Car wheels perform not only basic operational functions. It’s hard to imagine the stylish appearance of a vehicle without well-groomed and pleasing wheels. The choice of products on which tires will be installed must take into account a number of factors.

Tuning decisions should in no way be made to the detriment of the technical characteristics of the car. The selection of wheels for a VAZ-2107 will be successful if you take into account a number of technological and design features of the model.

Throughout the entire period of mass production, the VAZ 2107 was equipped with stamped wheels with a diameter of 13 inches (R13) for standard 175//70 R13 tires. Export versions, as an exception, were equipped with light alloy models of the same size.

In addition to diameter, there are a number of other parameters of car rims:

- width;

- bolt pattern;

- departure;

- centering hole.

The standard rim width of the VAZ-2107 of various models ranges from 5 to 5.5 inches. This size is of great importance for the directional stability of the car; the coefficient of adhesion to the road surface depends on it. Symbol: 5.0J or 5.5J.

The bolt pattern in production models is indicated by the symbols 4x98, where 4 is the number of holes for mounting bolts, 98 is the diameter in millimeters of the circle on which they are located. To put it simply, 98 mm is the distance between the central axes of opposite holes. Novice car enthusiasts underestimate another important parameter. The diameter of the hole itself affects the reliability of fastening the wheel to the hub; it must be taken into account when choosing mounting bolts.

Overhang is the distance between the plane of contact of the disk with the hub and the plane that conventionally cuts the rim in the center. There are positive and negative offsets. In the first case, the wheel is recessed into the arch, in the second it is moved towards its outer boundary or even protrudes beyond it. The standard offset of VAZ-2107 wheels is positive and amounts to 29 mm (ET29).

The centering hole for production models is marked with DIA 58.5. The numbers indicate the hub diameter in millimeters. The value of this parameter is important when choosing new disks; if the centering values do not match, a special sealing ring is additionally purchased. The tightness of the fit of the central hole of the disk to the hub is a determining factor; the correct operation of the tires and the absence of “runout” of the wheel depend on it.

Wheel disks

A car's wheel rims are part of its suspension. Like any other detail, they have their purpose.

Why are disks needed?

Wheel rims perform several functions at once:

- transmit torque from hubs or axle shafts to tires;

- ensure uniform distribution and compaction of tires around their seating circumference;

- contribute to their correct position relative to the car body and its suspension.

Types of rims

Today, there are two types of rims for car wheels: stamped and cast. The former are made of steel, the latter - from alloys of light but durable metals.

Stamped discs

Each type of wheel rim has its own advantages and disadvantages. The advantages of stamped ones include:

- low cost;

- reliability;

- resistance to shock loads;

- absolute maintainability.

In order to buy a regular “stamping”, just go to any auto store or market. A huge selection, low prices, constant availability on sale - this is what the undemanding car owner needs.

Stamped discs are reliable and maintainable

There is often no need to buy steel wheels, because they are practically eternal. It is almost impossible to break them. The main malfunction of such disks is deformation due to the wheel falling into a hole, hitting a curb, etc. However, this problem is solved by rolling it on a special machine, and at home - by leveling it with a hammer.

A deformed stamped disk can be easily repaired by rolling it on a special machine

As for the shortcomings, there are fewer of them. Basically, motorists note the lack of aesthetics and individuality, as well as the heavy weight, which affects fuel consumption. As for the appearance, indeed, the “stamping” does not differ in either design or attractiveness. They are all the same. But the heavy weight is a controversial issue, since it was taken into account when developing the car, therefore, the engine characteristics are designed for it.

Alloy wheels

Alloy wheels, first of all, give the car its individuality. With them the car becomes more beautiful and looks more modern. It is this factor that most influences the result of the choice between “stamping” and “casting”.

Alloy wheels are lighter and have a custom design

In most cases, car owners, when buying alloy wheels, do not even suspect that such products do not bend like steel ones under critical load, but split. They can, of course, be restored later using argon welding or other technologies, but it will not be possible to return them to their original technical characteristics.

In most cases, restoration of alloy wheels is impossible

Video: which discs are better

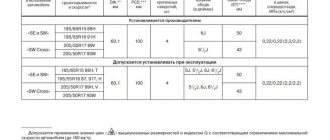

What tire sizes does the manufacturer recommend to install?

Tires for a car are a kind of “part” that is available in a large assortment, so when choosing, some difficulties may arise. Taking into account the manufacturer’s recommendations when choosing one option or another is an opportunity to avoid difficulties and obtain the appropriate ease of use.

The VAZ 2107 car is a multifunctional vehicle that is suitable for country trips, for driving around the city, for transporting large luggage (within the capabilities of a passenger car), and so on. And therefore, tires must be as strong, reliable and wear-resistant as possible to prevent inconvenience and danger.

According to manufacturers, the best option is considered to be 175/70R13 82T tires, since the ratio of the width of the tire profile to its height is an opportunity to get comfortable driving without disturbing the balance of the car.

The key feature of VAZ 2107 cars is that only 13 radius is ideal here, that is, the standard option that presents the car from its best side in terms of decorative and technical design. R14 and R15 are already non-standard sizes, so they slightly change the axis of the car, raising the body and “opening” the clearance between the bumper and the road surface.

Basic parameters of rims for VAZ 2107

Each part of any mechanism has its own characteristics and parameters, according to which it is actually selected. Discs are no exception. These parameters include:

- diameter;

- width;

- departure;

- hub center hole diameter;

- bolt pattern;

- drilling

Wheels of different cars have different parameters

Find out more about the characteristics of the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/gabarityi-vaz-2107.html

Disc diameter

Diameter is the main parameter that determines the possibility of installing a disk on a specific car. Standard VAZ 2107 wheels have a diameter of 13 inches.

The diameter of the disc determines its size

Naturally, the larger the wheel size, the better the car looks. Moreover, with larger rims, the car “swallows” small holes and road potholes better. On the “seven” you can install wheels no larger than 14 inches in size without changing tires or modifying the chassis.

Disc width

The width of the rim, or rather its rim, characterizes the width of the tire that can be used with it. The standard width of the “seven” disk is 5 inches, but parts up to 6 inches wide can be installed.

The diameter and width together determine the size of the disc. In the marking it is designated as follows: 13x5, 14x5, 15x5.5 or vice versa: 5x13, 5.5x14, etc.

The width of the tire depends on the width of the rim

Disc offset

Reach is probably the most difficult characteristic to understand. It determines the distance from the interface plane of the part with the hub to the conventional plane dividing the disk rim in half. Depending on the model, discs can have either positive or negative offset. In the first case, the mating plane of the part does not cross the conventional boundary, which divides it into two equal halves. Looking at a car equipped with wheels with a positive offset, it will seem to you that the wheels of the car seem to be recessed inside the arches. With a negative offset, on the contrary, the mating plane shifts toward the longitudinal axis of the car itself, and the disk “sticks out” outward.

The standard “seven” disk has an offset of + 29 mm. However, for this parameter a standard deviation in one direction or another is provided, equal to 5 mm. In other words, the VAZ 2107 will fit wheels with an offset from + 24 to + 34 mm. The amount of overhang is measured in millimeters and is indicated on the marking as follows: ET 29, ET 30, ET 33, etc.

With a positive offset, the wheel seems to be recessed in the arch, with a negative offset, it sticks out.

Changing the offset value of the “sevens”, most often in a negative direction, is used to give the appearance of the car a sporty style and aggressiveness. But here it is important not to overdo it. The fact is that when the offset changes in one direction or another, the distance between the point of attachment of the wheel to the suspension and the support point on the road surface also changes. And the more the standard distance is changed, the greater the load the wheel bearing will be subject to. In addition, the changes will also affect the car’s handling, and this is no longer safe.

Read about the repair of the front and rear hub of the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/stupica-vaz-2107.html

Center hole diameter

Any wheel rim is designed for a certain size of the hub, or rather, its centering flange. It is on this that the disk is mounted with its centering hole. For "seven" discs, the central hole has a diameter of 58.5 mm. In standard labeling this is designated as “DIA 58.5”. No deviations are allowed here, but some tuning enthusiasts manage to install on VAZ 2107 wheels with a smaller hole diameter by boring it, or a larger one by using special centering rings.

Centering rings are used when installing disks with a large diameter centering hole on a car.

Bolt pattern

A parameter such as the bolt pattern indicates the number of holes for mounting the disk and the diameter of the circle along which they are located. The factory 7 wheel rim has four holes for mounting bolts. They are located on one circle, the diameter of which is 98 mm. On the marking the bolt pattern is indicated as follows: “LZ/PCD 4x98”.

As you understand, installing wheels with a different bolt pattern on a VAZ 2107 simply won’t work, especially if its values differ not only in the size of the circle, but also in the number of holes. However, there is a way out, and more than one. The first option is to use special spacers between the disc and the hub. Such spacers have two bolt patterns: one standard for fastening to the hub, and the second for mounting the disk. The second option is suitable only for disks with the same number of bolts and a slight deviation from the diameter of the circle on which they are located. During installation, naturally, problems will arise with tightening the bolts at the final stage. It will not be possible to tighten them completely, which is why the wheel will dangle while moving. But this problem can be solved using special bolts with an offset center. You can either buy them or order them from a familiar turner.

The bolt pattern includes the number of mounting holes and the diameter of the circle on which they are located

Sverlovka

Such a parameter as drilling is necessary so that the car owner, when buying wheels, does not make a mistake with the size of the mounting holes. If they are larger than the diameter of the bolts, the disc will not fit tightly and will begin to wobble over time. If they are smaller, the bolts simply will not fit into the holes. The diameter of the holes for the mounting bolts in the standard 7 wheels is 12.5 mm. For fixation, M12x1.25 type bolts are used.

Drilling determines the diameter of the disk mounting holes

Which cars will fit wheels on the VAZ 2107?

Unfortunately, there are very few cars that have the same wheel parameters as the 7. VAZ 2107, in this sense, is almost unique. And it’s not at all about their diameter, width, or reach. It all comes down to the bolt pattern and the size of the hub hole.

Table: cars with similar wheel rim parameters

| brand, model | Year of issue | Hub hole diameter, mm | Bolt pattern | Reach, mm |

| Alfa Romeo 145, 146 | 1994–2001 | 58,1 | 4x98 | 35 |

| Alfa Romeo 155 | 1994–1998 | |||

| Alfa Romeo 164 | 1988–1998 | |||

| Alfa Romeo 33 | 1986–1996 | |||

| Fiat Barchetta | 1995 | |||

| Coupe 16V | 1995–2001 | |||

| Doblo | 2001 | |||

| Florino | 1995–2001 | |||

| Panda | 2003 | |||

| Punto I, II | 1994–2000 | |||

| Stilo | 2001 | |||

| Uno | 1985–1995 | |||

| Seat Ibizia / Malaga | 1985–1993 |

As for domestic cars, standard alloy wheels from VAZ 2112, VAZ 2170 can be installed on the “seven” without modifications. They have similar parameters.

But you don’t have to waste time searching for suitable stock drives. Today you can freely buy wheels of a wide variety of designs, made from various alloys. The cost of a set of good “wheels” for a VAZ 2107, depending on the characteristics and manufacturer, varies from 10 to 40 thousand rubles. Not cheap, of course, but beautiful.

Is it realistic to install sixteen-inch wheels on a VAZ 2107?

Probably, everyone who had to see the “seven” on sixteen- and even seventeen-inch disks was very interested in how they were “dragged” there. It's actually simple. In some cases, the owners of such cars do not even digest the arches. It's all about the height of the tire, which is expressed as a percentage of the height of the rubber profile to its width. And if for a stock tire it is 70%, then in order to put fifteen-inch wheels on the “seven”, you need to put rubber on them with a height of 40–50%.

When installing larger diameter wheels on a VAZ 2107, low-profile tires are used

To install sixteen- and seventeen-inch wheels, it is better to raise the car a little using special spacers for shock absorbers, or increase the size of the arches by cutting them out. As for the tire profile height, it is better if it is no more than 25%.

More information about tuning the VAZ-2107: https://bumper.guru/klassicheskie-modeli-vaz/tyuning/tyuning-salona-vaz-2107.html

Video: VAZ 2107 on seventeen-inch wheels

What wheels were installed on different bodies and configurations?

When selecting new wheels for any car, including the domestic VAZ-2107, it is necessary to take into account a number of factors specific to this particular model. Traditionally, most cars that rolled off the Volzhsky Automobile Plant assembly line had the most budget-friendly wheel options. The VAZ-2107 was equipped with 13-inch stamped steel elements with standard tires in size 175/70R13.

Starting from 1982 until the end of mass production in 2012, the “seven” was produced in 13 modifications. One of them, namely the VAZ-21077, was developed specifically for export to the UK. In this version, more expensive, alloy wheel versions were installed on it.

Knowing the basic technical parameters of a wheel rim, you can determine its compatibility with a specific car model. In addition to the diameter, you need to take into account such indicators as:

- Rim width.

- PCD – diagram for drilling mounting holes (bolt pattern).

- ET – disc ejection.

- DIA is the diameter of the central hole.

As for the bolt pattern and the central hole, everything here is traditional for the old Tolyatti models. These indicators are strictly tied to the parameters of the hub. In numerical terms, they look like this: 4x98 mm and 58.5 mm, respectively: 4 is the number of fastening points, 98 mm is the distance between the centers of opposite mounting holes, 58.5 mm is the diameter of the hole located in the center of the disk.

Rim width is measured in inches. In the VAZ-2107 this indicator is equal to the values 5 and 5.5. Knowing the width of the rim, you can understand how wide the tire should be. In the marking this value is written as follows: 5J and 5.5J.

Full coincidence of the central hole of the disk with the corresponding parameter of the hub helps to accurately center the disk during installation, which has a positive effect on the service life of the tires and eliminates wheel runout when driving.

Tires for VAZ 2107

The safety of the car driver and his passengers depends even more on the characteristics and condition of the car’s tires. Their choice must be approached very carefully, and in no case should you skimp.

Types of tires by seasonal use

According to seasonal use, tires are divided into:

- winter;

- summer;

- all-season.

The first ones are made of soft rubber and have a special tread. At the same time, each manufacturer tries to increase the tread area, because the larger it is, the better the tire will perform on winter roads.

The larger the tread area, the better the tire performs on slippery roads.

Summer tires are rougher, and their tread pattern is designed more for better grip on wet surfaces and drainage of water from the plane of contact between the tire and the road.

Summer tire tread is designed for wet grip

All-season tires are a generalized version of the first two types. If the “all-season” tire is really of high quality, then in winter it copes with its duties normally, but in the summer it is significantly inferior to summer tires in terms of the quality of grip on wet surfaces.

High-quality all-season tires do a good job in winter

VAZ 2107 tire parameters

Like wheels, car tires have their own parameters. These include:

- profile width (the width of the tire itself, measured in millimeters);

- height (expressed as a percentage of the profile height to the width, measured as a percentage);

- landing diameter (determines the inner diameter of the tire, measured in inches);

- load capacity (indicates the maximum load per tire, measured in kgf);

- permissible speed value (indicates the estimated maximum permissible speed, measured in km/h).

VAZ 2107 leaves the assembly line of the plant shod with thirteen-inch radial tires with a profile width of 175 or 165 mm and a height of 70%. Standard tires are designed for 190 km/h and a load on one wheel not exceeding 470 kgf.

Tires, like wheels, have their own parameters

It is impossible not to mention the tire pressure, because the vehicle’s cross-country ability, its driving performance, and fuel consumption depend on it. The manufacturer of the VAZ 2107 recommends observing the following pressure indicators.

Table: recommended tire pressure for VAZ 2107

| Load | Tire parameters | Recommended pressure, bar | |

| front tires | rear tires | ||

| In the cabin there is a driver and up to 3 passengers | Width - 175 mm Height - 70% Fitting diameter - 13 inches | 1,7 | 2,0 |

| Width - 165 mm Height - 70% Fitting diameter - 13 inches | 1,6 | 1,9 | |

| 4–5 people in the cabin and cargo in the trunk | Width - 175 mm Height - 70% Fitting diameter - 13 inches | 1,9 | 2,2 |

| Width - 165 mm Height - 70% Fitting diameter - 13 inches | 1,8 | 2,1 | |

The choice between beauty and functionality of wheels should be based on how you use the car. If it is intended for city car rides, or participates in exhibitions of tuned cars, festive motorcades, then alloy wheels and low-profile tires are an ideal option. If the car is used daily in our off-road conditions for work, then it is better to install “stamping” on it with standard tires.

Features of wheel sizes for the most popular VAZ models

Among several dozen VAZ modifications, the most popular models over the entire 50 years were only 2 of them, as can be judged by the number of copies sold. The wheel sizes for these cars had the following parameters, which varied depending on the year of manufacture, technical equipment and equipment of the car:

VAZ is the latest modification of the “classic”, produced on the plant’s conveyors for 30 years: from 1982 to 2012. During this time, it never changed its appearance, and the disc bolt pattern was the same - 4x98 with a central hole diameter of 58.6 mm.

The width of the rim varied slightly depending on the model year.

If in 1982 the plant produced models with tire dimensions ranging from 5J to 5.5J, then at the end of production the concern increased the permissible size to 6J.

You might be interested in Domestic alloy wheels for cars

The radius of the wheels invariably varied from R13 to R15, which made it possible to alternate them by season, periodically changing the side profile of the tire, or immediately use all-season tires with a diameter of R14.

The VAZ 2107 tire size invariably consisted of only 3 main parameters - 175/70/R13, 185/60/R14 and 185/55/R15. The last of the listed parameters was actively in demand among lovers of fast driving on smooth city roads.

On a note.

As for the R13 rubber, it allowed the driver to feel as comfortable as possible when driving over rough terrain, as well as in winter, when the high cord profile took part in adhesion to the road surface. But the most popular parameter remained the universal size R14 and the largest number of tires were sold in this dimension.

If we look at the concern’s earlier cars, we can see that the wheelbase of the Zhiguli has remained virtually unchanged for more than 40 years. This leads to moral backwardness of the technical equipment of the plant's products. At the same time, the lack of new developments greatly reduces both the speed of release from the assembly line and the cost of engineering equipment, which leads to a very attractive retail price for the vehicle.

VAZ 2114. Produced in a smaller range - from 2001 to 2013. The car was just a restyled modification of the classic “nine”. The legacy of the outdated model did not affect the high popularity of this Lada, and all the wheels that were installed on hubs in the basic version had the same traditional bolt pattern 4x98, DIA 58.6 mm.

European standard bolt pattern 4x100 for Lada X-Ray

Like the bolt pattern of the VAZ 2114, the width of the wheel rims was not much different from the “seven” and fluctuated between 5J – 6J for the entire production period. As for radius, the concern has completely eliminated the 15-inch diameter from the factory equipment, without prohibiting drivers from installing this parameter as an option. The bolt pattern of VAZ 2114 wheels in the current size also made it possible to install standard 4x100 wheels in accordance with the sizes usual for Europe.

Not a single Lada model has ever looked aggressive; the hallmark of the product was practicality and reliability in operation. The concern did not use extreme overhang indicators, and the wheels were always hidden under the body arches. The average ET limit values for both VAZ 2107 and 2114 were ET25...35 mm, and deviations from this characteristic obligated drivers to install additional mudguards on the side parts of the body and change the design of the hubs, making them more durable to avoid deformations.

Important!

The bolt pattern of the VAZ 2114 wheels, as well as all other dimensions of the hub and disks, were used on the brand’s followers - Kalina and Priora. With the arrival of new management at the domestic concern, this parameter ceased to exist altogether, since the plant had a new orientation to the West and possible import of products to the nearest CIS countries.

5 studs on VAZ 2121 wheels

Wheel spacers for SS20 SPORT wheels

Wheel spacers (or wheel spacers) are an attribute of the sporty style of a car. Installing spacers under the wheels allows you to increase the wheelbase of the car, give it a more aggressive and sporty appearance, as well as improve driving dynamics, stability and controllability of the car.

Applicability

- VAZ 2108-2199

- VAZ 2110-2112

- VAZ 2113-2115

- VAZ 1117-1119 (Lada Kalina)

- VAZ 2170-2172 (Lada Priora)

- VAZ 2190-2194 (Lada Granta)

- VAZ 2123

- VAZ 2121/2131

- Chevrolet NIVA

- Chevrolet Lacetti

Advantages of using SS20 wheel spacers in VAZ cars

- widens the vehicle track;

- gives the car a more aggressive and sporty look;

- makes it possible to install wider tires and rims on the car that differ in offset from the original ones;

- allows you to avoid wheel rims and tires from touching suspension parts;

- increases stability and reduces the likelihood of the vehicle tipping over during high-speed cornering;

- made of light and durable aluminum alloy, using high-precision equipment, with strict observance of parallelism and axial runout.

Guarantee

Wheel spacers (or wheel spacers) are an attribute of the sporty style of a car. Installing spacers under the wheels allows you to increase the wheelbase of the car, give it a more aggressive and sporty appearance, as well as improve driving dynamics, stability and controllability of the car.

Wheel spacers are made of lightweight and durable aluminum alloy, using high-quality equipment, with strict observance of parallelism and axial runout. Spacers SS20 SPORT are designed for all brands of VAZ and Chevrolet Lacetti cars.

Wheel spacers SS20 for VAZ cars with a thickness of up to 12 mm inclusive are manufactured without a central shoulder. Over 12 mm thick with a central collar.

Centering the wheels of standard VAZ vehicles relative to the axis of rotation of the hub is carried out along the chamfers of the mounting holes of the wheel rims and the conical surfaces of the wheel bolts. The presence or absence of a central flange on the track expansion spacer does not in any way affect the alignment of the wheel relative to the hub. Those. Regardless of whether there is a shoulder on the spacer or no such shoulder, the wheel will in any case be centered on the hub using the bolts.

The wheel spacer itself is centered relative to the hub along the central hole, which fits onto the hub shoulder.

We accept orders for the production of wheel spacers of any complexity for all cars.

What non-standard sizes can be supplied?

The VAZ 2107 car is a classic that can be tuned and improved using simple and very affordable methods. Among the most relevant is the bottom of the car by using wheels of a larger radius than stated by the manufacturer. But here you need to take into account some points to avoid inconvenience when using:

- The main place of operation of the vehicle. As practice shows, when using a car outside the city, a high bottom position simplifies movement, since in conditions of uneven road surfaces the likelihood of the car skidding and damaging the bumpers is reduced.

- Personal requirements of the motorist. For some, it is ideal when the car is “lowered”, and for others, when its position is a little higher than the standard. Determining personal requirements is an opportunity to avoid inconvenience when choosing and using a car.

Experimental option

There are even experimental options when the R18 is installed on the “seven”, thanks to which the car takes on the appearance of an SUV. But here you need to take into account a couple of nuances:

- Manufacturers do not just come up with optimal wheel radii for their cars, since they take into account the technical parameters and capabilities of the vehicle, so any deviations are fraught with a violation of driving comfort.

- It is necessary to adjust the suspension so that the car can cope smoothly with uneven road surfaces without creating inconvenience for passengers.

- There is a possibility that the wheels will touch the car body when the steering wheel is turned completely, and this not only creates inconvenience, but can also cause a violation of safety when driving the vehicle.

- The use of a large diameter is fraught with a violation of the geometric properties of the car body, so it is advisable to consult with specialists who will evaluate the technical properties of the car and determine whether the selected 18th wheel radius is suitable.

It is best to select wheels for reasons of not only beauty, but also practicality, so that the car does not create inconvenience when driving on any terrain.

How to avoid wheel theft

To protect wheels from theft, some use “secrets,” as they are called. This is a bolt that cannot be unscrewed with standard tools, but only with an individual special key, available only to the owner of the car.

Various methods are used to protect such fasteners. For example, the head of a bolt can be made in the shape of an irregular polygon or a completely arbitrary figure; one of the profiles is sometimes shifted to the side. A perforated profile with holes of various diameters and depths is also used. You cannot determine the reliability of secrets by looking at their profile; it is more important to use products from proven and reliable manufacturers.

Usually, in order not to ruin the secret bolt, it is tightened with less force. Because of this, such wheel bolts in the VAZ 2109 are placed one on each wheel. Unfortunately, in our country there are still people who like to “take off” your car’s shoes, so the topic of secret locks remains relevant for now.

All these secrets make it difficult for lovers of easy money to remove the wheels, they make it difficult. Because if you have time, you can unscrew everything, but thieves have little time.

Therefore, in order to most effectively protect your wheels, you should follow several rules.

- It is better to buy expensive secrets, this helps to avoid matching products. Because when producing unique secrets, after some time the cycle repeats, and there is some chance of repetition of parts. But in expensive products such coincidences are excluded.

- If you buy alloy wheels, it is better to choose ones in which the secrets would be “recessed” inside the disk rather than on the surface. They are more difficult to unscrew.

- It is worth purchasing bolts with a flat pattern at the top of the head, which is not sharpened to a key. (For example, an asterisk or a heptagon). That is, the drawing should be as unusual and flat as possible.

The price on the Internet for regular wheel bolts is from 14, and for “secret” ones from 160 rubles.

Bolts are made from different materials. This can be steel with an admixture of molybdenum or steel coated with nickel, chromium, etc., sometimes even titanium. Coated bolts have a nice appearance. But don’t think that this is the best choice. The problem is that any bolts are susceptible to corrosion. And the technology of nickel or chromium coating with sufficient stability has not yet been created. After a year, coated bolts will inevitably lose their beauty. Therefore, the appearance of the bolts is practically unrelated to their operational data. The most important factors are strength, thread pitch, length and type of bolt head.

To change wheels yourself, you need to know how to properly unscrew and tighten the wheel bolts. To do this, you should look at the photos and videos. There are a lot of such materials on the Internet. There are also instructions online for tightening bolts using a torque wrench.

It is especially important when installing new bolts after approximately 50 km to check the tightness of all bolts. Most likely, some of them will have to be tightened up!