In recent years, life in Russia has changed dramatically, and the arrival of various official dealers of world-famous foreign car brands, as well as the availability of car loans, have done their job - the volume of foreign cars sold began to exceed the number of domestically produced “iron horses” sold. However, the fact that the famous flagship of the AvtoVAZ concern, 2107, was produced from 1982 to 2012, that is, for 30 years, suggests that Russians have not lost their love for Russian car brands. Along with sales and service of “Zhiguli”, to this day you can find various accessories for “classics” on the shelves of car shops, including rims.

Stamped discs

Their advantages are unpretentiousness, low cost, high wear resistance, and ductility. This means that if it falls into a hole, the disc can be dented, but cannot be split or broken. A bent disk can be easily straightened even with an ordinary hammer. Stamped wheels are so cheap that cars with them don’t take their shoes off at night.

As for the disadvantages, the most important one is the large weight, which affects acceleration, braking and inertia. The result is worse handling and higher fuel consumption. In addition, from a purely aesthetic point of view, all cars look the same. Rust can also be a disadvantage, since factory paint is usually short-lived. Also, the stamping should be washed well in spring and autumn to avoid unnecessary noise and corrosion by salt.

Alloy wheels

Casting is fashionable, cool, modern. In addition, such disks can be 20-30% lighter than stamped ones, because they are made from a light metal alloy, they are less susceptible to corrosion and are more durable. The low-pressure casting technology itself increases the strength of products.

Externally, alloy wheels have an individual look; there are design bureaus that produce new shapes and follow fashion.

Functionally, the ride on alloy wheels is smoother, acceleration is improved, and fuel consumption is lower.

But there is also a “other side of the coin”. The disadvantage of alloy wheels is the continuation of their advantages. That is, when it gets into a hole, a cast disk does not crumple like a stamped one. But under supercritical load it simply bursts, splits - and its place is in an alloy processing workshop, or in the trash.

This is all due to the fragility of the disk. In addition, the cost of casting is higher and the service life is shorter. An important disadvantage is the transmission of all shocks to the suspension, since the disc cannot absorb them using its own deformation. Therefore, before deciding which wheels to install, decide where and why you will drive the car.

When choosing a wheel, the most important thing should be that it matches the car model. Thus, installing disks with a low profile is not suitable for summer residents, and installing heavy and durable disks will not save on fuel consumption. If you make a mistake in choosing the size, then the wheel may “shuffle” the fender liners when turning, or, which is a real shame, cannot be installed at all.

What quantitative parameters do standard wheels have for the classic VAZ 2107?

- There are 4 holes for mounting bolts, the diameter of the circle (more precisely, the diameter of the circle on which the holes are located is 98 mm. Sometimes this is indicated as (LZ*PCD): 4*98. This means that there is 98 mm between two diametrically opposite holes.

- Drilling for bolts is characterized not only by the size between the holes, but also by the diameter of the holes themselves. In the case of the VAZ 2107 it is 12.5 mm. Drilling holes is a parameter that is not immediately paid attention to, as always, first admiring the “size”. And in vain. It must be remembered that the disc manufacturer is obliged to very accurately calculate the fixation of the wheel to the hub, since a minimal discrepancy between the centers of the disc and the hub causes dangerous beating, which can ultimately tear off the wheel. Drilling must be done with an accuracy of tenths of a millimeter.

- The disk is designed for a hub with a central hole diameter of 58.5 mm. The hub size is designated as follows: (DIA 58.5). The fact is that ordinary and solid-looking wheel bolts do not at all center the wheel to the hub, as mentioned above. They just tightly connect the flange and disk. It is the central hole in the disk that helps to correctly orient the disk, and therefore the wheel, relative to the hub. If you decide to purchase wheels made of light alloys, then remember that for accurate alignment you may need to use an adapter ring, which are sold quite freely in large stores.

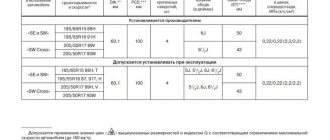

- The diameter of the wheels for the VAZ 2107 should be between 13-15 inches, and they are designated as R 13-R The standard size is 13 inches. This size refers to the diameter of the disc rim.

- The width of the disk (more precisely, the width of the rim of the disk) in inches for the VAZ 2107 ranges from 5 to 6 inches. Few people pay attention to this parameter, since they primarily look at the diameter. But it is the width that affects the stability of the entire tire, and therefore reliability.

Wheel disks

A car's wheel rims are part of its suspension. Like any other detail, they have their purpose.

Why are disks needed?

Wheel rims perform several functions at once:

- transmit torque from hubs or axle shafts to tires;

- ensure uniform distribution and compaction of tires around their seating circumference;

- contribute to their correct position relative to the car body and its suspension.

Types of rims

Today, there are two types of rims for car wheels: stamped and cast. The former are made of steel, the latter - from alloys of light but durable metals.

Stamped discs

Each type of wheel rim has its own advantages and disadvantages. The advantages of stamped ones include:

- low cost;

- reliability;

- resistance to shock loads;

- absolute maintainability.

In order to buy a regular “stamping”, just go to any auto store or market. A huge selection, low prices, constant availability on sale - this is what the undemanding car owner needs.

There is often no need to buy steel wheels, because they are practically eternal. It is almost impossible to break them. The main malfunction of such disks is deformation due to the wheel falling into a hole, hitting a curb, etc. However, this problem is solved by rolling it on a special machine, and at home - by leveling it with a hammer.

Recommendations for use

Alloy wheels for the VAZ 2107 are installed on the vehicle without additional elements. Typically, standard wheel bolts are used for this, which can be easily unscrewed using a standard wheel wrench. This approach greatly simplifies the life of car thieves; experts recommend purchasing a set of so-called secrets.

Alloy wheels mounted on a VAZ 2107 car, with the help of this type of fastener, can significantly reduce the risk of their theft. When choosing wheels for your car, you should pay attention, first of all, to the recommended parameters. The issue of choosing the appearance of the wheels is decided by car owners in accordance with their own ideas.

Basic parameters of rims for VAZ 2107

Each part of any mechanism has its own characteristics and parameters, according to which it is actually selected. Discs are no exception. These parameters include:

- diameter;

- width;

- departure;

- hub center hole diameter;

- bolt pattern;

- drilling

Disc diameter

Diameter is the main parameter that determines the possibility of installing a disk on a specific car. Standard VAZ 2107 wheels have a diameter of 13 inches.

Naturally, the larger the wheel size, the better the car looks. Moreover, with larger rims, the car “swallows” small holes and road potholes better. On the “seven” you can install wheels no larger than 14 inches in size without changing tires or modifying the chassis.

Disc width

The width of the rim, or rather its rim, characterizes the width of the tire that can be used with it. The standard width of the “seven” disk is 5 inches, but parts up to 6 inches wide can be installed.

The diameter and width together determine the size of the disc. In the marking it is designated as follows: 13x5, 14x5, 15x5.5 or vice versa: 5x13, 5.5x14, etc.

Disc offset

Reach is probably the most difficult characteristic to understand. It determines the distance from the interface plane of the part with the hub to the conventional plane dividing the disk rim in half. Depending on the model, discs can have either positive or negative offset. In the first case, the mating plane of the part does not cross the conventional boundary, which divides it into two equal halves. Looking at a car equipped with wheels with a positive offset, it will seem to you that the wheels of the car seem to be recessed inside the arches. With a negative offset, on the contrary, the mating plane shifts toward the longitudinal axis of the car itself, and the disk “sticks out” outward.

The standard “seven” disk has an offset of + 29 mm. However, for this parameter a standard deviation in one direction or another is provided, equal to 5 mm. In other words, the VAZ 2107 will fit wheels with an offset from + 24 to + 34 mm. The amount of overhang is measured in millimeters and is indicated on the marking as follows: ET 29, ET 30, ET 33, etc.

Changing the offset value of the “sevens”, most often in a negative direction, is used to give the appearance of the car a sporty style and aggressiveness. But here it is important not to overdo it. The fact is that when the offset changes in one direction or another, the distance between the point of attachment of the wheel to the suspension and the support point on the road surface also changes. And the more the standard distance is changed, the greater the load the wheel bearing will be subject to. In addition, the changes will also affect the car’s handling, and this is no longer safe.

Center hole diameter

Any wheel rim is designed for a certain size of the hub, or rather, its centering flange. It is on this that the disk is mounted with its centering hole. For "seven" discs, the central hole has a diameter of 58.5 mm. In standard labeling this is designated as “DIA 58.5”. No deviations are allowed here, but some tuning enthusiasts manage to install on VAZ 2107 wheels with a smaller hole diameter by boring it, or a larger one by using special centering rings.

Bolt pattern

A parameter such as the bolt pattern indicates the number of holes for mounting the disk and the diameter of the circle along which they are located. The factory 7 wheel rim has four holes for mounting bolts. They are located on one circle, the diameter of which is 98 mm. On the marking the bolt pattern is indicated as follows: “LZ/PCD 4x98”.

As you understand, installing wheels with a different bolt pattern on a VAZ 2107 simply won’t work, especially if its values differ not only in the size of the circle, but also in the number of holes. However, there is a way out, and more than one. The first option is to use special spacers between the disc and the hub. Such spacers have two bolt patterns: one standard for fastening to the hub, and the second for mounting the disk. The second option is suitable only for disks with the same number of bolts and a slight deviation from the diameter of the circle on which they are located. During installation, naturally, problems will arise with tightening the bolts at the final stage. It will not be possible to tighten them completely, which is why the wheel will dangle while moving. But this problem can be solved using special bolts with an offset center. You can either buy them or order them from a familiar turner.

Sverlovka

Such a parameter as drilling is necessary so that the car owner, when buying wheels, does not make a mistake with the size of the mounting holes. If they are larger than the diameter of the bolts, the disc will not fit tightly and will begin to wobble over time. If they are smaller, the bolts simply will not fit into the holes. The diameter of the holes for the mounting bolts in the standard 7 wheels is 12.5 mm. For fixation, M12x1.25 type bolts are used.

Parameters of standard bolts

The disks are fastened with a 19 mm wrench using steel bolts M12x1.25x27, where 12 indicates the diameter, 1.25 is the thread pitch, 27 is the length of the threaded part. The seat has a cone shape for reliable fixation and centering.

The use of bolts that do not meet the technical requirements leads to vibration of the wheel and contributes to its separation.