushing.